Treatment method for coating photoluminescence luminescent powder

A technology of photoluminescence and processing methods, applied in the direction of luminescent materials, chemical instruments and methods, etc., to achieve the effects of reducing production costs, overcoming the problem of light attenuation, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0021] The reagents used in the experiment are magnesium acetate (analytical grade), isopropanol (analytical grade), and trifluoroacetic acid (chemical grade). The fluorescent powder is BaMgAl10O17:Eu, hereinafter referred to as BAM.

[0022] Dissolve 0.005 mol of magnesium acetate in 15 ml of isopropanol, add 2 ml of trifluoroacetic acid (TFA) and an equal amount of distilled water, stir for 2 h, then add isopropanol to dilute the solution to 300 ml. 0.2% by mass (MgF 2 / BAM) Add BAM fluorescent powder into the solution, soak and stir for 15 minutes, evaporate to dryness at 80°C for 24 hours to obtain gel-coated BAM fluorescent powder, and then bake at 300°C for 15 minutes to obtain MgF 2 Encapsulated BAM phosphor.

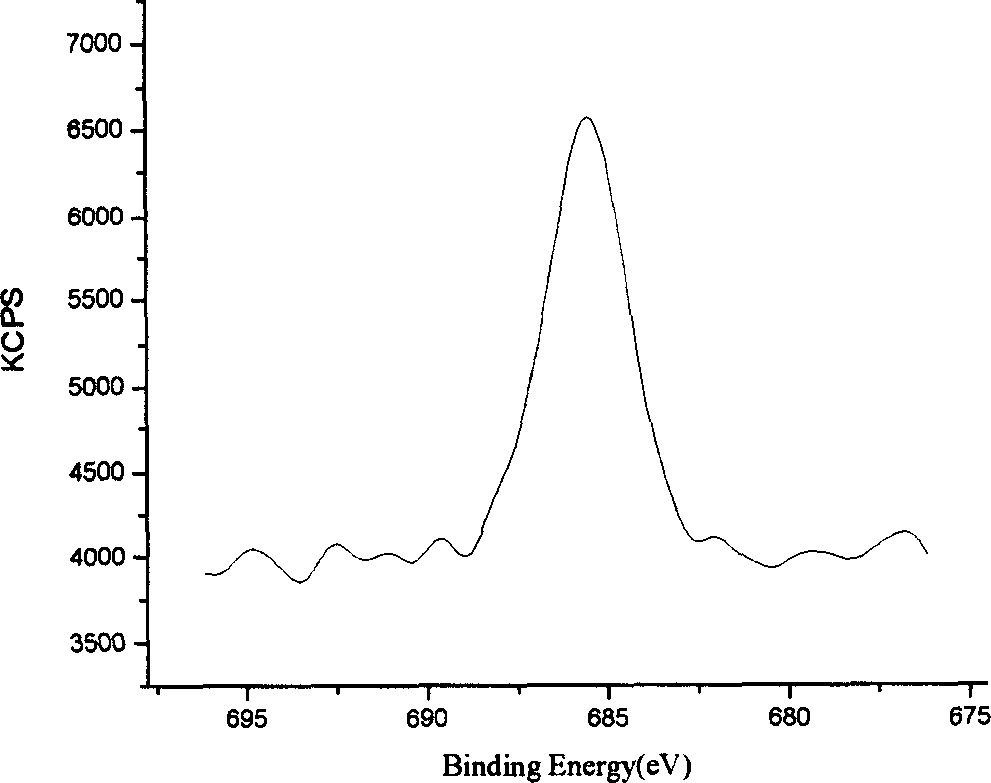

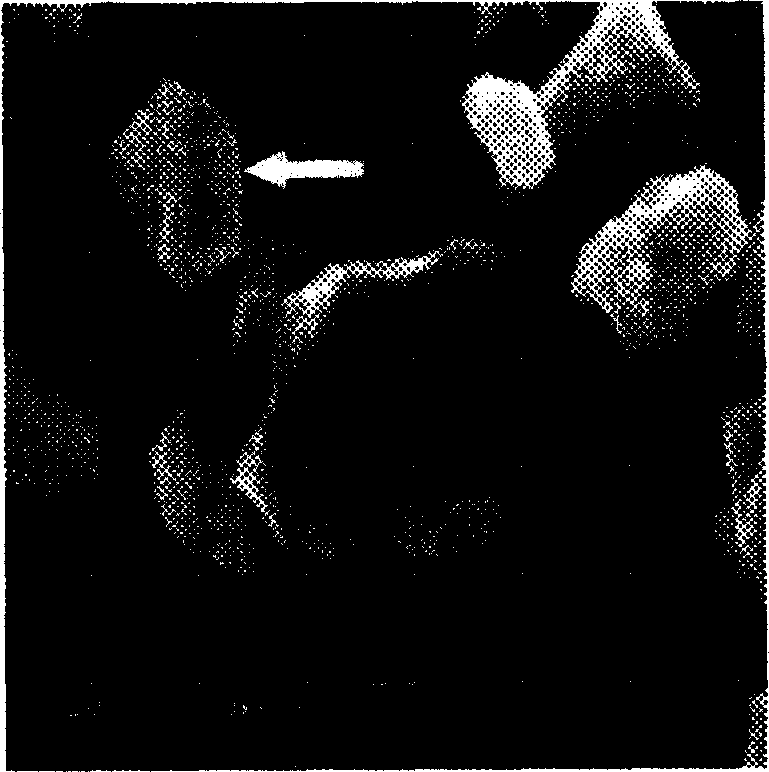

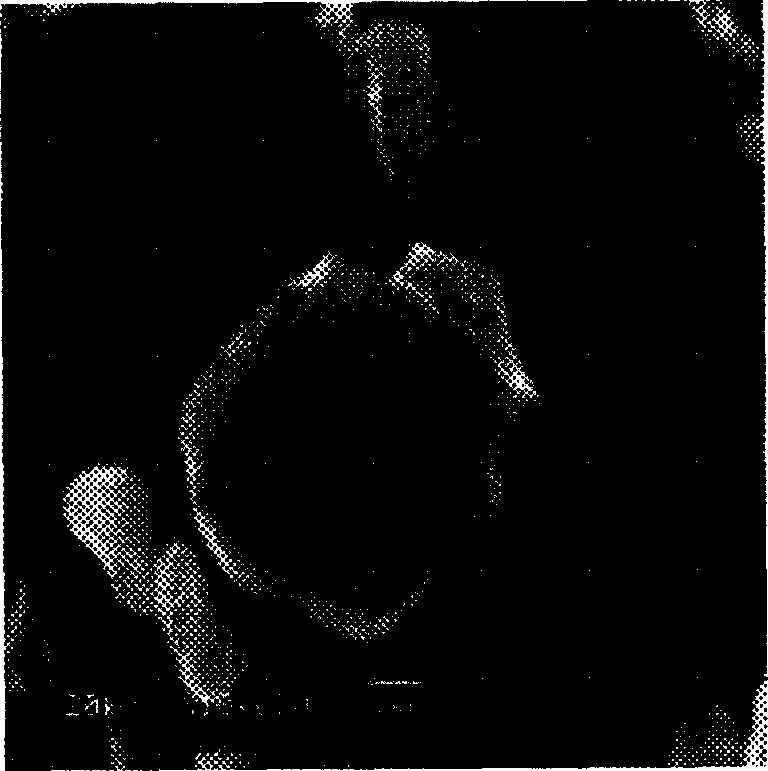

[0023] The ESCA LAB 210 type multifunctional electron spectrometer (VG company) is carried out photoelectron energy spectrum (XPS) measurement to the phosphor powder after the present invention is processed; With the JSM-5600LV low vacuum electron microscope (SE...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com