Pretreatment liquid, application of pretreatment liquid, and treatment method of heavy oil sludge

A technology of pretreatment liquid and treatment method, which is applied in sludge treatment, chemical instruments and methods, and immiscible solvent sludge treatment, etc., can solve the problems that the cleaning effect needs to be improved, the energy consumption is large, and the oil content of the residue is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

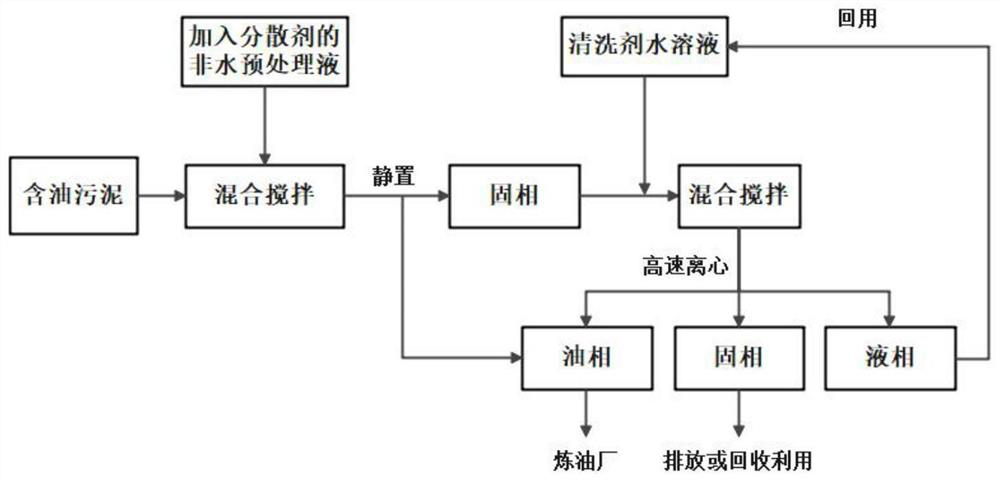

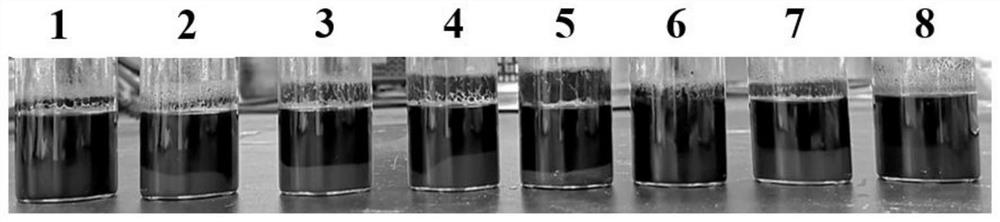

[0047] Add the asphaltene dispersant DP (p-dodecylphenol) with a mass fraction of 5% into the non-polar solvent n-heptane, stir evenly to obtain a pretreatment liquid, and take No. 1-8 oil sludge (see Table 1 for oil sludge characteristics) 2g each, and then add 6g of pretreatment solution, stir at 600r / min at 25°C for 30min, let stand for 2min to separate layers, and perform solid-liquid separation to obtain a solid phase; sodium dodecylbenzenesulfonate and partial pentahydrate Mix sodium silicate at a mass ratio of 1:3, add water three times and stir evenly to obtain 10wt.% cleaning agent, stir the solid phase and 6g of cleaning agent at 700r / min for 30min at 60°C, and clean the oil-containing The sludge is centrifuged for 5 minutes in a centrifuge with a centrifugal speed of 5000r / min to achieve three-phase separation of oil, water and solid, and the treated thick oil sludge is obtained.

Embodiment 2

[0049] Add the asphaltene dispersant DBSA (p-dodecylbenzenesulfonic acid) with a mass fraction of 5% into the non-polar solvent n-dodecane, stir evenly to obtain a pretreatment liquid, and take No. 1 to No. 8 oil sludge (for oil sludge characteristics, see Table 1) each 2g, then add 6g of pretreatment solution respectively, after stirring at 600r / min at 25°C for 60min, let stand for 3min to separate layers, and carry out solid-liquid separation to obtain a solid phase; Mix sodium silicate at a mass ratio of 1:1, add water three times and stir evenly to obtain 5wt.% cleaning agent, stir the solid phase and 6g cleaning agent at 400r / min for 30min at 40°C, and clean the oil-containing The sludge is centrifuged in a centrifuge with a centrifugal speed of 6000r / min for 5 minutes to achieve three-phase separation of oil, water and solid, and the treated thick oil sludge is obtained.

Embodiment 3

[0051] Add the asphaltene dispersant CDEH (N,N-bis(hydroxyethyl)cocamide) with a mass fraction of 3% into the non-polar solvent kerosene, stir evenly to obtain the pretreatment liquid, take No. 1 and No. 4 oil sludge ( See Table 1 for sludge characteristics) each 2g, then add 2g of pretreatment solution respectively, stir at 500r / min for 30min at 25°C, let stand for 3min to separate layers, and perform solid-liquid separation to obtain a solid phase; sodium fatty alcohol ether carboxylate Mix with sodium carbonate at a mass ratio of 1:1, add water three times and stir evenly to obtain 5wt.% cleaning agent, stir the solid phase and 8g of cleaning agent at 500r / min for 60min at 50°C, and clean the oil-containing The sludge is centrifuged for 5 minutes in a centrifuge with a centrifugal speed of 5000r / min to achieve three-phase separation of oil, water and solid, and the treated thick oil sludge is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com