Annular brazing filler metal cleaning method and cleaning device

A cleaning device and solder technology, applied in the direction of metal material coating process, etc., can solve the problems of rework, waste of cleaning agent solution, low efficiency, etc., and achieve the effect of automatic control, precise control of time, and improvement of process effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

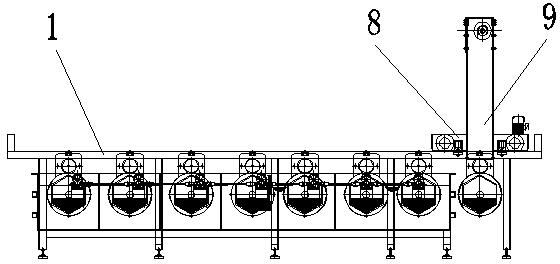

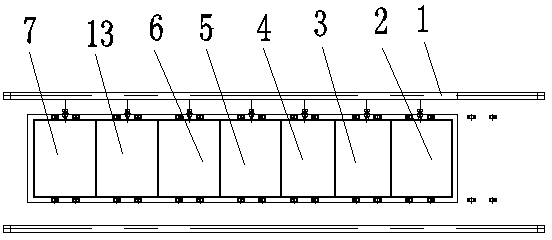

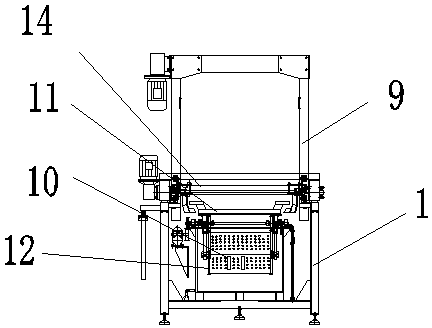

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0025] Example.

[0026] In this embodiment, the method for cleaning the annular solder includes the following steps.

[0027] 1) The annular solder is deoxidized in sulfuric acid solution for 180-240 seconds. The deoxidation effect is good, and ceramic beads are used in the process to improve the deoxidation effect. This operation is carried out in the deoxidation tank 2.

[0028] 2) Rinse with water for 30-60 seconds. This operation is carried out in No. 1 rinse tank 3 . Can remove residues on the drum and on the surface of the solder.

[0029] 3) Use an aqueous solution of metal cleaning agent with a mass percentage concentration of 2-5% to degrease the annular solder at a temperature of 40-60 degrees Celsiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com