Preparation method of strongly-fragrant rapeseed oil

A technology of rapeseed oil and rapeseed, which is applied in the field of preparation of fragrant rapeseed oil, can solve the problems of insufficient fragrance of rapeseed oil, etc., and achieve the effects of reducing the residual oil rate of cakes, strong fragrance, and preventing harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

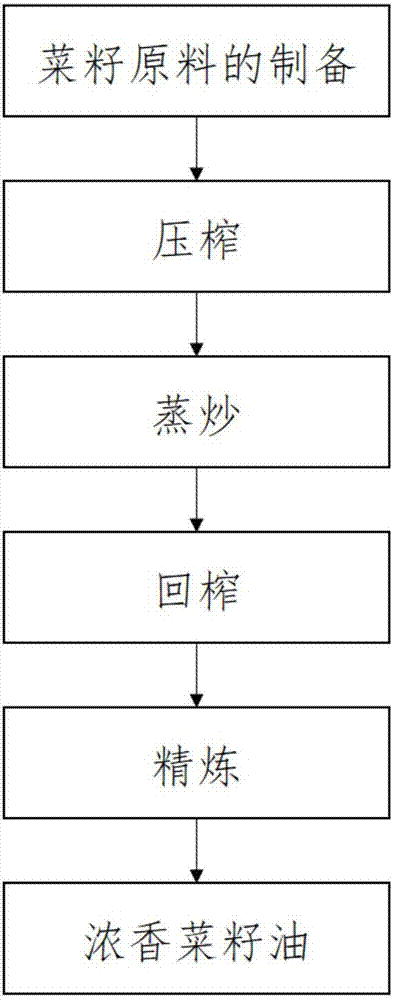

[0021] Such as figure 1 Shown, the invention provides a kind of strong fragrant rapeseed oil preparation method, comprises the steps:

[0022] Step 1. The rapeseed with a moisture content of 14-18% is sequentially subjected to impurity removal, water washing, and tempering treatment to obtain rapeseed raw materials with a moisture content of 6-8%, and the rapeseed raw materials are divided into pressed rapeseed Raw material and back-pressed rapeseed raw material, the mass ratio of said pressed rapeseed raw material to said back-pressed rapeseed raw material is 3:1.

[0023] Step 2: Squeeze the pressed rapeseed raw material, first heat the pressed rapeseed raw material to 105-110°C, press for 10-20 minutes, continue heating to 110-115°C, and keep pressing for 20-20°C After 40 minutes, press rapeseed crude oil and press cake are obtained, and the oil content of the press cake is 8-10%.

[0024] Step 3, crushing the pressed cake and mixing it with the returned rapeseed raw mate...

Embodiment 1

[0028] The rapeseed with a moisture content of 16% is sequentially removed from impurities, washed with water, and tempered to obtain a rapeseed raw material with a moisture content of 7%, and the rapeseed raw material is divided into a pressed rapeseed raw material and a back-pressed rapeseed raw material Carry out pressing treatment to described pressed rapeseed raw material, first described pressed rapeseed raw material is heated to 108 ℃, presses 15 minutes, continues heating to 112 ℃, and keeps pressing 30 minutes, obtains pressed rapeseed crude oil and Pressed cake, the oil content of the pressed cake is 9%; the pressed cake is crushed and mixed with the repressed rapeseed raw material to obtain a mixed rapeseed raw material, and the mixed rapeseed raw material is steamed and fried , the steaming and frying process is as follows: crush the pressed cake and mix it with the repressed rapeseed raw material to obtain the mixed rapeseed raw material. In the first stage, the mi...

Embodiment 2

[0030]The rapeseed with a moisture content of 14% is sequentially removed from impurities, washed with water, and tempered to obtain a rapeseed raw material with a moisture content of 6%, and the rapeseed raw material is divided into a pressed rapeseed raw material and a back-pressed rapeseed raw material Carry out pressing treatment to described pressed rapeseed raw material, first described pressed rapeseed raw material is heated to 105 ℃, presses 10 minutes, continues heating to 110 ℃, and keeps pressing 20 minutes, obtains pressed rapeseed crude oil and Pressed cake, the oil content of the pressed cake is 8%; the pressed cake is crushed and mixed with the repressed rapeseed raw material to obtain a mixed rapeseed raw material, and the mixed rapeseed raw material is steamed and fried , the steaming and frying process is as follows: crush the pressed cake and mix it with the repressed rapeseed raw material to obtain the mixed rapeseed raw material. In the first stage, the mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com