Low-temperature cold pressing method for linseed oil

A production method, linseed oil technology, applied in the direction of fat oil/fat production, fat production, etc., can solve the problems of carotenoid loss, vitamin composition loss, protein denaturation, etc., and achieve the goal of improving the economic benefits of enterprises and resource utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

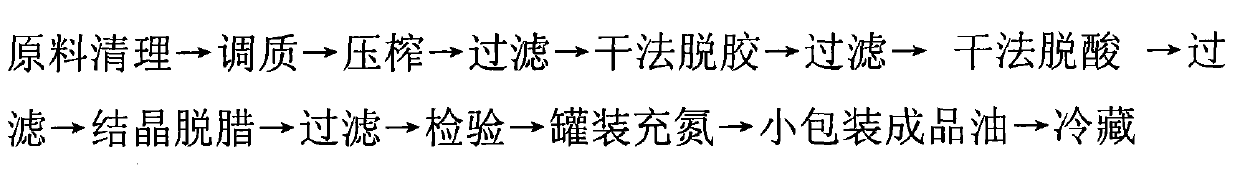

Method used

Image

Examples

Embodiment Construction

[0023] Embodiment: In order to ensure the quality of cold-pressed linseed oil, the quality of raw material of linseed is strictly controlled at first. It is required that the raw materials must be cleaned up with a purity of over 99.5%. The raw materials cannot be wetted by water, because the raw materials that have been exposed to water will become moldy. The raw materials should not contain impurities such as rapeseed and bitter mustard, and should not contain metal, sand and stone energy sundries. The raw materials are best harvested in the same year, and old materials cannot be used.

[0024] 10,000kg of linseed raw materials must be tempered before being squeezed, and the moisture content of the raw materials should be controlled between 8-10%. The pressing process uses a twin-screw oil press. The raw materials are not fried or steamed before being squeezed, but directly squeezed at room temperature for one time. The maximum oil output temperature during pressing is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com