Treatment method for grease adsorbed adsorbent

An adsorbent and grease technology, which is applied in the direction of recovering fat oil/fatty acid from waste materials, producing fat, and recycling fatty substances, can solve the problems of large equipment investment, high gas pressure, and increased equipment investment, so as to reduce production costs, The effect of improving economic value and saving resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

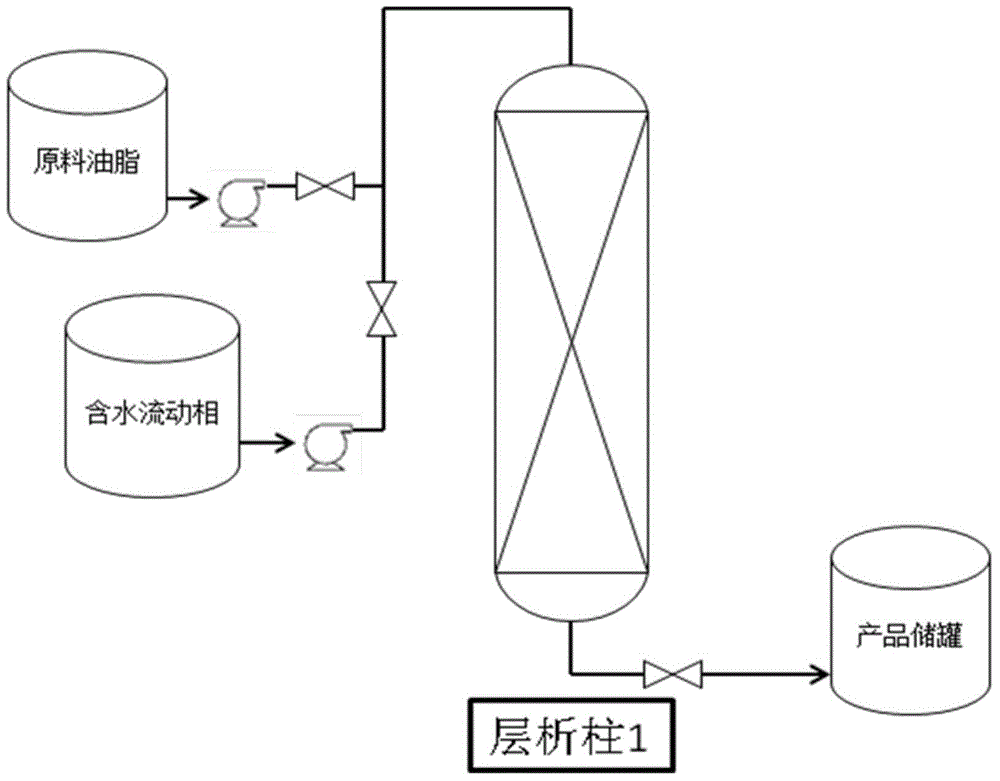

[0178] Pack the column according to the adsorbent scheme in Table 1 to obtain the chromatographic column of Examples 1-8.

[0179] The column chromatography of Examples 1-8 was used to perform column chromatography on 30-fold column volume of soybean oil to purify and prepare high-quality soybean oil, and to determine the weight of the residual oil of the waste filler adsorbent to calculate the residual oil rate of the waste filler adsorbent.

[0180] After the purification process, configure the mobile phase according to the scheme in Table 1, and switch to a new mobile phase, make the aqueous mobile phase pass through the adsorbent column at a certain flow rate (specifically as shown in Table 1), and collect the discharged soybean oil until it is seen The aqueous mobile phase was discharged, the addition of the aqueous mobile phase was stopped, and the final residual oil rate was measured. At the same time, the anisidine value, acid value, peroxide value, color and absorbance of t...

Embodiment 9-14

[0201] Using rapeseed oil, palm oil, corn oil, rice oil, fish oil, and algae oil instead of soybean oil, respectively, column chromatography was performed according to the method of Example 1, and the subsequent chromatography column treatment process. The residual oil amount and grease index of the adsorbent before and after treatment were measured.

Embodiment 15-22

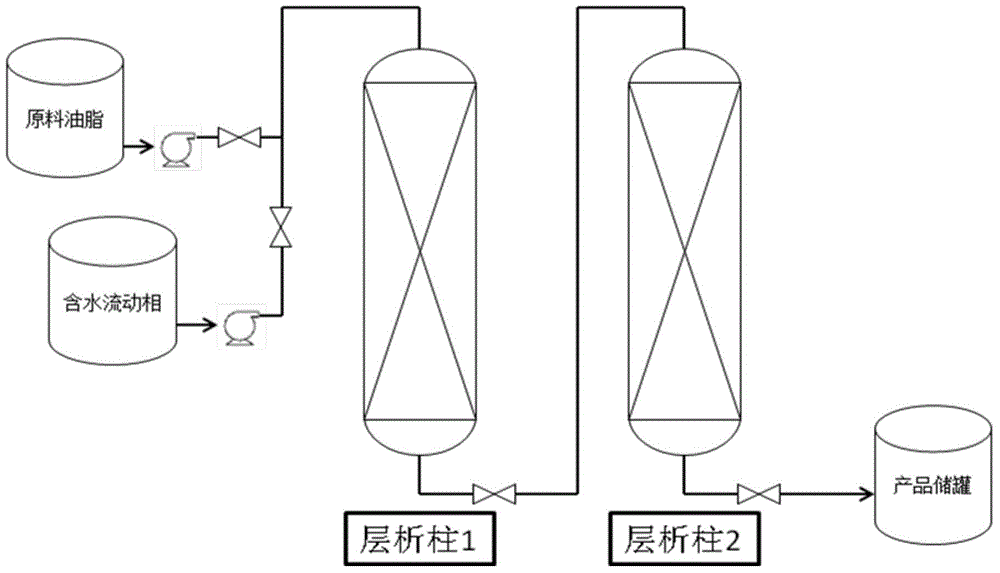

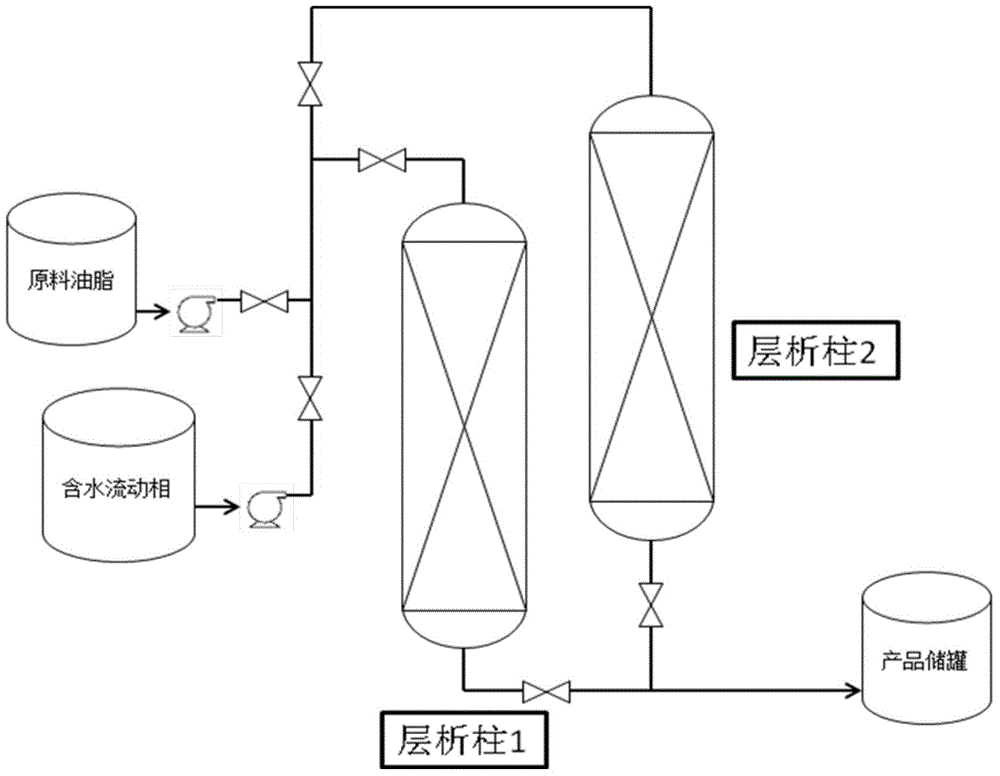

[0208] Prepare multiple chromatography columns, and each column is packed according to the scheme in Table 4 to obtain the chromatography column group of Examples 15-22. The connection mode between the chromatography column groups is series (as attached figure 2 As shown), the column set of Examples 15-22 was used to perform column chromatography on 30 times the column volume of soybean oil to purify and prepare high-quality soybean oil, and to determine the residual oil of the waste packed adsorbent of each chromatography column. After the purification process is over, configure the mobile phase according to the scheme in Table 4, and switch to the new mobile phase at 0.56L / h·cm 2 The flow rate through the chromatography column group is collected, the discharged soybean oil is collected until a small amount of new mobile phase is discharged, the addition of new mobile phase is stopped, and the final adsorbent residual oil amount and oil index of each chromatography column are me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com