Method for producing degreasing peanut protein powder at low-temperature

A defatted peanut and protein powder technology, applied in the directions of food preparation, protein food ingredients, protein composition of vegetable seeds, etc., can solve the problems of losing the application value of food processing functional characteristics, small protein denaturation, and high equipment investment, and achieve peanut protein High utilization rate, small protein denaturation, and good functional properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

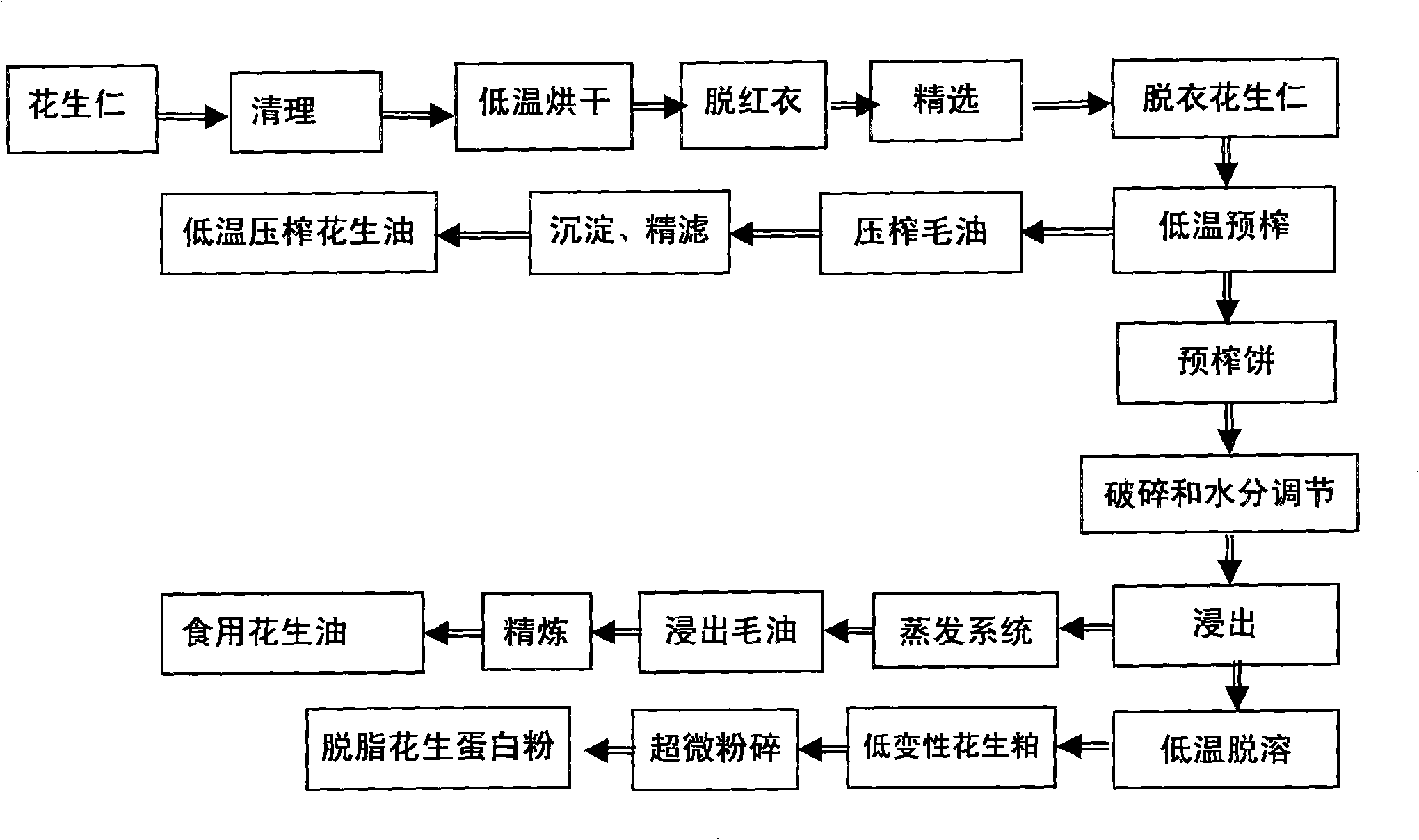

Image

Examples

Embodiment 1

[0018] After cleaning and grading, the peanuts are dried at low temperature, and then the red coat is removed by a half-grain machine, and the discolored kernels (mildewed kernels) are selected and removed to become uncoated peanut kernels, and then directly use a low-temperature screw oil press (patent number: ZL02290849. 8) Carry out a low-temperature pre-pressing, control the rotating speed at 17 rpm, press the oil at a low-temperature pressing temperature from 65°C to room temperature, and obtain a low-temperature pre-pressing cake and low-temperature pressing oil with a residual oil rate of 16%; low-temperature pre-pressing The crushed cake was crushed to a particle size of 10mm, and the water content was controlled at 8%. The low-temperature pre-pressed cake was leached with 6# solvent oil in an extractor, the leaching temperature was 50°C, and the solvent ratio was 1:1.2, and the extracted mixed oil and wet Meal. The extracted mixed oil is evaporated and stripped to obt...

Embodiment 2

[0020] After cleaning and grading, the peanut kernels are dried at low temperature. The temperature of the hot air is lower than 90°C, and the temperature of the material is lower than 60°C to minimize protein denaturation. grains) become stripped peanut kernels and directly use a low-temperature screw oil press to carry out a low-temperature pre-pressing, the control speed is 20 rpm, and the oil is pre-pressed at a low temperature at a temperature of 65°C to room temperature, and the residual oil rate is 17. % of low-temperature pre-pressed cake and low-temperature pressed oil; the low-temperature pre-pressed cake is crushed to a particle size of 8mm, and the moisture is controlled at 5%; the low-temperature pre-pressed cake is leached with 6# solvent oil in an extractor, and the leaching temperature is 55°C. The solvent ratio is 1:1.1 to obtain leached mixed oil and wet meal. . The extracted mixed oil is evaporated and stripped to obtain peanut extracted crude oil, which is...

Embodiment 3

[0022] After the peanuts are cleaned and graded, they are dried at low temperature, and then the red coat is removed by a half-grain machine, and the discolored kernels (mildewed kernels) are selected and removed to become uncoated peanut kernels. After that, they are directly pre-pressed with a low-temperature screw press to control The rotation speed is 23 rpm, and the oil is pre-pressed at a low temperature at an input temperature of 65°C to room temperature to obtain a low-temperature pre-pressed cake and low-temperature pressed oil with a residual oil rate of 17%; the low-temperature pre-pressed cake is crushed to a particle size of The low-temperature pre-pressed cake is leached with 6# solvent oil in the extractor, the leaching temperature is 55°C, and the solvent ratio is 1:1.5 to obtain leaching mixed oil and wet meal. . The extracted mixed oil is evaporated and stripped to obtain peanut extracted crude oil, which is then refined into edible peanut oil. The drained w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com