Dispersing agent for removing oil from shale gas oil-based drilling cuttings

An oil-based drill cuttings and dispersant technology, which is applied in the field of dispersants for shale gas oil-based drill cuttings for oil removal, can solve problems such as long time consumption, and achieve the effects of simple equipment, low energy consumption, and simple processing methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

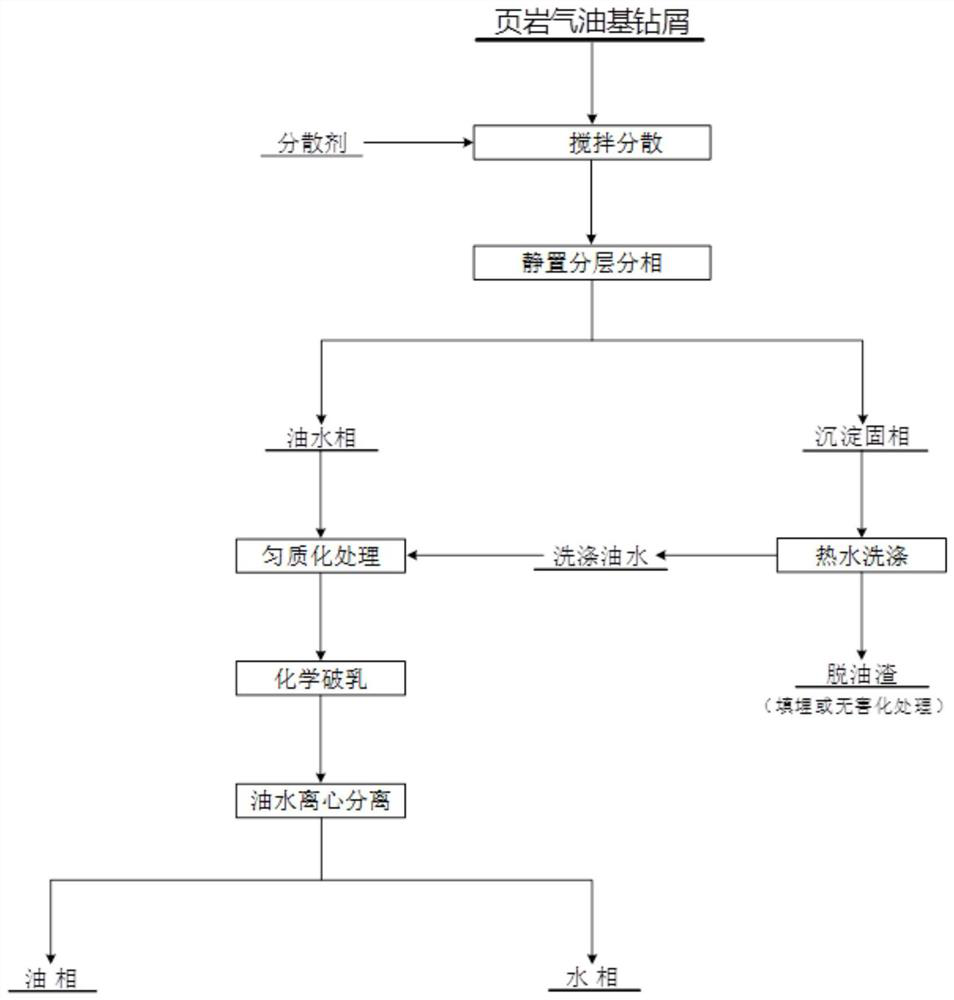

Method used

Image

Examples

Embodiment 1

[0043] A dispersant for shale gas oil-based drilling cuttings degreasing and a degreasing method thereof, specifically:

[0044] a. Degreasing and dispersing agent for shale gas oil-based drilling cuttings: 20 parts of inorganic alkali sodium hydroxide, 1 part of organic base triethylenediamine, 2 parts of surfactant, 0.3 parts of defoamer tributyl phosphate, hexametaphosphoric acid 10 parts of sodium; the surfactant is a mixture of cationic surfactant and nonionic surfactant, 1 part of octadecyltrimethylammonium chloride and 1 part of Tween; water is added to prepare the dispersant to a mass fraction of 10% solvent;

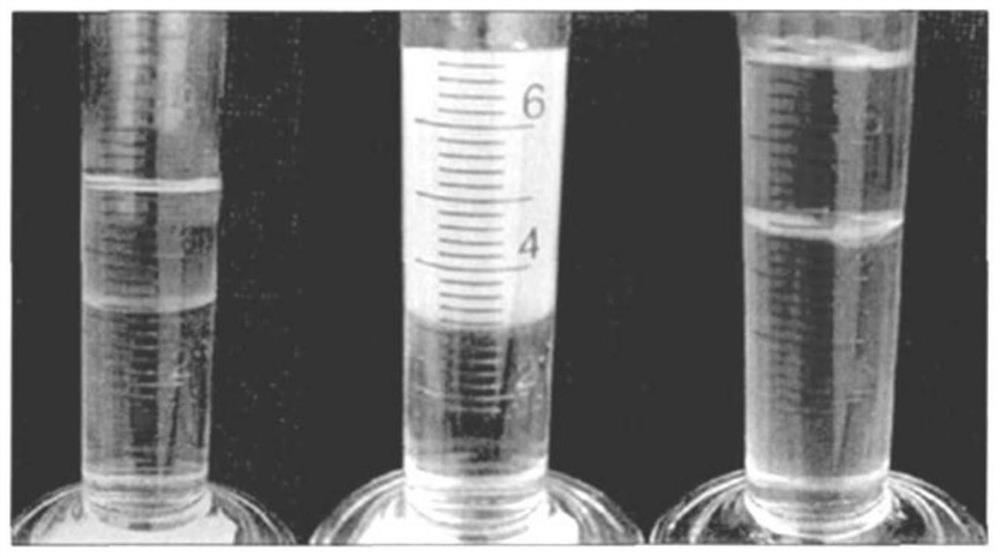

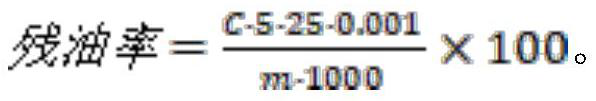

[0045] b. Weigh 400g of oil-based cuttings in beaker 1, then add 600g of oil-removing and dispersing agent, stir at room temperature, the stirring speed is 150rpm-450rpm, and the stirring time is 50min. In beaker 2, place the remaining solid phase in 50-90°C hot water, the volume ratio of hot water to solid phase is 1.5:1, continue stirring for 40-90 minutes, p...

Embodiment 2

[0048] A dispersant for shale gas oil-based drilling cuttings degreasing and a degreasing method thereof, specifically:

[0049] a. Degreasing and dispersing agent for shale gas oil-based drilling cuttings: 40 parts of inorganic alkali sodium carbonate, 0.5 part of organic base triethylamine, 2 parts of surfactant, 0.5 part of defoamer tributyl phosphate, 20 parts of sodium hexametaphosphate Surfactant is a mixture of cationic surfactant and nonionic surfactant, 1 part of octadecyltrimethylammonium chloride and 1 part of Span; water is added and the dispersant is mixed with a mass fraction of 5% solvent;

[0050] b. Weigh 500g of oil-based cuttings in beaker 1, then add 1000g of oil-removing and dispersing agent, stir at room temperature, the stirring speed is 150rpm-450rpm, and the stirring time is 50min. In beaker 2, place the remaining solid phase in 50-90°C hot water, the volume ratio of hot water to solid phase is 2:1, continue to stir for 40-90 minutes, pour the oil-wate...

Embodiment 3

[0053] A dispersant for shale gas oil-based drilling cuttings degreasing and a degreasing method thereof, specifically:

[0054] a. Degreasing and dispersing agent for shale gas oil-based drilling cuttings: 30 parts of inorganic alkali sodium hydroxide, 1.5 parts of organic base triethylenediamine, 1.5 parts of surfactant, 0.3 parts of defoaming agent tributyl phosphate, hexametaphosphoric acid 20 parts of sodium; the surfactant is a mixture of cationic surfactant and nonionic surfactant, 0.75 part of cetyltrimethylammonium bromide and 0.75 part of spar; water is added to prepare the dispersant to a mass fraction of 15% solvent;

[0055] b. Weigh 400g of oil-based drilling cuttings in beaker 1, add 600g of oil-removing and dispersing agent, stir at a temperature of 50°C, the stirring speed is 150rpm-450rpm, and the stirring time is 50min, and let it stand for stratification; Pour it out and put it in beaker 2, put the rest of the solid phase in hot water at 50-90°C, the volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com