Patents

Literature

48results about How to "Avoid affecting heat transfer efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

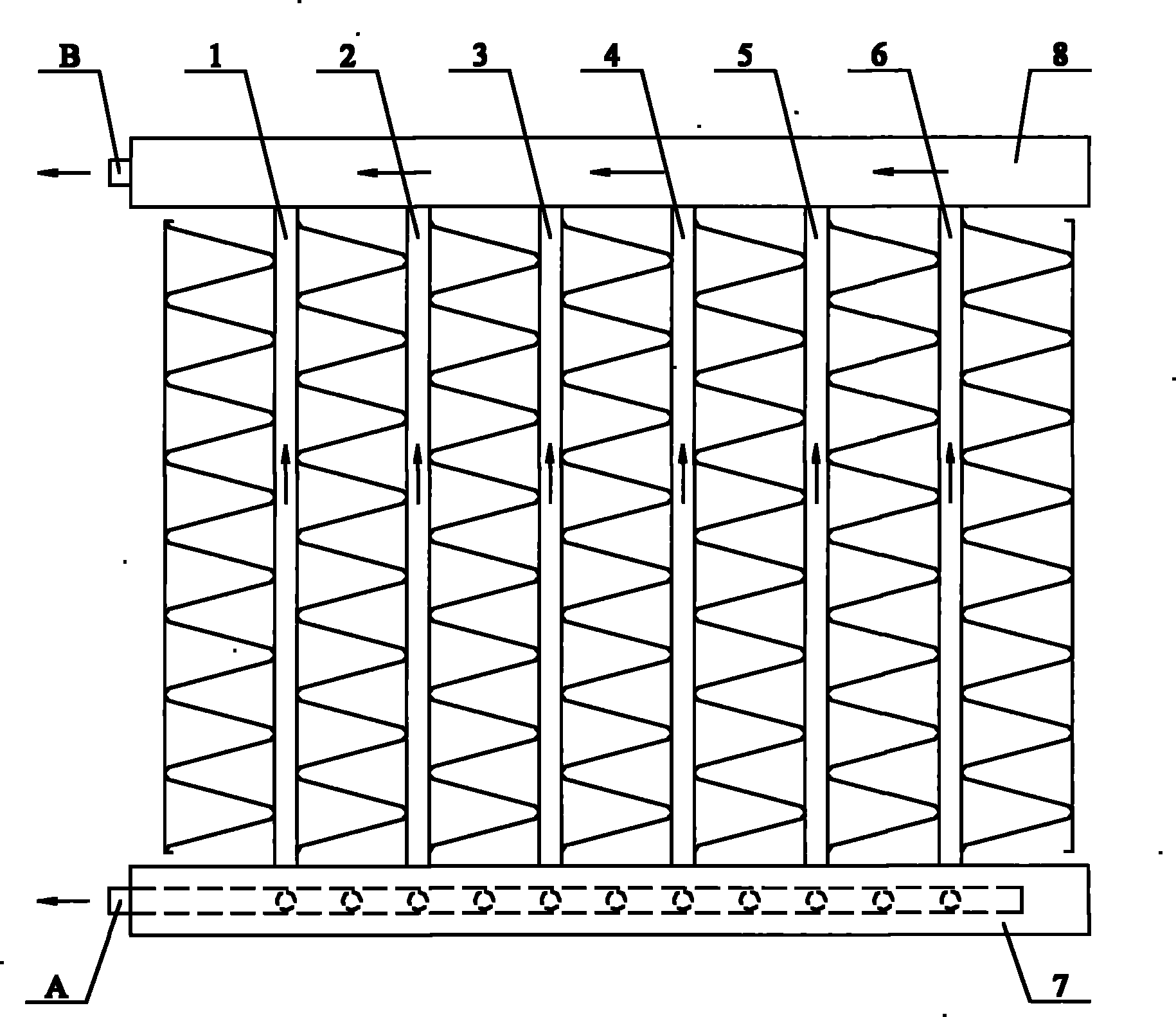

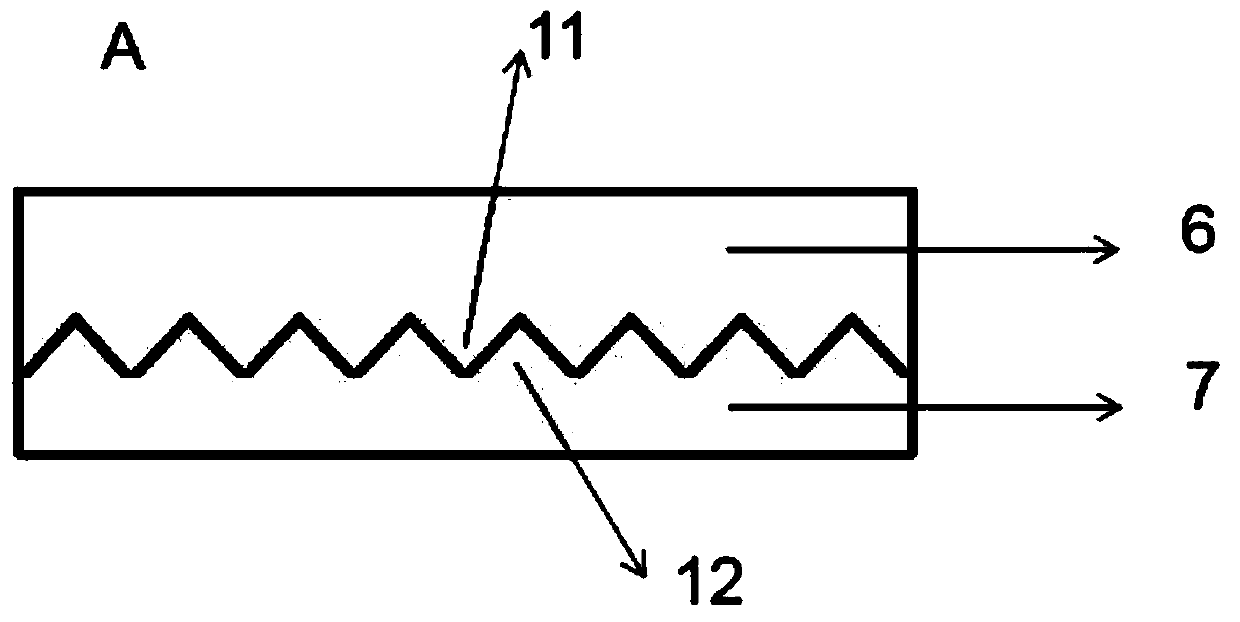

Microchannel heat exchanger

InactiveCN101858698AAddressing uneven distributionAvoid affecting heat transfer efficiencyStationary conduit assembliesHeat exchanger casingsEngineeringVolumetric Mass Density

The invention discloses a microchannel heat exchanger, which comprises two collector tubes, a plurality of flat tubes and a plurality of fins, wherein the ends of the two collector tubes on the same side are respectively provided with a refrigerant inlet and a refrigerant outlet; the flat tubes are orderly arranged between the two collector tubes in the longitudinal direction of the collector tubes, and each flat tube is provided with a plurality of flow holes which are respectively communicated with the two collector tubes; each fin is arranged between adjacent flat tubes; and the flow resistance of the flat tubes gradually decreases from the inlet and outlet of the collector tubes, thereby balancing the flow resistance in each flow path. The invention effectively solves the problem of nonuniform refrigerant flow distribution, and preventing unfavorable partial heat emission from affecting the heat exchange efficiency of the complete machine. Preferably, the variation in the flow resistance of the flat tube is the variation of flow area of the flat tube. Preferably, the density of each flat tube is changed, so that different partial regions have different refrigerant flows. The invention has the advantage of reasonable and reliable structural design.

Owner:SANHUA HLDG GRP +1

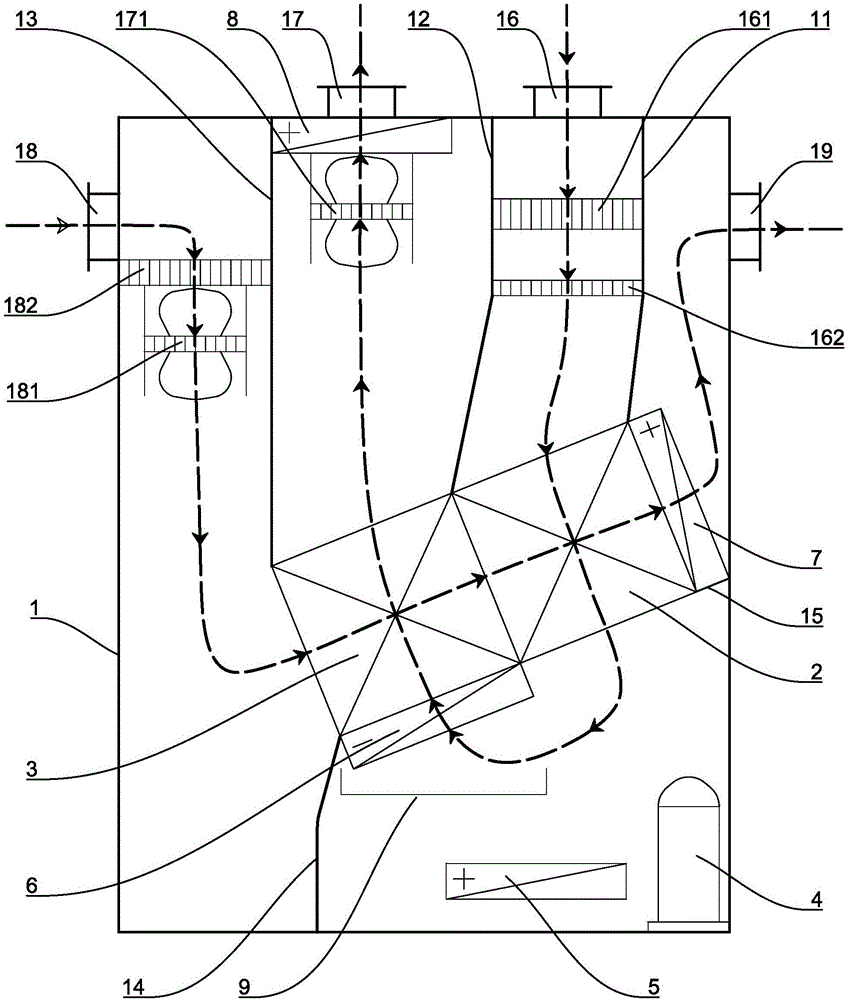

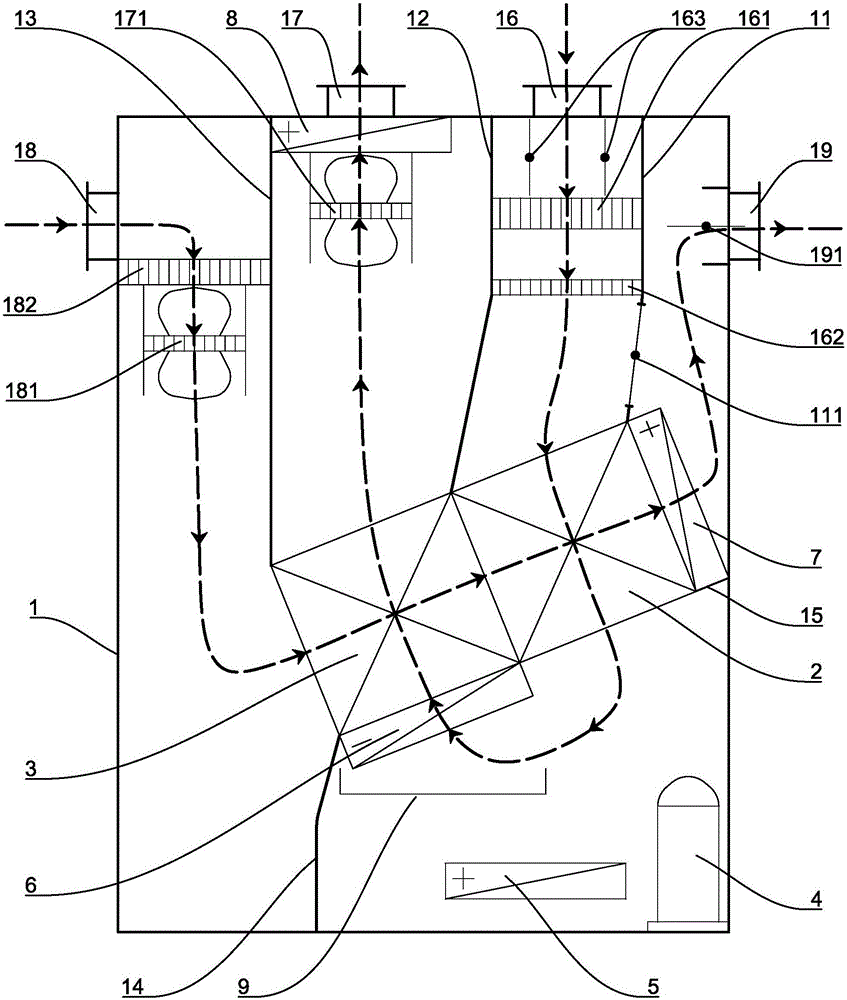

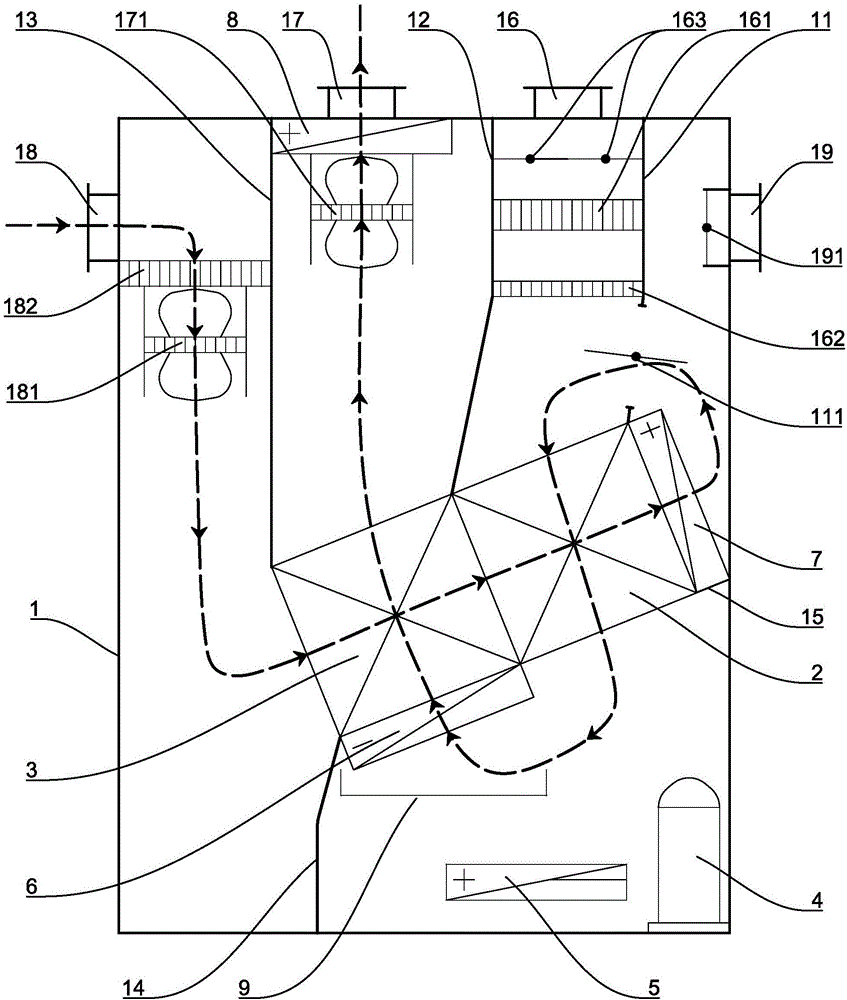

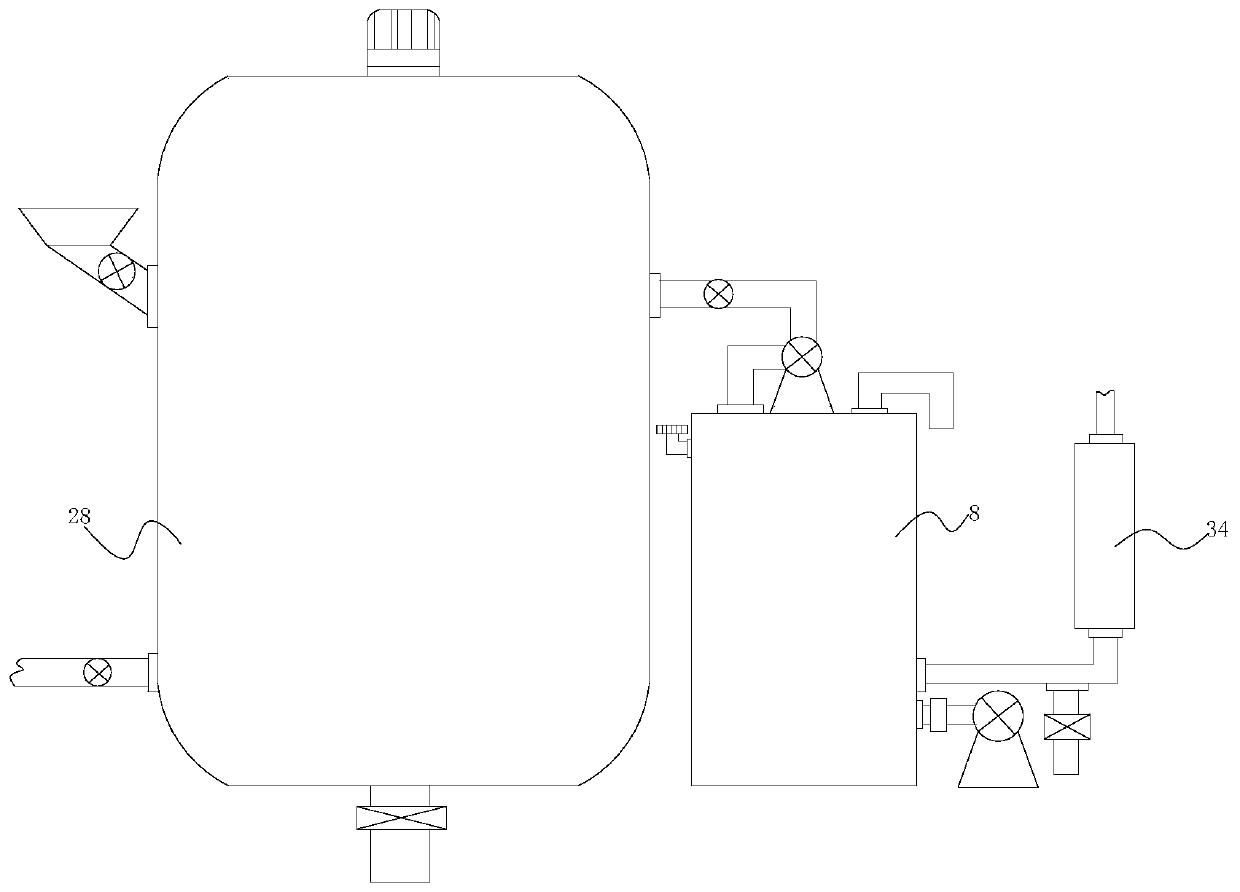

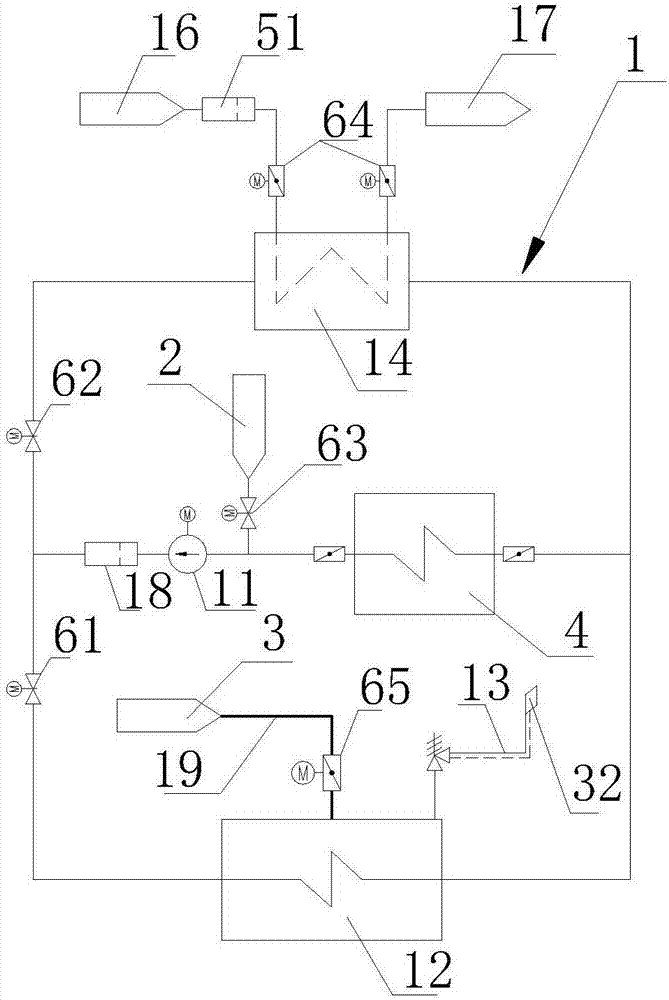

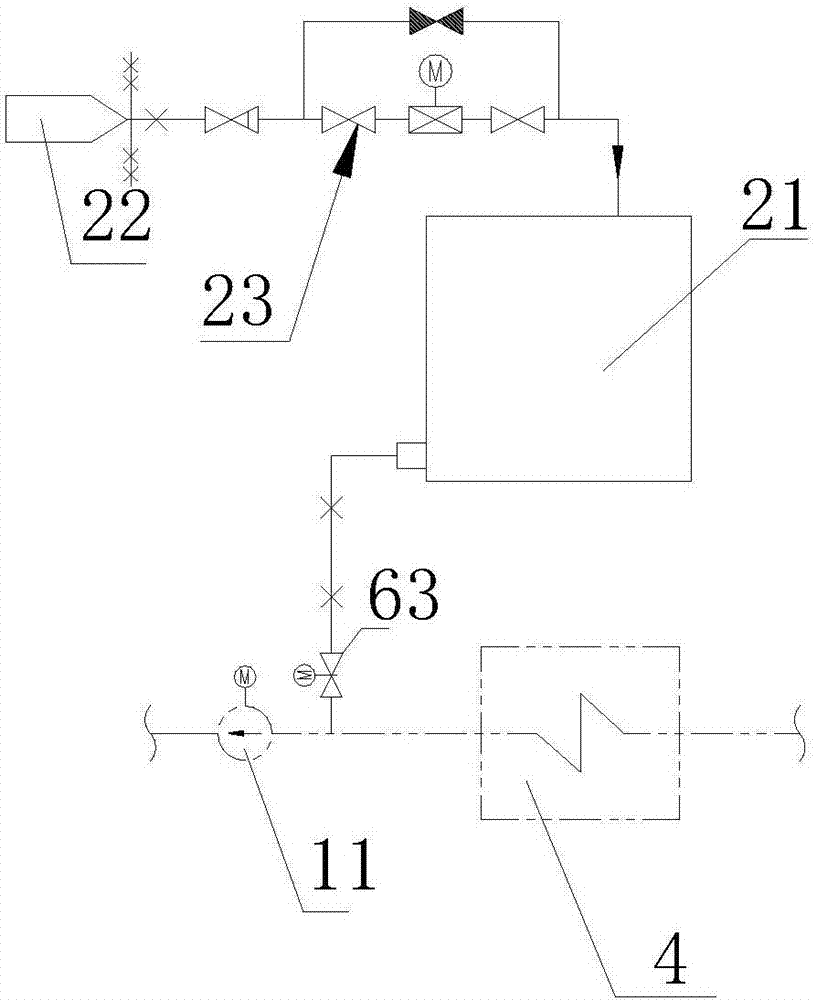

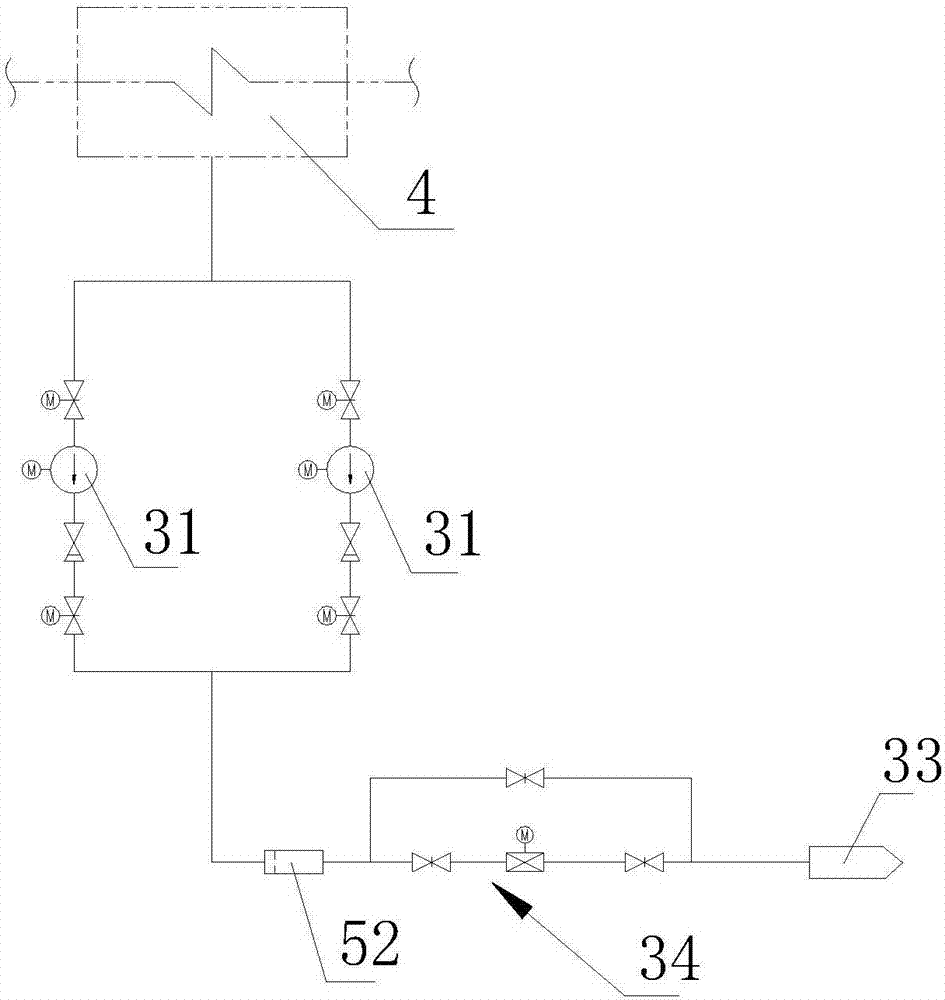

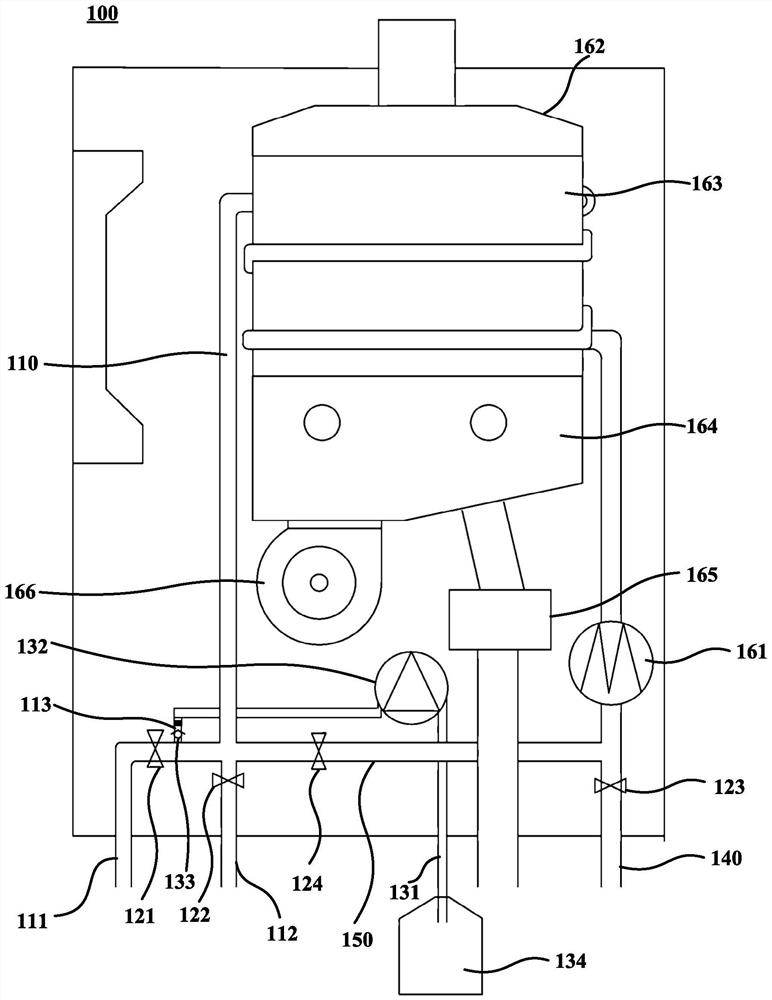

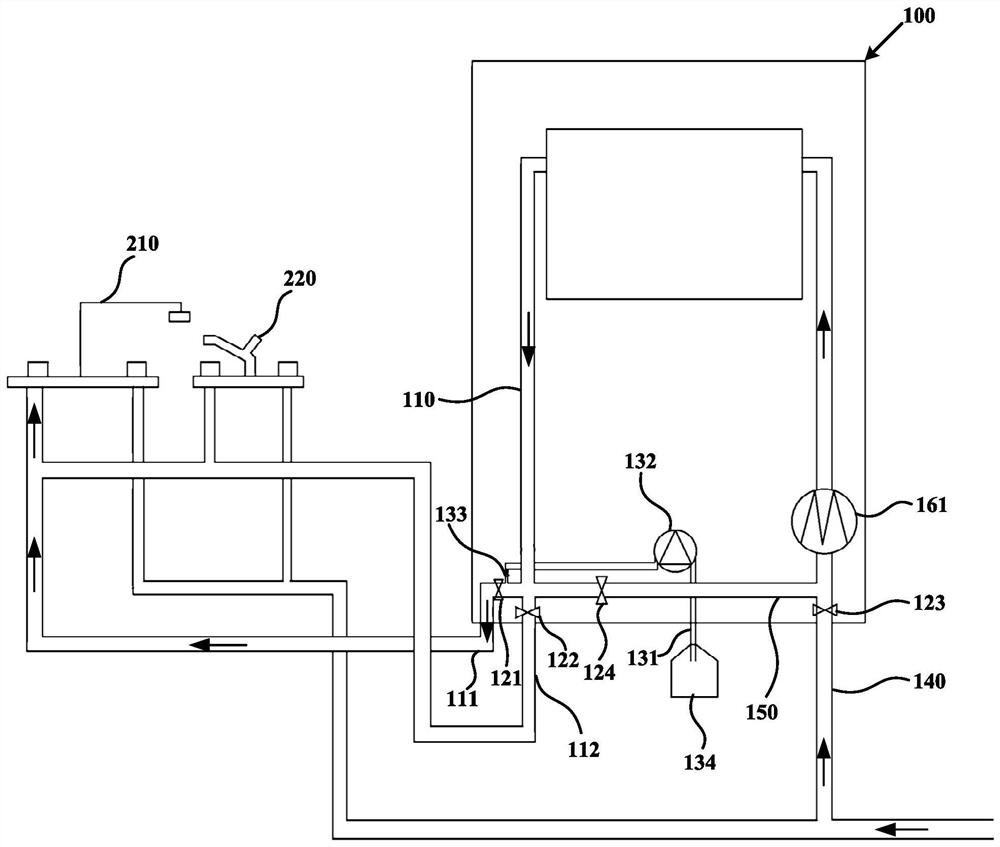

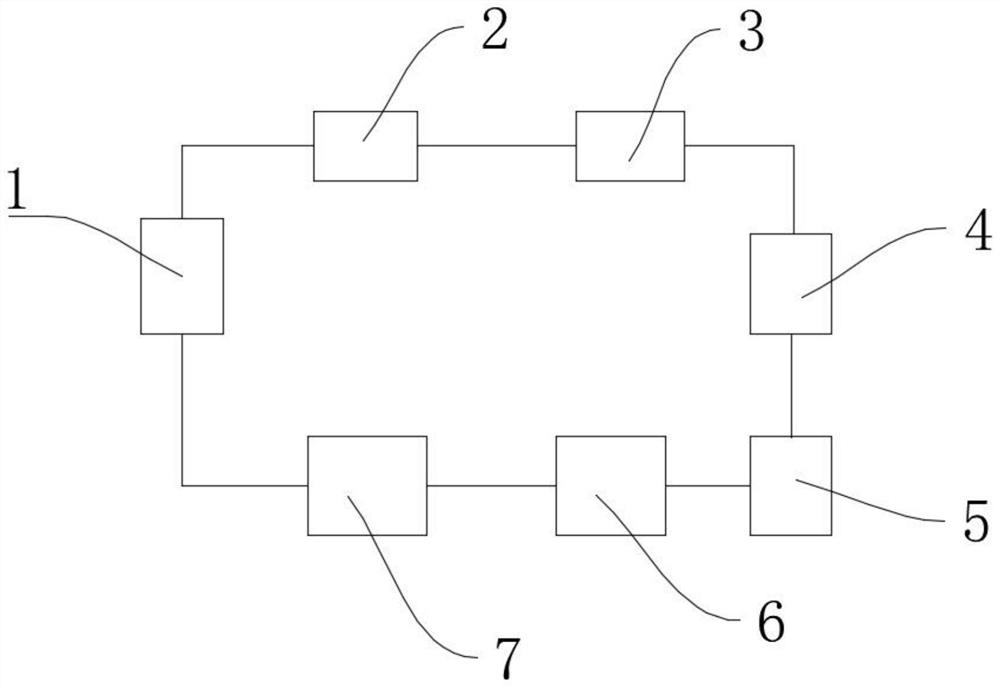

Fresh air handling unit with internal circulation and heat recovery

ActiveCN106839354ASimple structureImprove heat recoveryEnergy recovery in ventilation and heatingMechanical apparatusBusiness efficiencyFresh air

The invention relates to a fresh air handling unit with internal circulation and heat recovery. The fresh air handling unit comprises a shell, a first plate heat exchanger, a second plate heat exchanger, a compressor, a water-cooling condenser and an evaporator, the first plate heat exchanger and the second plate heat exchanger are arranged side by side, a first partitioning plate is arranged between the upper side of the right end of the first plate heat exchanger and the top wall of the shell, a second partitioning plate is arranged between the connecting position of the first plate heat exchanger and the second plate heat exchanger and the top wall of the shell, a third partitioning plate is arranged between the upper side of the left end of the second plate heat exchanger and the top wall of the shell, a fourth partitioning plate is arranged between the lower side of the left end of the second plate heat exchanger and the bottom wall of the shell, and a fifth partitioning plate is arranged between the lower side of the right end of the first plate heat exchanger and the right wall of the shell. A fresh air port and an air delivery port are formed in the top wall of the shell, an air-returning port and an air-discharging port are formed in the left side wall and right side wall of the shell, and the evaporator is arranged on the lower side of the second plate heat exchanger side by side. The fresh air handling unit has the advantages of being simple in structure and high in heat recovery rate and energy efficiency ratio, and can achieve intelligent control and low-energy-consumption operation.

Owner:HUNDRED TECH CO LTD

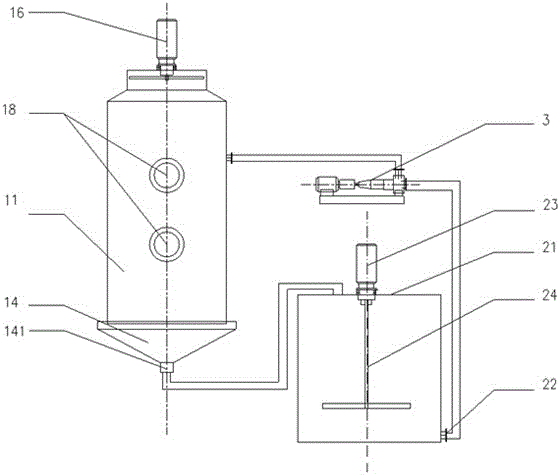

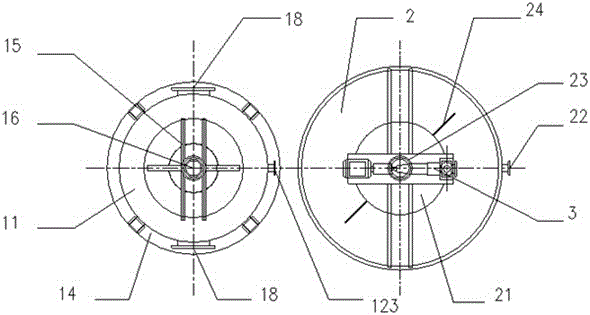

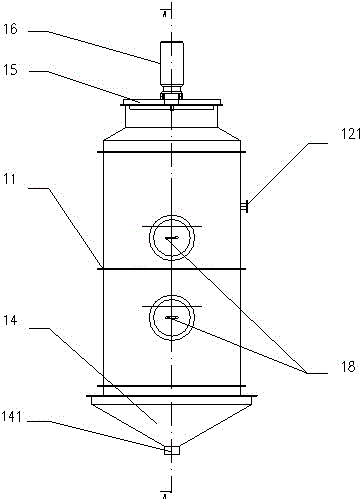

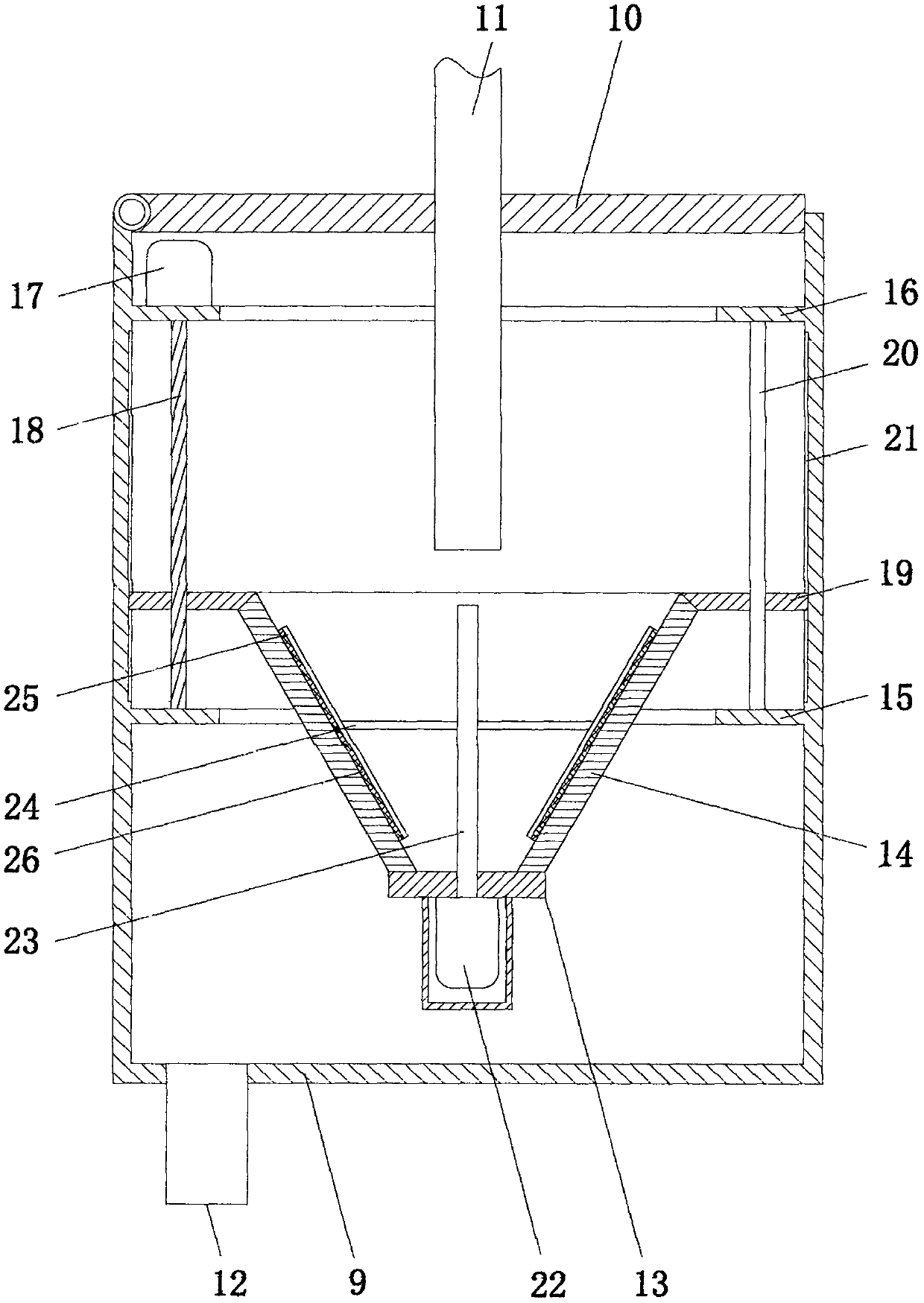

Cooling crystallization device

InactiveCN107519660ASmall footprintLow costSolution crystallizationHeat exchange cooling cystallizationCooling towerSmall footprint

Cooling and crystallization equipment, which includes a cooling tower, a crystallization tank and a circulating pump. The cooling tower also includes a cylinder, a spray device, a material sieve plate and a fan. There is an air inlet at the bottom of the cylinder and an air outlet at the top. At the air outlet of the body, the spray device includes a feed pipe, an elbow and a nozzle. The feed pipe penetrates into the cylinder from the outside of the cylinder. One end of the elbow is connected to the feed pipe and the other end is connected to the nozzle. The nozzle is located in the cylinder. The material screen The plate is set under the nozzle, the material sieve plate is provided with sieve holes, and the crystallization tank is provided with a feed port and a discharge port. The feed port of the crystallization tank is connected with the cooling tower, and the discharge port is connected with one end of the circulation pump. One end is connected to the sprinkler of the cooling tower. Compared with the cooling and crystallization equipment in the prior art, the present invention not only occupies a small area, is low in cost, and is convenient for maintenance, but also has low operating costs, is not easy to block parts, and has high cooling and crystallization efficiency.

Owner:LEIYANG JINYUE SCI & TECH DEV

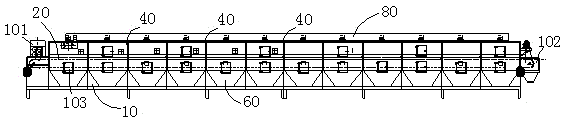

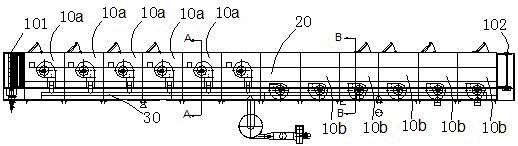

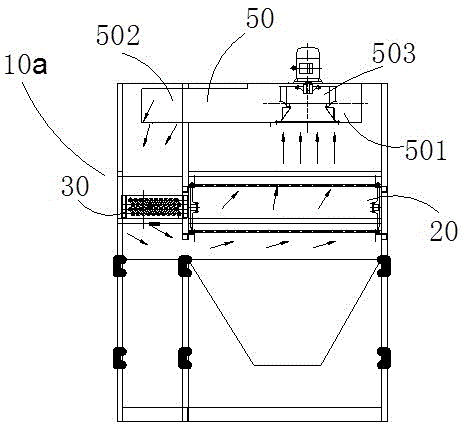

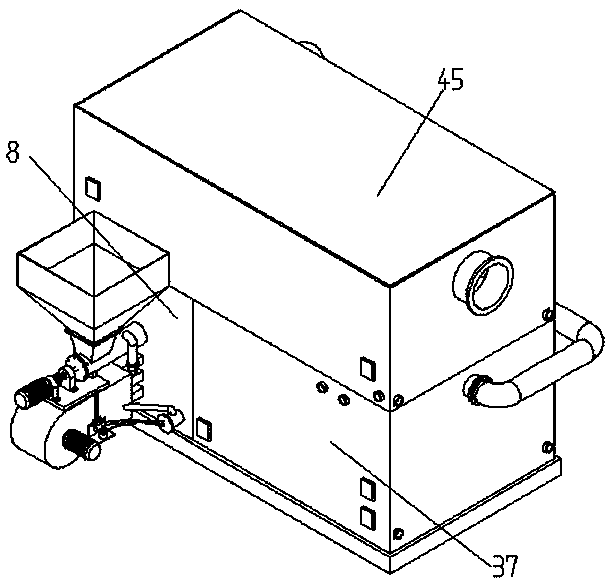

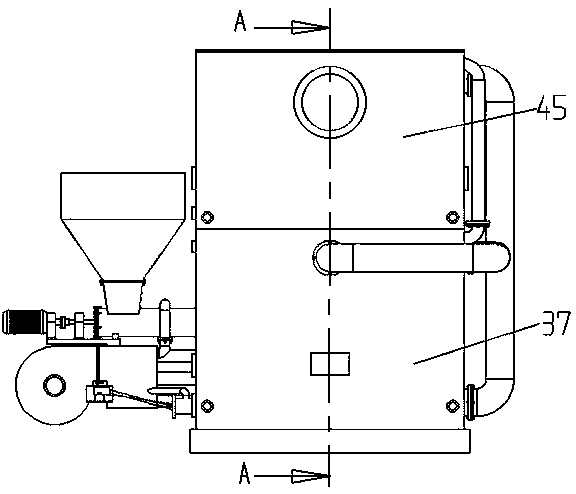

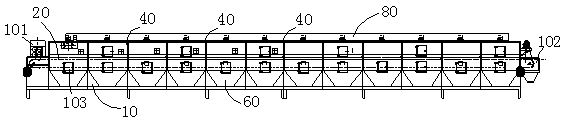

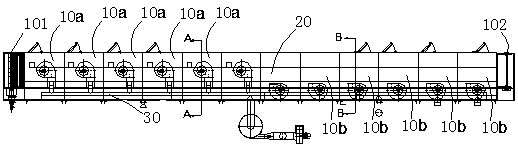

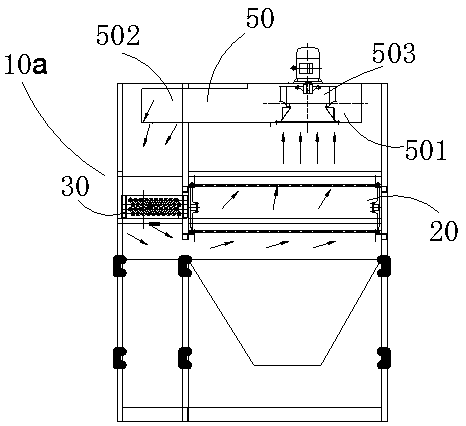

Belt type drier

ActiveCN105627713AAvoid it happening againHigh recovery rateDrying gas arrangementsDrying machines with progressive movementsEngineeringUltimate tensile strength

The invention relates to the technical field of drying equipment, in particular to a belt type drier. The belt type drier is characterized in that the drier comprises a drying box, a conveying net belt arranged in the drying box, heat exchangers arranged in the drying box, a plurality of partition plates, air flue assemblies and hopper assemblies, wherein a feed inlet and a discharge outlet are formed in the two ends of the drying box in the length direction; the multiple partition plates are uniformly arranged in the drying box in the length direction of the drying box, the inner space of the drying box is divided into a plurality of drying units through the partition plates, the multiple drying units comprises the multiple first drying units and the multiple second drying units, and the first drying units and the second drying units are sequentially arranged in the direction from the feed inlet to the discharge outlet; the air flue assemblies are arranged at the tops of inner spaces of all the drying units in a one-to-one correspondence mode; the hopper assemblies are arranged at the bottoms of the inner spaces of all the drying units in a one-to-one correspondence mode. The belt type drier has a good drying effect, raise dust is effectively prevented from being produced, the yield is increased, the material recovery rate is increased, and the labor intensity is relieved.

Owner:江苏太阳臣干燥科技有限公司

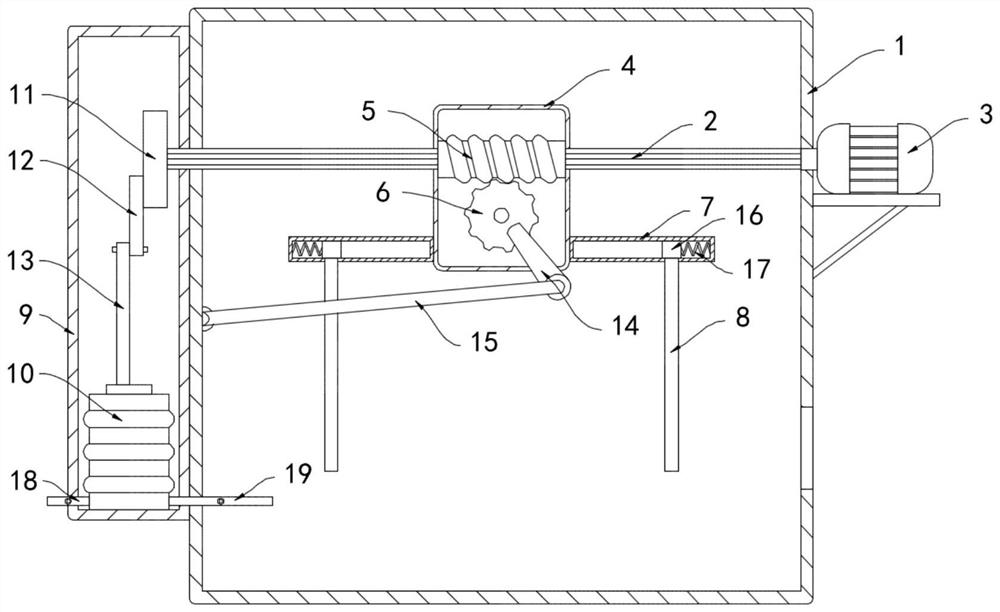

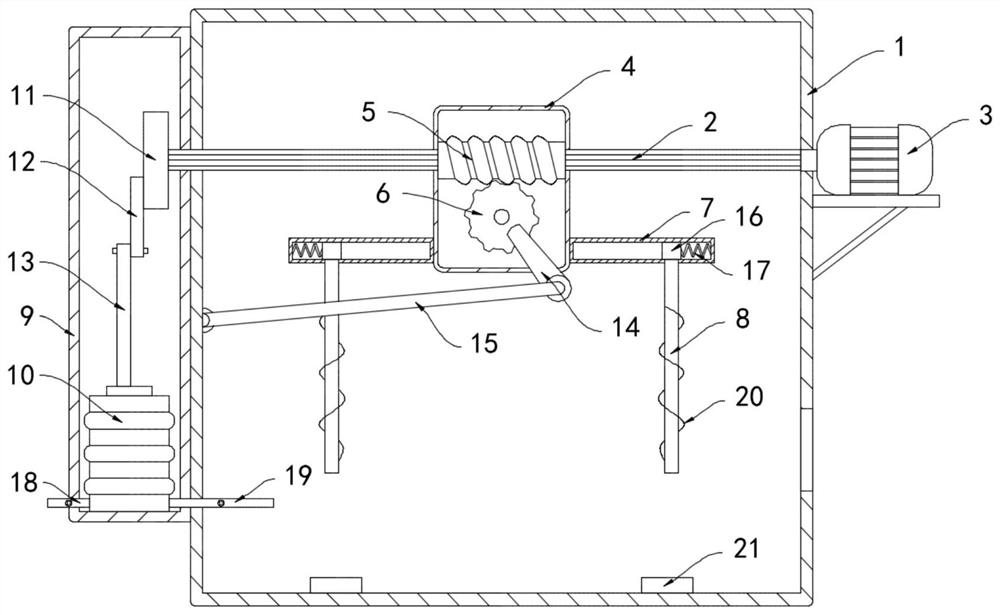

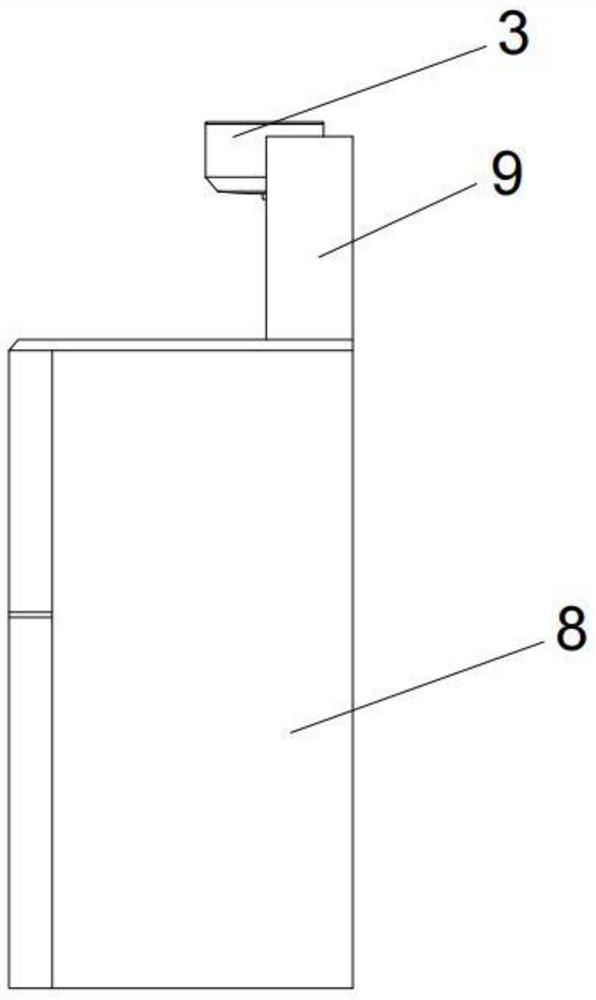

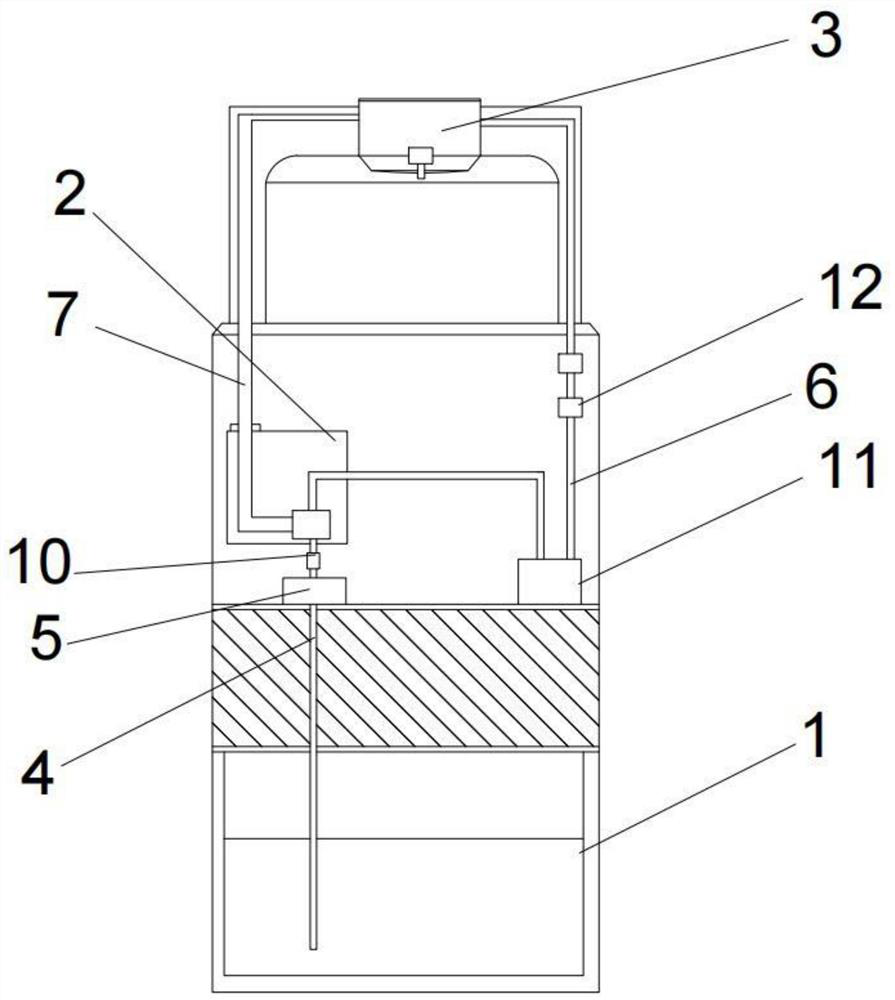

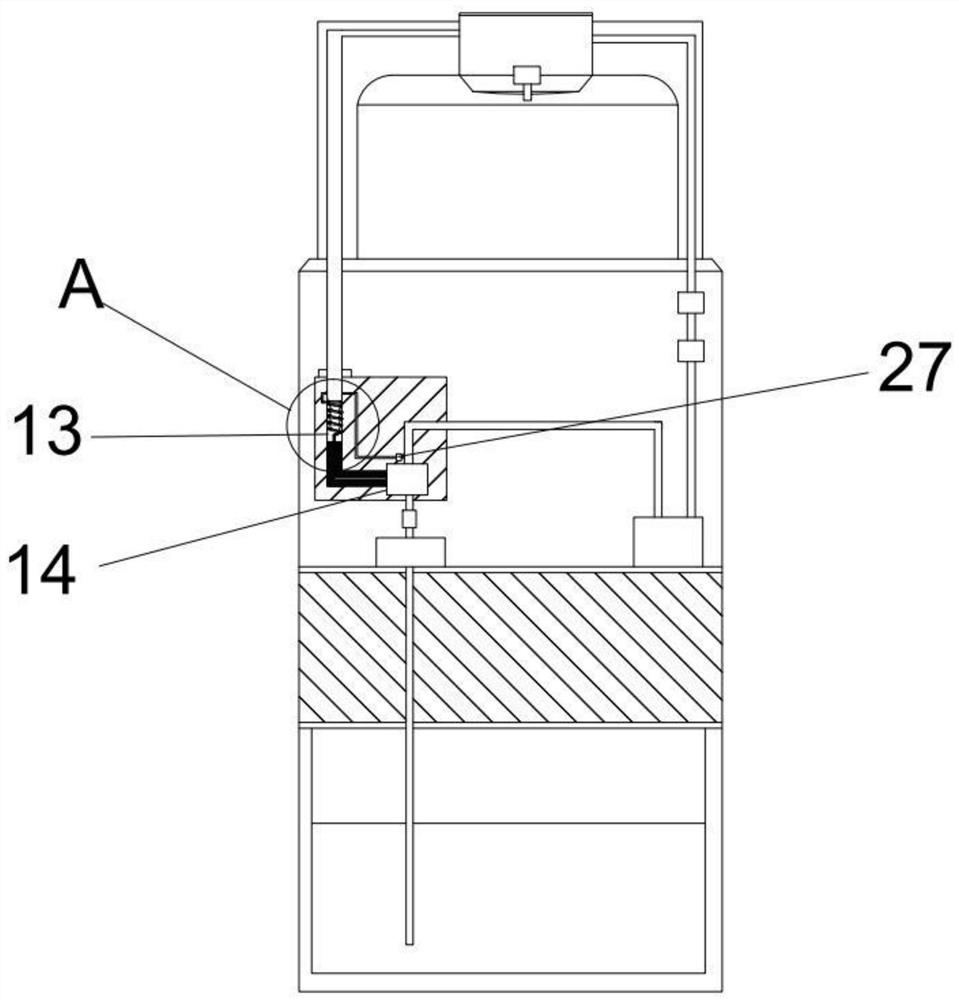

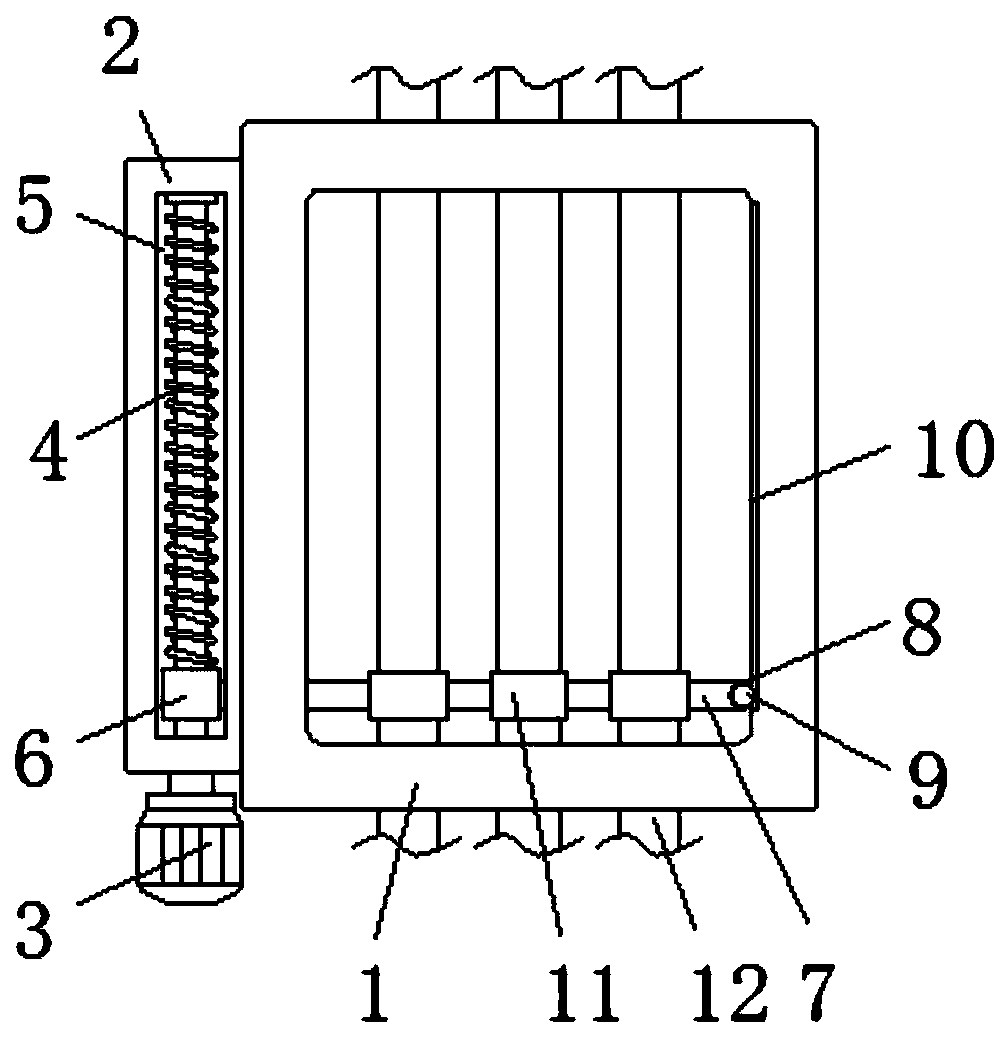

Self-dust-falling overheat protection device for electromechanical equipment

InactiveCN111757654ASpeed up cooling and heat dissipationImprove cooling effectElectrostatic cleaningModifications by conduction heat transferElectric machineryEngineering

The invention belongs to the field of electromechanical equipment and particularly relates to a self-dust-falling overheat protection device for electromechanical equipment. The protection device comprises a box body, wherein the inner side wall of the box body is rotationally connected with a horizontally-arranged sliding rod; a driving motor is mounted on the side wall of the box body; an outputshaft of the driving motor extends into the box body and is coaxially fixed with the sliding rod; the sliding rod is sleeved with a shell in a sliding mode; the inner side wall of the shell is rotationally connected with a worm; a circular cavity is formed in the worm in a delay axis direction; and the worm is slidably sleeved with the sliding rod; a worm wheel is arranged in and rotatably connected with the shell; the worm wheel is connected with the worm in a meshed mode; the worm wheel is connected with the inner side wall of the box body through a transmission mechanism; sliding grooves are fixedly formed in the side walls of the two sides of the shell; and cooling fins are slidably connected to the lower ends of the sliding grooves. Electromechanical equipment can be cooled through the cooling fins and telescopic air bags at the same time, operation is stable and efficient, and the possibility of overheating damage to the electromechanical equipment is greatly reduced.

Owner:符必容

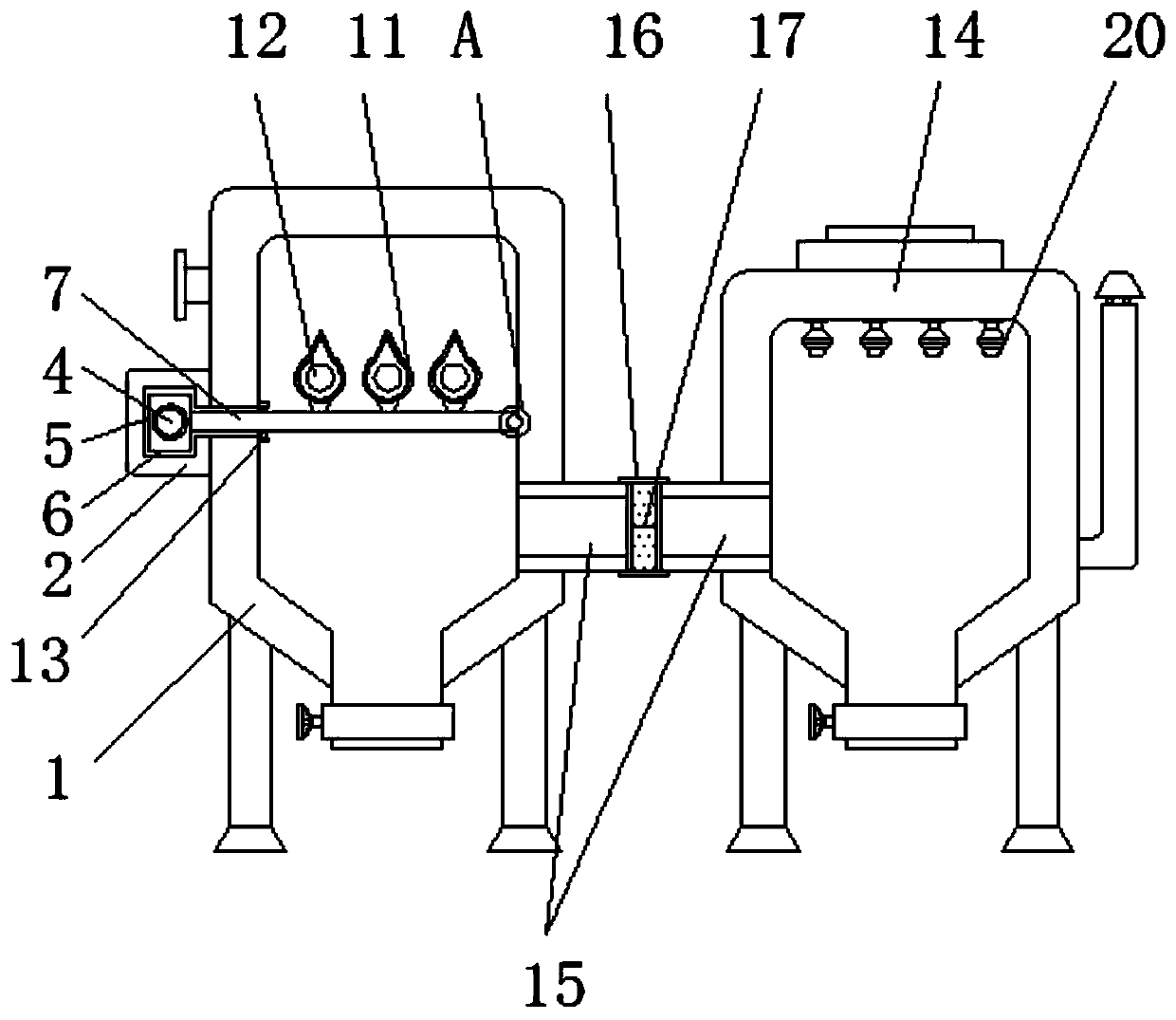

Biomass particle suspension combustion boiler

InactiveCN104075314AReduce energy consumptionIncrease the heat exchange areaFluidized bed combustionApparatus for fluidised bed combustionWater storageThermodynamics

The invention relates to a biomass particle suspension combustion boiler. The biomass particle suspension combustion boiler comprises a combustion chamber, a heating chamber and a waste heat recovery chamber, wherein a smoke inlet I and a smoke outlet I are formed in the heating chamber, a water storage chamber I is arranged in the heating chamber, a heat exchange device I is arranged in the water storage chamber I, and the heat exchange device I comprises N (N is greater than or equal to 1) stage heat exchange pipes I; one end of a first stage heat exchange pipe I is communicated with the smoke inlet I, the other end of the first stage heat exchange pipe I is communicated with one end of a second stage heat exchange pipe I through a first stage gathering cavity I, the other end of the second stage heat exchange pipe I is communicated with one end of a third stage heat exchange pipe I through a second stage gathering cavity I and the like, and the other end of the N-1 heat exchange pipe I is communicated with one end of an N stage heat exchange pipe I through an N-1 stage gathering cavity I; the other end of the N stage heat exchange pipe I is communicated with the smoke outlet I, a dust removing opening I is formed in the first gathering cavity I and / or part or all of the other gathering cavities I, and the dust removing opening I is communicated with the shell of the heating chamber.

Owner:山东东工新能源科技有限公司

A production process of ultrasonic-assisted freezing and vacuum-frying edible mushrooms

ActiveCN103892255BEasy to removeAvoid affecting heat transfer efficiencyFood dryingFood ultrasonic treatmentVacuum pressureUltrasonic assisted

The invention relates to an ultrasonic-assisted freezing and vacuum frying production process of edible fungi. The process is used for solving the problem that no relatively perfect pre-drying technique for the vacuum low-temperature frying of the edible fungi exists at present. The process disclosed by the invention comprises the following steps: (1) selecting edible fungus raw materials; (2) carrying out ultrasonic pre-drying at the ultrasonic frequency of 28kHz, at the ultrasonic power of 80-120W, under the vacuum pressure of 5-10kPa and at the temperature of 20-45 DEG C till the water content is 20-30%; (3) carrying out quick-freezing at the temperature of minus 50-minus 30 DEG C till the edible fungi are completely frozen; (4) carrying out vacuum frying for 5-20 minutes under the vacuum pressure of 0.1-5kPa and at the oil temperature of 80-90 DEG C; (5) carrying out vacuum deoiling under the vacuum pressure of 0.1-5kPa; (6) carrying out seasoning; (7) carrying out inert gas filling packaging to obtain finished products. The process disclosed by the invention is capable of stably maintaining the shape and the color of the fried edible fungi.

Owner:ZHEJIANG FORESTRY ACAD

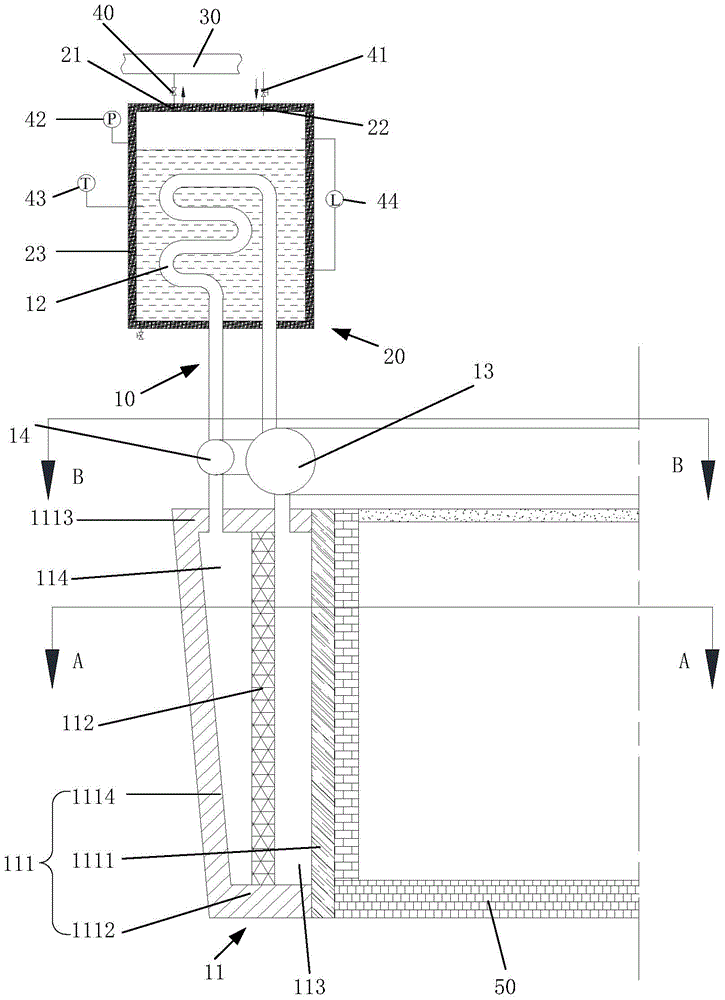

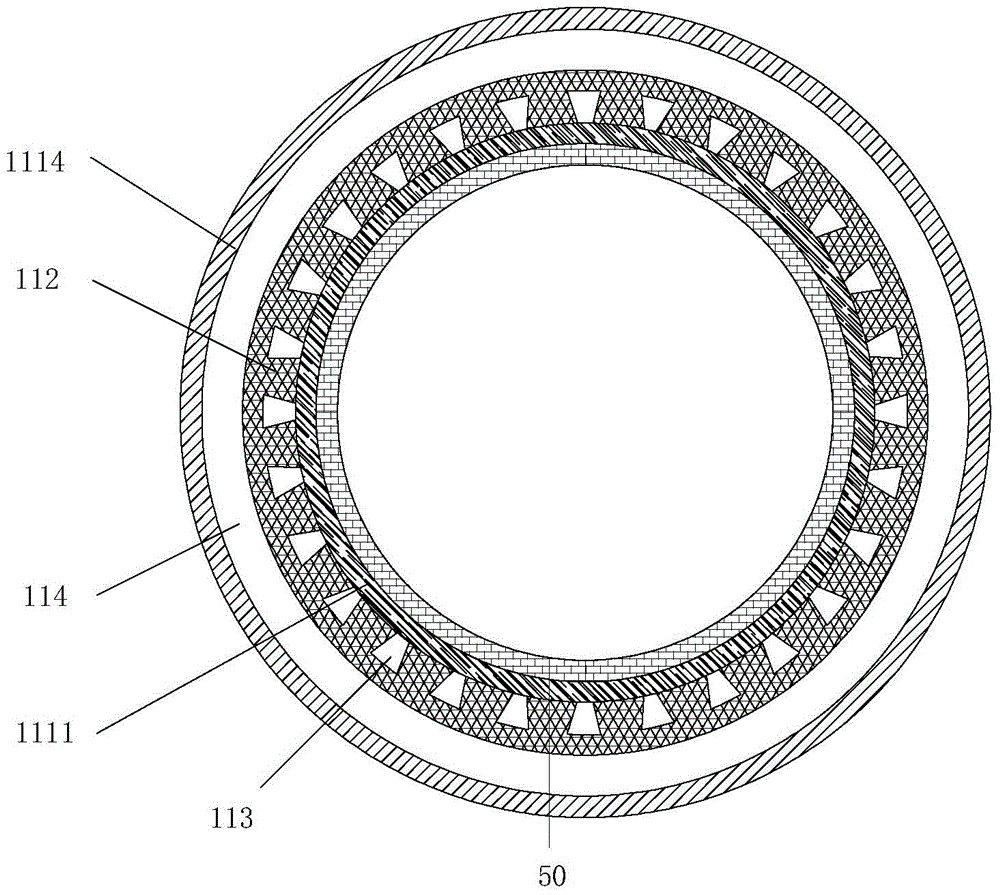

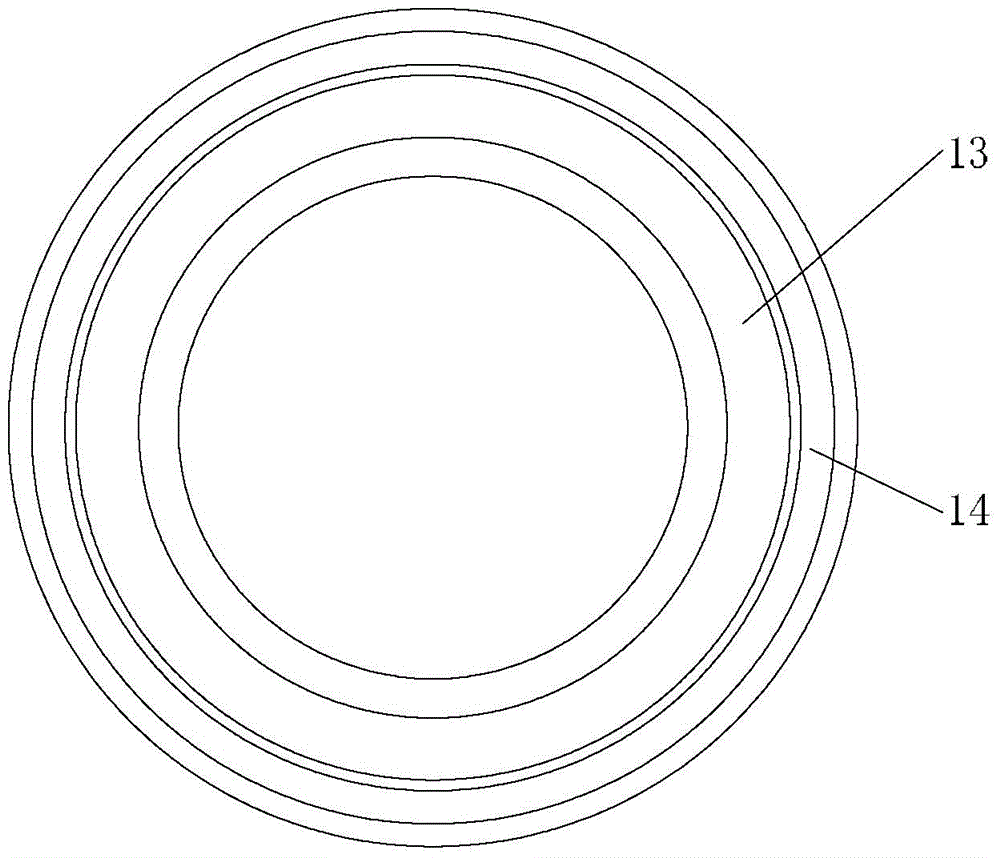

Waste heat recovery system of steel slags

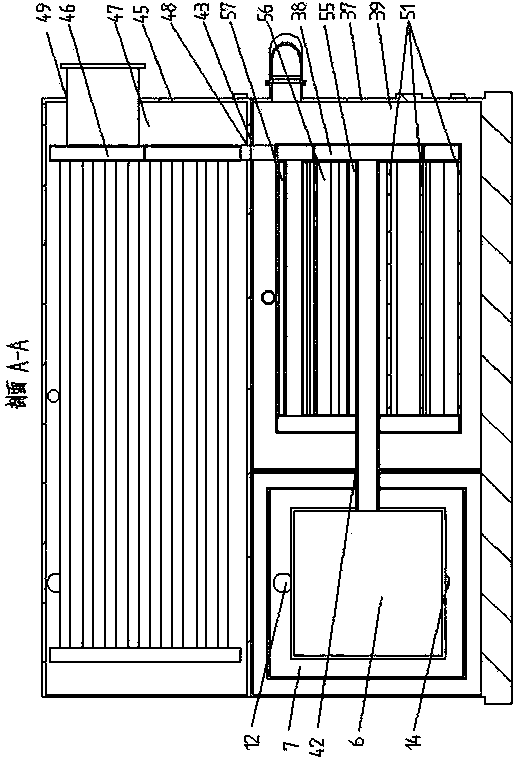

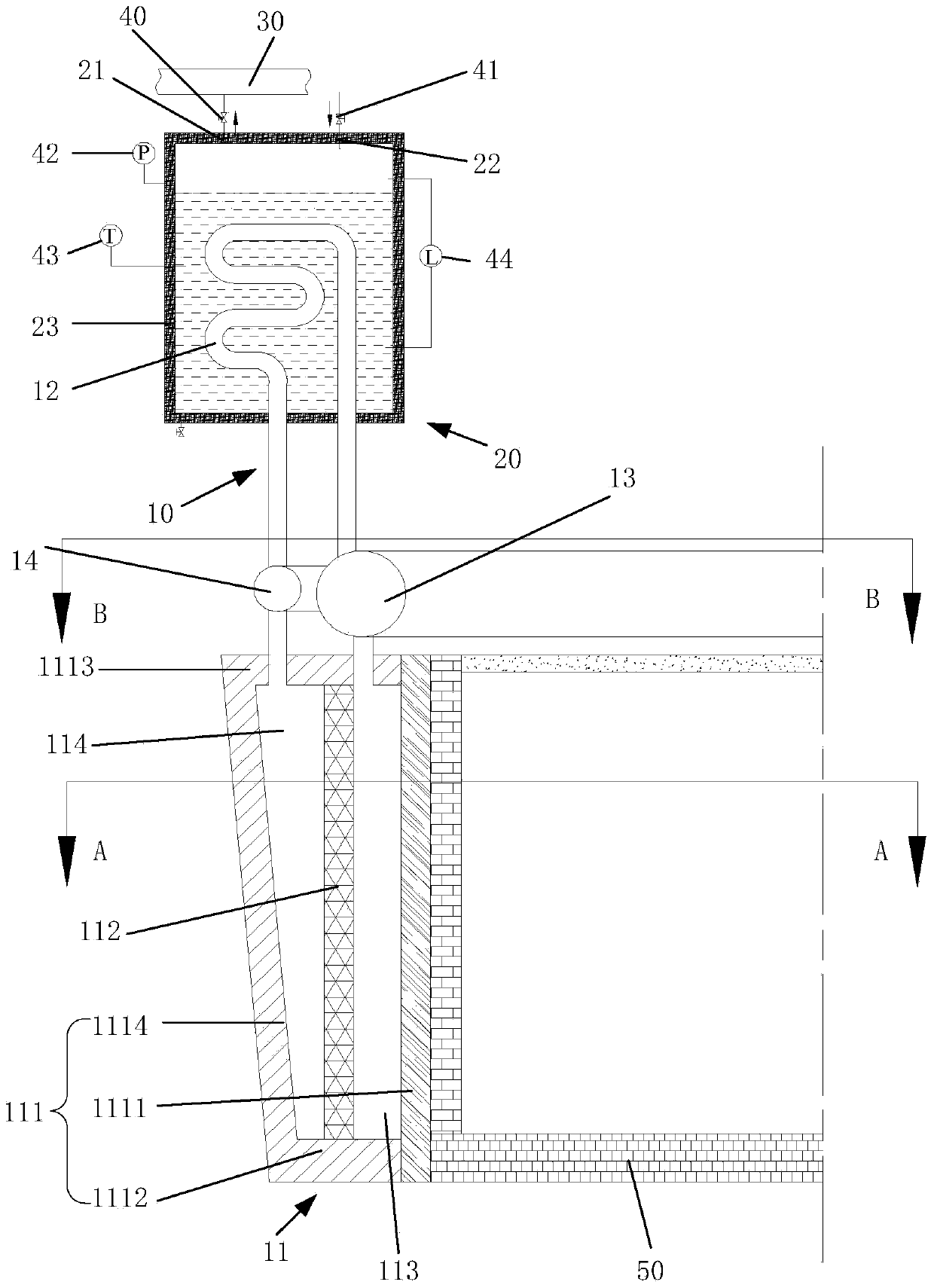

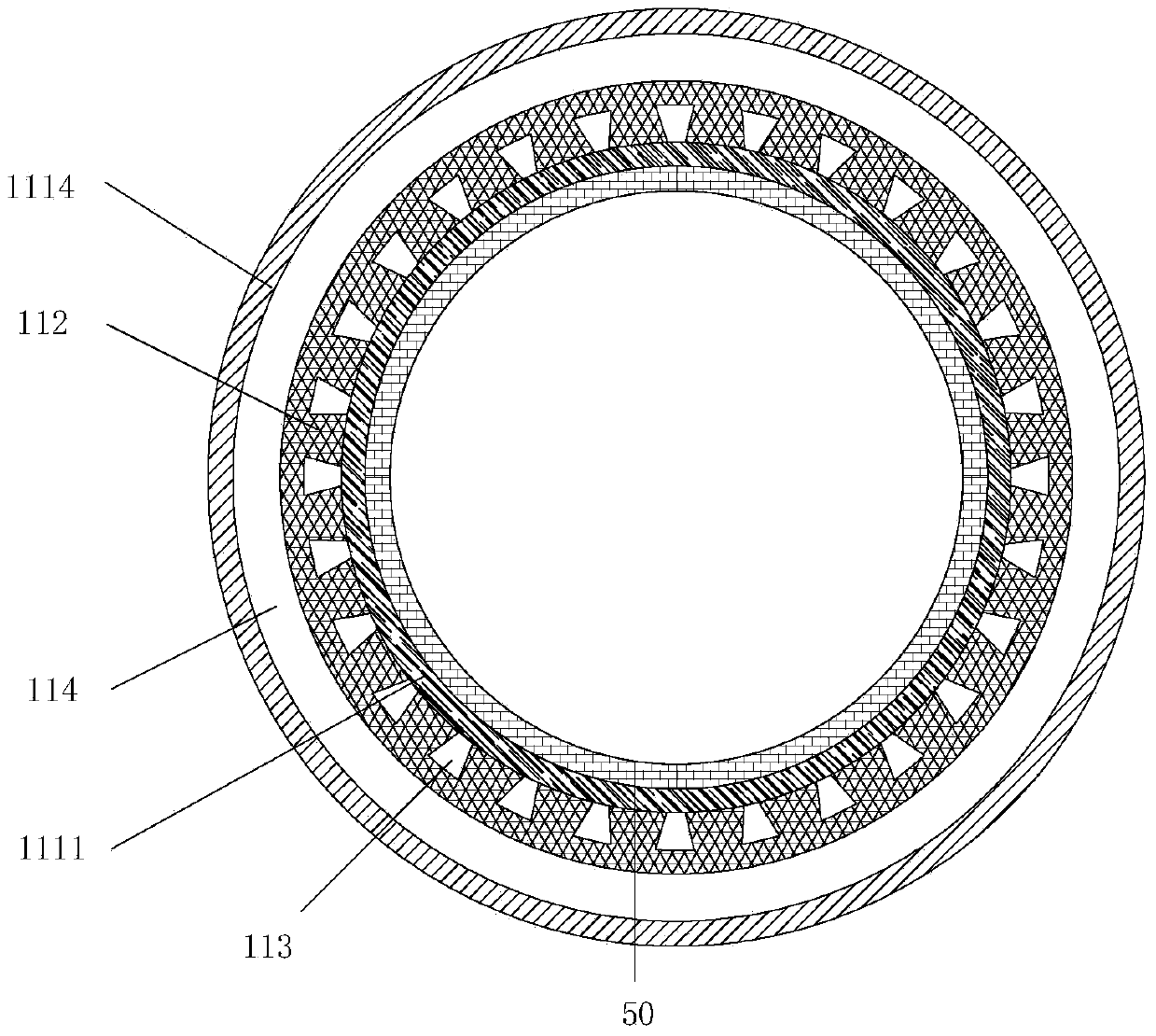

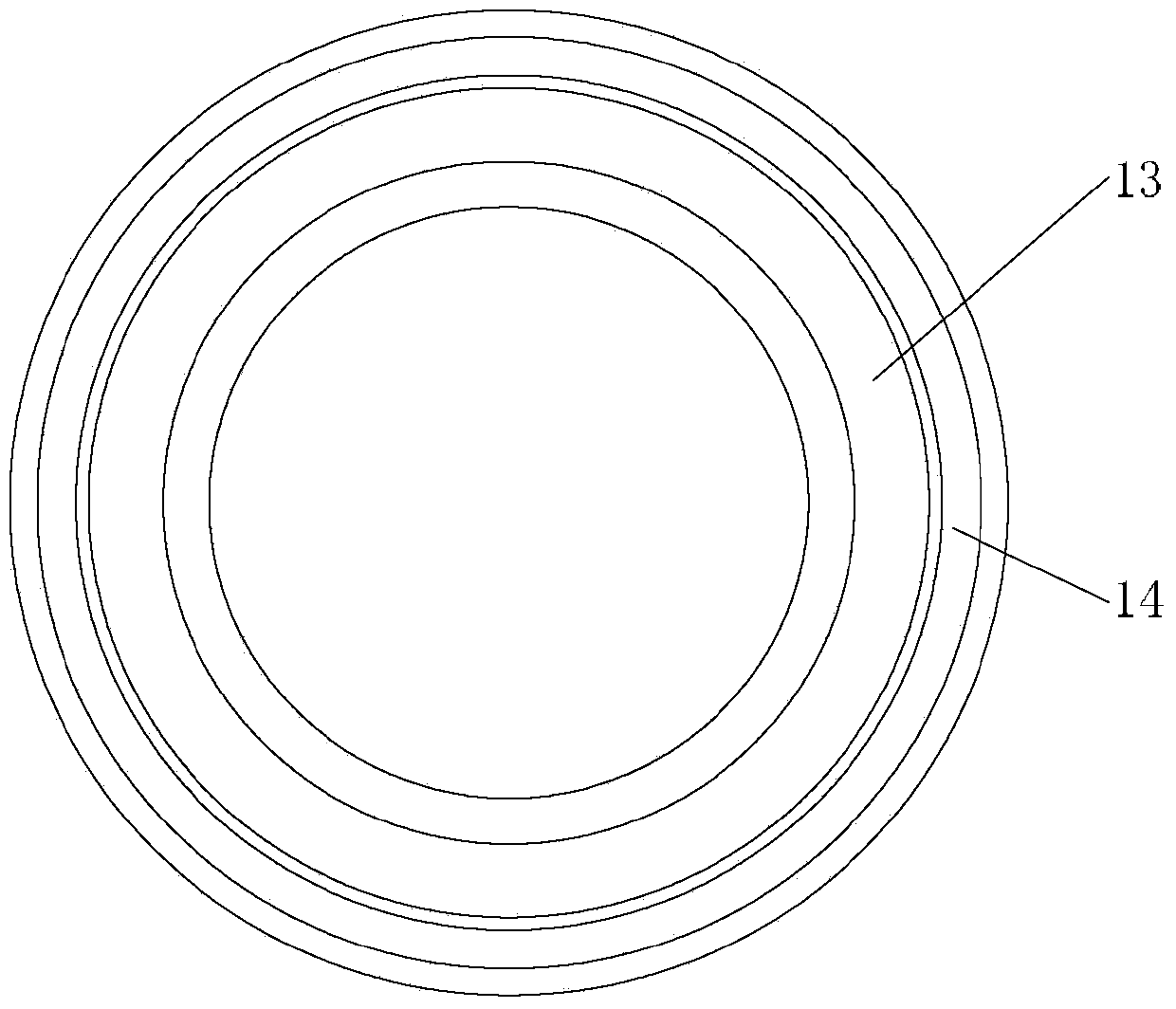

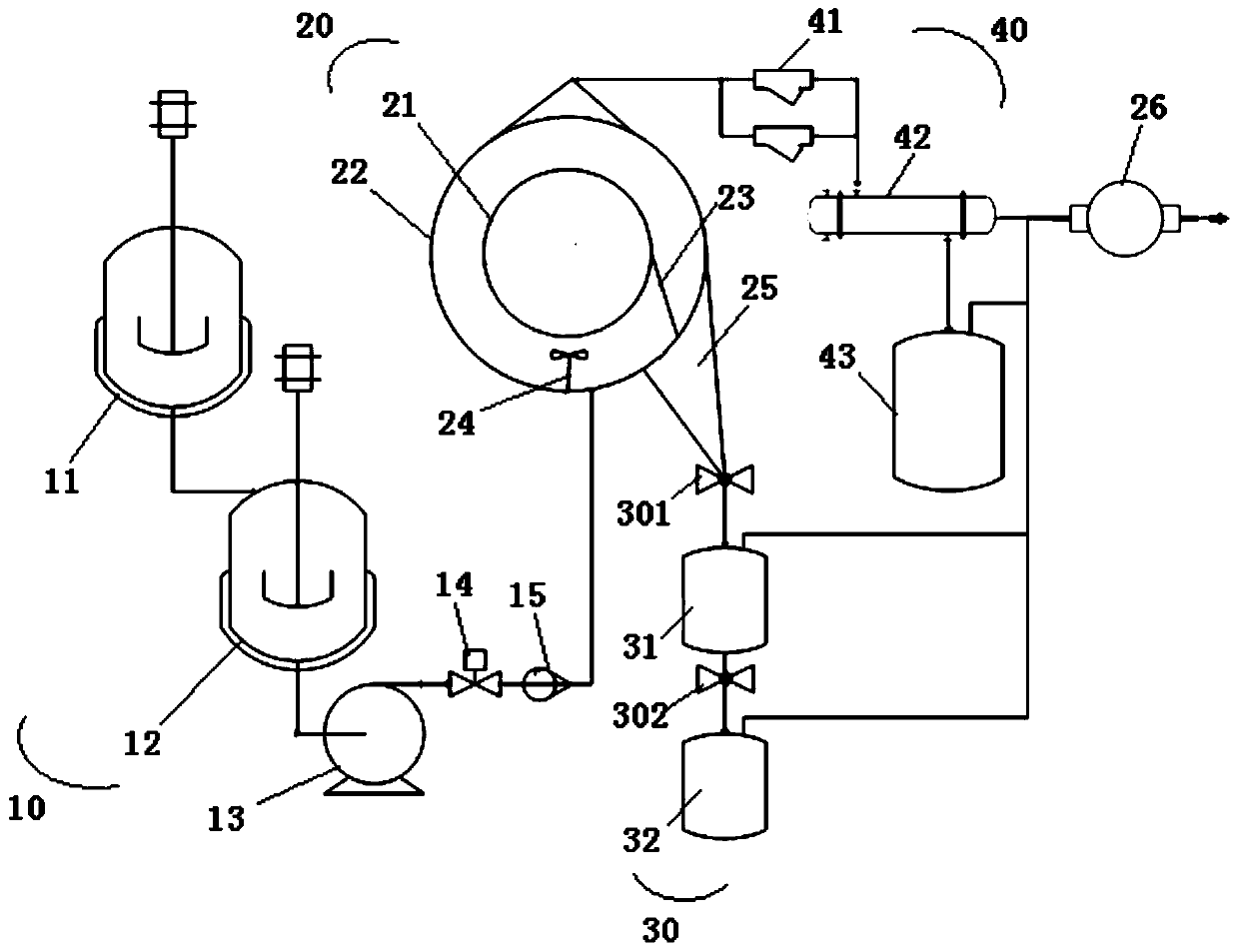

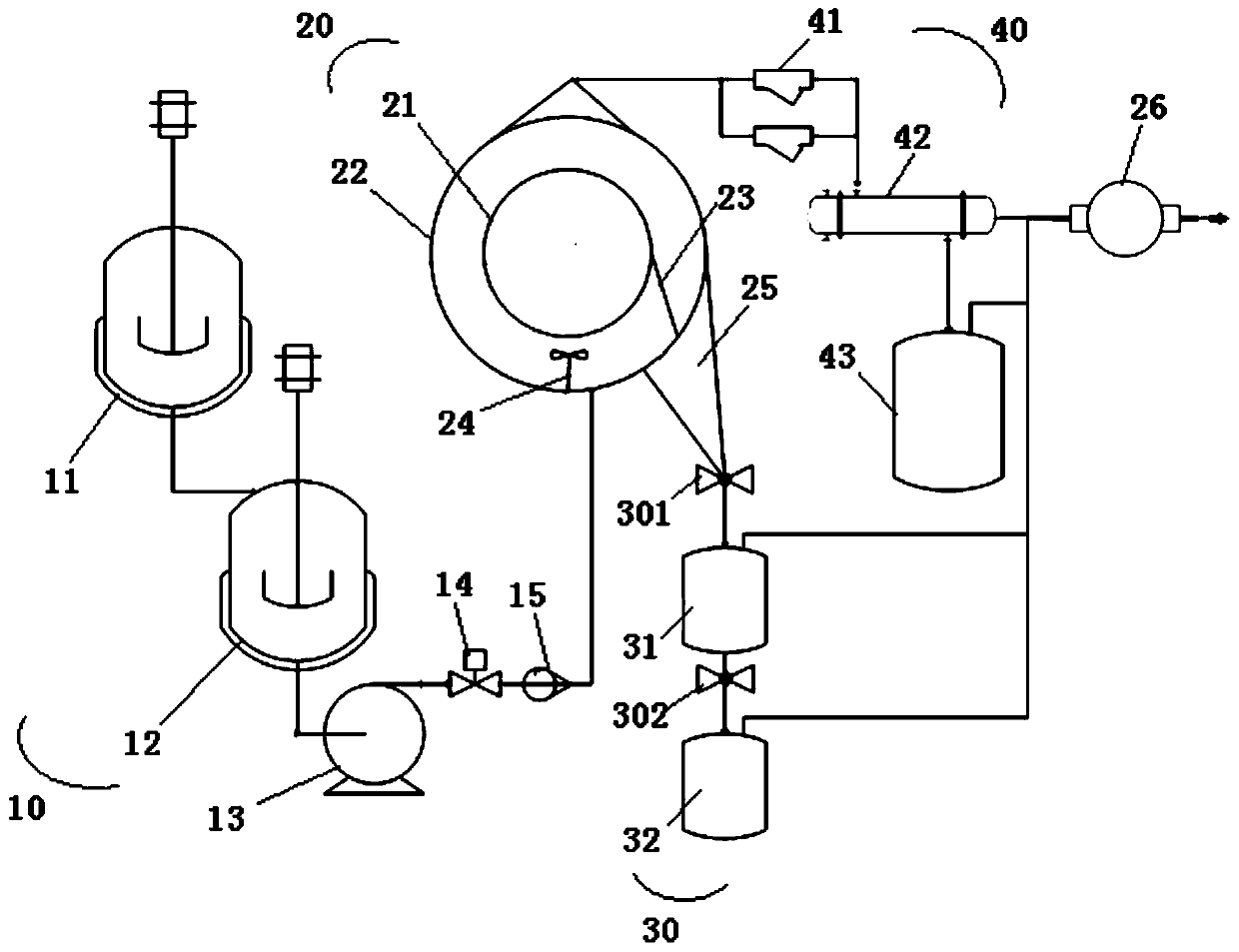

ActiveCN104046711AImprove recycling effectSimple structureSteam generation using hot heat carriersLiquid mediumSlag

The invention discloses a waste heat recovery system of steel slags. The system comprises a heat pipe and a heating device, wherein the heating device is provided with a chamber in which a liquid medium is accommodated; a steam discharge port communicated with the chamber is formed on the side wall of the heating device; the steam discharge port is communicated with a steam pipe net by virtue of a pipeline; a steam discharge valve is installed on the pipeline between the steam pipe net and the steam discharge port; the heat pipe comprises an evaporator and a condenser; the evaporator comprises a body which is sleeved on the outer wall of a hot-braising device and is internally provided with a circular groove, and a capillary core which is accommodated in the circular groove and is connected with the inner side wall of the circular groove. The circular groove surrounds outside the hot-braising device, the capillary core divides the circular groove into a first runner and a second runner, the first and second runners are communicated by virtue of a gap of the capillary core, and the outlets of the first and second runners are respectively communicated with the inlet and outlet of a condenser by virtue of pipelines. The waste heat recovery system of steel slags disclosed by the invention is capable of recovering heat in the steel slags.

Owner:WISDRI ENG & RES INC LTD

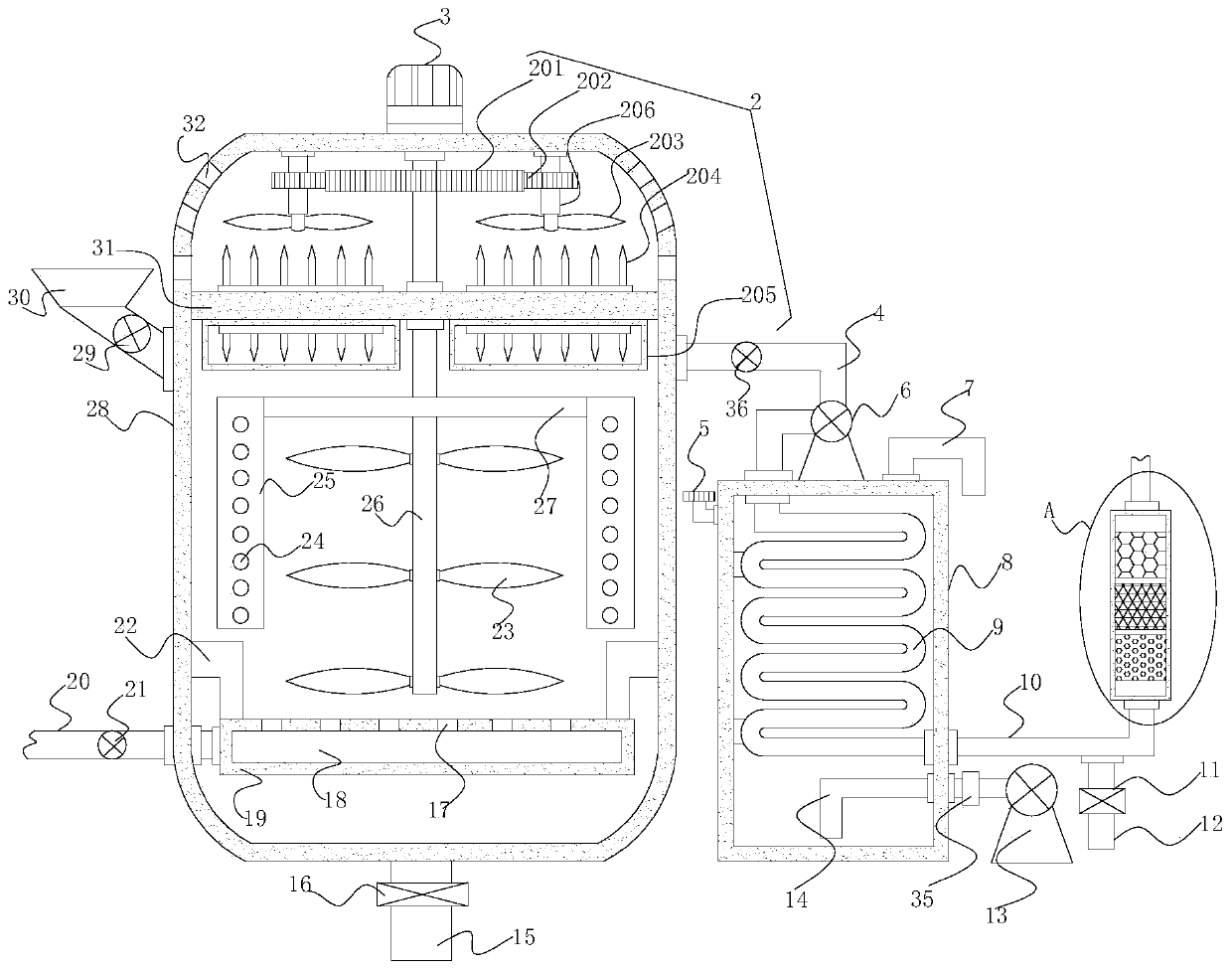

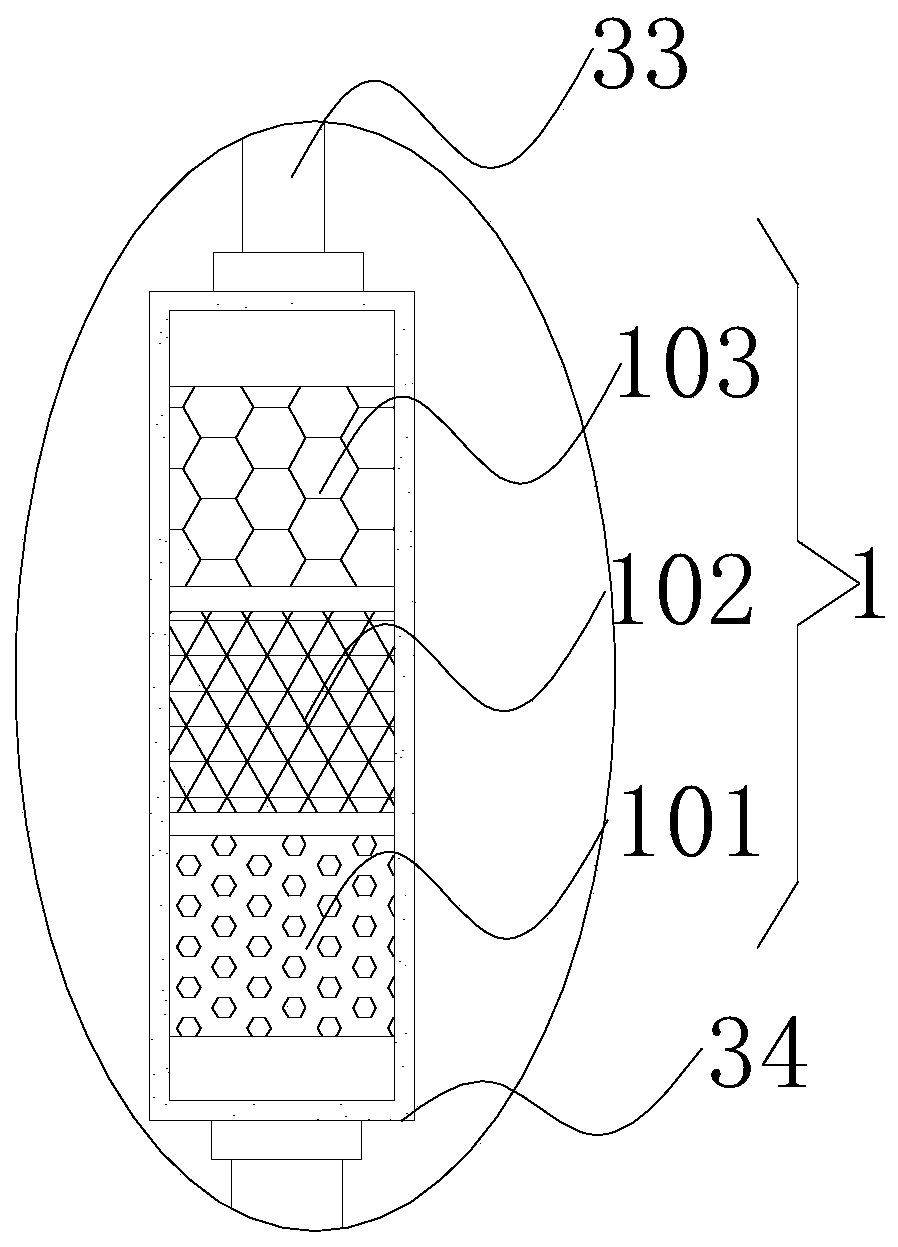

Online multi-fluorination system

PendingCN109731538ASpread evenlyIncrease contact areaDispersed particle filtrationChemical/physical/physico-chemical stationary reactorsFiltrationWater storage tank

The invention discloses an online multi-fluorination system, and relates to the technical field of fluorination reaction. The online multi-fluorination system comprises a filtration and purification device, an auxiliary cooling device, a shell, a water storage tank and a box, the outer surface of one side of the shell is fixedly connected with a feeding hopper, a third valve is arranged on the feeding hopper, the bottom of the shell is fixedly connected with a discharging pipe, a second valve is arranged on the discharging pipe, the inner walls of two sides of the shell are fixedly connected with connecting supports, the shell is fixedly connected with an air distribution plate through the connecting supports, one side of the shell is fixedly connected with an air inlet pipe, a one-way valve is arranged on the air inlet pipe, one end of the air inlet pipe penetrates the inside of the shell and is communicated with the inside of the air distribution plate, a partition plate is fixedly mounted on the inner wall of the shell, and a second rotating rod is rotatably mounted at the inner bottom of the shell. The online multi-fluorination system is reasonable in design and compact in structure, potential safety hazards can be reduced, health security of workers is improved, and environmental pollution is reduced.

Owner:绵阳市鑫瑞龙扬科技有限责任公司

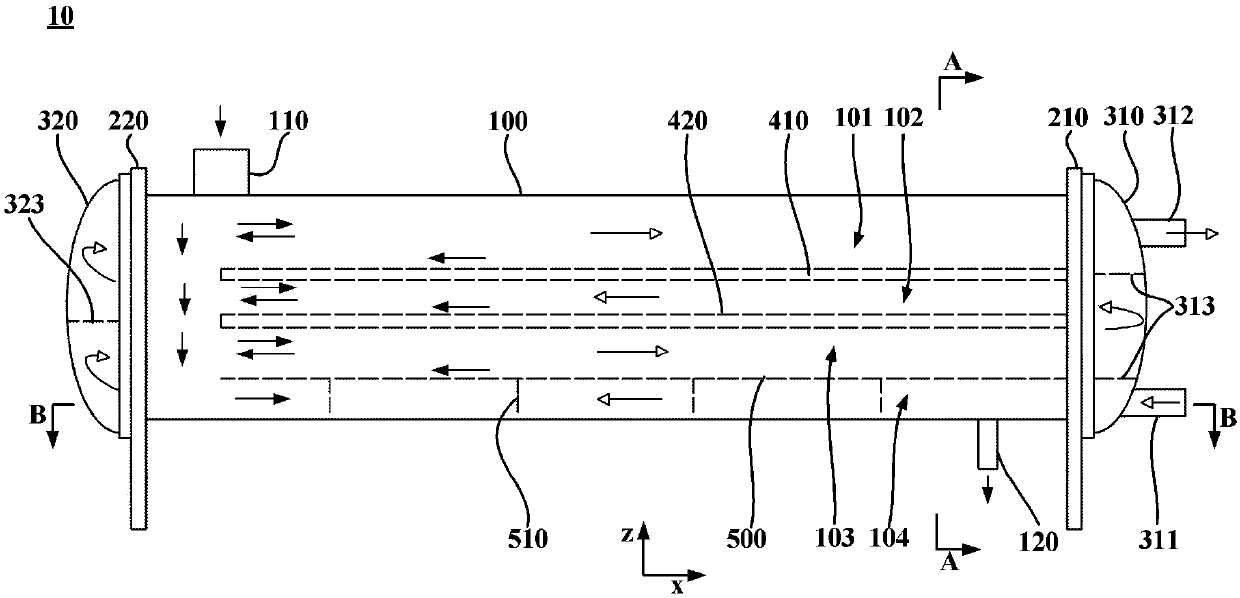

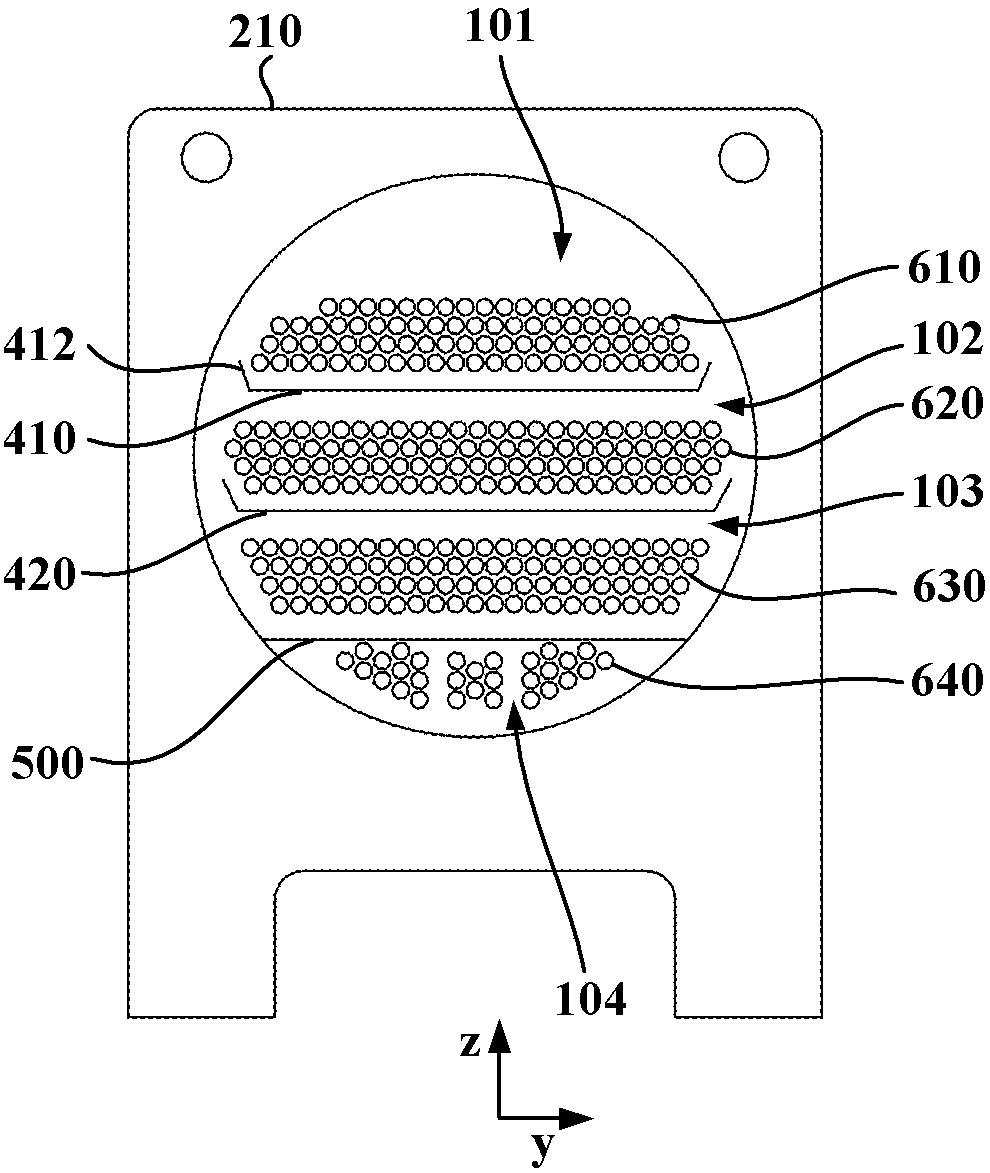

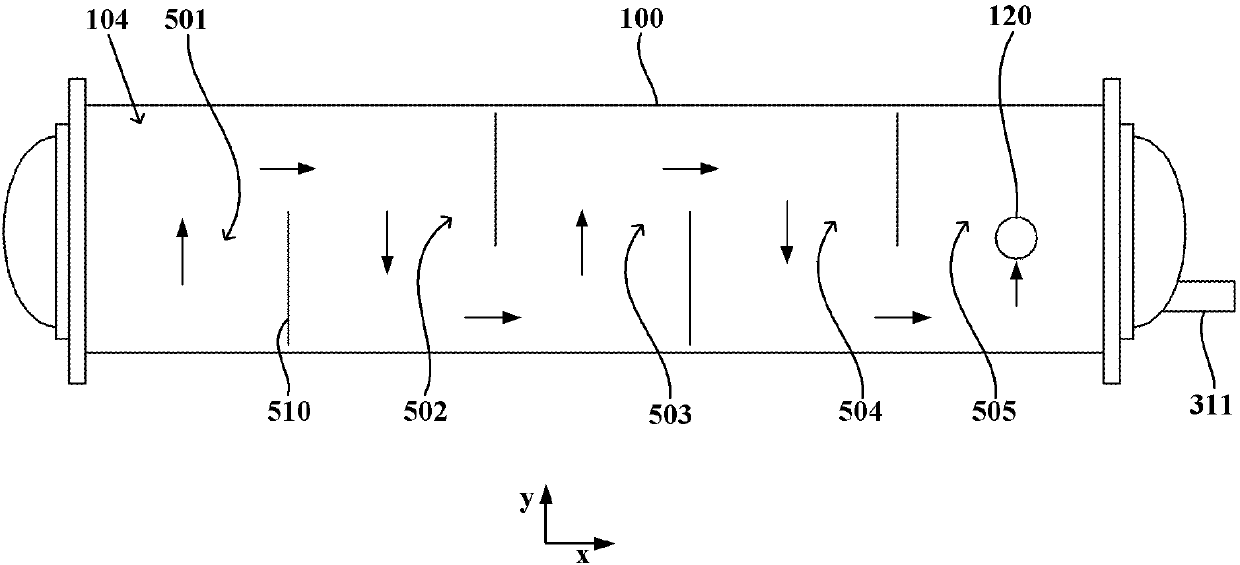

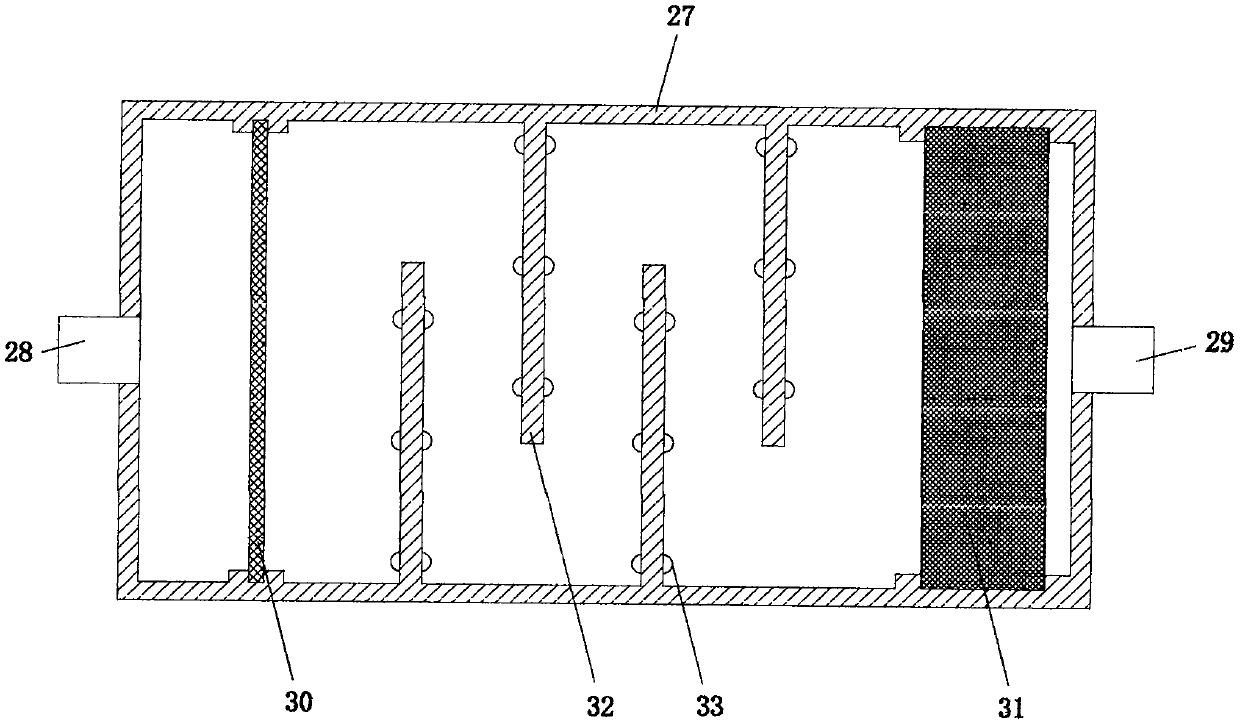

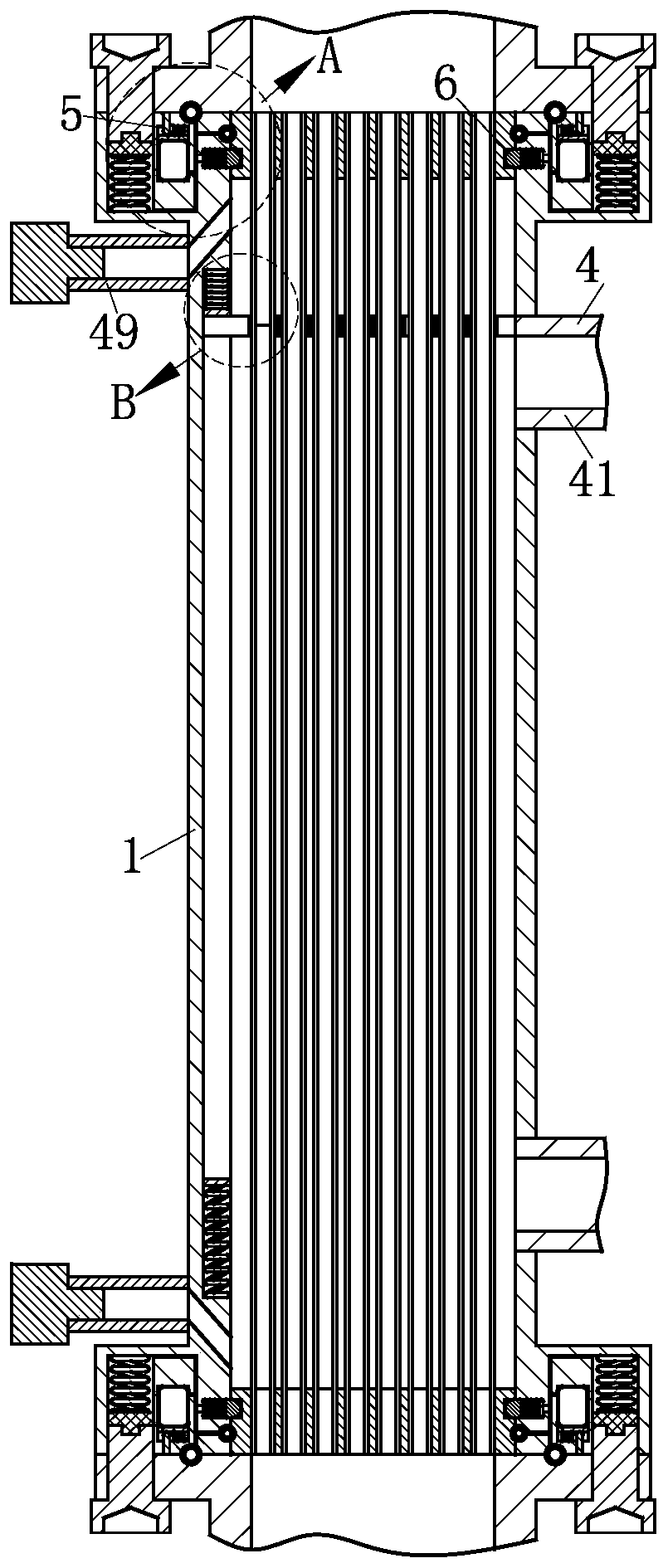

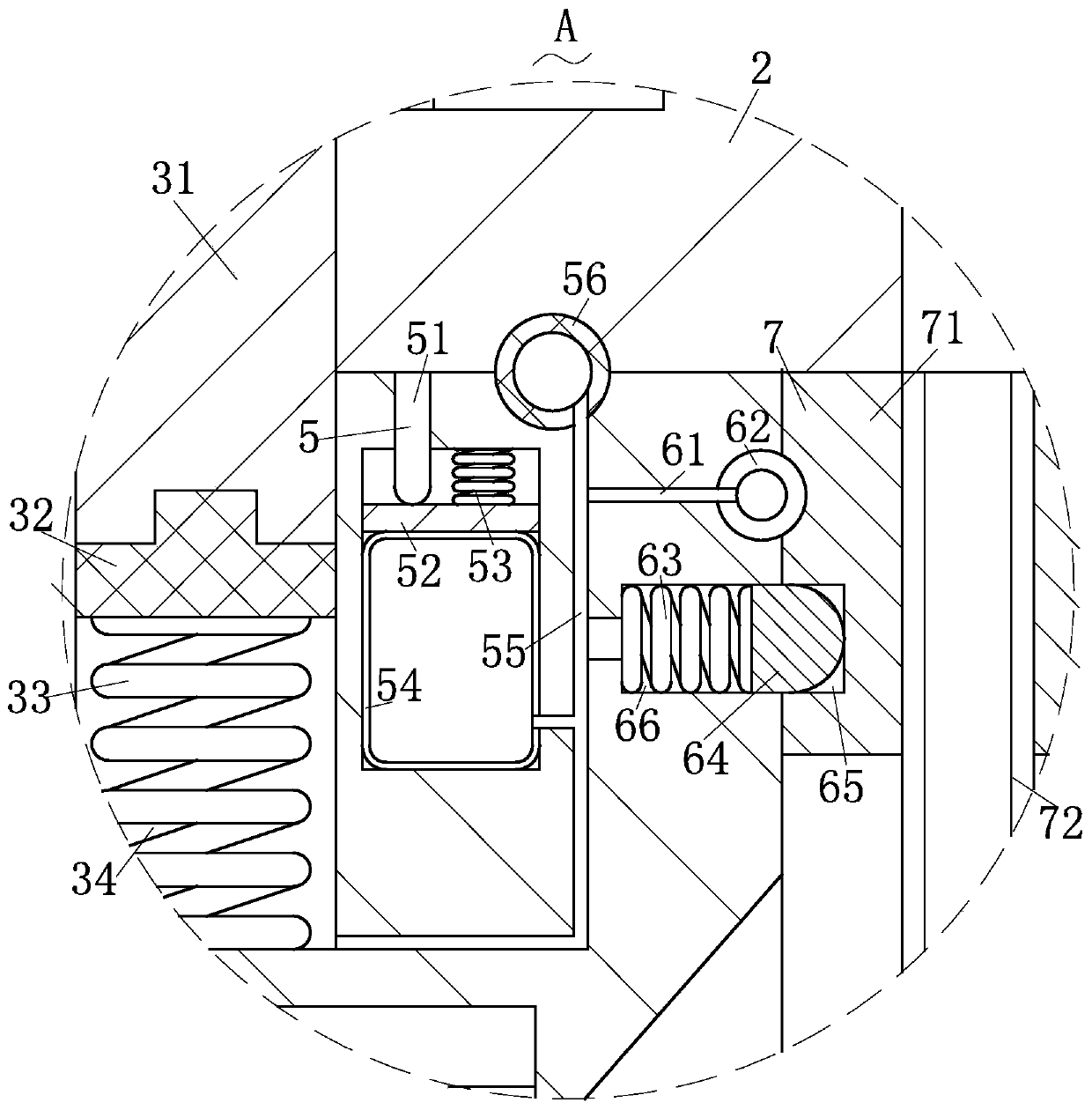

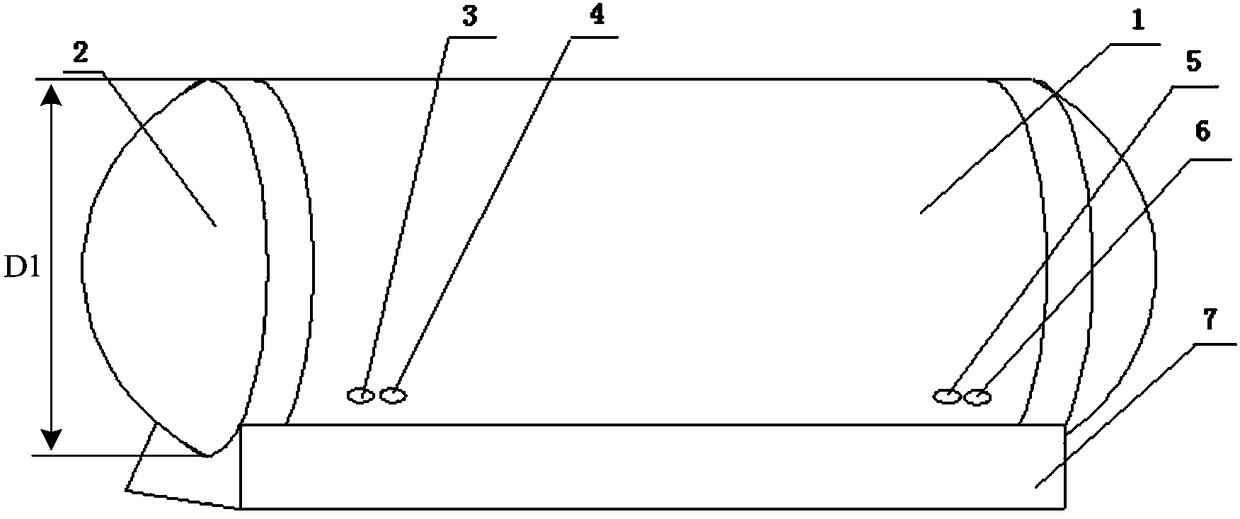

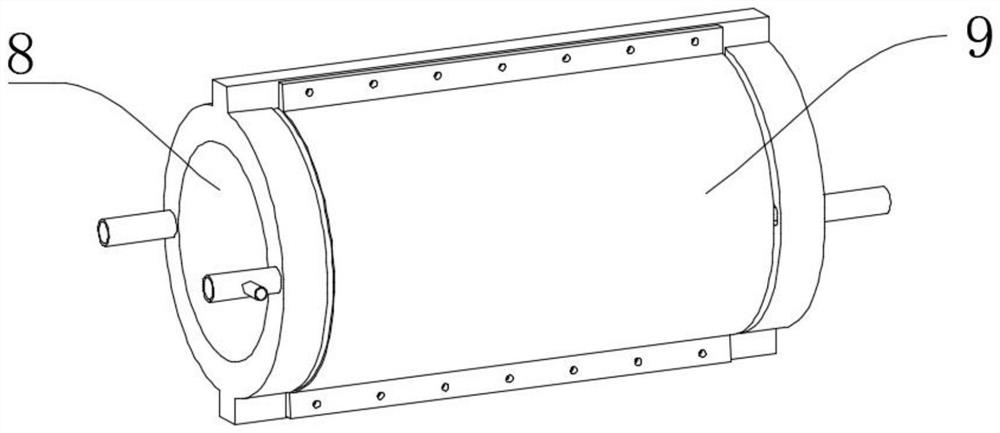

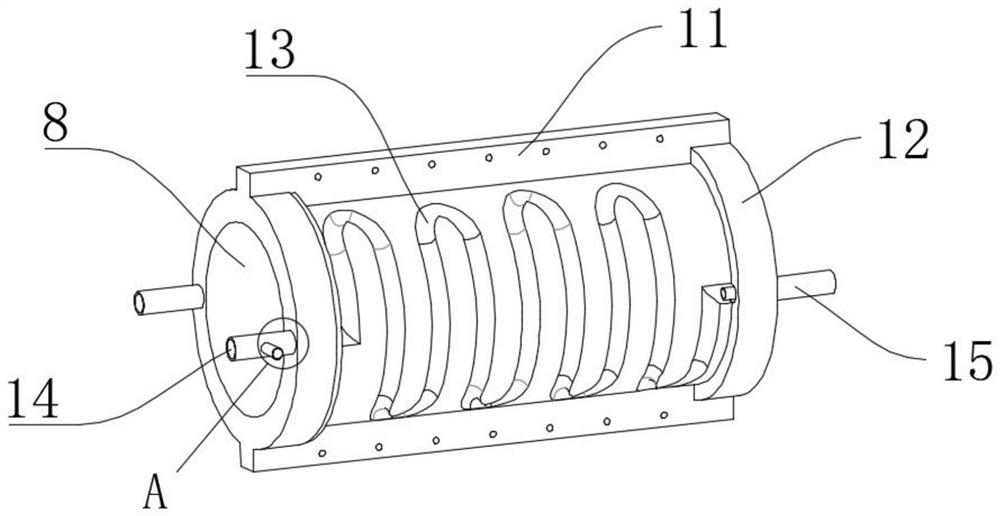

Shell-and-tube condenser

ActiveCN107806723AExtend process timeExtend heat exchange timeEvaporators/condensersAdverse effectEngineering

The invention provides a shell-and-tube condenser which comprises a shell, a first tube plate, a second tube plate, multiple layers of heat exchanging tubes, and a plurality of liquid collecting plates, wherein the axis of the shell extends horizontally; a gas inlet for feeding refrigerant gas and a liquid outlet for discharging refrigerant liquid; the first tube plate and the second tube plate cover two axial ends of the shell in a sealing manner; cooling water circulates in the multiple layers of heat exchanging tubes; the multiple layers of heat exchanging tubes are arranged in the shell inthe axial direction; the liquid collecting plates divide the interior of the shell into a plurality of heat exchanging areas arranged vertically; the multiple layers of heat exchanging tubes are distributed in the heat exchanging areas; each of the liquid collecting plates extends in the axial direction of the shell; the first end of each of the liquid collecting plates in the length direction isconnected with the first tube plate; and the second end of each of the liquid collecting plates in the length direction and the second tube plate are arranged at an interval, so that the refrigerantliquid on the liquid collecting plate flows out of the second end. The shell-and-tube condenser can lower the adverse effect of a liquid film on the heat exchanging efficiency of the heat exchanging pipes.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD +1

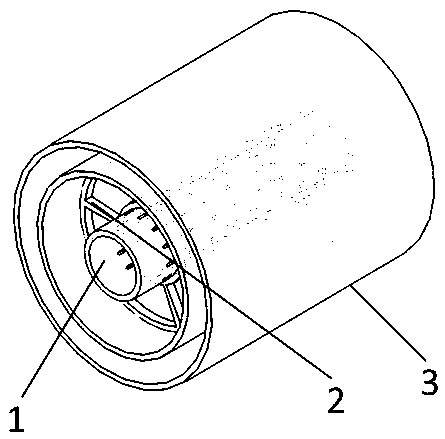

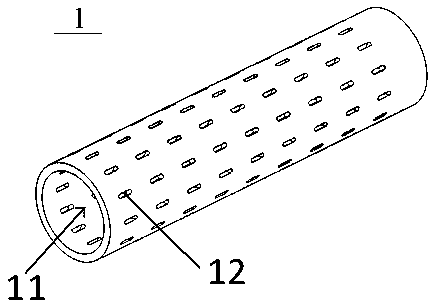

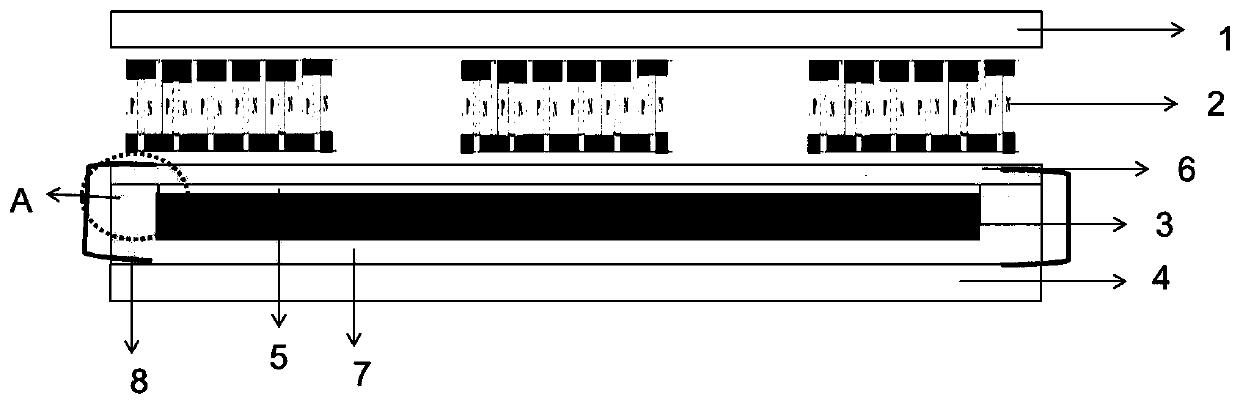

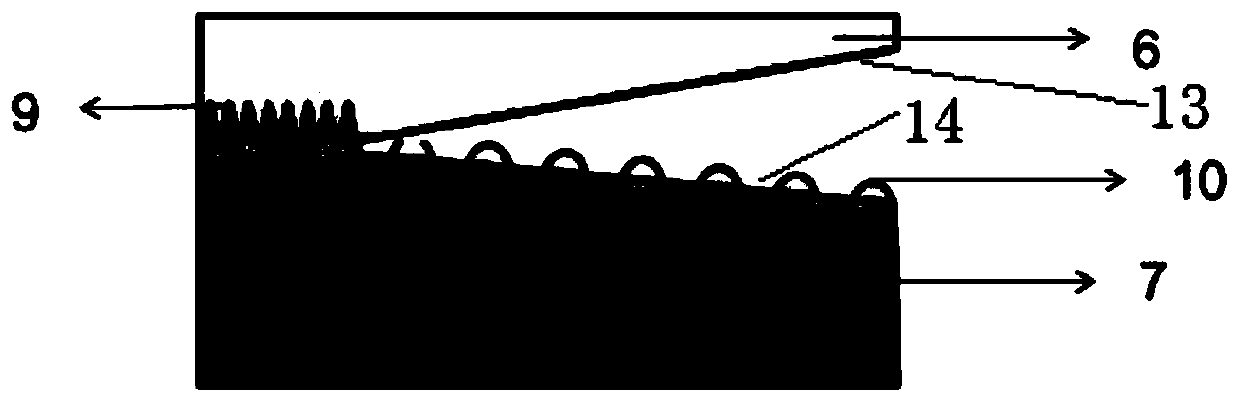

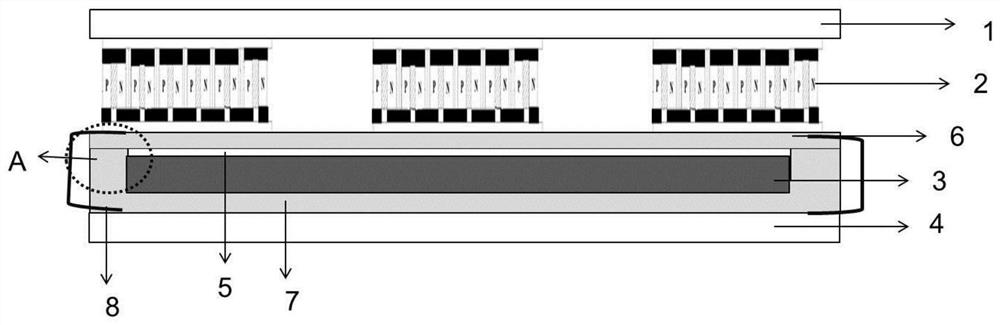

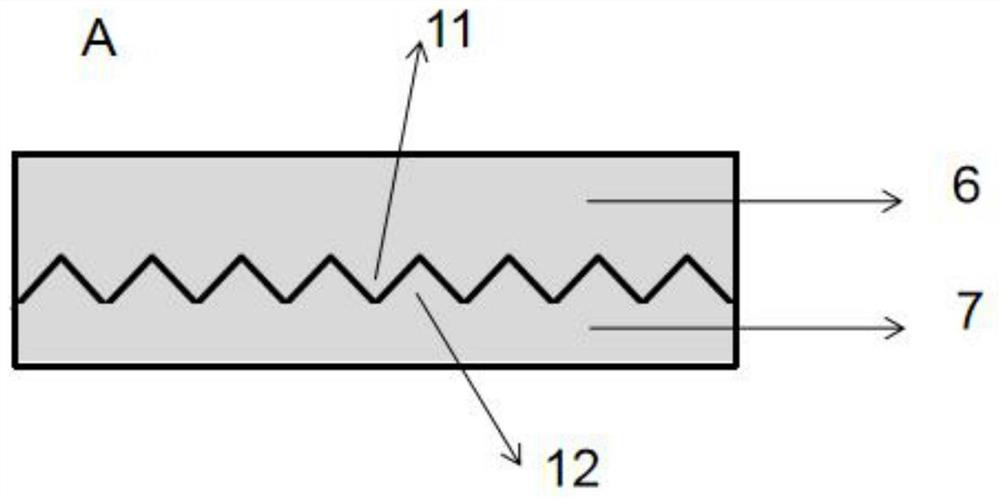

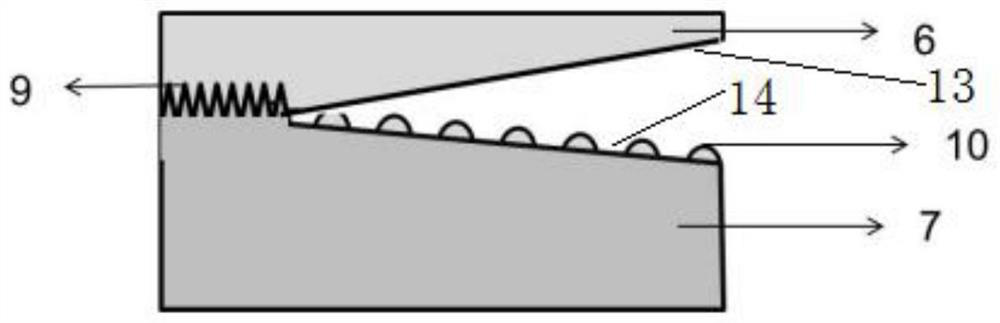

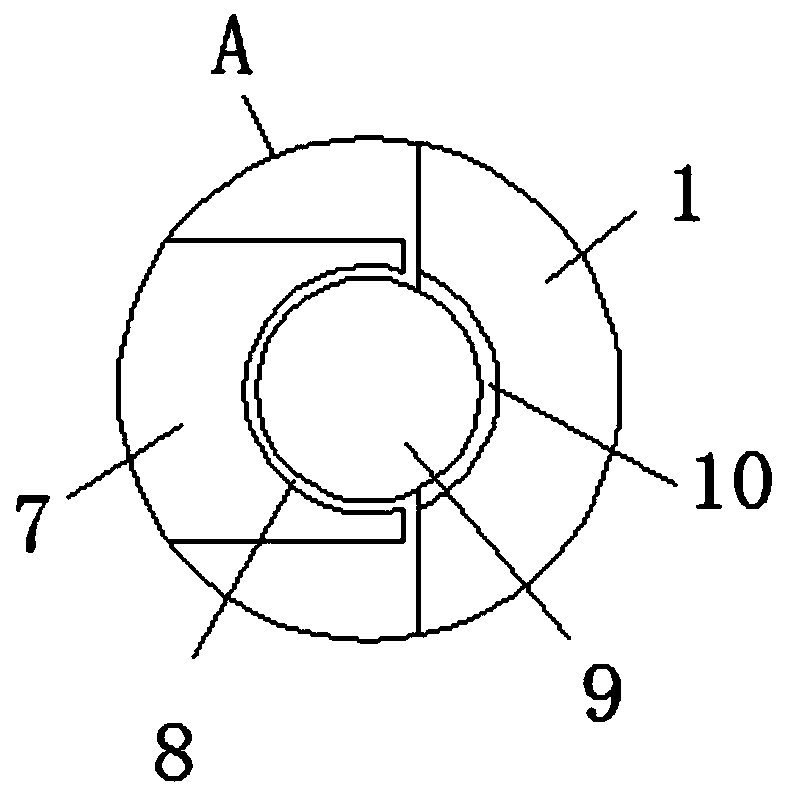

Cryogenic-liquid forced cooling cable structure

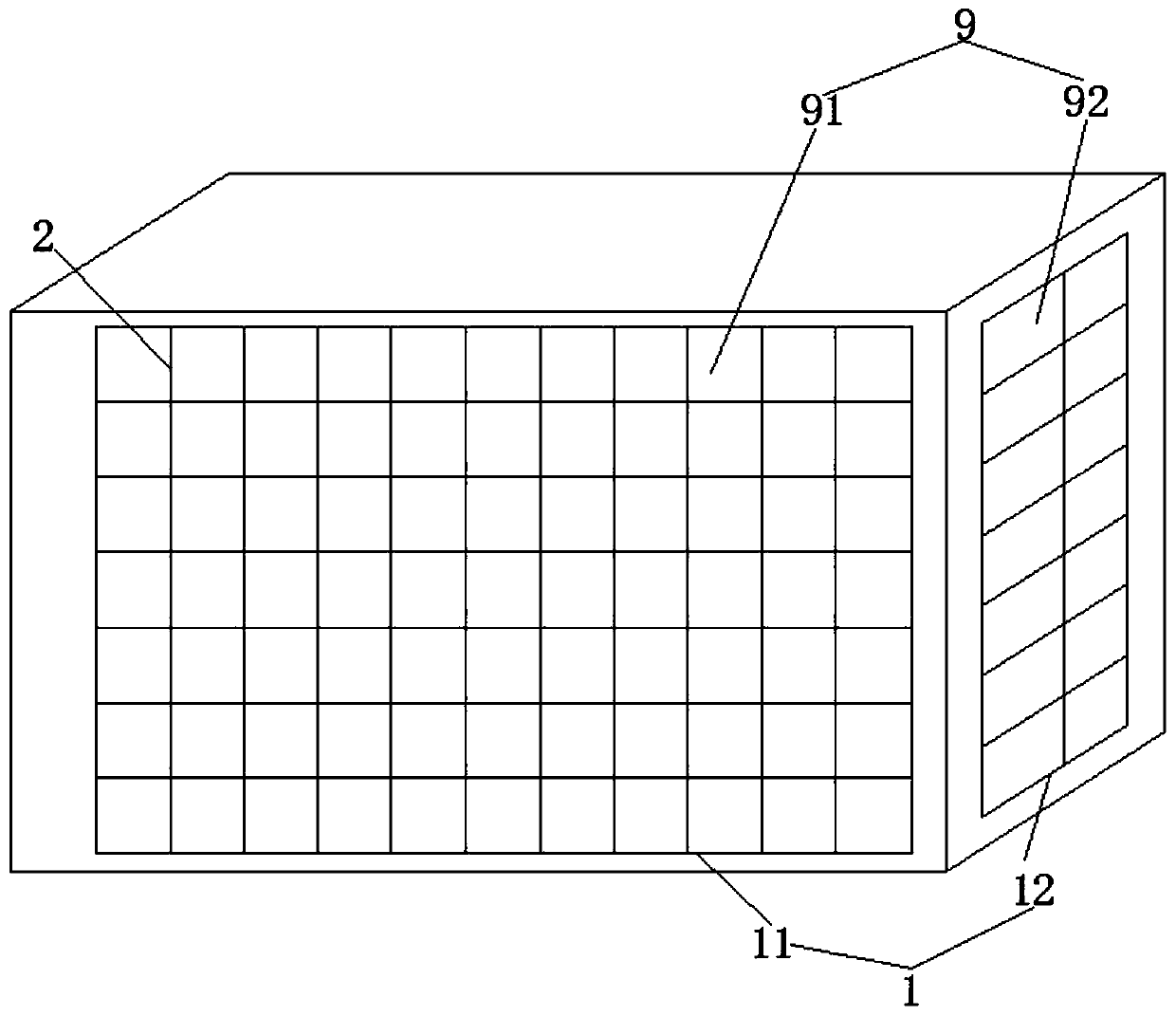

PendingCN109390078AIncreased disorderAvoid affecting heat transfer efficiencySingle tube conductorsInsulated cablesElectrical conductorThermal insulation

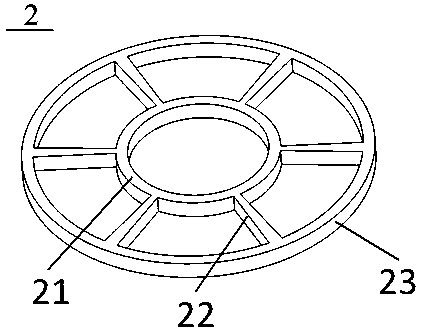

The embodiment of the invention discloses a cryogenic-liquid forced cooling cable structure, and the structure comprises a conductor (1), a plurality of supports (2) and a thermal insulation tube (3),wherein the conductor (1), the plurality of supports (2) and the thermal insulation tube (3) are sequentially from the inside to the outside. The conductor (1) is a hollow metal tube, and a side wallof the metal tube is provided with through holes (12) at intervals. The interior of the conductor forms a cryogenic-liquid channel (11), and the supports (2) are each of a hollow-out structure formedby the processing of a non-metal material, and sleeve the conductor (1) at certain intervals. The thermal insulation tube (3) is a high-vacuum thermal insulation tube, and the conductor (1) is disposed in the thermal insulation tube (3) in a coaxially sleeved manner through the supports (2). According to the embodiment of the invention, the structure can improve the thermal conduction efficiencyand avoid the skin effect during the transmission of a large current.

Owner:SHENZHEN POWER SUPPLY BUREAU

Recycle device and recycle method for solvent in coal liquefaction residue raffinate

ActiveCN110041958ARealize comprehensive utilizationRelieve stressHydrocarbon oils refiningGas phasePulp and paper industry

The invention provides a recycle device and a recycle method for a solvent in coal liquefaction residue raffinate. The device comprises a raw material supply unit, a roller drying unit, a residue-fixing material-discharging unit and a gas-liquid separation unit, wherein the raw material supply unit is used for preparing the mixture of the coal liquefaction residue raffinate and an extracting solvent; the roller drying unit comprises a vacuum roller scraper blade drying machine, and is connected with the raw material supply unit, used for carrying out vacuum roller scraper blade drying on the mixture and further provided with a gas phase outlet and a solid phase outlet; the residue-fixing material-discharging unit is connected with the solid phase outlet of the roller drying unit; and the gas-liquid separation unit is provided with a gas phase inlet and used for carrying out condensing on gas discharged from the gas phase outlet and gas-liquid separation. The device provided by the invention is utilized to recycle the solvent in the coal liquefaction residue raffinate, a recycle system can operate efficiently and stably for a long period, and has the advantages of high heat transferefficiency, high treatment efficiency and the like.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

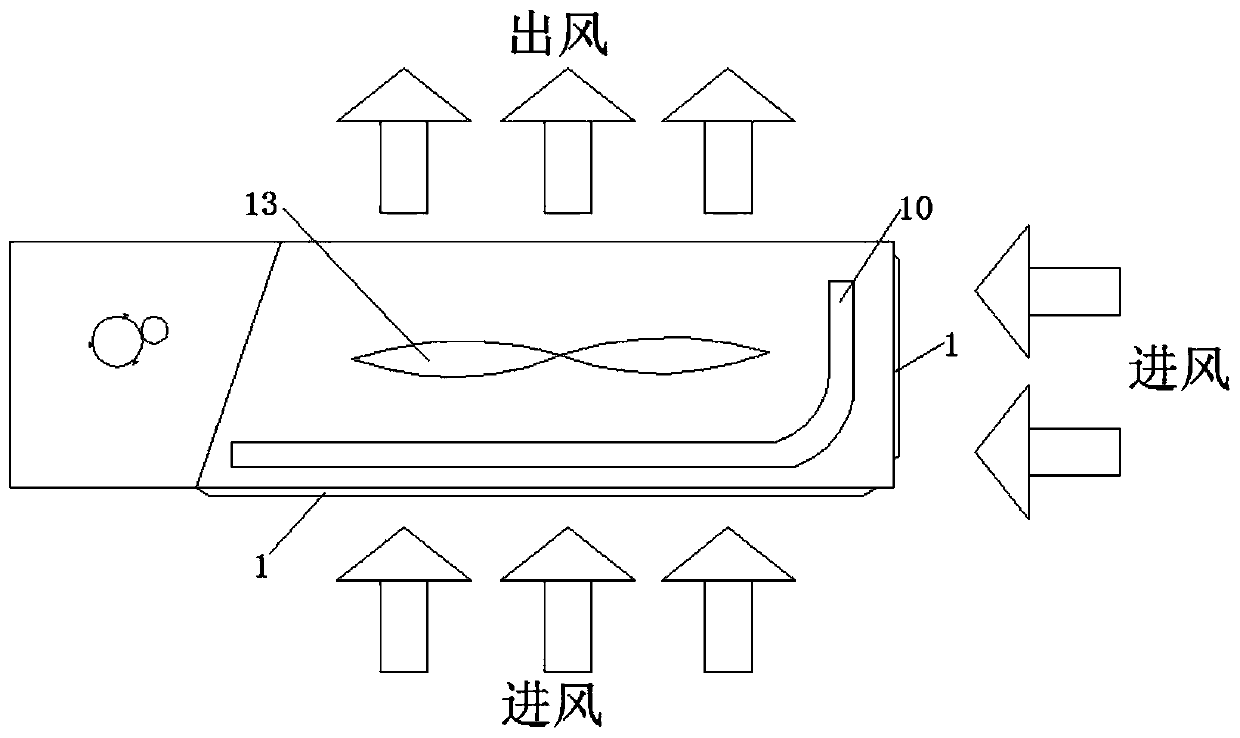

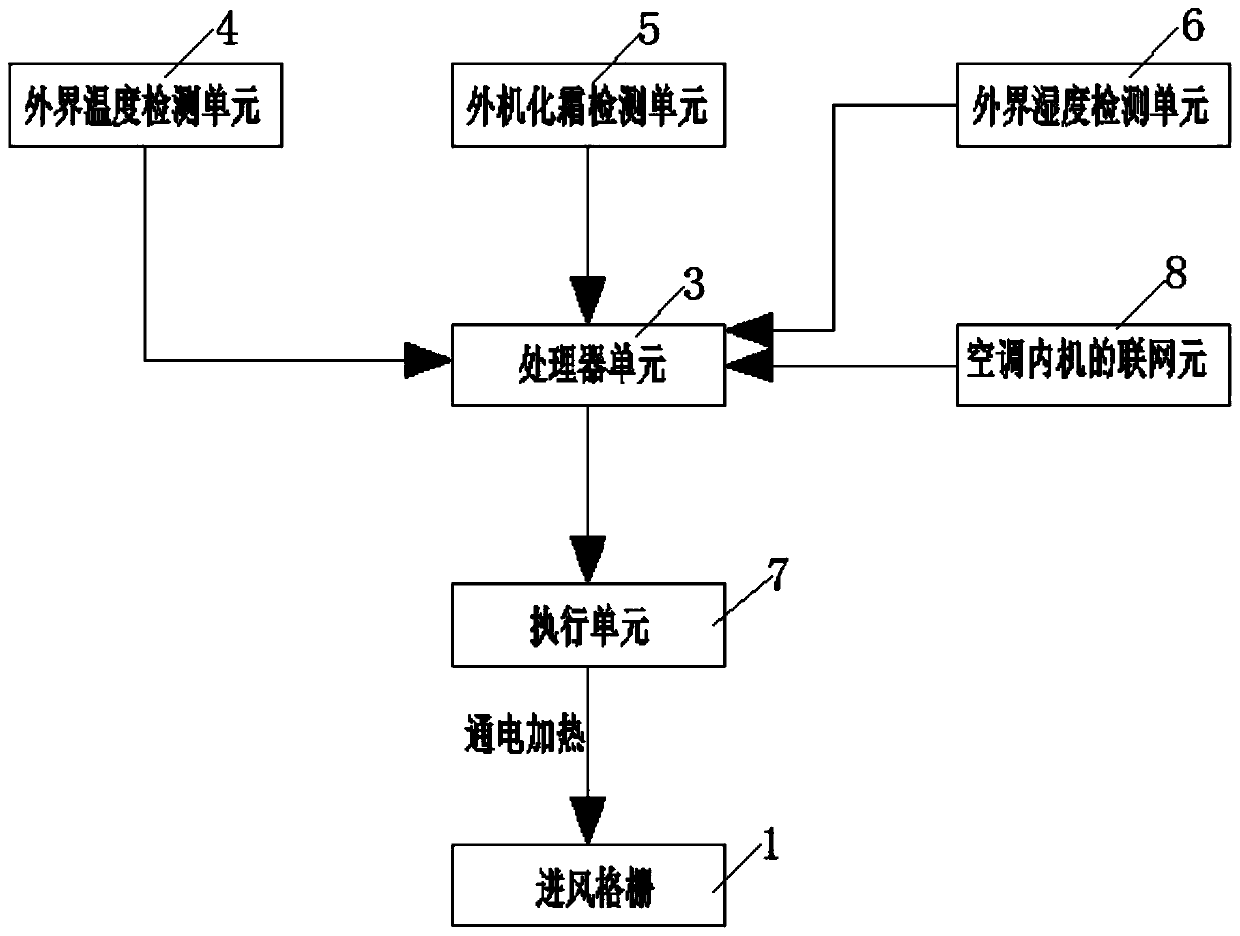

Anti-freezing device for air conditioner external unit, anti-freezing control method of air conditioner external unit and air conditioner

InactiveCN111156658AAvoid affecting heat transfer efficiencyHas anti-freezing effectMechanical apparatusLighting and heating apparatusAir volumeMechanics

Owner:GREE ELECTRIC APPLIANCES INC

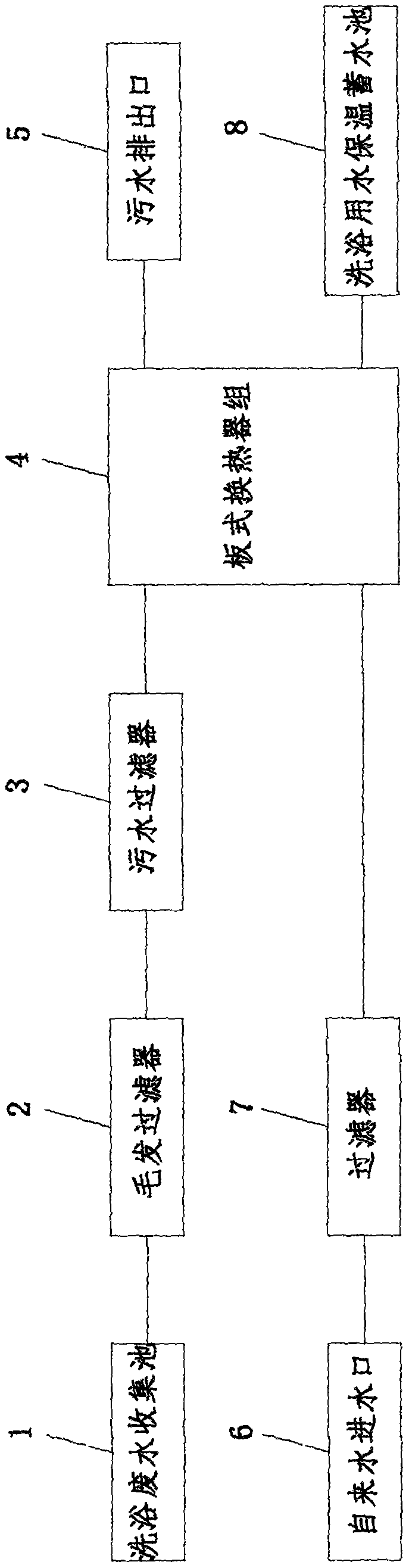

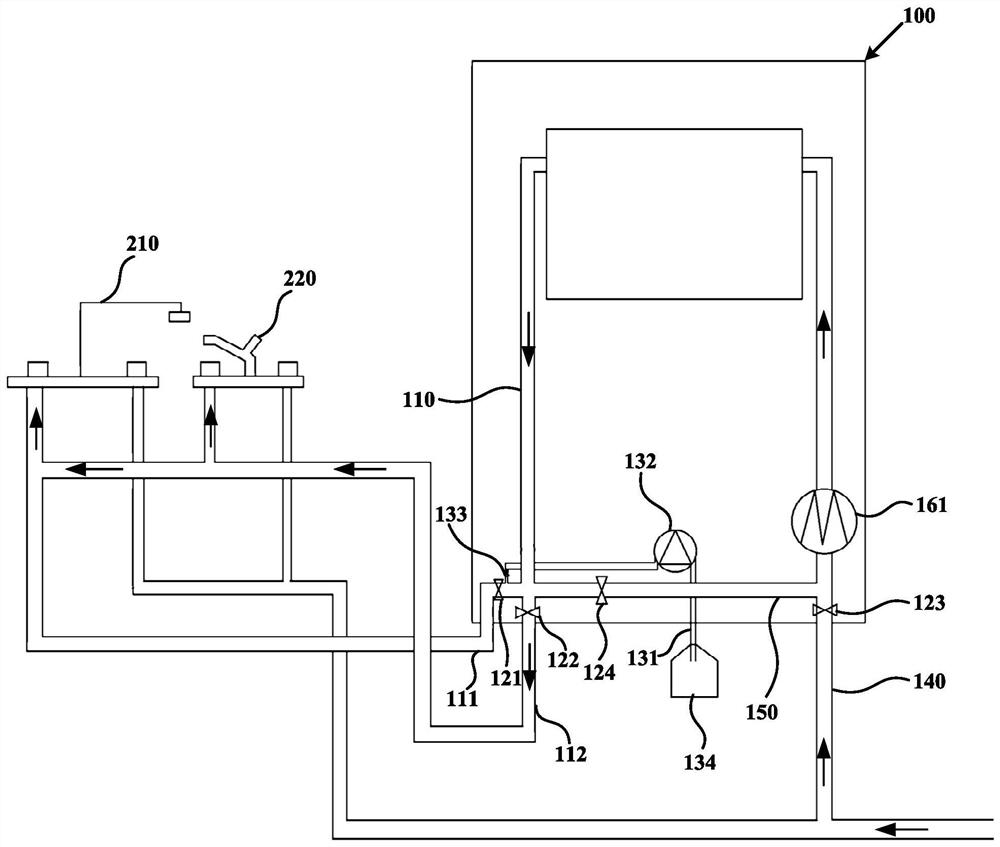

Waste heat recovery system for bathing wastewater

InactiveCN110526475AReduce cloggingGrowth circulationWater/sewage treatment by irradiationSpecific water treatment objectivesWater storage tankWaste heat recovery unit

The invention discloses a waste heat recovery system for bathing wastewater. The waste heat recovery system comprises a bathing wastewater collection tank; the bathing wastewater collecting tank is connected with a water outlet of a bathroom and is used for collecting bath wastewater; the bathing wastewater collecting tank is connected to a sewage inlet of a plate heat exchanger group through a sewage pipeline; a hair filter and a sewage filter are sequentially mounted on the sewage pipeline; a purified water inlet of the plate heat exchanger group is connected with a tap water inlet through apurified water pipeline; a filter is mounted in the purified water pipeline; a sewage discharge port and a purified water discharge port are formed in the plate heat exchanger group; and the purifiedwater discharge port is connected with a bathing water heat preservation water storage tank. According to the waste heat recovery system, bathing wastewater is reasonably treated, heat in the wastewater can be fully recycled, and bathing water is preheated through waste heat of the wastewater, so that heat waste is reduced, energy is saved, and heating cost is reduced.

Owner:孙军

A belt dryer

ActiveCN105627713BAvoid it happening againHigh recovery rateDrying gas arrangementsDrying machines with progressive movementsUltimate tensile strengthMechanical engineering

The invention relates to the technical field of drying equipment, in particular to a belt type drier. The belt type drier is characterized in that the drier comprises a drying box, a conveying net belt arranged in the drying box, heat exchangers arranged in the drying box, a plurality of partition plates, air flue assemblies and hopper assemblies, wherein a feed inlet and a discharge outlet are formed in the two ends of the drying box in the length direction; the multiple partition plates are uniformly arranged in the drying box in the length direction of the drying box, the inner space of the drying box is divided into a plurality of drying units through the partition plates, the multiple drying units comprises the multiple first drying units and the multiple second drying units, and the first drying units and the second drying units are sequentially arranged in the direction from the feed inlet to the discharge outlet; the air flue assemblies are arranged at the tops of inner spaces of all the drying units in a one-to-one correspondence mode; the hopper assemblies are arranged at the bottoms of the inner spaces of all the drying units in a one-to-one correspondence mode. The belt type drier has a good drying effect, raise dust is effectively prevented from being produced, the yield is increased, the material recovery rate is increased, and the labor intensity is relieved.

Owner:江苏太阳臣干燥科技有限公司

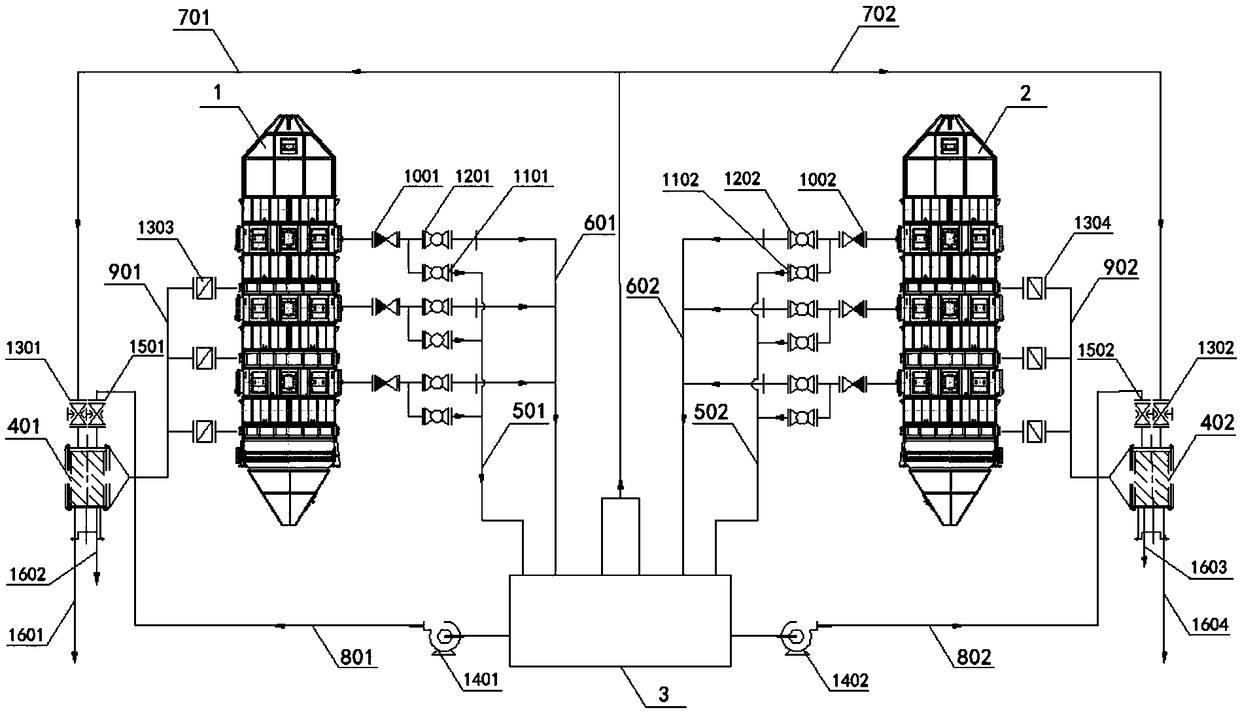

High-efficiency heat energy utilization system and method of conditioning tower high-temperature condensed water

InactiveCN109029045APrevent leakageReduce back pressureHeat recovery systemsRecuperative heat exchangersThermal energyEngineering

The invention belongs to the technical field of heat energy utilization, and particularly relates to a high-efficiency heat energy utilization system and method of conditioning tower high-temperaturecondensed water. According to the high-efficiency heat energy utilization system of the conditioning tower high-temperature condensed water, a first conditioning tower is connected with a condensed water tank through a first by-pass pipe and a first drain pipe, and a second conditioning tower is connected with the condensed water tank through a second by-pass pipe and a second drain pipe. The condensed water tank is connected with a first hot wind heat exchanger and a second hot wind heat exchanger correspondingly through a first air delivery pipe and a second air delivery pipe, and the condensed water tank is connected with the first hot wind heat exchanger and the second hot wind heat exchanger correspondingly through a first water delivery pipe and a second water delivery pipe. The first hot wind heat exchanger is connected with the first conditioning tower through a first hot wind pipeline, and the second hot wind heat exchanger is connected with the second conditioning tower through a second hot wind pipeline. The high-temperature condensed water generated by the conditioning towers and low-pressure flash steam generated in the condensed water tank are further used for performing heat transfer with air to supply hot wind for the conditioning towers for recycling of the heat energy, and comprehensive heat energy is saved by 10%.

Owner:JIUSAN OILS & GRAINS IND GRP CO LTD +1

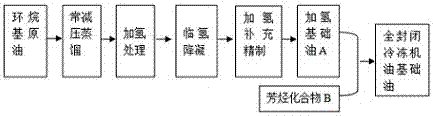

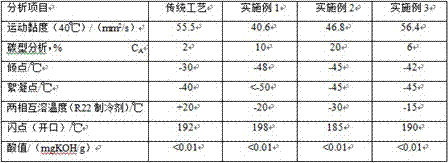

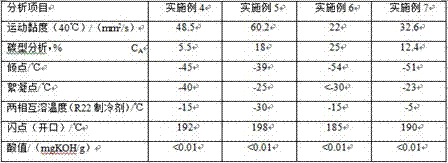

Environment-friendly base oil for fully-enclosed refrigerator oil and preparation method thereof

InactiveCN107118798AImprove compatibilityGuaranteed normal operationTreatment with hydrotreatment processesBase-materialsChemistryHeat transfer efficiency

The invention discloses environment-friendly base oil for fully-enclosed refrigerator oil and a preparation method thereof. The basic oil is obtained by mixing hydrogenated base oil with an aromatic compound, wherein the 40-degree kinematic viscosity of the hydrogenated base oil is 20 to 100mm<2> / s, and the %C[A] is 0; the 40-degree kinematic viscosity of the aromatic compound is 10 to 200mm<2> / s and the %C[A] is 5% to 50%. A production process disclosed by the invention is environment-friendly and clean, and production of three wastes such as waste furfural and waste clay is avoided, so that the harm to the health of a human body and environment pollution are avoided; the obtained fully-enclosed refrigerator oil and a freon HCFC refrigerant have excellent compatibility, so that mechanical faults in a refrigeration cycle operation and influence on heat transfer efficiency caused by early separation of oil-agent can be avoided.

Owner:CNOOC TAIZHOU PETROCHEM CO LTD

Energy-saving automatic tea making machine

The invention discloses an energy-saving automatic tea making machine. The energy-saving automatic tea making machine comprises a water storage assembly, a hot water container assembly and a hot water assembly, wherein the hot water container assembly is installed on the upper portion of the water storage assembly, the water storage assembly communicates with the hot water container assembly through a water inlet pipe, and a first water pump is installed on the water inlet pipe; a hot water liner unit is externally connected with a water outlet pipe; the hot water assembly communicates with the water outlet pipe; the top of the hot water assembly is provided with a fumigation pipeline; the fumigation pipeline communicates with the hot water container assembly; and steam generated by the hot water assembly is conveyed into the hot water container assembly through the fumigation pipeline and used for heating water in the hot water container assembly. According to the invention, the steam generated by the hot water assembly is conveyed into the hot water container assembly through the fumigation pipeline and used for heating water in the hot water container assembly, so heat needed by subsequent water boiling is reduced, a large amount of steam generated by water boiling is fully utilized, and energy waste is avoided.

Owner:NINGBO LANGMU DRINKING WATER EQUIP TECH CO LTD

Thermoelectric device with firm structure

ActiveCN109951107AEasy to move aroundPrevent overflowGenerators/motorsEngineeringTemperature difference

The invention relates to a thermoelectric device with a firm structure. The device comprises a thermoelectric device and a heat transfer part. A heat transfer member is provided between a heat sourceand the thermoelectric device. The upper and lower parts of a cavity are detachably connected through a connecting part, wherein the connection is tooth-shaped connection. A tooth-shaped part I is arranged on the bottom surface of the connecting part of the upper part of the cavity, and a tooth-shaped part II matched with the tooth-shaped part I on the bottom surface of the connecting part of theupper part of the cavity is arranged on the top surface of the connecting part of the lower part of the cavity. A phase change material is arranged in the cavity, and a plurality of bulges are arranged at the bottom close to the edge part, thereby alleviating the flowing speed of the phase-change material to a certain extent, and enabling the phase-change material flowing to the position to absorbheat slowly, so as to reduce the temperature difference between the phase-change material flowing down from the edge and the phase-change material in the center of the bottom, prevent the sputteringcaused by too large temperature difference of the phase-change material from affecting the heat transfer efficiency and damage to a heat transfer component, and prevent the phase-change material fromflowing to the edge.

Owner:朱梁锋

Steel slag waste heat recovery system

ActiveCN104046711BImprove recycling effectSimple structureSteam generation using hot heat carriersWaste heat recovery unitLiquid medium

The invention discloses a waste heat recovery system of steel slags. The system comprises a heat pipe and a heating device, wherein the heating device is provided with a chamber in which a liquid medium is accommodated; a steam discharge port communicated with the chamber is formed on the side wall of the heating device; the steam discharge port is communicated with a steam pipe net by virtue of a pipeline; a steam discharge valve is installed on the pipeline between the steam pipe net and the steam discharge port; the heat pipe comprises an evaporator and a condenser; the evaporator comprises a body which is sleeved on the outer wall of a hot-braising device and is internally provided with a circular groove, and a capillary core which is accommodated in the circular groove and is connected with the inner side wall of the circular groove. The circular groove surrounds outside the hot-braising device, the capillary core divides the circular groove into a first runner and a second runner, the first and second runners are communicated by virtue of a gap of the capillary core, and the outlets of the first and second runners are respectively communicated with the inlet and outlet of a condenser by virtue of pipelines. The waste heat recovery system of steel slags disclosed by the invention is capable of recovering heat in the steel slags.

Owner:WISDRI ENG & RES INC LTD

High-capacity medium-temperature phase-change heat storage and heat release system for thermal power plant and heat storage and heat release method of system

PendingCN107062970AReduce shipping costsReduce the difficulty of transportationHeat storage plantsHeat exchange apparatusThermal energy storage systemEngineering

The invention discloses a high-capacity medium-temperature phase-change heat storage and heat release system for a thermal power plant, and relates to a heat storage system. The system comprises a closed circulating system, a constant-pressure system, a draining system, a water supply pipeline, a water return pipeline, flow measuring devices, a steam pipeline and a safety valve; a heat storage heater and a heat release cooler are connected with a heat storage device and are both connected with the first flow measuring device; the heat storage device is sequentially connected with the constant-pressure system, a closed circulating pump and the first flow measuring device; a desalted water system is connected with a high-pressure expansion water tank, and the high-pressure expansion water tank is connected with the heat storage device; one end of each heat supply network draining pump is connected with the heat storage device, and the other end of each heat supply network draining pump is sequentially connected with a second water level adjusting valve set and a water return pipe network. According to the high-capacity medium-temperature phase-change heat storage and heat release system for the thermal power plant, rolling supports arranged at the bottom of the system absorb heat to be expanded, therefore, an expansion joint arranged on the heat storage device is removed, and the effect is good. The invention further relates to a heat storage and heat release method of the high-capacity medium-temperature phase-change heat storage and heat release system for the thermal power plant.

Owner:CENT SOUTHERN CHINA ELECTRIC POWER DESIGN INST CHINA POWER ENG CONSULTING GROUP CORP

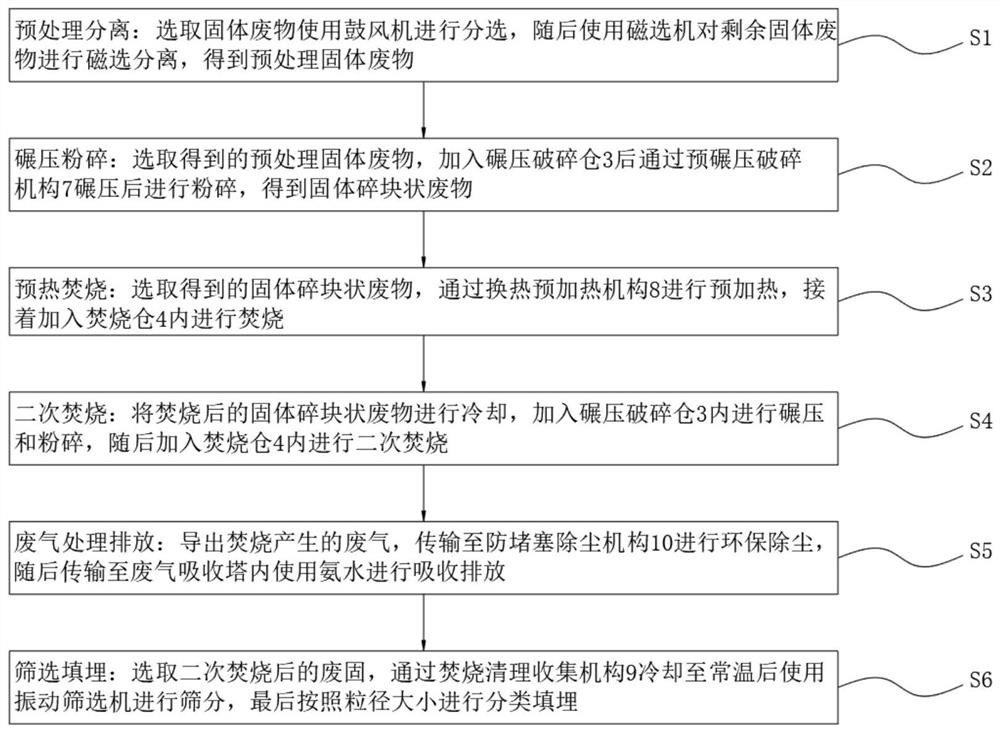

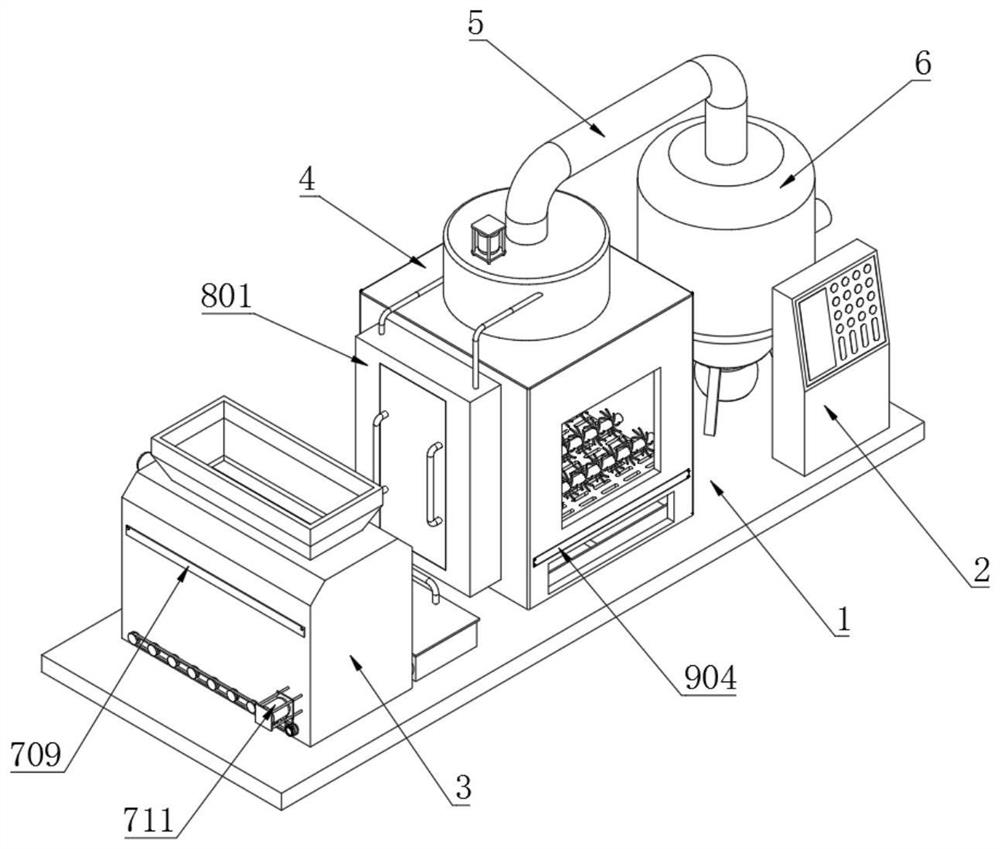

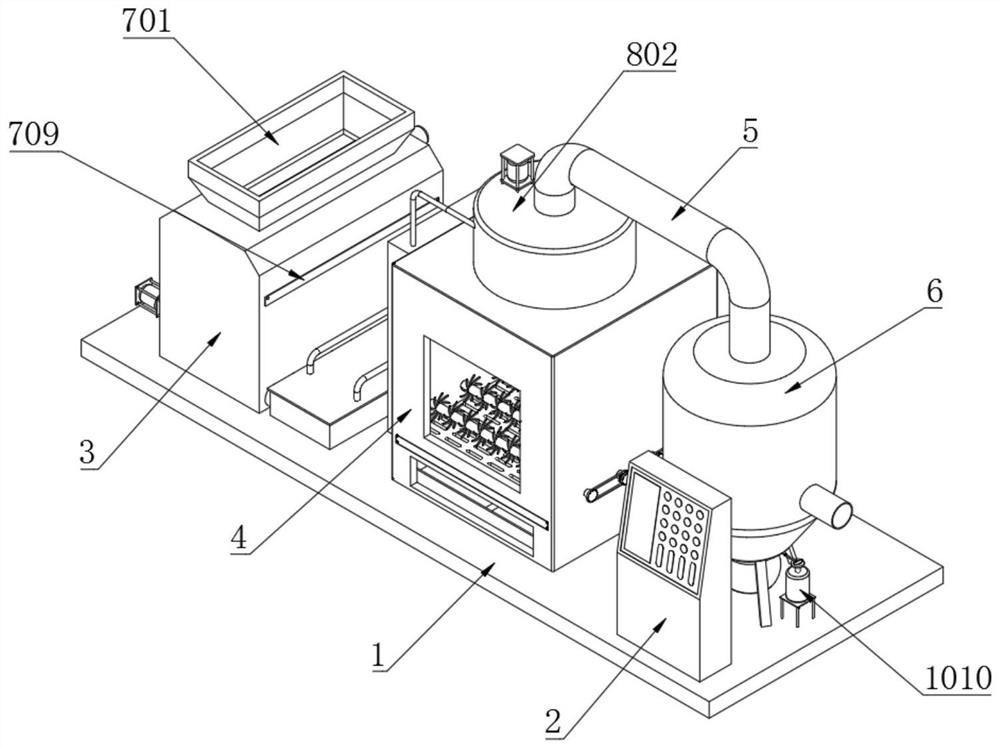

Environment-friendly efficient waste solid treatment method

InactiveCN111928253AScientific and reasonable structureSafe to useSievingScreeningPollutantPre treatment

The invention discloses an environment-friendly efficient waste solid treatment method. The method includes the following steps of pretreatment separation, grinding and crushing, preheating and incineration, secondary incineration, waste gas treatment and discharging as well as screening and landfill treatment. An incineration furnace comprises a base plate; a control panel is mounted on one sideof the top end of the base plate; a grinding and crushing bin is mounted in the position, corresponding to one side of the control panel, of the top end of the base plate; and an incineration bin is mounted in the position, corresponding to one side of the grinding and crushing bin, of the top end of the base plate. The method is scientific and reasonable in structure and safe and convenient to use, winnowing and magnetic separation are performed on solid waste firstly, then grinding and crushing are performed on the solid waste, incineration and cooling are performed on the solid fragmented waste, then ammonium hydroxide absorbing and discharging are performed on waste gas, and finally, screening and landfill treatment are performed on waste solids by a vibrating screening machine, so that the environment-friendliness during solid waste treatment is improved, pollutants contained in the discharged gas to the air are reduced, and the solid waste treatment efficiency and effect are improved.

Owner:冯静敏

A robust thermoelectric device

The invention relates to a thermoelectric device with a firm structure. The device comprises a thermoelectric device and a heat transfer part. A heat transfer member is provided between a heat sourceand the thermoelectric device. The upper and lower parts of a cavity are detachably connected through a connecting part, wherein the connection is tooth-shaped connection. A tooth-shaped part I is arranged on the bottom surface of the connecting part of the upper part of the cavity, and a tooth-shaped part II matched with the tooth-shaped part I on the bottom surface of the connecting part of theupper part of the cavity is arranged on the top surface of the connecting part of the lower part of the cavity. A phase change material is arranged in the cavity, and a plurality of bulges are arranged at the bottom close to the edge part, thereby alleviating the flowing speed of the phase-change material to a certain extent, and enabling the phase-change material flowing to the position to absorbheat slowly, so as to reduce the temperature difference between the phase-change material flowing down from the edge and the phase-change material in the center of the bottom, prevent the sputteringcaused by too large temperature difference of the phase-change material from affecting the heat transfer efficiency and damage to a heat transfer component, and prevent the phase-change material fromflowing to the edge.

Owner:朱梁锋

Water heater

PendingCN112880198AAvoid wastingAvoid using effectsFluid heatersMechanical apparatusThermal waterMechanical engineering

The invention provides a water heater. The water heater comprises a water outlet pipe, a water supply valve group, a functional liquid input device and a flow statistics device. The tail end of the water outlet pipe is connected with a first water distribution pipe and a second water distribution pipe. The water supply valve group is configured to open the first water distribution pipe and close the second water distribution pipe under the condition that the water heater operates in the first water outlet mode. The functional liquid input device is configured to be started under the condition that the water heater operates in the first water outlet mode so as to convey bath foam to the water outlet pipe to mix the bath foam into hot water output by the first water distribution pipe. The flow statistics device is used for carrying out statistics on the usage amount of the bath foam, and when the usage amount of the bath foam is larger than or equal to the preset usage amount, the water heater enters the second water outlet mode, the functional liquid input device is shut down, and the water supply valve group closes the first water distribution pipe and opens the second water distribution pipe. According to the water heater, it can be guaranteed that a user enjoys a healthy bathing function, and meanwhile the phenomenon that the bath foam is wasted or excessively used is effectively avoided.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD +1

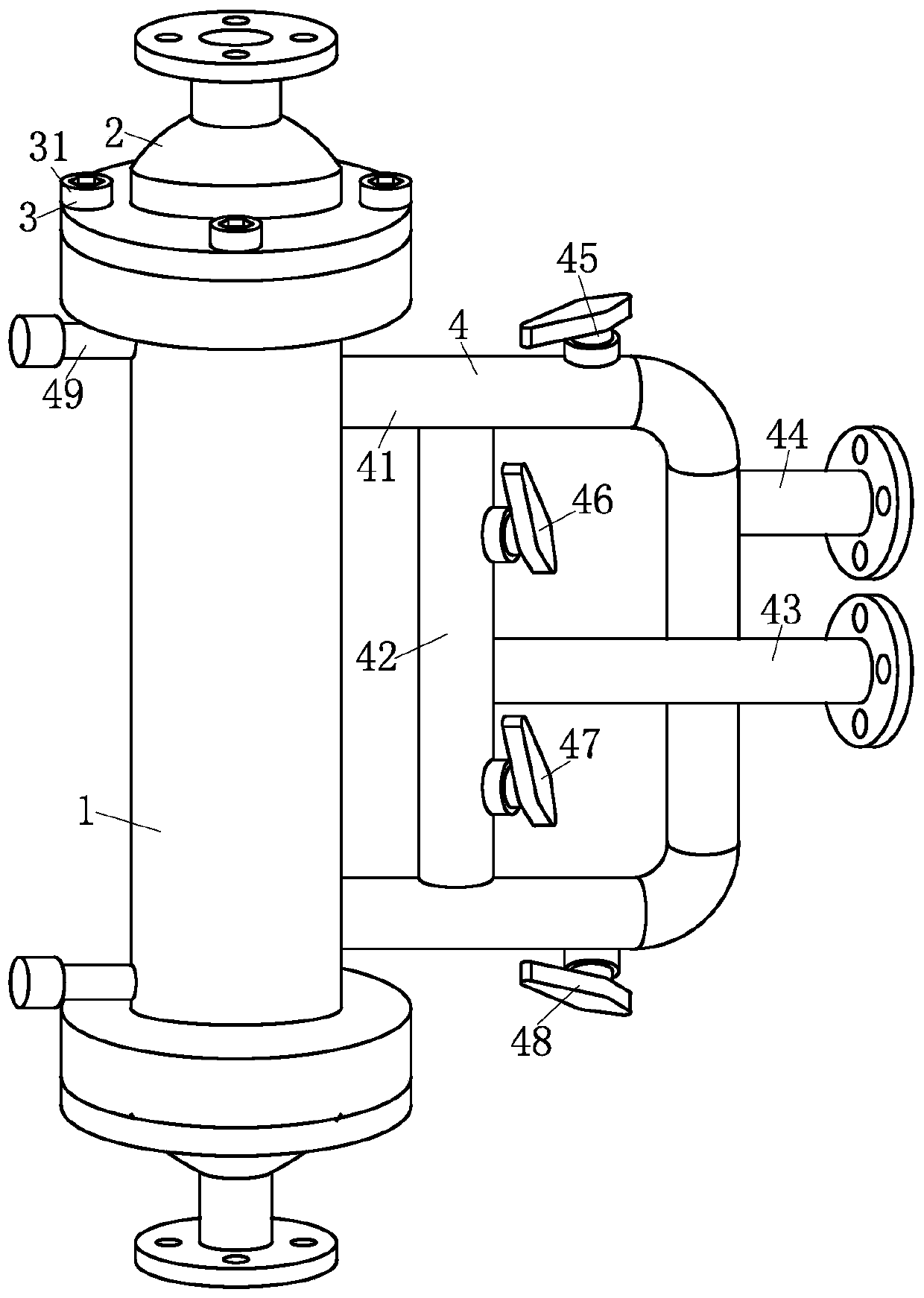

Heat exchange device for composite methyl alcohol evaporator

ActiveCN110553523AClean up in timeGuaranteed heat transfer efficiencyHeat exhanger sealing arrangementStationary tubular conduit assembliesAlcoholEngineering

The invention relates to the field of methyl alcohol processing production, in particular to a heat exchange device for a composite methyl alcohol evaporator. The heat exchange device comprise a cylinder body, a sealing cover, a fixing structure, a scale removing structure, a sealing structure, a limiting structure and a heat exchange structure. When a first valve body and a third valve body are closed, and a second valve body and a fourth valve body are opened, external water enters the cylinder body from the upper end of the cylinder body, at the moment, water entering from a water inlet inthe upper end flushes a piston to the other end of the cylinder body, a metal ring is arranged between a heat exchange pipe and the piston, and connected with the heat exchange pipe in a sliding manner, therefore the piston drives the metal ring to slide on the exterior of the heat exchange pipe in the sliding process under the flushing force effect of the water, thus water scale on the exterior of the heat exchange pipe can be cleared away in time, flushing force of the water is far larger than elasticity of a second spring, and therefore the piston does not obstruct a water outlet in the lower end.

Owner:PUCHENG CLEAN ENERGY CHEM CO LTD

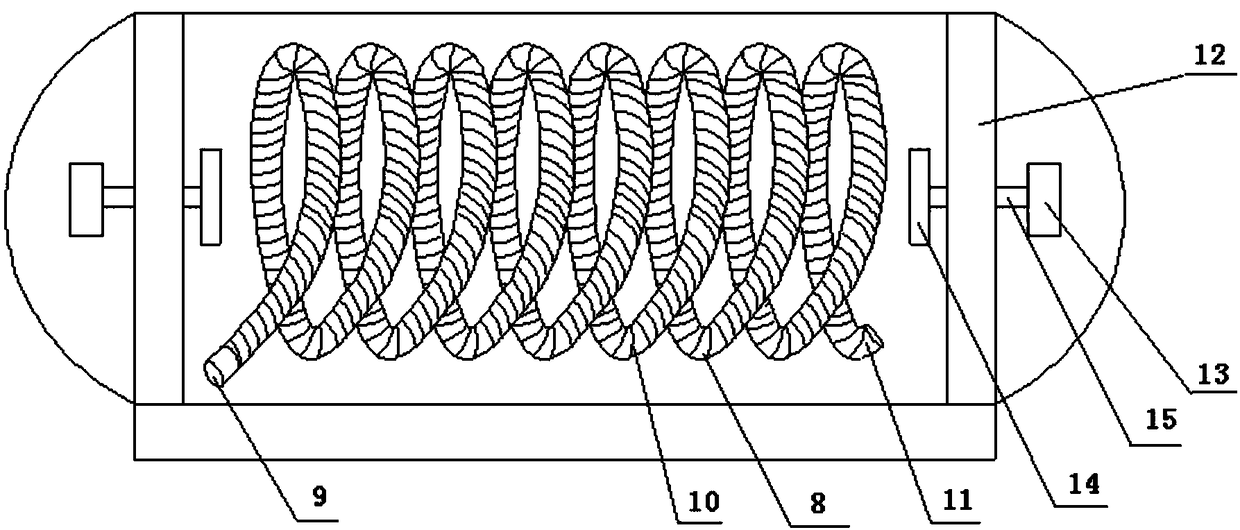

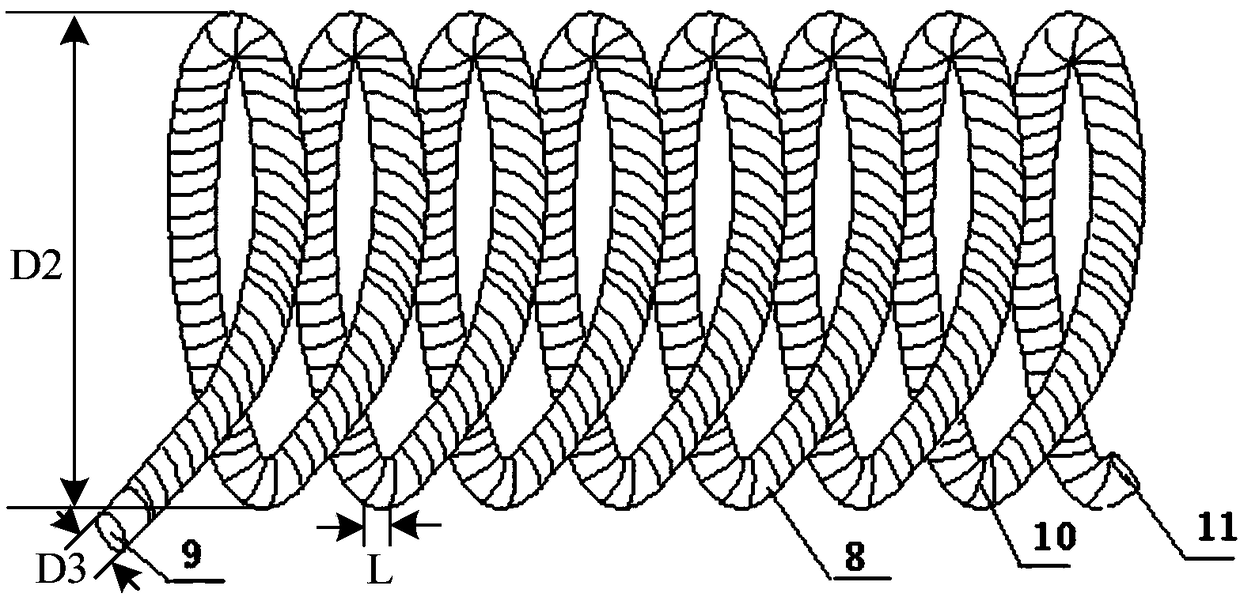

Heat exchanger for accelerating heat exchange and heat exchange method

InactiveCN108571903AImprove heat transfer efficiencyIncreased flushing forceStationary tubular conduit assembliesHeat transfer modificationSpecific gravityCorrosion

The invention provides a heat exchanger for accelerating heat exchange and a heat exchange method. The heat exchanger comprises a shell, end sockets, a liquid stirring device, a heat exchange pipe, stirring driving devices, the liquid stirring device and the heat exchange pipe are arranged in the shell, and the stirring driving devices are arranged in the end sockets. A heat exchange medium entersthe shell through a heat exchange medium feeding port, and flows out of the shell through a heat exchange medium discharging port. Materials enter the heat exchange pipe in the shell through a material feeding port and flow out of the heat exchange pipe through a material discharging port. The heat exchange medium is stirred, so that the heat exchange medium is in full contact with the heat exchange pipe, and the materials and the heat exchange medium achieve energy interchange through the pipe wall of the heat exchange pipe. According to the heat exchanger, the heat exchange medium is promoted to accelerate motion through the stirring device, and the heat exchange efficiency is improved. The thread screw heat exchange pipe is adopted, the scouring force of the materials on the pipe wallis greatly increased, and condensation and scale formation of the pipe wall are avoided; scale formation prevention and energy saving are balanced by optimizing the size of the heat exchange pipe; theheat exchange pipe is made from aluminum-based alloy containing nano-graphite, the heat transferring performance is high, corrosion resistance is achieved, the application range is wide, the specificgravity is small, and the weight is low.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Inert gas circulating device of dry quenching system

PendingCN113583691AEasy to cleanAvoid affecting the heat conduction effectCoke quenchingEnergy inputProcess engineeringSoot

The invention discloses an inert gas circulating device of a dry quenching system. The inert gas circulating device comprises a dry quenching furnace, a primary dust remover, a dry quenching waste heat boiler, a secondary dust remover, a primary cooling device, a fan and a secondary cooling device; the dry quenching system inert gas circulating device is composed of the dry quenching furnace, the primary dust remover, the dry quenching waste heat boiler, the secondary dust remover, the primary cooling device, the fan and the secondary cooling device, and the primary cooling device is composed of the heat exchanger body, the outer shell and the heat exchange pipeline, the heat exchanger body and the outer shell are provided with the first mounting groove and the second mounting groove correspondingly, so that the air cavity is formed between the first mounting groove and the second mounting groove, and workers can conveniently and regularly clean the side walls of the first mounting groove and the second mounting groove through detachable mounting between the heat exchanger body and the outer shell; therefore, the heat conduction effect of the device is prevented from being influenced by soot accumulation, and the heat exchange efficiency is further prevented from being influenced.

Owner:QINGDAO DESHIPU MACHINERY IND

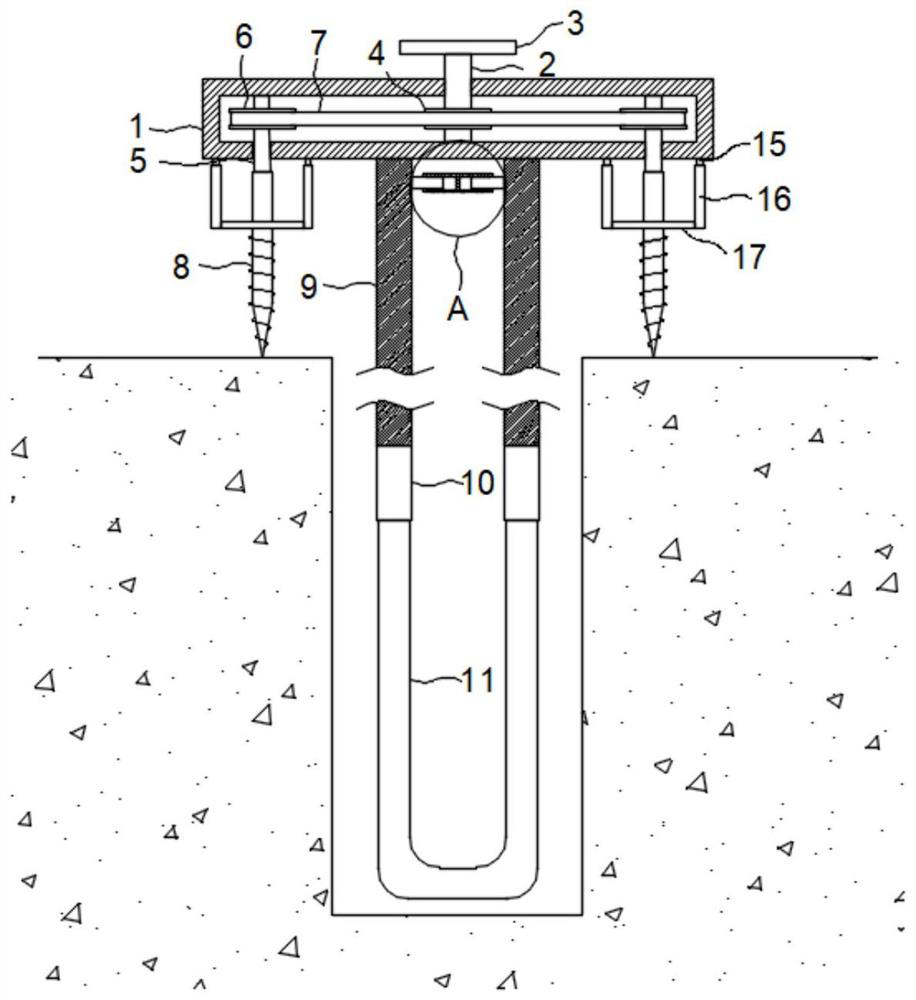

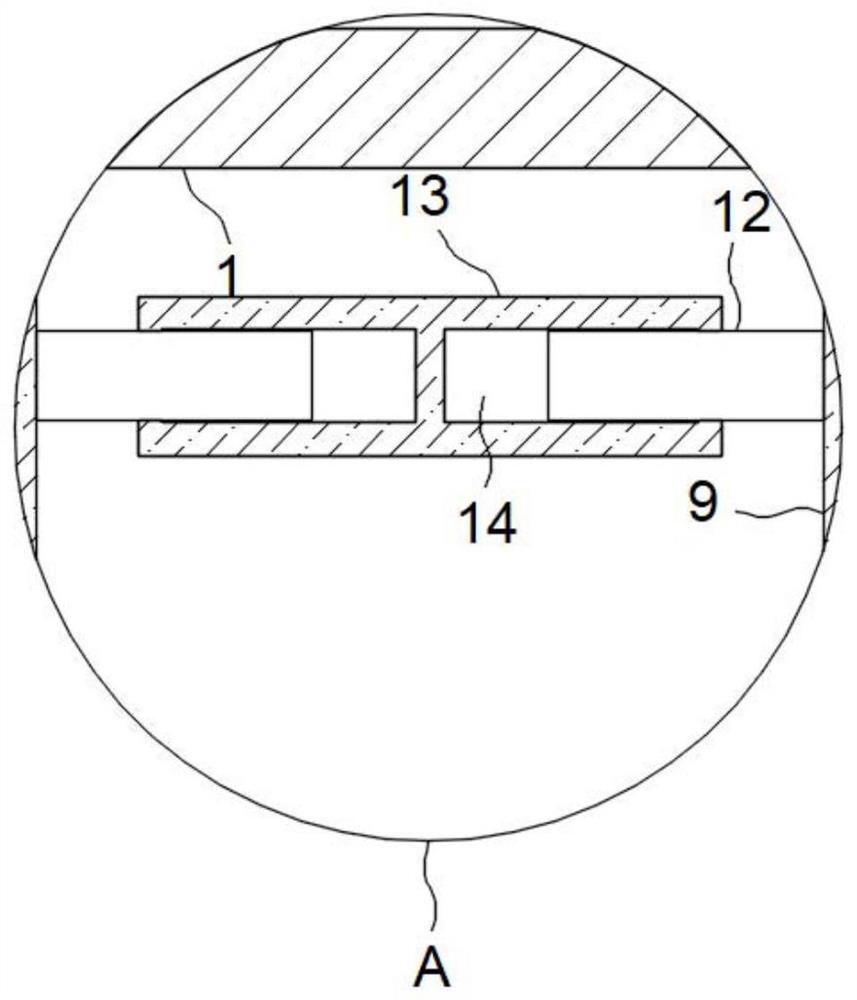

Floating-preventing device for buried pipe of ground source heat pump

ActiveCN111854226AAvoid Heat Exchange EfficiencyImprove work efficiencyCollector components/accessoriesHeat pumpsHeat pumpTransmission belt

The invention discloses a floating-preventing device for a buried pipe of a ground source heat pump. The device comprises a mounting plate. A rotating shaft is rotatably inserted onto the mounting plate in a penetrating manner, a driving wheel is fixedly connected to the rotating shaft, threaded rods are symmetrically and rotatably inserted onto the mounting plate in a penetrating manner, driven wheels are fixedly connected to the threaded rods, a transmission belt is arranged between the driven wheels and the driving wheel, threaded sleeves are in threaded connection to the threaded rods, limiting mechanisms are symmetrically arranged on the mounting plate, connecting rods are symmetrically and slidably connected to the bottom side of the mounting plate, drive pipes are fixedly connectedto the connecting rods, and U-shaped pipes are slidably connected to the drive pipes. By connecting the drive pipes to the U-shaped pipes, laying the U-shaped pipes down to a drilled hole with an appointed depth, the threaded sleeves are attached to the ground. Then, by rotating a rotating rod to rotate the rotating shaft to drive the driving wheel to rotate, and by rotating the driven wheels by means of action of the transmission belt to drive the threaded rods to rotate, the threaded sleeves move downward into the ground to fix the device.

Owner:江苏悦达塞夫纳节能科技有限公司

Environment-friendly flue gas purification device for garbage incineration

InactiveCN110553277AEasy disassembly and cleaningAvoid affecting heat transfer efficiencyCombination devicesLighting and heating apparatusWater pipeRecovery function

The invention discloses an environment-friendly flue gas purification device for garbage incineration. The environment-friendly flue gas purification device comprises a heat exchange box, a motor anda spraying assembly, wherein a mounting strip is fixed on the outer side of the heat exchange box; the motor is arranged at the end part of the mounting strip; the output end of the motor is connectedwith a screw rod which is in shaft connection with the interior of a movable groove; the movable groove is arranged in the mounting strip; the outer side of the screw rod is in threaded connection with a movable block; a movable rod is fixed on one side of the movable block; the movable rod penetrates through the inner wall of the heat exchange box and is positioned in the heat exchange box; positioning blocks are installed on the outer side of a filter screen and positioned in positioning grooves; the positioning grooves are formed in the end parts of guide pipes; and the spraying assembly is installed on the top of a spraying box. According to the environment-friendly flue gas purification device for garbage incineration, flue gas is purified through filtering and spraying, meanwhile, the waste heat recovery function is achieved, impurities on water pipes can be conveniently removed, and the filter screen can be conveniently disassembled and cleaned.

Owner:徐丽仙

Heat dissipating device for integrated water-cooling straight seal high-power electronic components and manufacturing method thereof

ActiveCN103337587AGood cooling effectAvoid Thermal BottlenecksSemiconductor devicesElectrically conductiveTantalum nitride

The invention discloses a heat dissipating device for integrated water-cooling straight seal high-power electronic components. An aluminum oxide insulating layer, a buffer layer, a primary conducting layer, a secondary conducting layer and a weldable layer are arranged on the surface of a radiator in sequence; or the aluminum oxide insulating layer, a tantalum nitride layer, the buffer layer, the primary conducting layer, the secondary conducting layer and the weldable layer are arranged on the surface of the radiator in sequence. The manufacturing method of the heat dissipating device comprises the following steps: 1) forming the aluminum oxide insulating layer on the surface of the radiator; 2) forming the buffer layer; 3) forming the primary conducting layer; 4) forming the secondary conducting layer; 5) plating weldable layer metal; or the manufacturing method comprises the following steps: 1) forming the aluminum oxide insulating layer on the surface of the radiator; 2) forming the tantalum nitride layer; 3) forming the buffer layer; 4) forming the primary conducting layer; 5) forming the secondary conducting layer; 6) plating weldable layer metal. The heat dissipating device is good in heat dissipation effect.

Owner:HUIZHOU LEADAO ELECTRONICS MATERIAL

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com