Microchannel heat exchanger

A micro-channel heat exchanger and flow-through technology, which is applied in the direction of heat exchange equipment, heat exchanger type, heat exchanger shell, etc., can solve the problem of uneven flow distribution of refrigerant, and achieve the solution of uneven flow distribution and structural design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

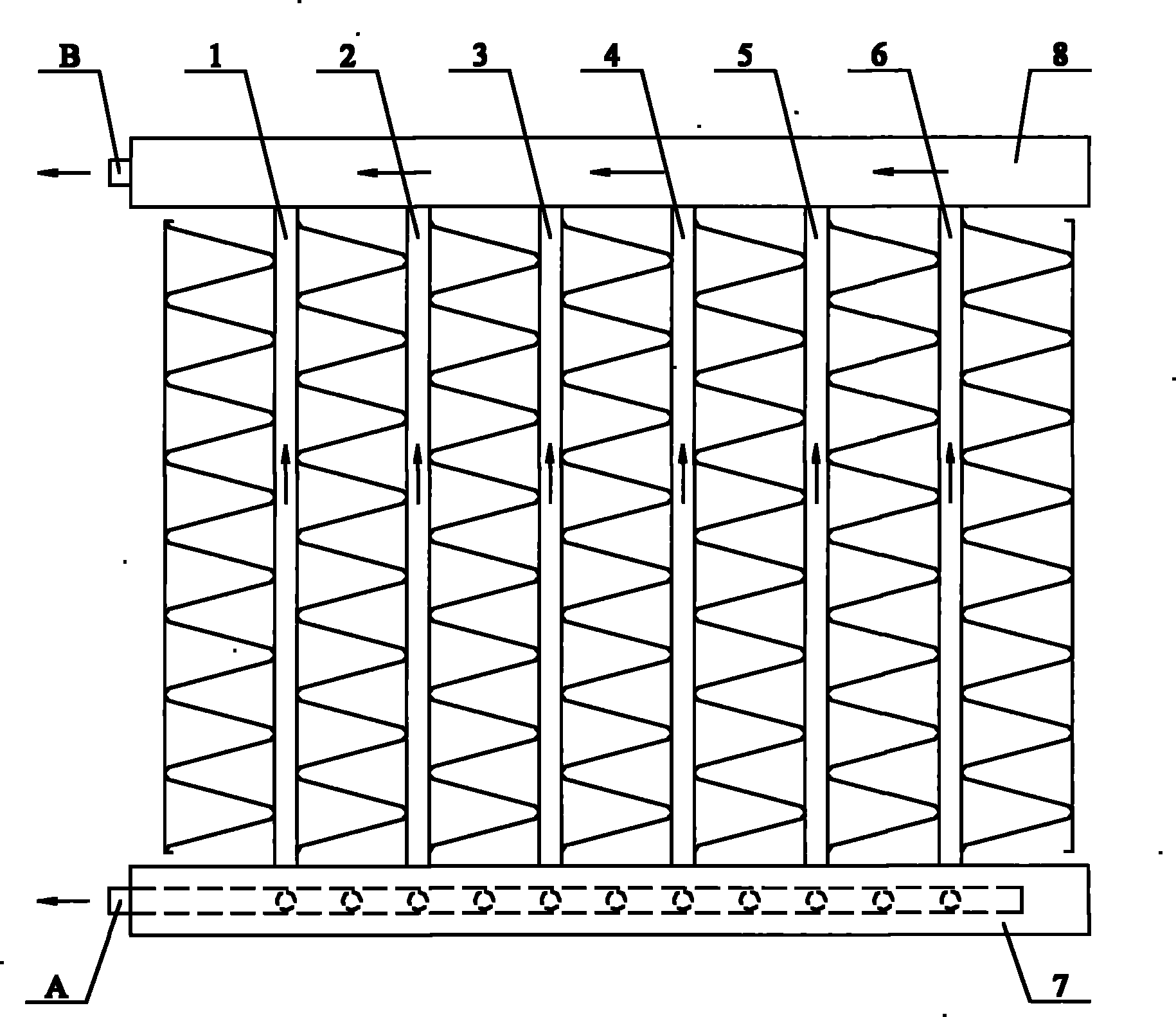

[0028] The composition of the micro-channel heat exchanger in this embodiment and the connection relationship between the components are the same as those in the prior art, and will not be described in detail herein. The overall structure can be found in figure 1 .

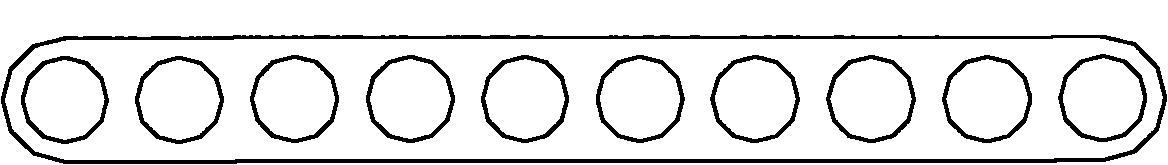

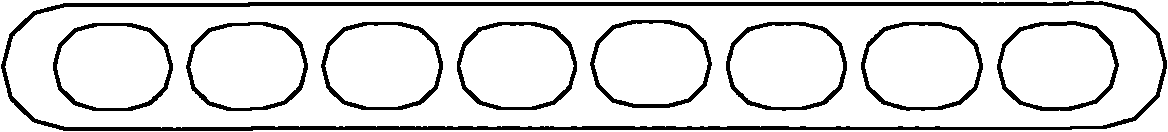

[0029] In this example, the flow resistance of each flat tube is adjusted by changing the flow area of each flat tube. For details, please refer to figure 2 , image 3 and Figure 4 , respectively show the schematic cross-sections of three flat tubes with different flow areas. As shown in the figure, relatively speaking, figure 2 The flat tube shown in is a small-diameter flow hole, image 3 The flat tubes shown in are medium-bore flow holes, Figure 4 The flat tube shown in is a large bore orifice.

[0030] Without loss of generality, the following figure 1 The six flat tubes shown in are taken as an example to illustrate the arrangement of flat tubes with different flow apertures.

[0031] The flow...

Embodiment 2

[0035] In this example, the flow resistance of each flat tube is also adjusted by changing the flow area of each flat tube. For details, please refer to Figure 5 , Figure 6 and Figure 7 , respectively show the schematic cross-sections of three kinds of flat tubes with different widths. As shown in the figure, relatively speaking, Figure 5 The flat tube shown in has a smaller width, Figure 6 The flat tubes shown in have wider widths, Figure 7 The width of the flat tube shown in is the largest.

[0036]The arrangement principle of flat tubes with different widths in this embodiment is the same as that in Embodiment 1. The flow resistance of the first flat tube 1 and the second flat tube 2 is small, and the Figure 5 Smaller width flat tubes shown in . The process resistance of the third flat tube 3 and the fourth flat tube 4 is relatively large, and the Figure 6 Wider width flat tubes shown in . The flow resistance of the fifth flat tube 5 and the sixth flat t...

Embodiment 3

[0040] In this example, the flow resistance of each flat tube is also adjusted by changing the flow area of each flat tube. For details, please refer to Figure 8 , Figure 9 and Figure 10 , respectively show the schematic cross-sections of three flat tubes with different thicknesses. As shown in the figure, relatively speaking, Figure 8 The thickness of the flat tube shown in is smaller, Figure 9 The thickness of the flat tube shown in is wider, Figure 10 The thickness of the flat tube shown in is the largest.

[0041] The arrangement principle of flat tubes with different thicknesses in this embodiment is the same as that in Embodiments 1 and 2. The flow resistance of the first flat tube 1 and the second flat tube 2 is small, and the Figure 8 Flat tubes of smaller thickness shown in . The process resistance of the third flat tube 3 and the fourth flat tube 4 is relatively large, and the Figure 9 Wider flat tubes of thickness shown in . The flow resistance o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com