Novel secondary air system for opposed firing boiler and working method thereof

A technology of hedging combustion and secondary air, applied in combustion methods, combustion equipment, transportation of non-combustible liquids/gases, etc., can solve the problem of uneven flow distribution in the secondary air box, and solve the problem of uneven flow distribution and facilitate uniform distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

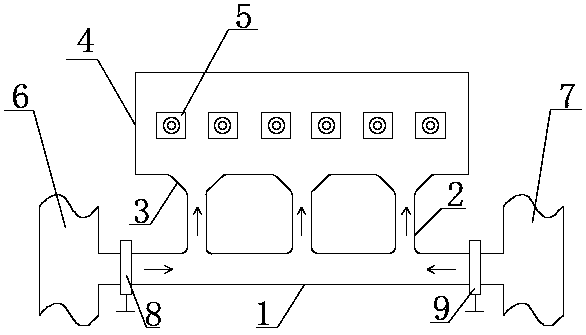

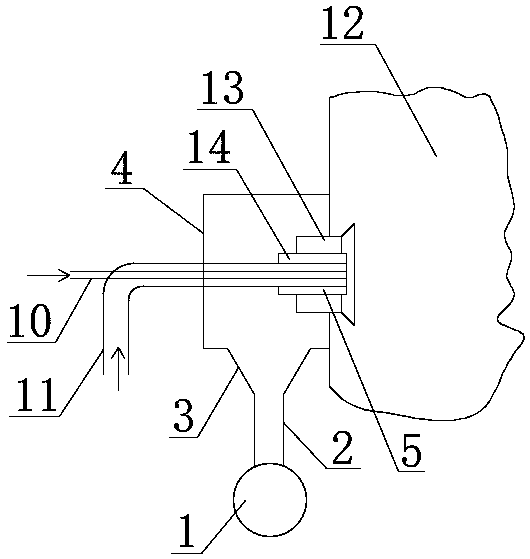

[0023] see Figure 1 to Figure 2 , the new secondary air system used in this embodiment for opposed combustion boilers includes secondary air layer pipe 1, secondary air branch pipe 2, flare 3, secondary air box 4, burner 5, A side secondary air Main duct 6, B-side secondary air main duct 7, A-side regulating damper 8, B-side regulating damper 9, central air duct 10, primary air duct 11, outer secondary air door 13 and inner secondary air door 14.

[0024] The secondary air layer pipe 1 is connected to the secondary air box 4 through the secondary air branch pipe 2, and the flare 3 is located between the secondary air branch pipe 2 and the secondary air box 4; one end of the secondary air layer pipe 1 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com