Pneumatic main breaking electromagnetic valve

A solenoid valve and spool technology, applied in the field of 25kV electrified railway pneumatic vacuum circuit breaker, pneumatic main break solenoid valve, can solve the problems of poor reliability, difficult to popularize and apply, complex structure, etc., to achieve high reliability, simple and compact structure, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

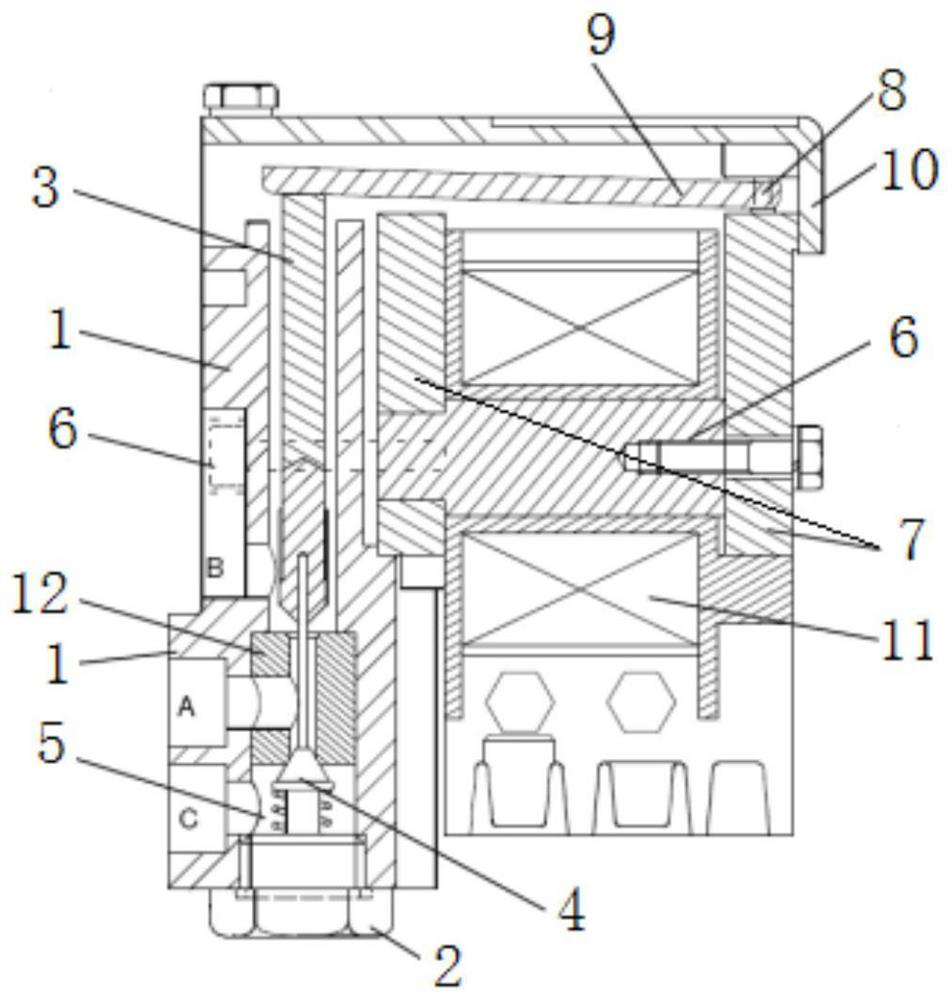

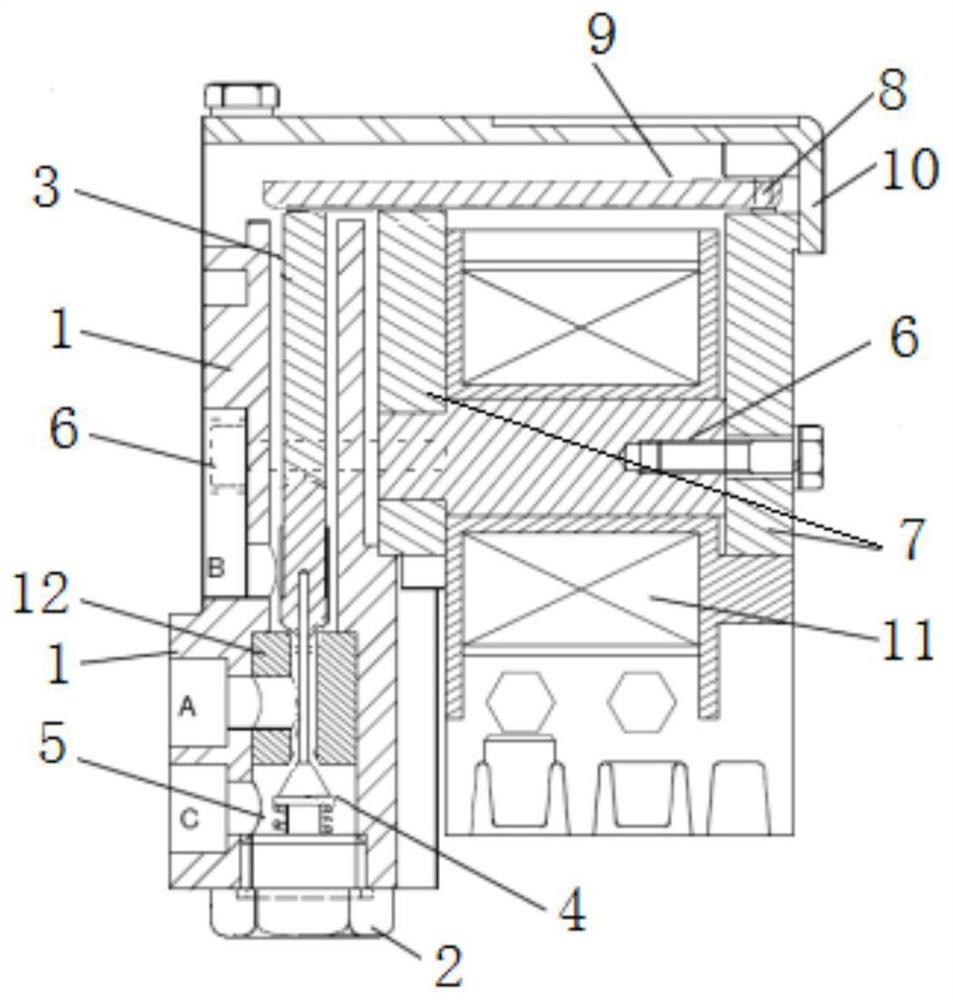

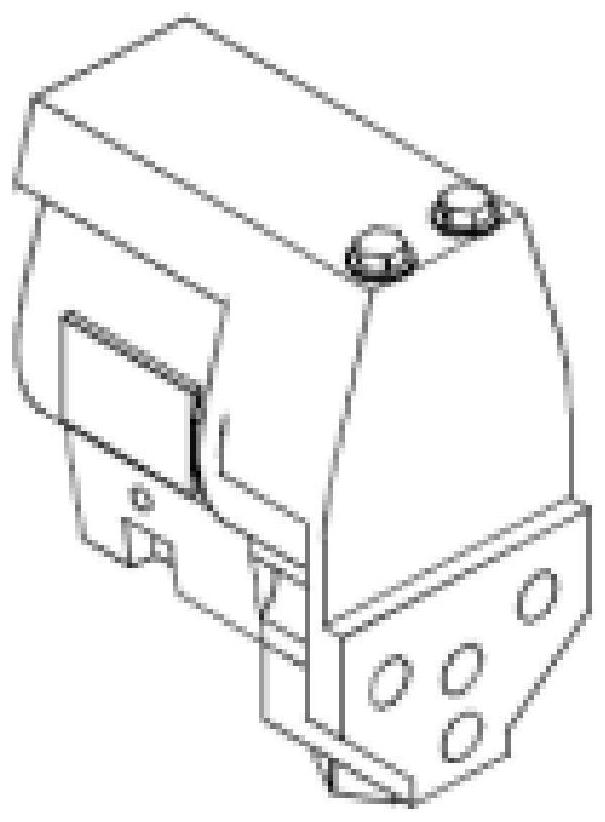

[0046] Such as figure 1 , figure 2 , image 3 As shown, the solenoid valve is assembled in the vacuum circuit breaker (such as figure 1 ),include:

[0047] Valve body 1, screw plug 2, upper valve core 3, lower valve core 4, spring 5, fastening screw 6, static armature 7, pin 8, moving armature 9, cover 10, coil 11, valve seat 12, air circuit Part of the air inlet C, the air outlet A is on the valve seat 12, and the air outlet B is on the valve body 1. The valve body 1 and the cover 10 form the main structure of the solenoid valve. The static armature 7, the moving armature 9, and the coil 11 are packaged inside the valve body 1. The fastening screw 6 fixes the static armature 7 on the valve body 1. The spring 5 is compressed and assembled. At the bottom of the lower spool 4, the lower spool 4 and the upper spool 3 are plugged and assembled, and the screw plug 2 is assembled at the bottom of the valve body 1, and is used to block the air inlet air path. The pin 8 fixes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com