A combined water tray and air conditioner

A water tray and combined technology, which is applied in the direction of heating, condensation prevention, space heating and ventilation details, etc., can solve the problem that the water tray cannot be ventilated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

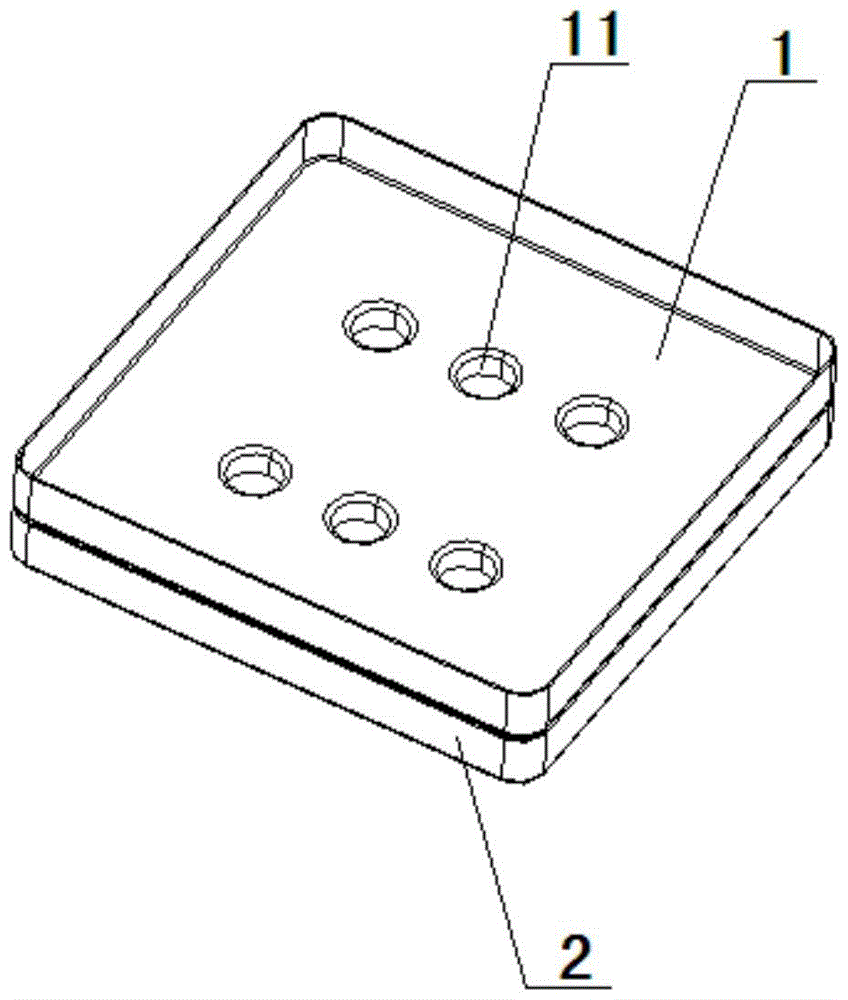

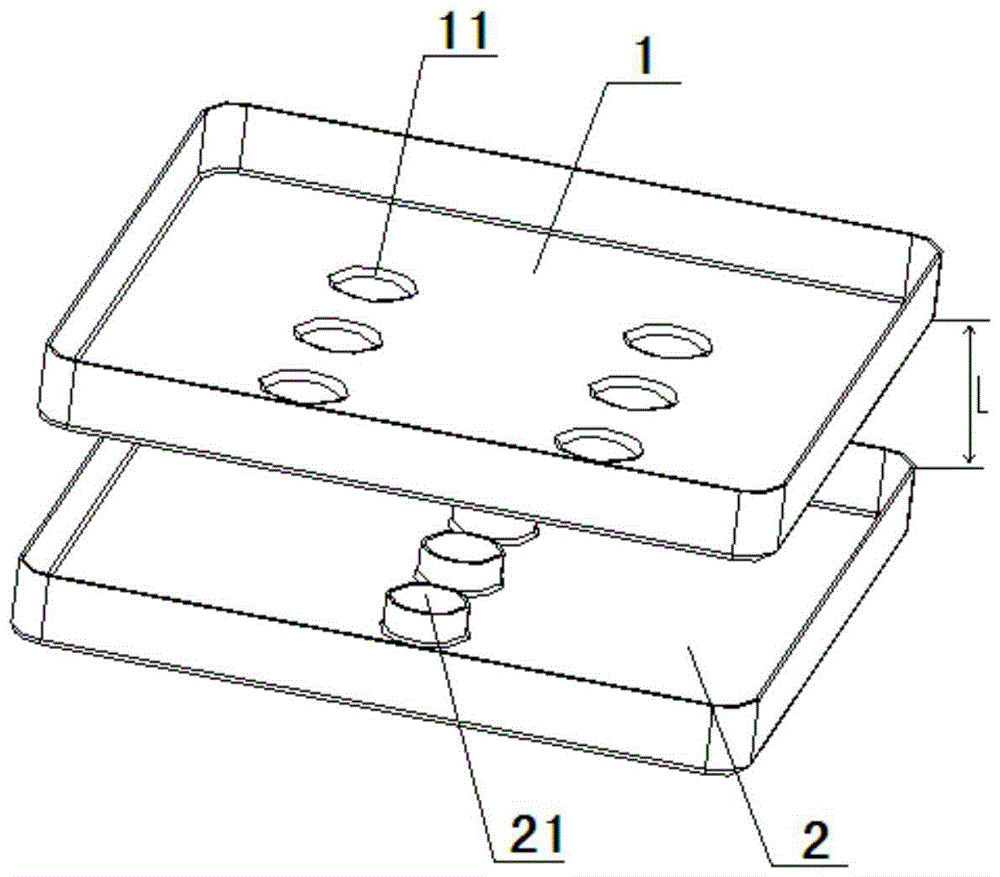

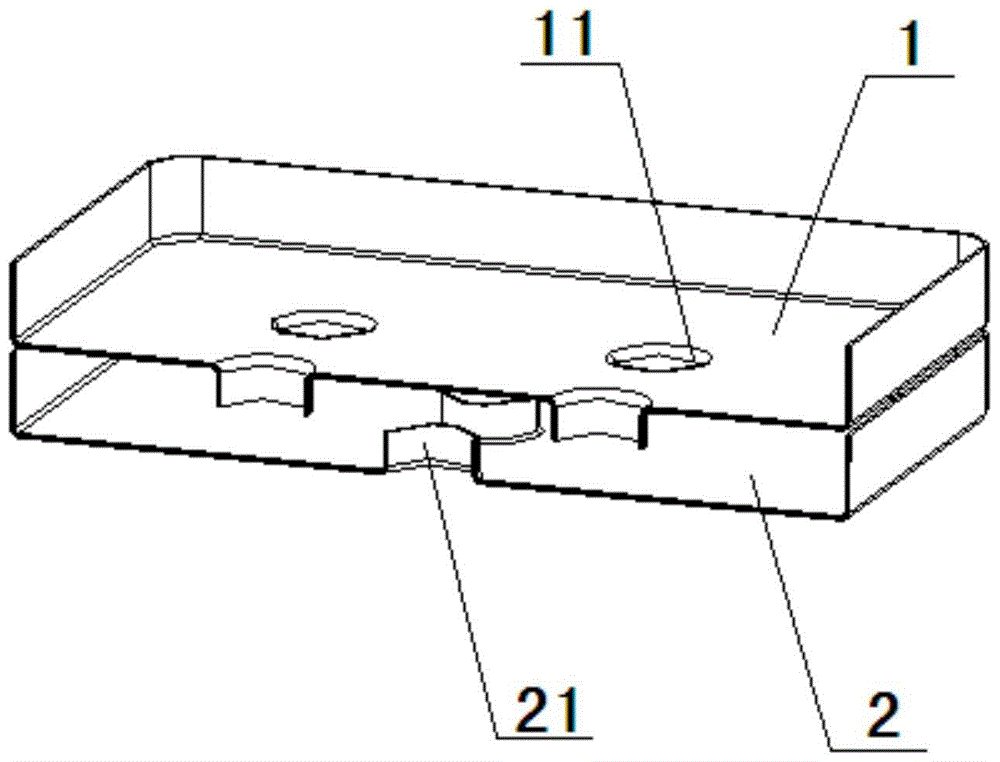

[0037] Such as Figure 1-Figure 7 As shown, it is a combined water receiving tray proposed in this embodiment. The combined water receiving tray has a two-layer structure, including a top water receiving tray 1 and a bottom water receiving tray 2. The top water receiving tray 1 is located at the bottom to receive water. plate 2 above.

[0038] Such as image 3 As shown, the top water tray 1 is provided with a first through hole 11 for the condensed water falling from the heat exchanger to flow from the top water tray 1 into the bottom water tray 2, and the bottom water tray 2 Ventilation holes 21 are provided for allowing wind to enter the bottom water tray 2 , and the first through holes 11 and the ventilation holes 21 are arranged staggered from each other. The specific meaning of the mutual staggering mentioned in the present invention is that under normal use conditions, the projection of the first through hole 11 on the bottom drain tray 2 and the ventilation hole 21 ca...

Embodiment 2

[0049] Such as Figure 8 As shown, it is a combined water tray structure proposed in this embodiment, including a top water tray 1 and a bottom water tray 2, the top water tray 1 is provided with a first through hole 11, and the bottom water tray 2 Ventilation holes 21 are arranged on the top, and bottom drain outlets 22 are arranged at the bottom of the side wall of the bottom water tray 2 . The difference between this embodiment and Embodiment 1 is that, in this embodiment, a top drain port 12 is also provided at the bottom of the side wall of the top water tray 1 . The setting of the top drain port 12 can share the workload of the bottom drain port 22 to a certain extent, so that a part of condensed water can be discharged from the top drain port 12, and prevent the bottom water tray 2 from being drained from the ventilation port due to too much condensed water. 21 overflows.

Embodiment 3

[0051] This embodiment proposes a combined water receiving tray, including a top water receiving tray and a bottom water receiving tray near the heat exchanger. The first through hole of the water receiving tray, the bottom of the water receiving tray is provided with a ventilation hole for air to pass through. The difference between this embodiment and the first embodiment is that it further includes a middle water receiving tray arranged between the top water receiving tray and the bottom water receiving tray. The middle water tray is provided with a second through hole for guiding the condensed water to the bottom water tray, and the second through hole may or may not be a flanging hole. When the second through hole is a flange hole, the flange of the second through hole faces the same direction as the direction of gravity.

[0052] In this embodiment, the positional relationship between the first through hole on the top water receiving tray and the second through hole on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com