Environment-friendly efficient waste solid treatment method

A treatment method and an environment-friendly technology, applied in the field of environment-friendly high-efficiency solid waste treatment, can solve the problems affecting the treatment efficiency and treatment effect of solid waste, the thoroughness of solid waste incineration, and the manual screening of solid waste. Conduction and storage, safe and convenient use, and the effect of increasing environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

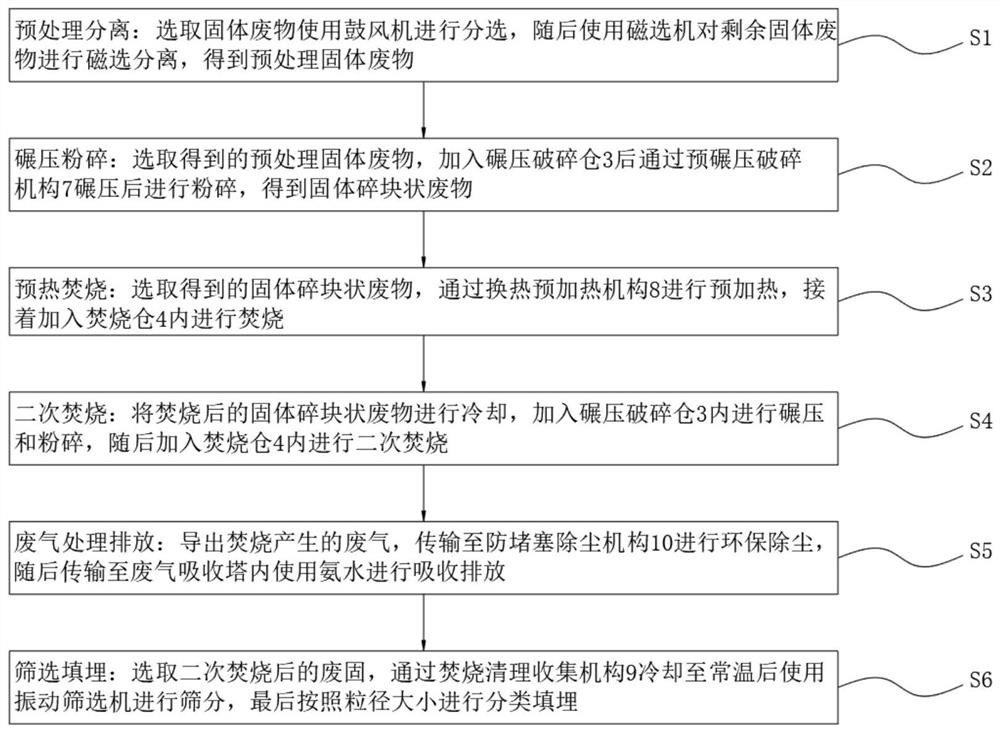

[0069] Such as figure 1 As shown, the present invention provides a technical solution, an environmentally friendly and efficient waste solid treatment method, comprising the following steps:

[0070] S1. Pretreatment and separation: select solid waste to be sorted with a blower, and then use a magnetic separator to perform magnetic separation on the remaining solid waste to obtain pretreated solid waste;

[0071] S2. Rolling and crushing: select the obtained pretreated solid waste, put it into the rolling and crushing bin 3, and then crush it through the pre-rolling and crushing mechanism 7 to obtain solid waste in the form of pieces;

[0072] S3, preheating incineration: select the obtained solid fragment waste, preheat it through the heat exchange preheating mechanism 8, and then put it into the incineration bin 4 for incineration;

[0073] S4. Secondary incineration: cooling the incinerated solid fragments, putting them into the rolling and crushing bin 3 for rolling and c...

Embodiment 2

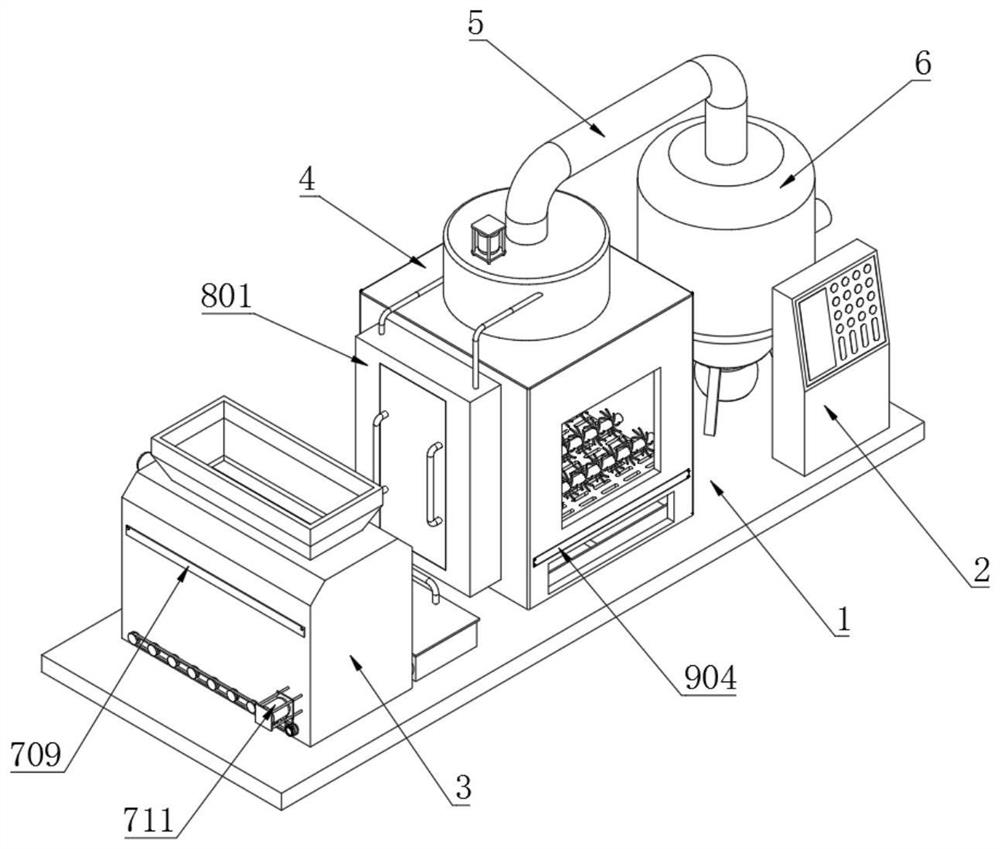

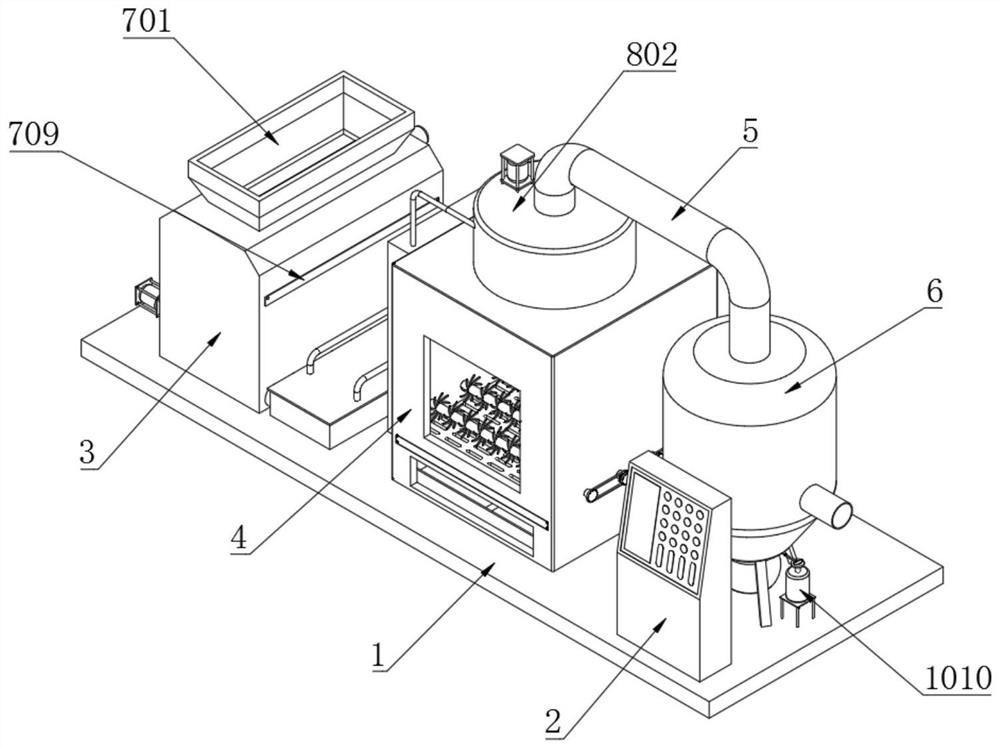

[0078] Such as Figure 2-17 As shown, the present invention provides a technical solution, an environmentally friendly and efficient waste solid treatment method, the rolling crushing bin 3 is installed on the top of the base plate 1, and a control panel 2 is installed on the top side of the base plate 1, and the top of the base plate 1 corresponds to the roller. An incineration bin 4 is installed on one side of the crushing bin 3, and a flue pipe 5 is connected to the top of the incineration bin 4, and a dust removal bin 6 is installed on a position corresponding to the side of the incineration bin 4 on the top of the substrate 1;

[0079] A pre-rolling crushing mechanism 7 is installed inside the rolling crushing bin 3, and the pre-rolling crushing mechanism 7 includes a waste solid addition bin 701, a rolling motor 702, a crushing motor 703, a transmission gear 704, a transmission tooth chain 705, and a crushing roller. 706, crushing roller 707, crushing cutter 708, embedde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com