Recycle device and recycle method for solvent in coal liquefaction residue raffinate

A coal liquefaction residue and recovery device technology, which is applied in the field of coal chemical industry, can solve the problems of difficult long-term, efficient and stable operation of the recovery system, and achieve superior economic and ecological benefits, reduced impact, and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

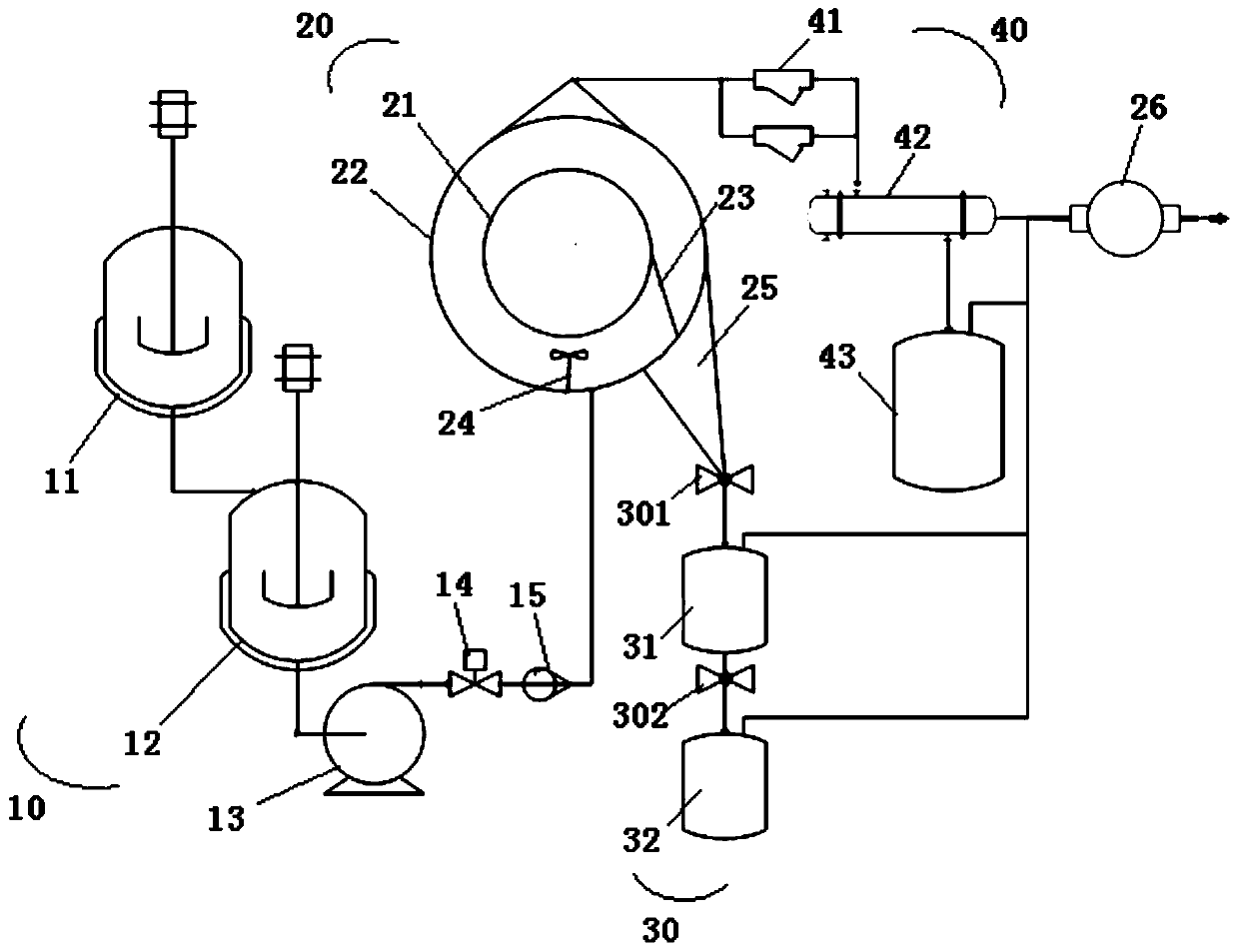

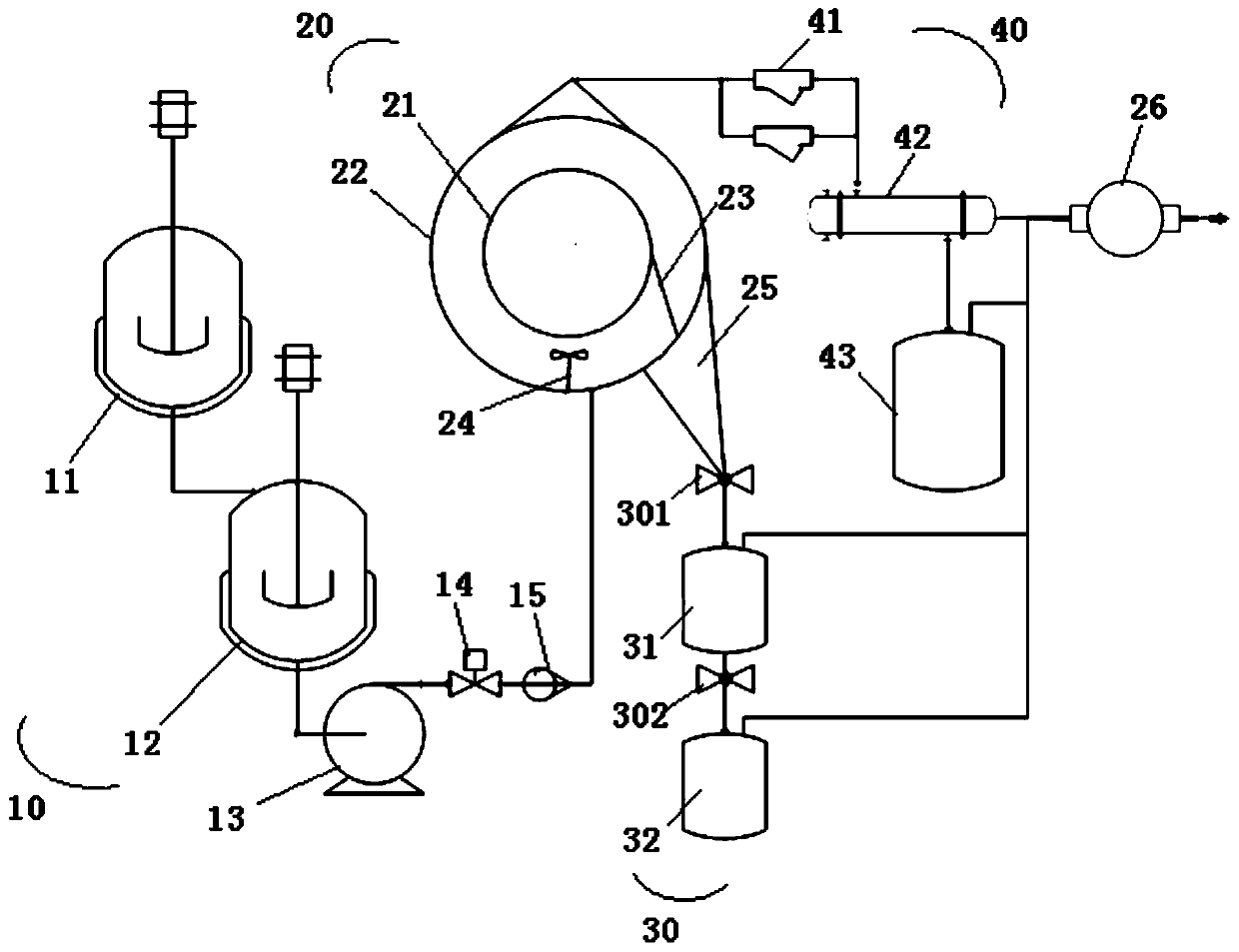

[0059] specific use figure 1 The shown setup performs solvent recovery:

[0060]Add the coal liquefaction residue raffinate to the coal liquefaction residue raffinate supply device, raise the temperature to 140°C and stir for 6 hours, and add the extraction solvent to the raffinate and extraction solvent mixing device at a mass ratio of 1:0.3, raise the temperature to 160°C and After stirring for 6 hours, a mixed solution suitable for stable transportation was obtained. Through the delivery pump, control valve and flow meter, the qualified mixed liquid is fed into the drum dryer from the bottom of the mixing tank for drying. The vacuum degree of the dryer is 10KPa, the rotating speed of the heating drum is 4r / min, and the temperature of the drum is 300°C. The temperature is 280°C. After the solid phase material passes through the scraper and the solid phase material discharge bin, it is finally discharged into the dry solid slag bin through the rotary discharge valve and the...

Embodiment 2

[0062] specific use figure 1 The shown setup performs solvent recovery:

[0063] Add the coal liquefaction residue raffinate to the coal liquefaction residue raffinate supply device, raise the temperature to 140°C and stir for 6 hours, and add the extraction solvent to the raffinate and extraction solvent mixing device at a mass ratio of 1:0.3, raise the temperature to 160°C and After stirring for 6 hours, a mixed solution suitable for stable transportation was obtained. Through the delivery pump, control valve and flow meter, the qualified mixed liquid is fed into the drum dryer from the bottom of the mixing tank for drying. The vacuum degree of the dryer is 5KPa, the rotating speed of the heating drum is 4r / min, and the temperature of the drum is 350°C. The temperature is 280°C. After the solid phase material passes through the scraper and the solid phase material discharge bin, it is finally discharged into the dry solid slag bin through the rotary discharge valve and the...

Embodiment 3

[0065] specific use figure 1 The shown setup performs solvent recovery:

[0066] Add the coal liquefaction residue raffinate to the coal liquefaction residue raffinate supply device, raise the temperature to 140°C and stir for 6 hours, and add the extraction solvent to the raffinate and extraction solvent mixing device at a mass ratio of 1:0.3, raise the temperature to 160°C and After stirring for 6 hours, a mixed solution suitable for stable transportation was obtained. Through the delivery pump, control valve and flow meter, the qualified mixed liquid is fed into the drum dryer from the bottom of the mixing tank for drying. The vacuum degree of the dryer is 5KPa, the rotating speed of the heating drum is 4r / min, and the temperature of the drum is 350°C. The temperature is 200°C. After the solid phase material passes through the scraper and the solid phase material discharge bin, it is finally discharged into the dry solid slag bin through the rotary discharge valve and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com