High-efficiency heat energy utilization system and method of conditioning tower high-temperature condensed water

A high-temperature condensing and conditioning tower technology, applied in heat recovery systems, heat exchangers, heat exchanger types, etc., can solve problems such as natural ecological pollution and energy waste, achieve thermal energy saving, smooth drainage, and avoid heat exchange efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

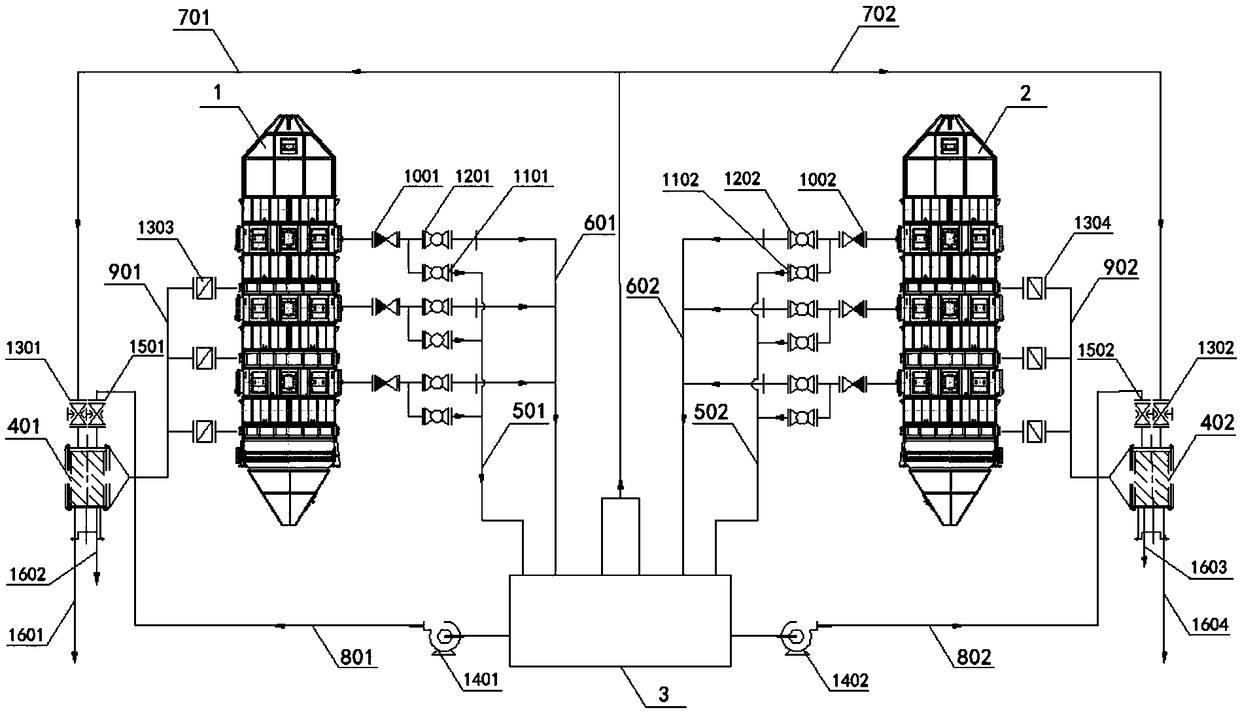

[0026] A high-efficiency thermal energy utilization system for high-temperature condensed water in a conditioning tower, comprising a first conditioning tower 1, a second conditioning tower 2, a condensed water tank 3, a first hot-air heat exchanger 401, and a second hot-air heat exchanger 402. The first conditioning tower 1 is connected to the condensed water tank 3 through the first bypass pipe 501 and the first drain pipe 601, and the second conditioning tower 2 is connected to the condensation water tank 3 through the second bypass pipe 502 and the second drain pipe 602. The water tank 3 is connected, the condensed water tank 3 is connected with the first hot air heat exchanger 401 through the first air pipe 701, and the condensed water tank 3 is connected with the second hot air heat exchanger 402 through the second air pipe 702, so The condensed water tank 3 is connected to the first hot air heat exchanger 401 through the first water delivery pipe 801, the condensed water...

Embodiment 2

[0028] A high-efficiency thermal energy utilization system for high-temperature condensed water in a conditioning tower, comprising a first conditioning tower 1, a second conditioning tower 2, a condensed water tank 3, a first hot-air heat exchanger 401, and a second hot-air heat exchanger 402. The first conditioning tower 1 and the second conditioning tower 2 are provided with three layers of steam pipelines in the upper, middle and lower parts, wherein each layer of steam pipelines in the first conditioning tower 1 is provided with a first check valve 1001, and the second The second check valve 1002 is installed on each layer of the steam pipeline of the second conditioning tower 2 to prevent the condensed water formed by steam condensation from flowing back into the steam pipeline.

[0029] The first conditioning tower 1 is connected to the condensed water tank 3 through the first bypass pipe 501 and the first drain pipe 601, and the second conditioning tower 2 is connected ...

Embodiment 3

[0033]A high-efficiency thermal energy utilization system for high-temperature condensed water in a conditioning tower, comprising a first conditioning tower 1, a second conditioning tower 2, a condensed water tank 3, a first hot-air heat exchanger 401, and a second hot-air heat exchanger 402. The first conditioning tower 1 and the second conditioning tower 2 are provided with three layers of steam pipelines in the upper, middle and lower parts, wherein each layer of steam pipelines in the first conditioning tower 1 is provided with a first check valve 1001, and the second The second check valve 1002 is installed on each layer of the steam pipeline of the second conditioning tower 2 to prevent the condensed water formed by steam condensation from flowing back into the steam pipeline.

[0034] The first conditioning tower 1 is connected to the condensed water tank 3 through the first bypass pipe 501 and the first drain pipe 601, and the second conditioning tower 2 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com