Self-dust-falling overheat protection device for electromechanical equipment

A technology for electromechanical equipment and overheating protection, which is applied in the construction of electrical equipment components, modification through conduction heat transfer, electrical components, etc., can solve problems such as poor heat dissipation, achieve stable operation, improve cooling effect, and good ventilation and heat exchange effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

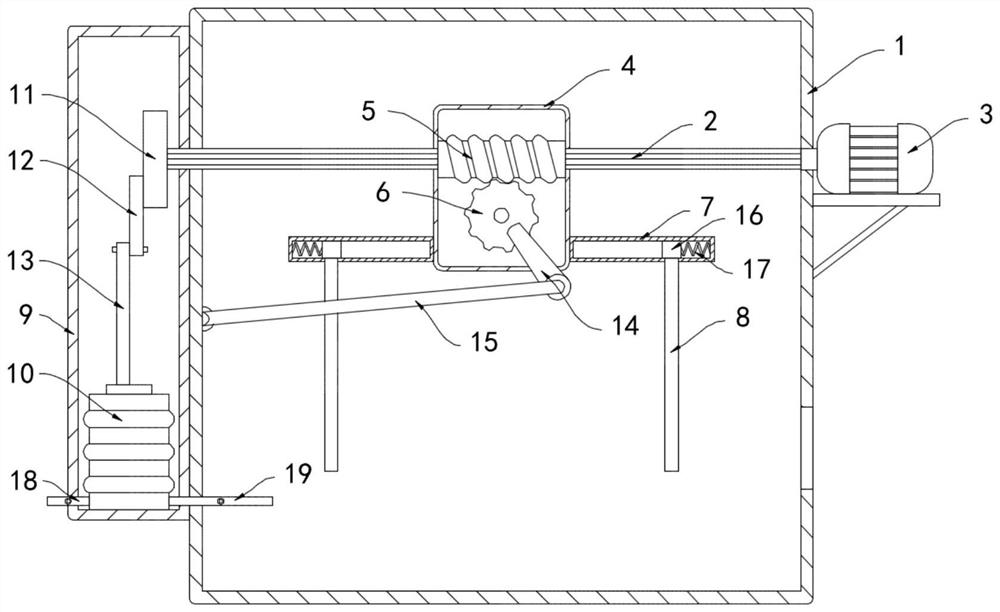

[0021] Such as figure 1 As shown, a self-dusting overheating protection device for electromechanical equipment includes a box body 1, a horizontally arranged slide bar 2 is rotatably connected to the inner side wall of the box body 1, and a drive motor 3 is installed on the side wall of the box body 1 to drive The output shaft of the motor 3 extends into the box body 1 and is coaxially fixed with the slide rod 2. The outside of the slide rod 2 is slidably sleeved with a housing 4. The inner wall of the housing 4 is connected with a worm 5 for rotation. The inner axis of the worm 5 is extended. The direction is provided with a circular cavity, the worm 5 is slidably socketed outside the slide rod 2, and the worm wheel 6 is connected to the housing 4 in rotation, the worm wheel 6 is meshed with the worm 5, and the worm wheel 6 is connected to the inner wall of the box body 1 through a transmission mechanism. The transmission mechanism includes a connecting rod 14 fixedly connect...

Embodiment 2

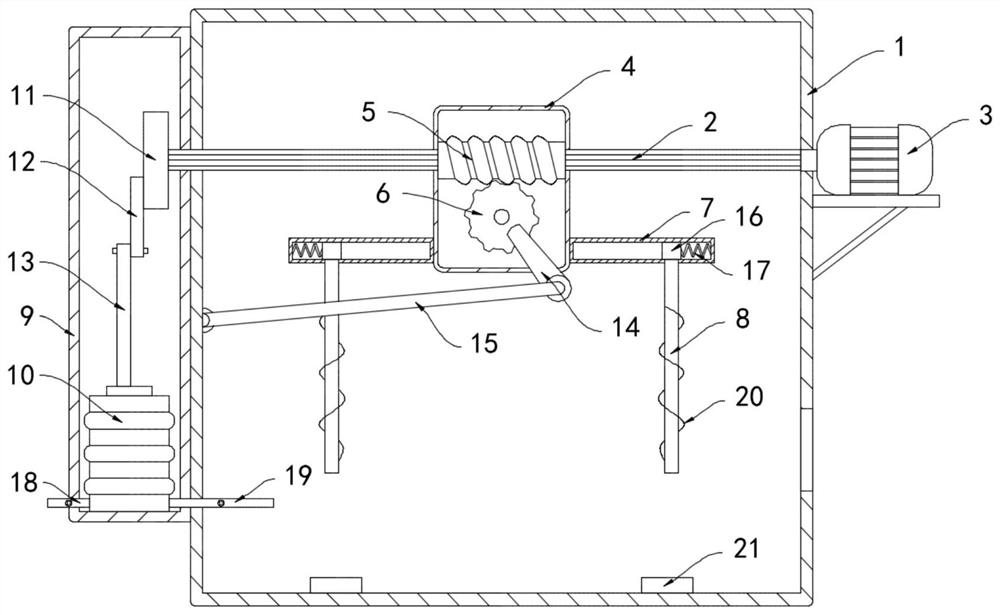

[0028] Such as figure 2 As shown, the difference between the present embodiment and the first embodiment lies in that: the heat sink 8 is wound with a conductive coil 20 , and the inner bottom surface of the box body 1 is fixed with a permanent magnet 21 .

[0029] In this embodiment, the heat sink 8 drives the conductive coil 20 to reciprocate in translation. According to the principle of electromagnetic induction, when the magnetic flux in the closed coil changes, an induced current is generated in the closed coil, and the conductive coil 20 is permanently in the process of reciprocating movement. The magnetic flux of the magnetic block 21 in the conductive coil 20 changes, and an induced current is generated in the conductive coil 20. When the heat sink 8 drives the conductive coil 20 to contact the electromechanical equipment, the dust attached to the surface of the electromechanical equipment can be sucked away, so as to avoid dust covering and affecting other components....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com