Welding-free air-cooled heat dissipation light emitting diode lamp

A light-emitting diode lamp, welding-free technology, which is applied to semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, light sources, etc., can solve the problems of manufacturing trouble, welding temperature false welding, overheating of lamp beads, etc., and save materials. and working hours, rapid heat dissipation and cooling, and the effect of accelerated cooling and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

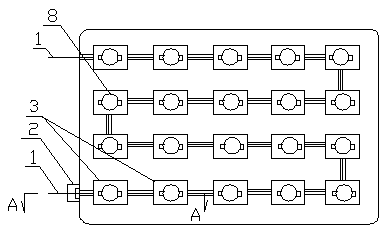

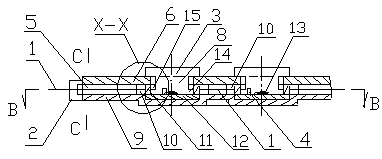

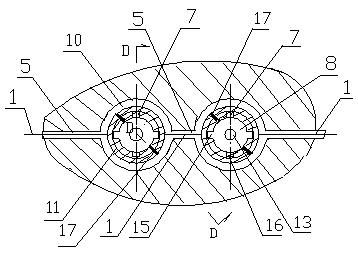

[0016] In the figure, the solder-free air-cooled heat dissipation light-emitting diode lamp is rectangular, and it consists of five rows, and each row is composed of five chips 3 (lamp beads) connected in series with conductive wire 1. The solder-free air-cooled heat dissipation emits light The diode lamp includes an upper substrate 6 and a lower substrate 9 which is sealed and fixed (sealed with glue or screws) to the upper substrate, grooves are arranged at intervals on the lower substrate, and grooves are arranged in the grooves to be flush with the upper surface of the lower substrate. The thermally conductive adhesive layer 12, the conductive ring 11 is fixedly arranged on the thermally conductive adhesive layer, and the insulating adhesive layer 17 is used in the middle of the conductive ring ( image 3 The position of the black line in the middle) is separated, and the insulating adhesive layer is separated by 45° to separate the conductive ring. The bottom surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com