A copper die casting system with high yield

A high-yield, copper mold technology, applied in the field of copper die-casting, can solve the problems of insufficient automation, affecting the physical characteristics of the copper mold, and poor compactness of the copper mold structure, so as to improve energy-saving and environmental protection characteristics, improve quality, and reduce clamping Slag effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

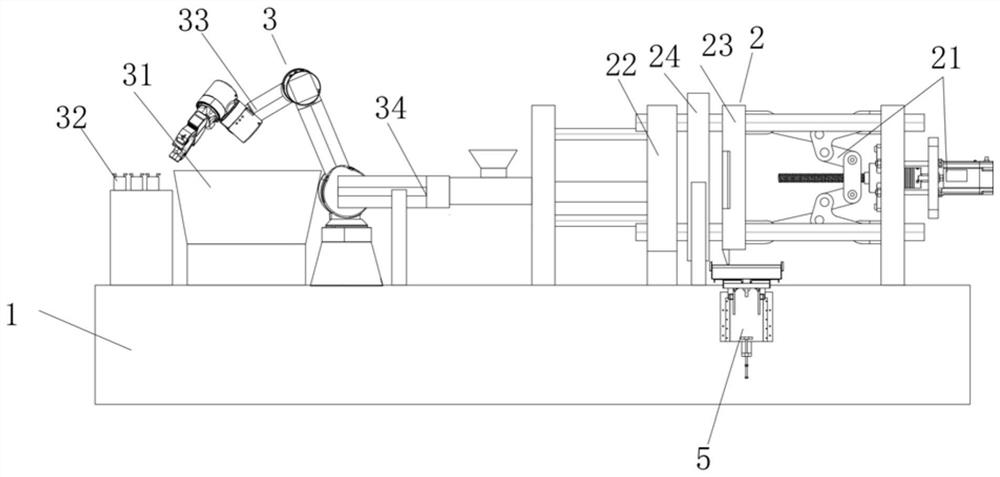

[0044] like figure 1 As shown, a copper mold die casting system with high yield includes: a machine base;

[0045] A mold module for forming a mold cavity;

[0046] a feeding module for injecting copper melt into the mold cavity;

[0047] The cooling module is used to cool the copper melt in the mold cavity to form a copper mold;

[0048] The discharge module is used to recover the copper molds completed by die casting;

[0049] The mold module includes a drive module, a fixed mold, a movable mold and a limit setting mechanism;

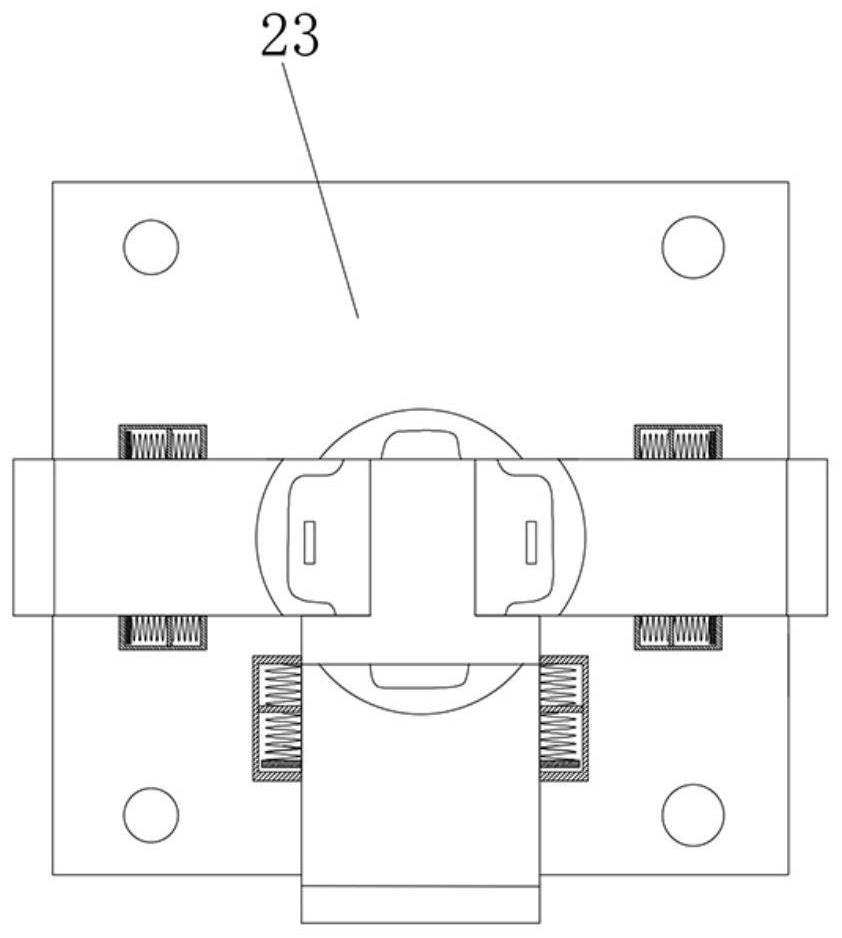

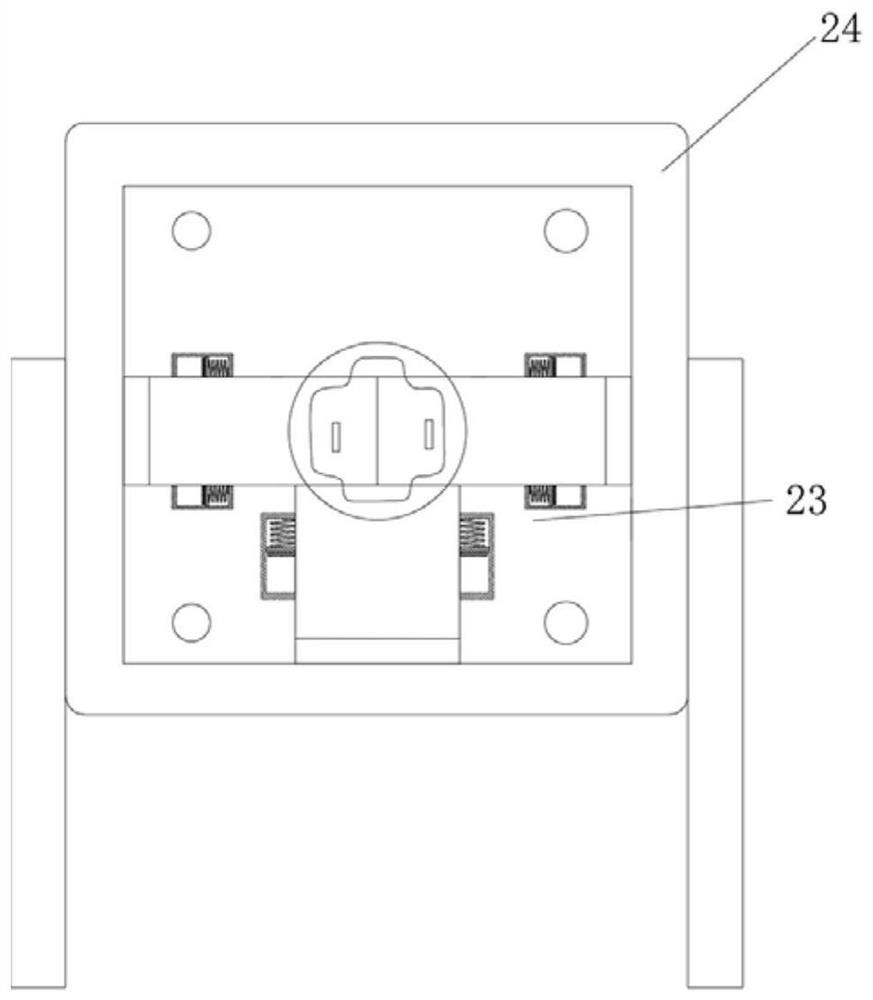

[0050] The movable mold and the fixed mold are configured so that when the movable mold is in the shrinkage forming state, the movable mold is combined with the fixed mold, and at the same time, the movable plates of each cavity of the movable mold are spliced together with the fixed mold to form a mold cavity, and the movable mold is in the middle space. In the separation state, the movable mold and the fixed mold are separated, and the movable p...

Embodiment 2

[0065] Embodiment 2, this embodiment is a further description of the above-mentioned embodiment. It should be understood that this embodiment includes all the foregoing technical features and further detailed description:

[0066] A copper mold die-casting system with high yield, comprising: a machine base;

[0067] A mold module for forming a mold cavity;

[0068] a feeding module for injecting copper melt into the mold cavity;

[0069] The cooling module is used to cool the copper melt in the mold cavity to form a copper mold;

[0070] The discharge module is used to recover the copper molds completed by die casting;

[0071] The mold module includes a drive module, a fixed mold, a movable mold and a limit setting mechanism;

[0072] The movable mold and the fixed mold are configured so that when the movable mold is in the shrinkage forming state, the movable mold is combined with the fixed mold, and at the same time, the movable plates of each cavity of the movable mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com