Shell-and-tube condenser

A condenser and shell-and-tube technology, applied in the field of shell-and-tube condensers, can solve the problems of reducing the heat exchange efficiency of the heat exchange tube and the heat exchange efficiency, so as to improve the heat exchange effect, increase the degree of subcooling, and prolong the heat exchange. The effect of thermal processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

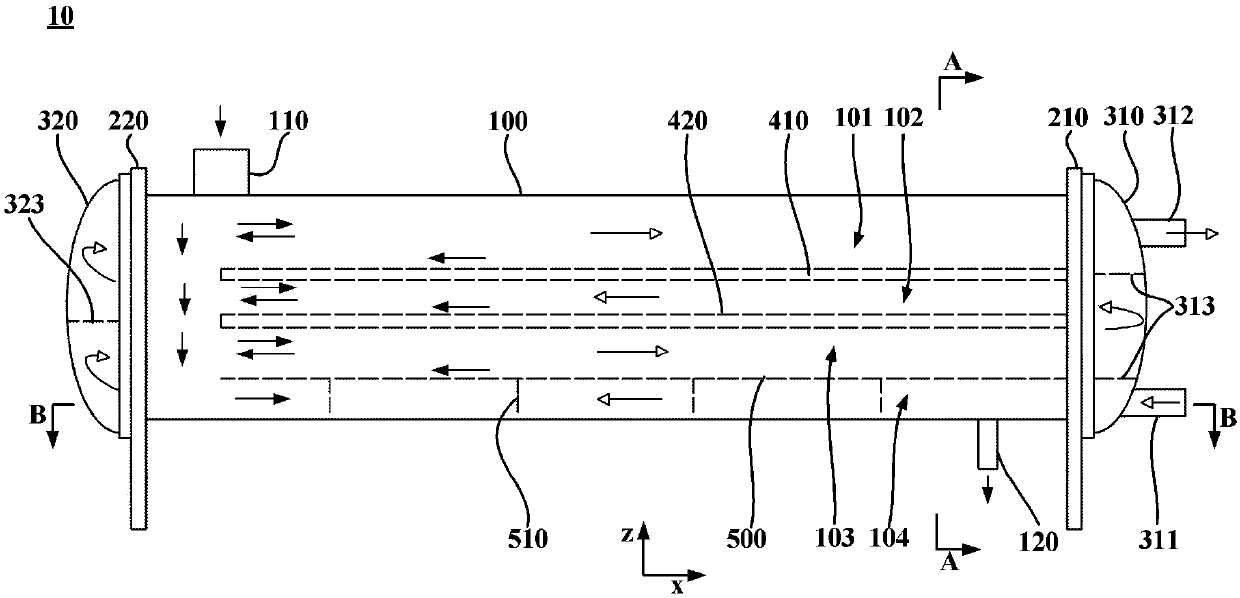

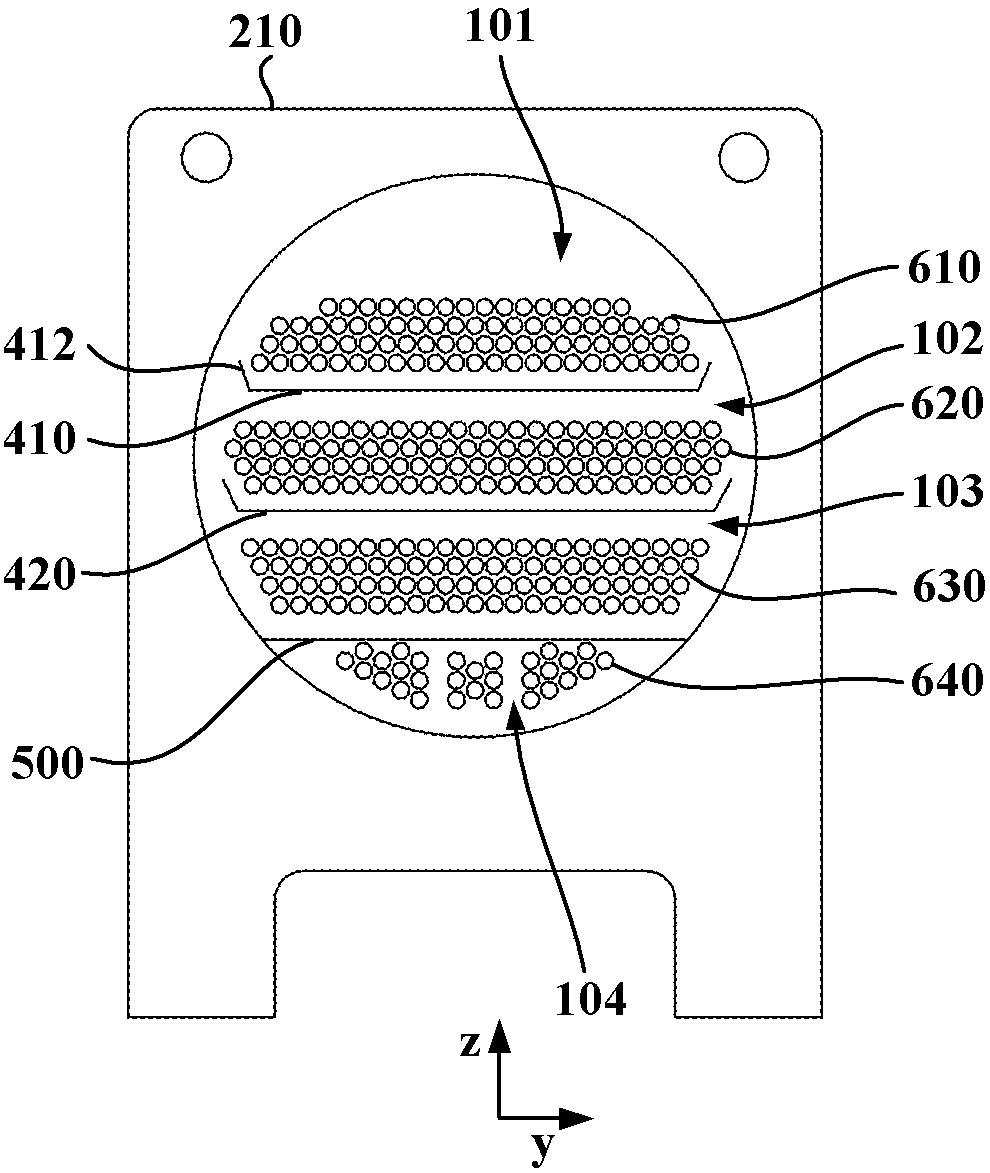

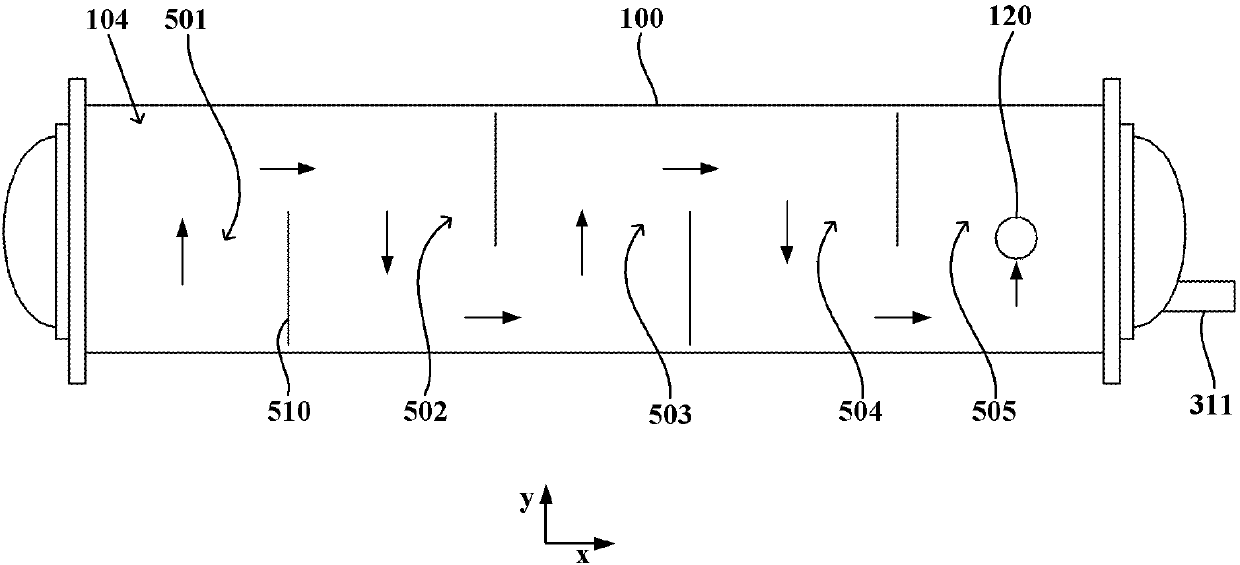

[0028] The following is based on Figure 1 to Figure 3 The shell and tube condenser of the present invention will be described in detail. figure 1 It is a structural schematic diagram of a shell-and-tube condenser according to an embodiment of the present invention, and a dotted line shows a part of the internal structure of the shell; figure 2 Yes figure 1 A-A sectional view of the shell-and-tube condenser shown; image 3 Yes figure 1 B-B sectional view of shell and tube condenser shown. figure 1 and image 3 For the sake of clarity, the heat exchange tubes are not shown, only the flow direction of the cooling water in the heat exchange tubes is indicated by hollow arrows, and the flow direction of refrigerant is indicated by solid arrows. In each figure, the x-axis is parallel to the axial direction of the casing, the y-axis is parallel to the width direction of the liquid collecting plate, and the z-axis is positively pointing upward.

[0029] like figure 1 and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com