Shunt and water replenishing boiler plate

A boiler plate and water replenishment technology, which is applied in the field of cast iron boiler boiler plates to achieve the effects of improving heat exchange efficiency, eliminating dead zone of water flow and prolonging process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

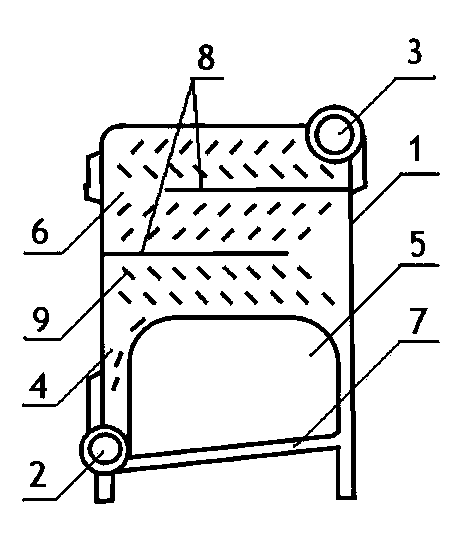

[0010] The invention includes a pot body 1, a water inlet pipe 2, a water outlet pipe 3, a side waterway 4, a hollow cavity 5, a water exchange chamber 6, a water diversion pipe 7, a water channel partition 8, a spoiler 9, and the upper part of the pot body 1 The water exchange chamber 6 is provided with a water outlet pipe 3 on one side, and the water exchange chamber 6 extends downward along the pot body 1, forming side waterways 4 on both sides of the pot body, and exiting at the lower end of the pot body 1. The opposite side of the water pipe 3 is provided with a water inlet pipe 2, and between the extended part of the pot piece water chamber 6 on the opposite side of the water inlet pipe 2 and the water inlet pipe 2, a diversion water pipe 7 with an inclination of 0~15° is arranged, and its diameter is smaller than that of the pot piece The thickness of the main body 1 is provided with a water channel partition 8 on the side wall of the pot body 1, which is layered and sta...

Embodiment 2

[0012] The lower part of the water exchange chamber 6, the side waterway 4, and the branch water pipe 7 form a hollow cavity 5. The flame burns in the hollow cavity 5 to form a radiant furnace. The medium water enters the pot body 1 from the water inlet pipe 2 and flows through the The side waterway 4 and the branch water pipe 7 enter the exchange water chamber 6, and the water flow is forced to disperse by the effect of the spoiler 9, and flows along the water channel formed by the water channel partition plate 8, and the water flow fills the entire pot body 1 as much as possible, and then Flow out from the water outlet pipe 3 to complete the whole heat exchange process.

[0013]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com