Hairpin type double-tube-plate heat exchanger and method for assembling heat exchanging tube and shell body thereof

A double tube sheet heat exchanger, hairpin technology, applied in indirect heat exchangers, heat exchanger types, fixed tubular conduit assemblies, etc., can solve problems such as fatal injuries, easy leakage, environmental pollution, etc. Extend heat exchange time, improve heat exchange efficiency, and avoid cross-contamination or chemical reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

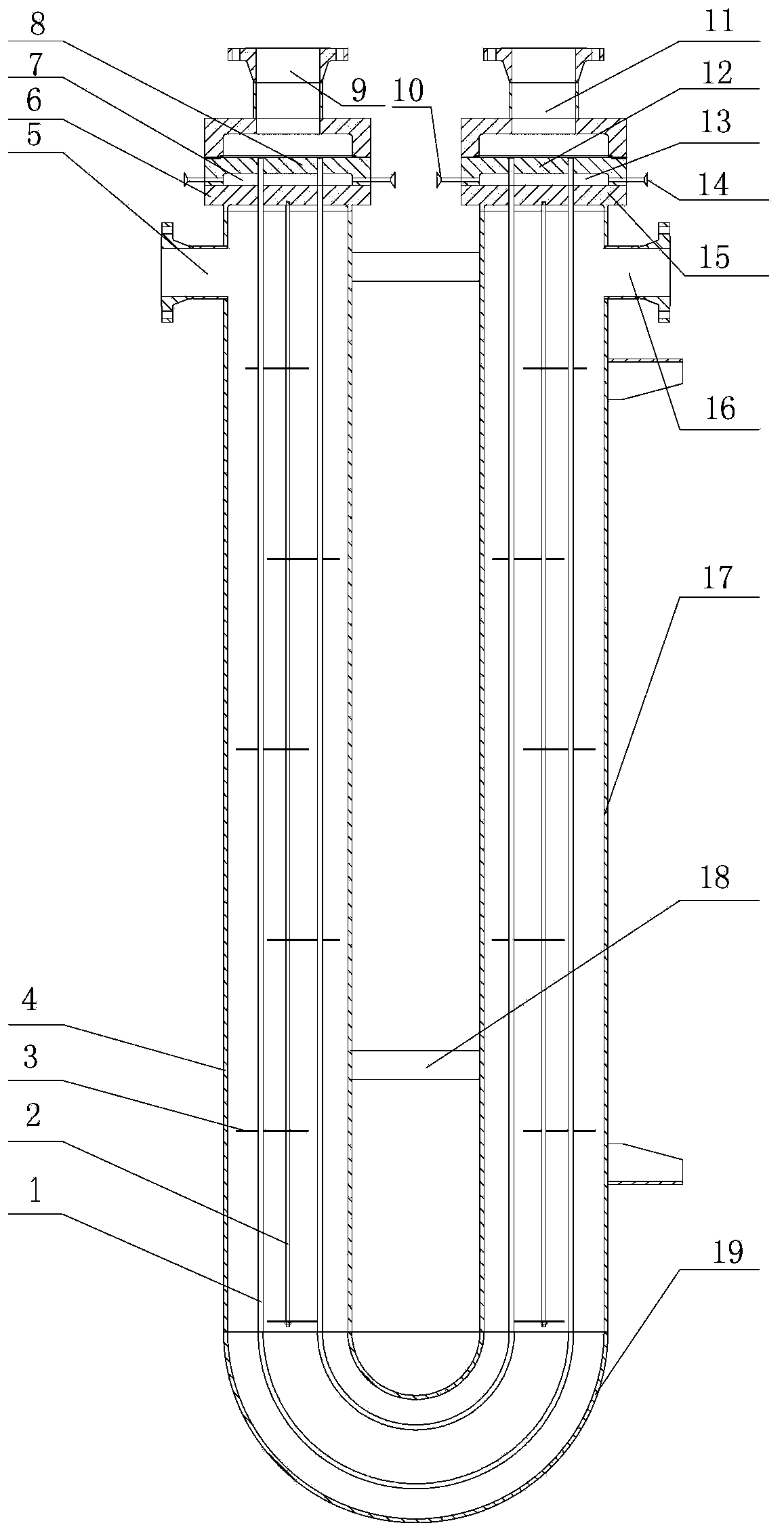

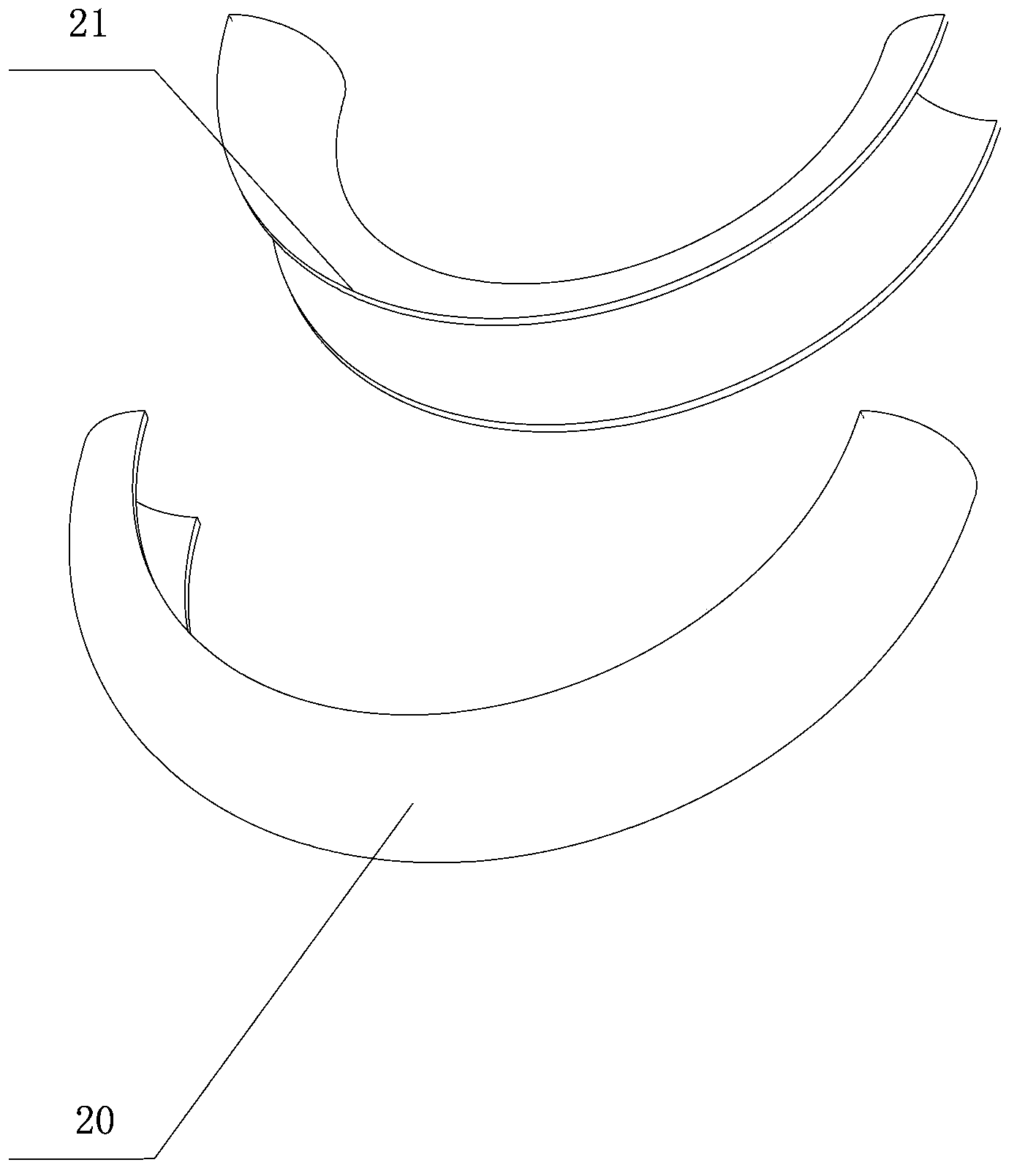

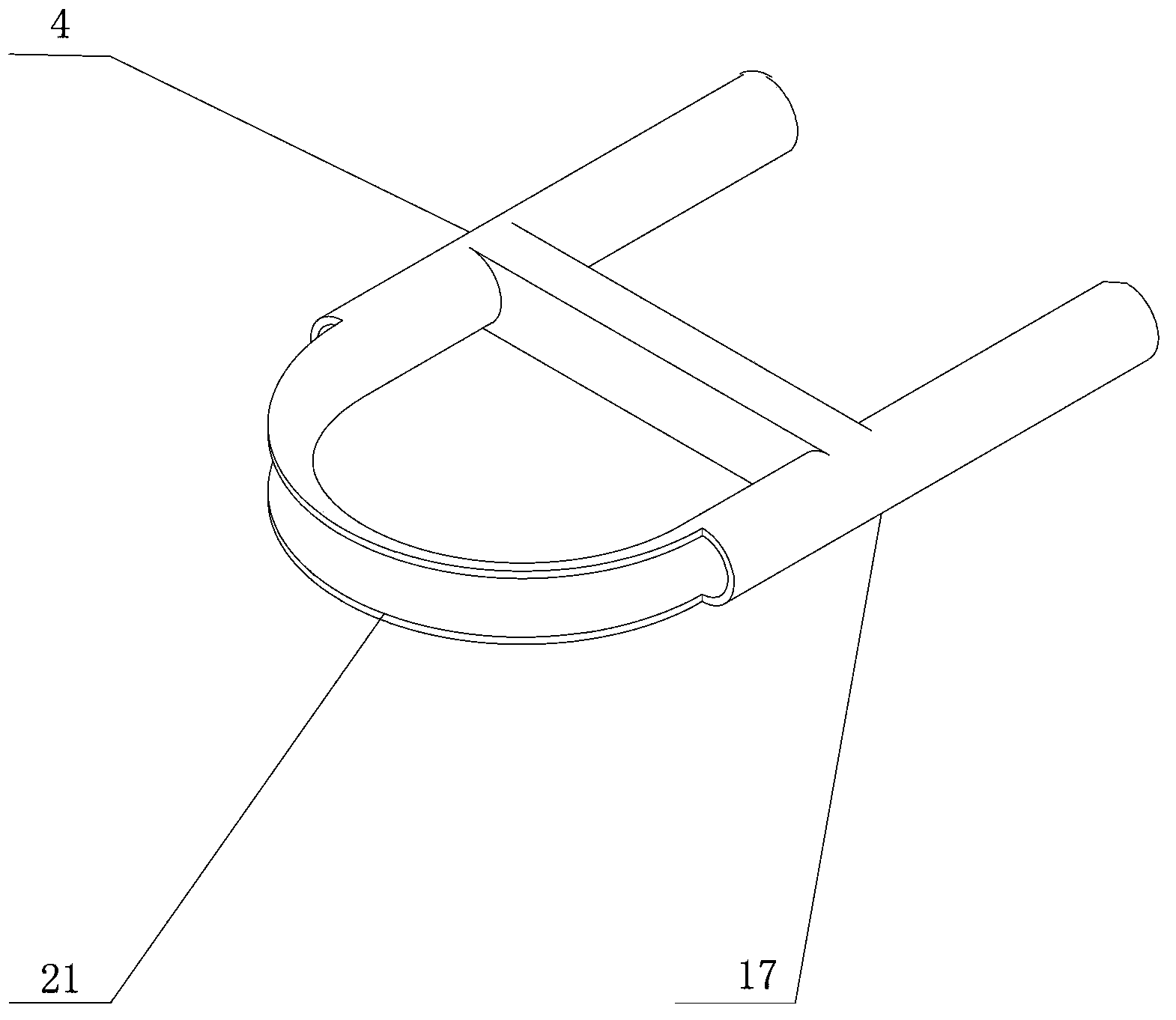

[0023] See figure 1 , the present invention has the basic structure of an ordinary shell and tube heat exchanger, including a casing, a first front tube sheet 6, a first rear tube sheet 9, a second front tube sheet 15, a second rear tube sheet 12, a fixed The distance tube 2 and the baffle plate 3; the baffle plate 3 is fixed on the distance tube 2, and the shell is set to a U shape, which is composed of three sections of the shell A section, the shell section B and the shell section C. The shell Section A and section B of the shell constitute the two arms of the U-shaped shell, and section C of the shell constitutes the curved section in the middle of the U-shaped shell; one end of section C of shell 19 is welded with section A of the shell 4, and the other end is The shell B section 17 is welded; the first front tube sheet 6 is welded on the shell section A of the heat exchanger, the second front tube sheet 15 is welded on the shell section B of the heat exchanger, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com