Biomass particle suspension combustion boiler

A biomass particle, suspended combustion technology, applied in the field of boilers, can solve problems such as excessive fuel consumption, damage to driving equipment, slow water heating rate, etc., to increase the heat exchange area, increase the heat exchange time, and speed up the heating rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

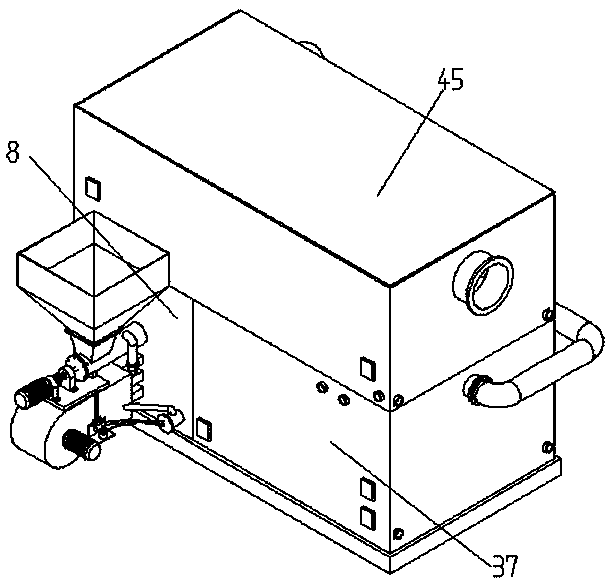

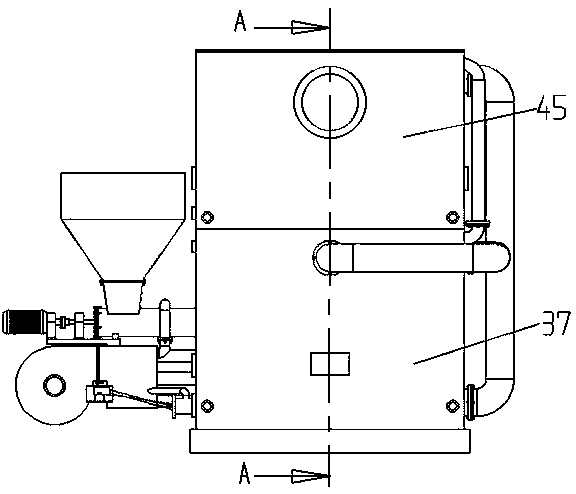

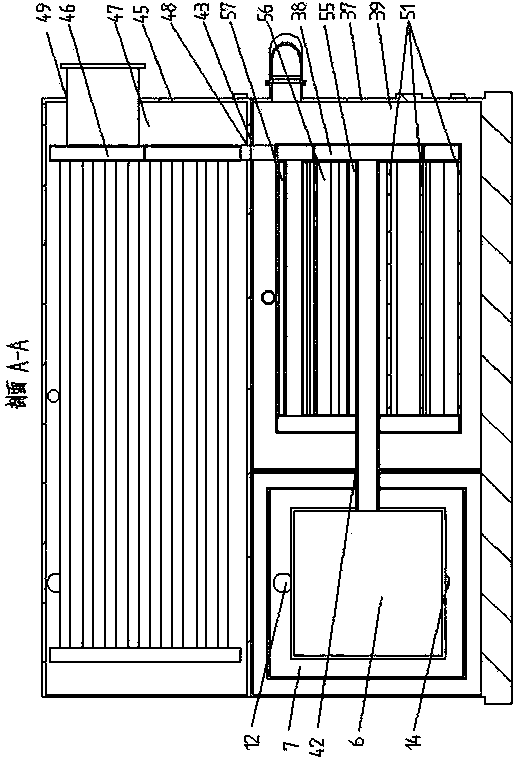

[0051] Such as Figure 1-4 , Figure 9 and Figure 14-18 As shown, a biomass particle combustion device for a boiler includes a combustion chamber 6, a feeding device, an air supply device and an automatic ignition device 28,

[0052] The air supply device includes a motor 1, a blower fan 4 driven by the motor 1, and a wind box 5 connected to the blower fan 4, and the top of the blower fan 4 and the blower box 5 is fixedly connected with a support plate 33;

[0053] The feeding device includes a motor 1 and a conveying auger 2 driven by the motor 1, the motor 1 is connected with the conveying auger 2 through a coupling 34, and a bracket 35 is also arranged between the motor 1 and the conveying auger 2 , the bracket 35 and the conveying auger 2 are fixed on the support plate 33, the top of the conveying auger 2 is provided with a storage hopper 3; the middle part of the conveying auger is provided with a vent 24, and the vent 24 The air duct 21 communicates with the air box ...

specific Embodiment approach 2

[0067] The difference with the above-mentioned specific embodiment 1 is: as Figure 5 As shown, the heat exchange device I38 includes four-stage heat exchange pipes I, and the four-stage heat exchange pipes I are arranged in a ring, and the first-stage heat exchange pipe I38.1 includes nine heat exchange pipes and is located in the The outermost periphery of the heat device I38, the second-stage heat exchange tube I38.3 includes seven heat exchange tubes, and the seven heat exchange tubes are evenly arranged inside the first-stage heat exchange tube I38.1, and the third-stage heat exchange tube I38.1 The heat pipe includes five heat exchange tubes, and the five heat exchange tubes are evenly arranged inside the second-stage heat exchange pipe I38.3, the fourth-stage heat exchange pipe I38.7 includes one heat exchange tube, and the fourth The first-stage heat exchange pipe I38.7 is located in the middle of the heat exchange device I38; the first-stage heat exchange pipe I38.1 c...

specific Embodiment approach 3

[0068] The difference with the specific embodiment 2 is: as Figure 6 and Figure 7 As shown, the heat exchange device I38 includes four-stage heat exchange pipes I, the four-stage heat exchange pipes I are connected in sequence, and arranged side by side and stacked in a matrix structure of 2X2, the smoke inlet I42 passes through the collection chamber I40 It is connected with the first-stage heat exchange pipe I38.1, and the first-stage heat exchange pipe I38.1 communicates with the second-stage heat exchange pipe I38.3 through the first-stage collection cavity I38.2, and the second-stage The heat exchange pipe I38.3 is arranged side by side on the side of the first heat exchange pipe I38.1, and the second heat exchange pipe I38.3 is connected with the third heat exchange pipe through the second heat exchange chamber I38.4 I38.5 are connected, the third-stage heat exchange pipe I38.5 is arranged side by side above the second-stage heat exchange pipe I38.3, and the third-sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com