Heat exchanger for accelerating heat exchange and heat exchange method

A heat exchanger and heat method technology, applied in the direction of heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of low fluidity of heat exchange medium and easy scaling of heat exchange tubes, so as to avoid Condensation fouling, solving extremely easy fouling, and the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

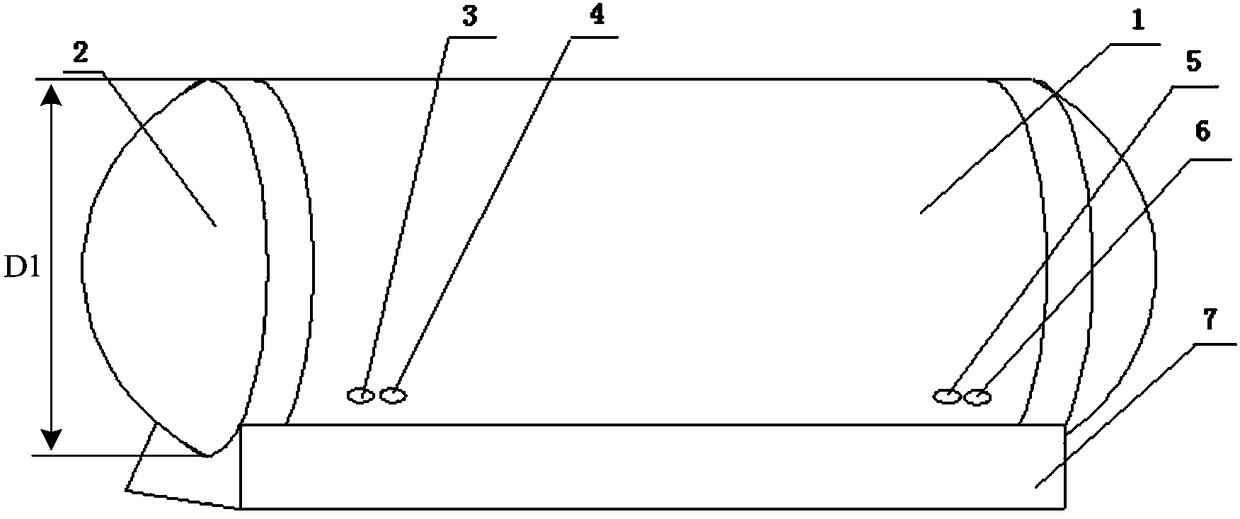

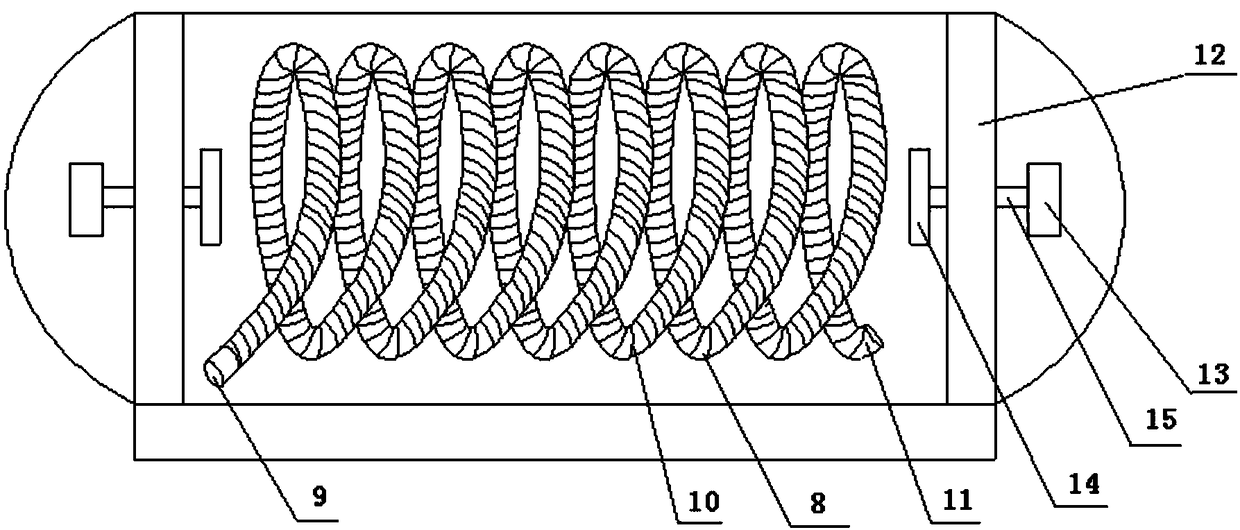

[0077] Such as Figure 1 ~ Figure 4 As shown, this embodiment provides a heat exchanger for accelerating heat exchange, and the heat exchanger for accelerating heat exchange at least includes:

[0078] Shell 1 , head 2 , base 7 , heat exchange tube 8 , separator 12 , electrode 13 , stirring paddle 14 and connecting shaft 15 .

[0079] Such as figure 1 As shown, the housing 1 is a barrel-shaped structure. In this embodiment, the housing 1 is a cylindrical structure, and the diameter of the housing 1 is D1. The housing 1 is arranged laterally on the base 7, the upper surface of the base 7 is an arc-shaped structure, which fits with the arc-shaped surface of the housing 1, and the lower surface of the base 7 is a plane , used to support the housing 1 to keep the housing 1 stable.

[0080] Such as Figure 1 ~ Figure 2 As shown, the two ends of the housing 1 are connected to the head 2, and the housing 1 is separated from at least one head 2 by a partition 12. In this embodimen...

Embodiment 2

[0089] This embodiment provides a heat exchanger for accelerating heat exchange. The structure of the heat exchanger for accelerating heat exchange is similar to that of Embodiment 1. The difference is that the liquid stirring device in this embodiment is a magnet, which is driven by stirring. The device is a magnetic stirring device.

[0090] Specifically, such as Figure 5 As shown, the stirring driving device includes a magnet 17 and a filter screen cover 16, and the stirring driving device is a magnetic stirring device 18. The filter screen cover 16 is fixed on the partition between the housing 1 and the head 2, and the magnet 17 is arranged in the filter screen cover 16 to limit the magnet 17 Between the filter screen cover 16 and the partition plate 12, the magnet 17 is prevented from rotating and hitting the heat exchange tube 8, which plays a protective role. The magnetic stirring device 18 controls the rotation of the magnet 17 through magnetic force, so as to stir ...

Embodiment 3

[0092] This embodiment provides a heat exchanger for accelerating heat exchange. The structure of the heat exchanger for accelerating heat exchange is similar to that of Embodiment 1. The difference is that the size of the heat exchange tubes in this embodiment is the same as that of Embodiment 1. The heat exchange tubes in the tubes are of different sizes.

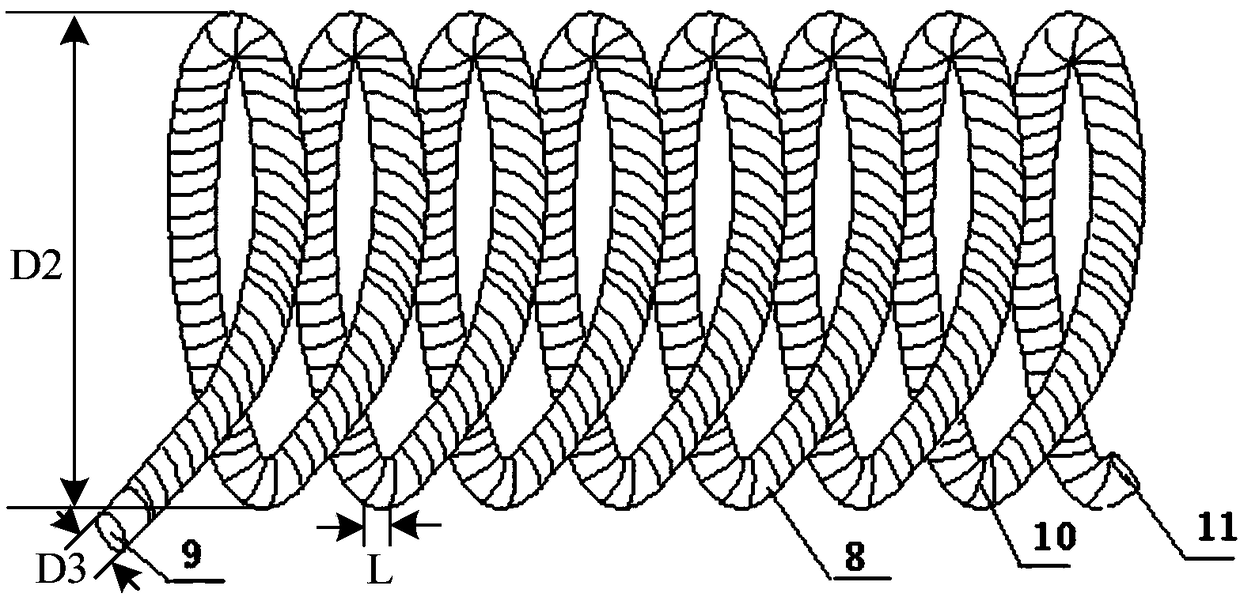

[0093] Specifically, the inner wall of the heat exchange tube 8 is provided with a screw thread 10, the pitch L of the screw thread 10 is 30 mm, and the groove depth H is 0.9 mm. The ratio of the helical diameter D2 of 8 was set to 0.18. The heat exchanger for accelerating heat exchange in this embodiment can also achieve the purpose of anti-fouling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com