Patents

Literature

106results about How to "Improve heat recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

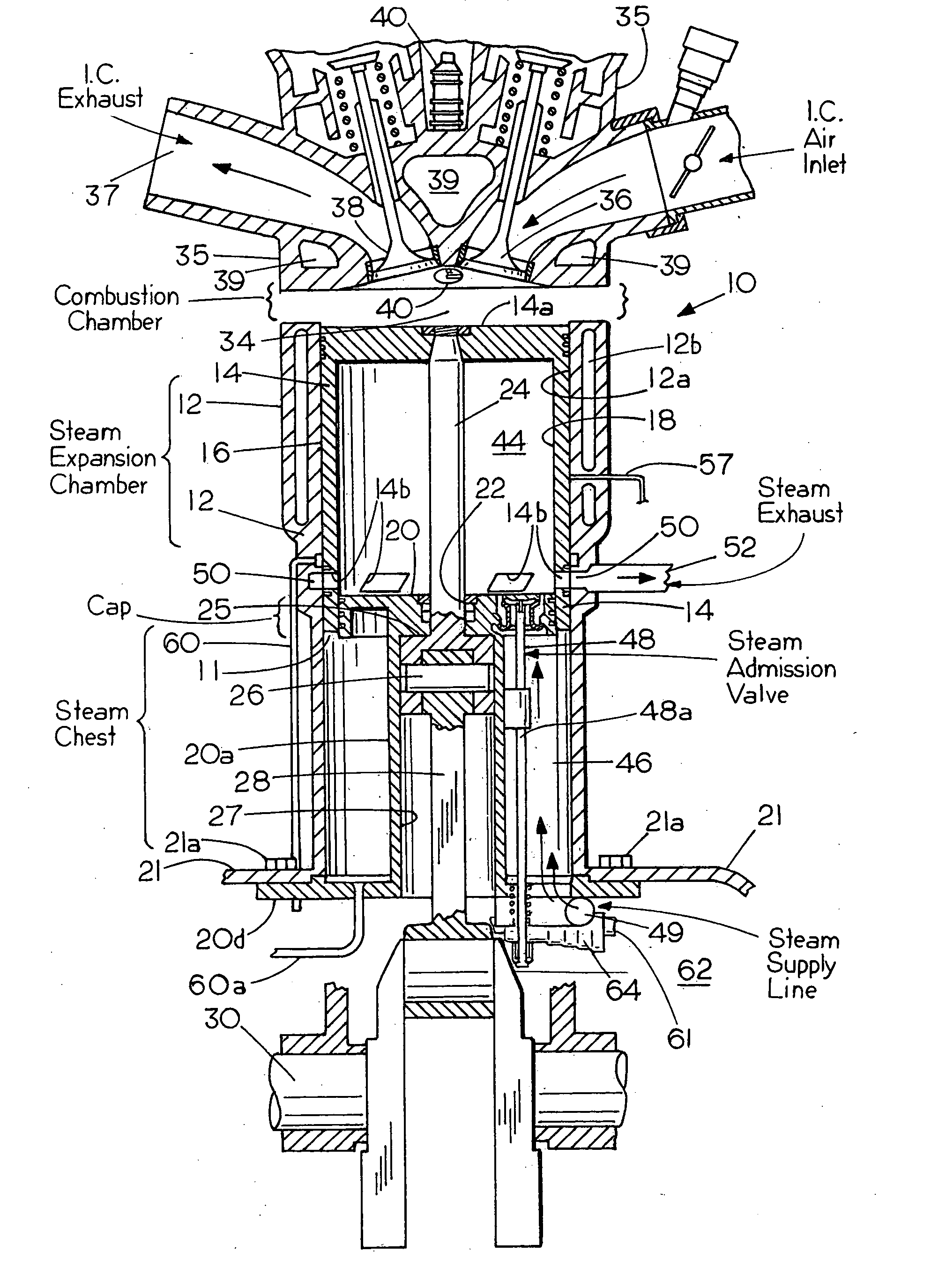

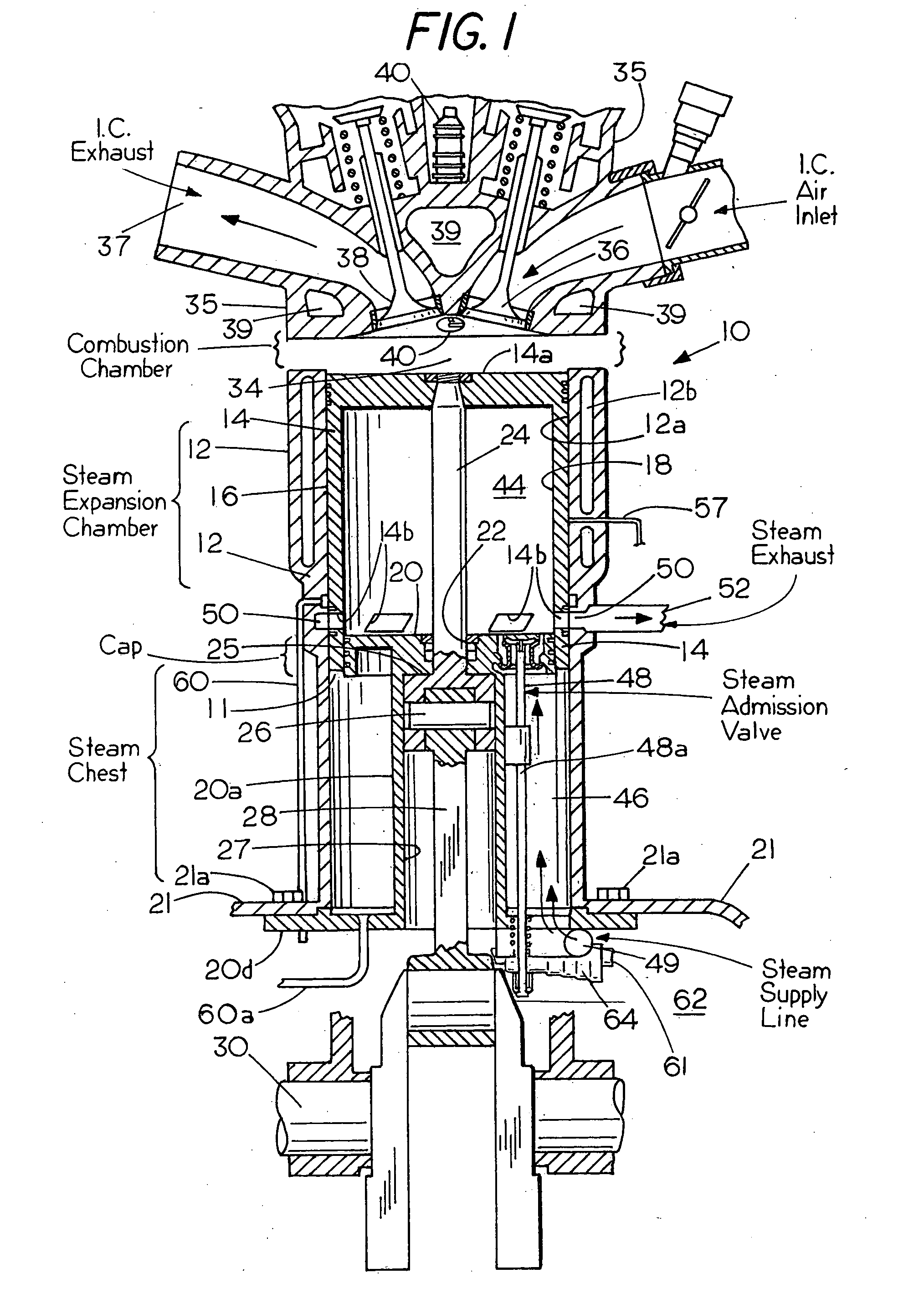

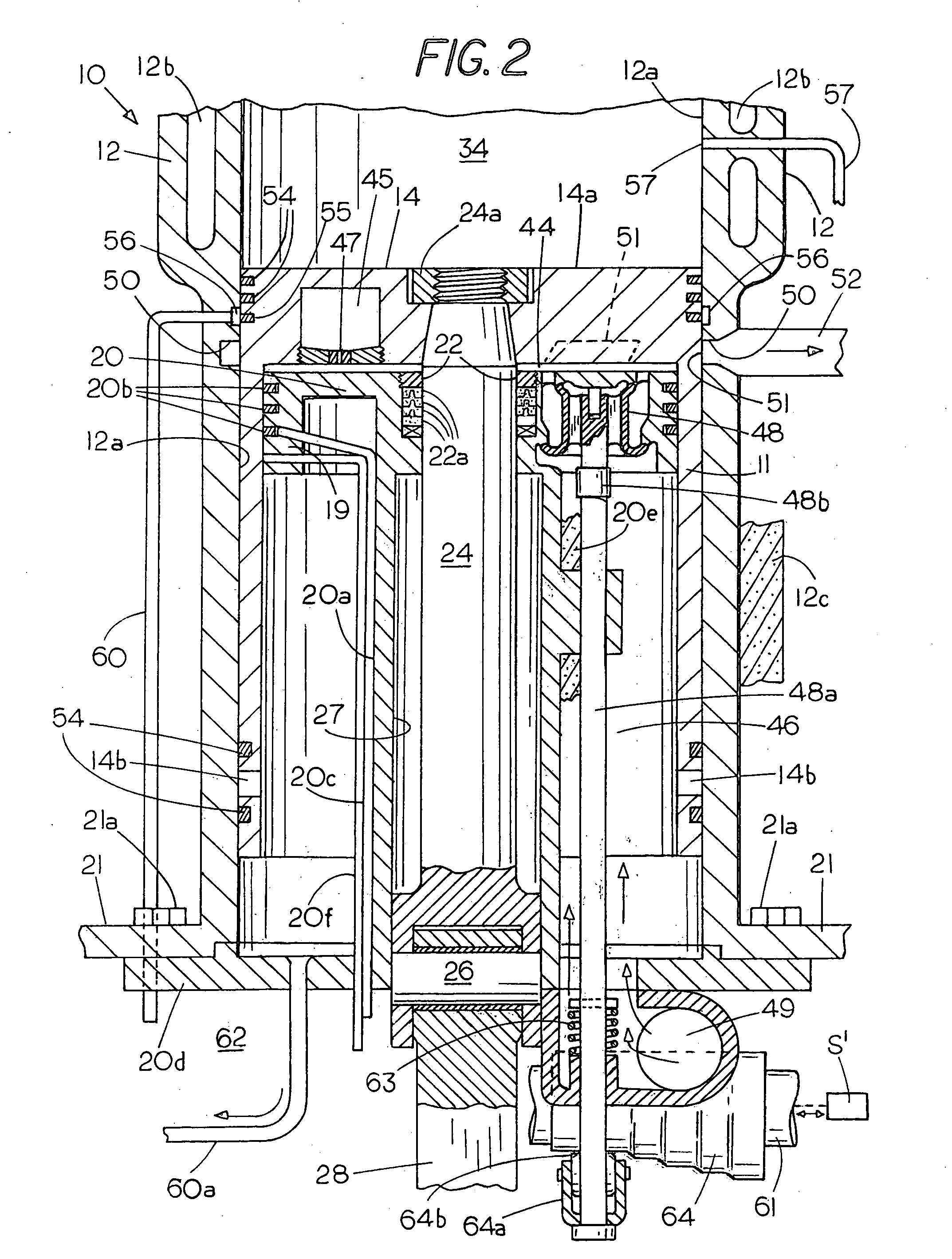

High efficiency dual cycle internal combustion engine with steam power recovered from waste heat

ActiveUS20090205338A1Operation efficiency can be improvedImprove efficiencyInternal combustion piston enginesSteam useCombustion chamberExhaust valve

A high efficiency combined cycle internal combustion and steam engine includes a cylinder having a piston mounted for reciprocation therein with an internal combustion chamber outward of the piston, a fixed cylinder cap sealingly and slideably mounted within the piston and a steam expansion / recompression chamber inside the piston adjacent the cylinder cap. The cylinder cap can be unheated or heated externally to reduce condensation of steam entering the steam chamber from a steam generator fired by waste combustion heat. Steam remaining in the cylinder when a steam exhaust valve closes at the top center position is recompressed during an inward stroke of the piston up to admission pressure prior to admitting the next charge of steam. One valve or a pair of retractable steam inlet valves connected in series within the cylinder cap act in cooperation with steam recompression and clearance volume to achieve an effective zero steam chamber clearance and a gain in mean Rankine cycle temperature to maximize efficiency. The amount of steam admitted each outward stroke is continuously regulated, e.g. by shifting the phase of one steam admission valve of a pair to vary their overlap for determining the steam mass admitted during each cycle to reduce specific fuel consumption. Other valves balance steam displacement with the steam generator output to use steam more efficiently. Engine coolant can be evaporated in a combustion chamber cooling jacket to form steam which is then superheated in a combustion exhaust manifold.

Owner:THERMAL POWER RECOVERY

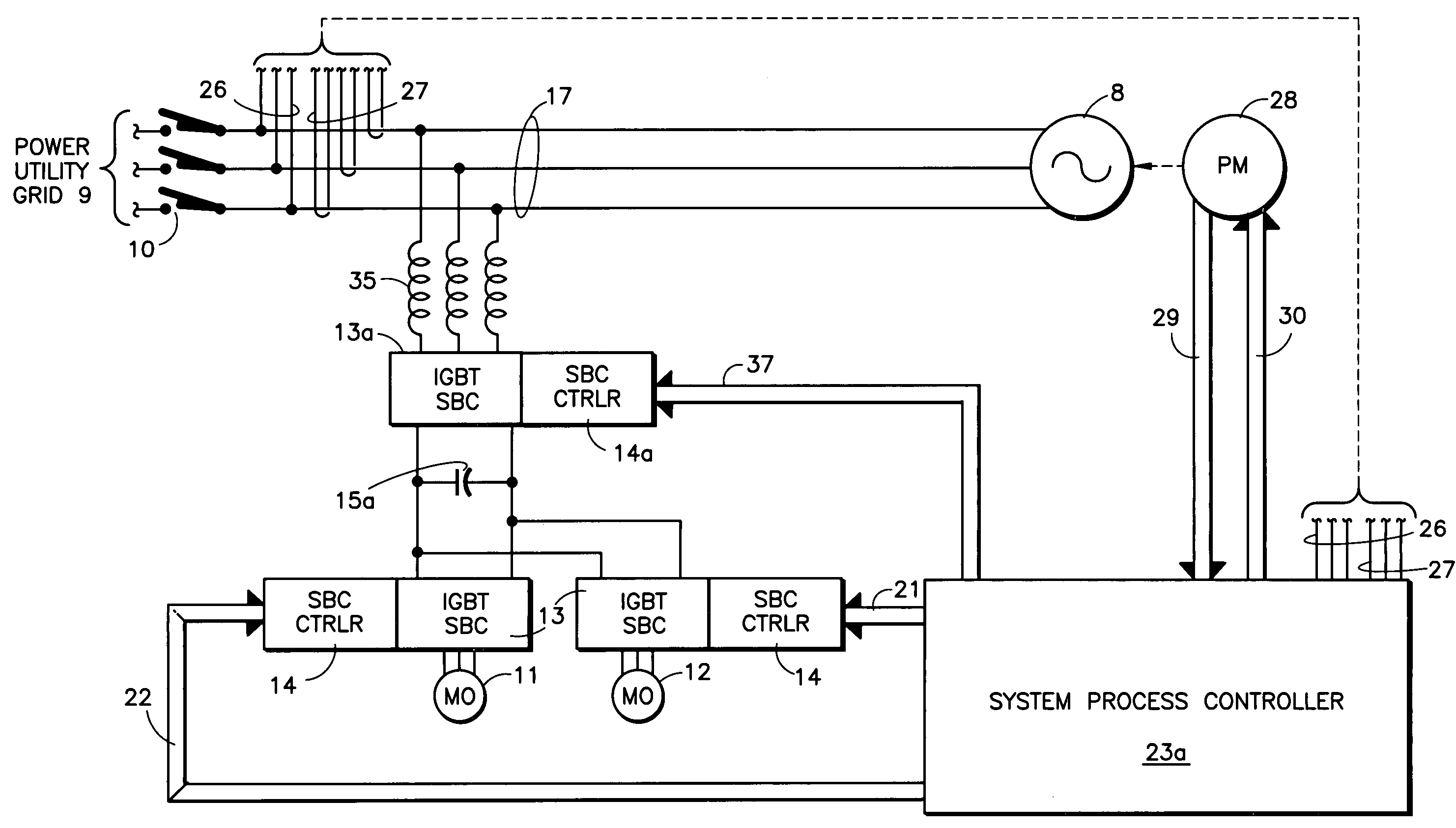

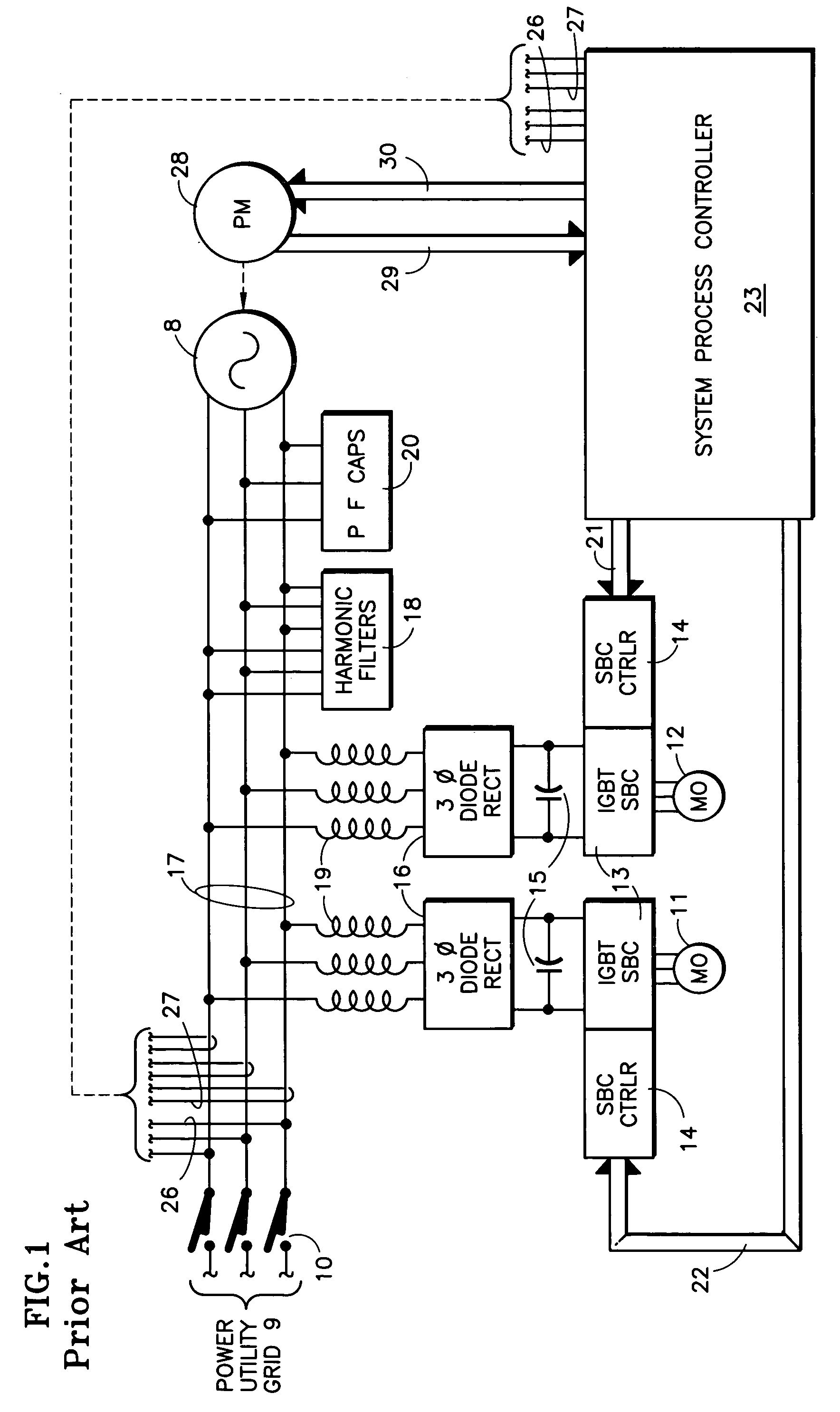

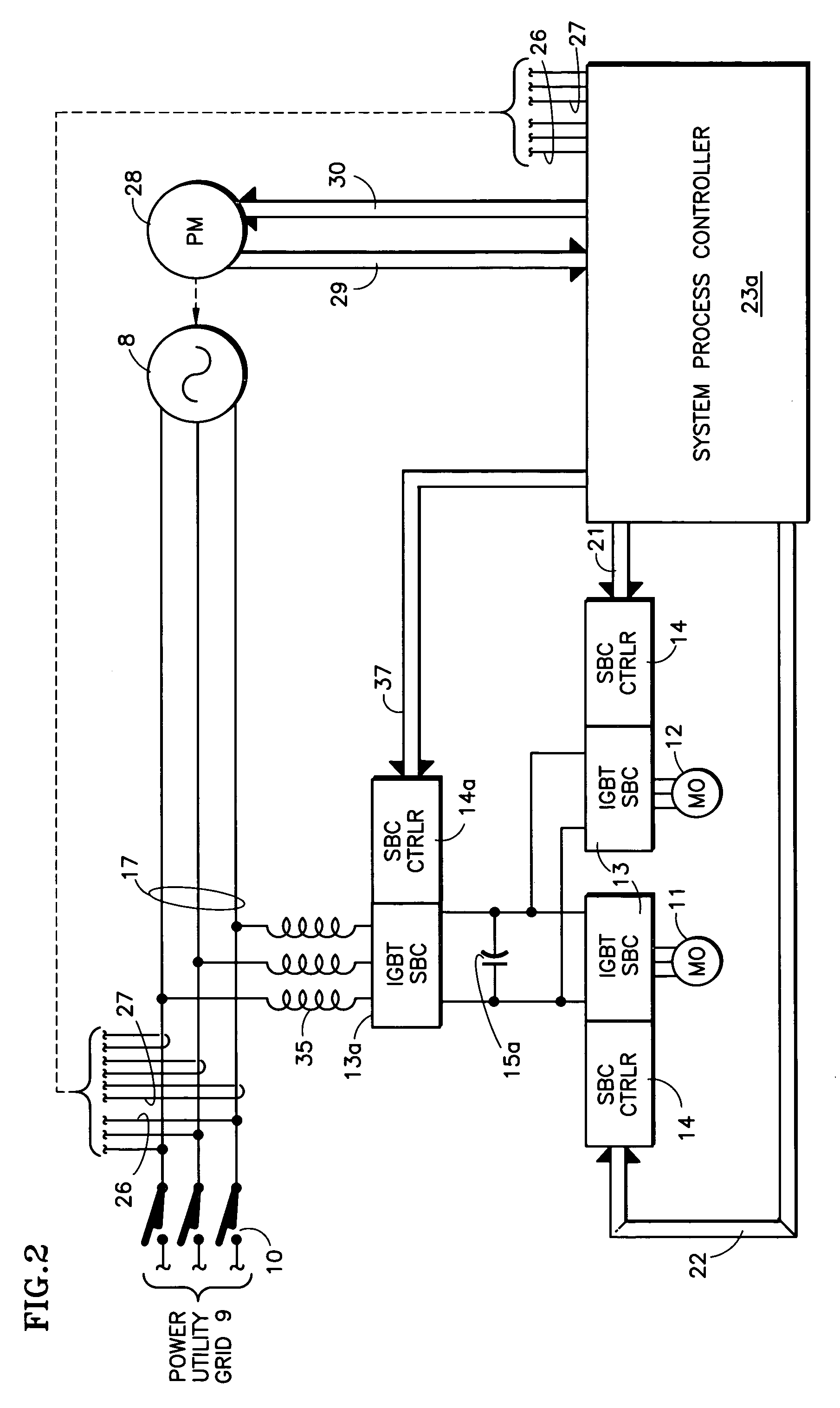

Quality power from induction generator feeding variable speed motors

InactiveUS7038329B1Without degrade qualityImprove heat recoveryBoards/switchyards circuit arrangementsAC motor controlDynamoPower grid

A prime mover (28) in a heat recovery system drives an induction generator (8) which feeds power to a utility grid (9) through a breaker (10) but also powers a load including auxiliary induction motors (11, 12). To provide acceptable waveform and power factor, the auxiliary equipment is driven through IGBT switched bridge converters (13) by DC voltage (15) generated by an IGBT switched bridge converter (13a), instead of three-phase diode rectifiers (16). The switched bridge converter controller (14a) is responsive to a system process controller (23a) which causes the switched bridge controller (13a) to be driven in response to the voltage (26) and current (27) on the generator bus (17). This eliminates the need for harmonic filters (18) and power factor capacitors (20) while improving the quality of the power generated. The controller (23a) trips the breaker if the voltage, frequency or power factor is out of limits.

Owner:UNITED TECH CORP

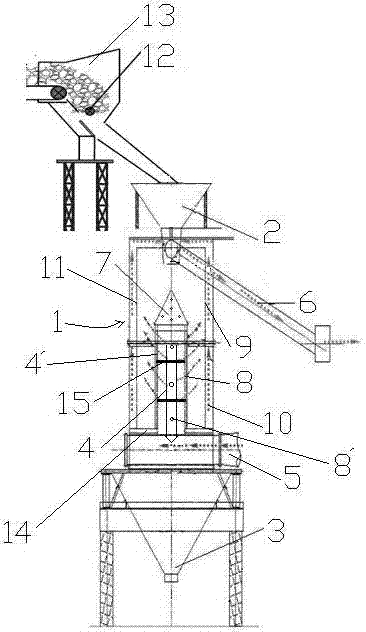

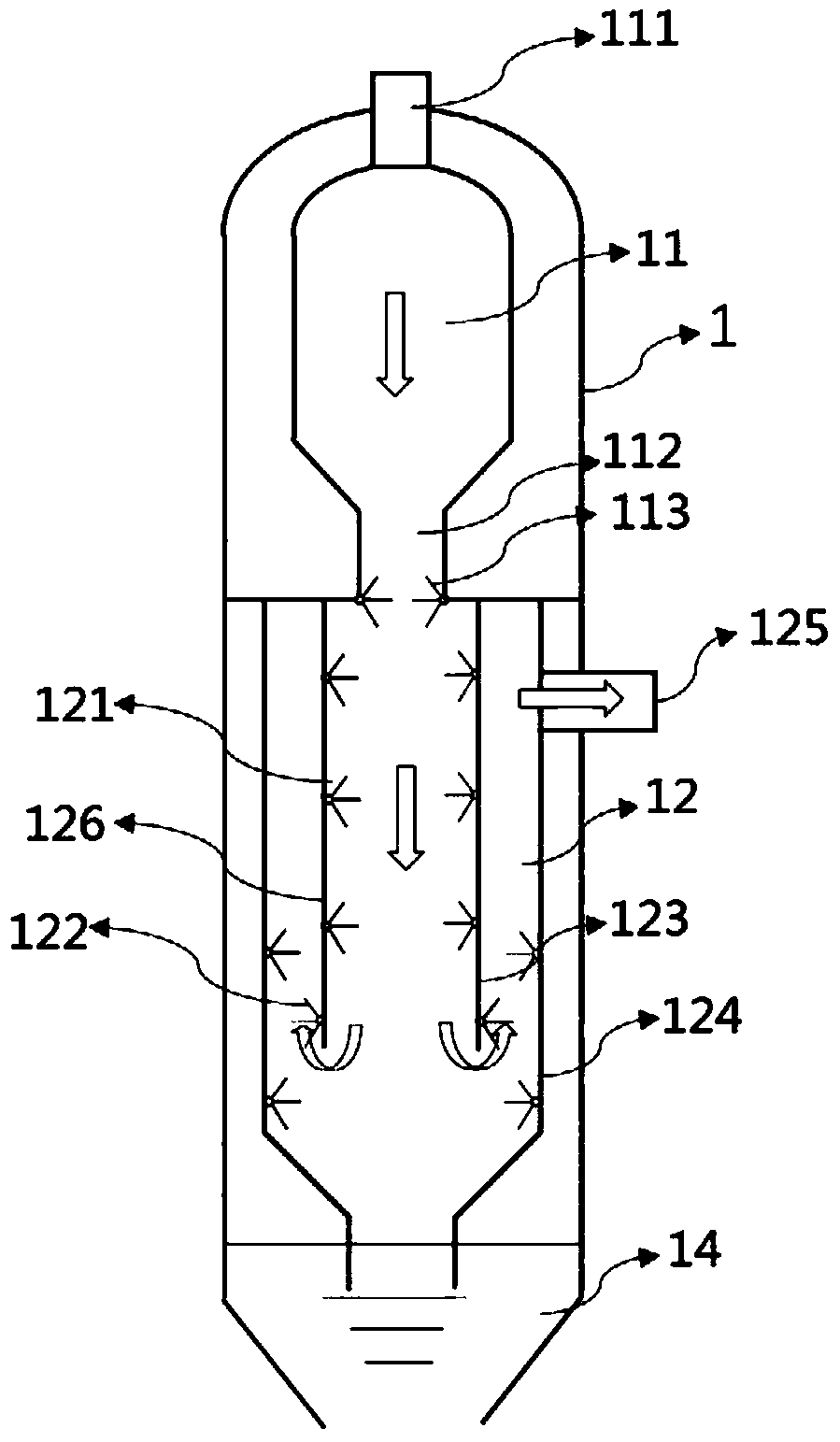

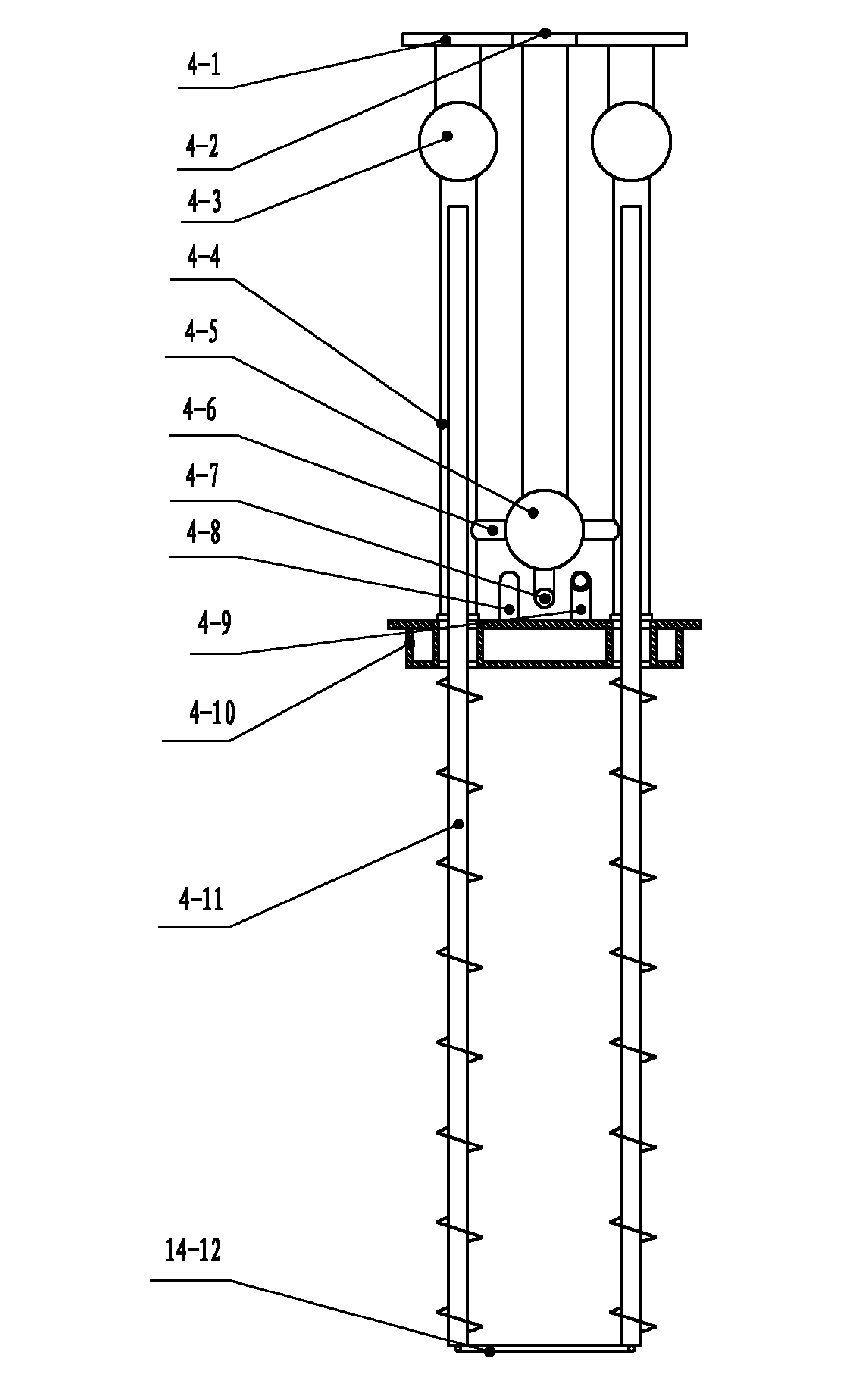

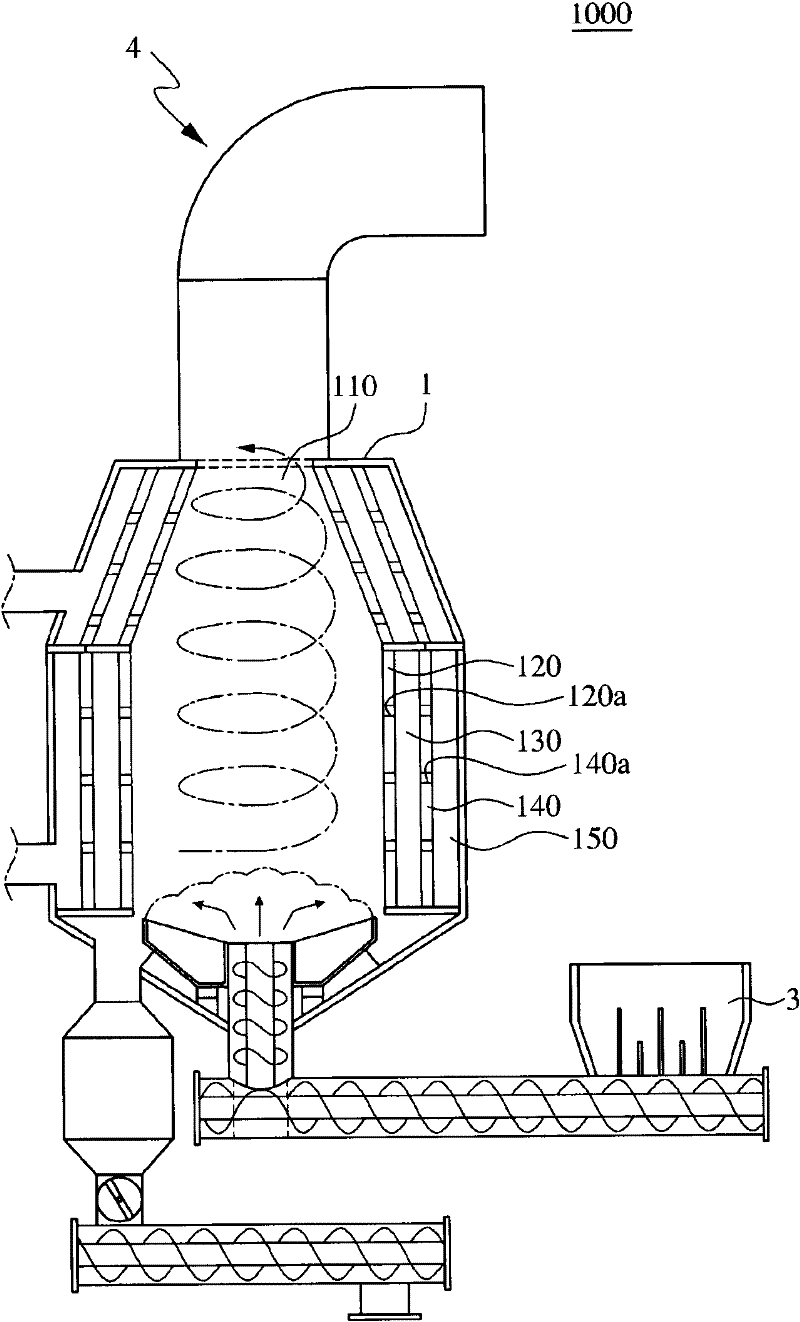

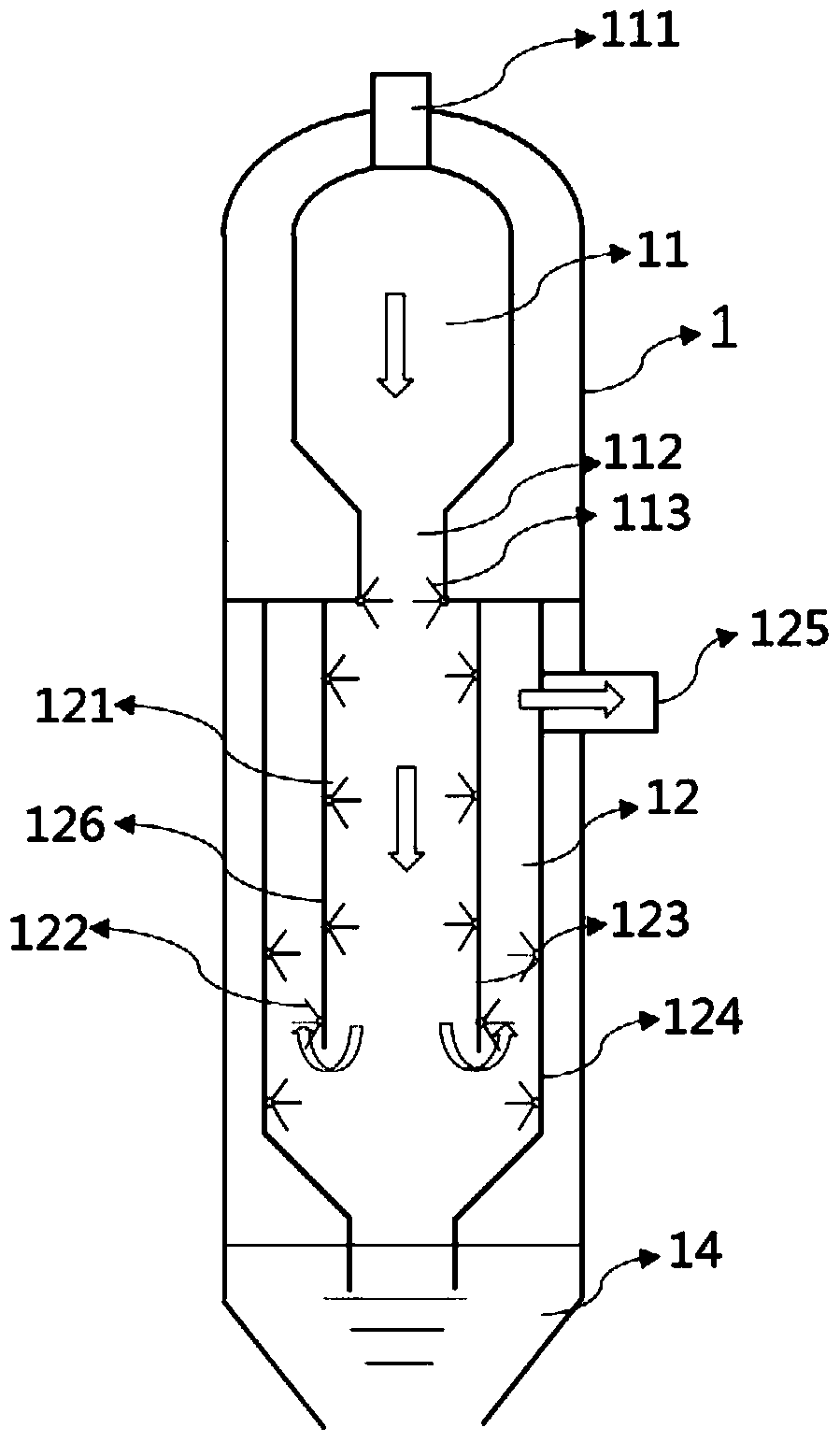

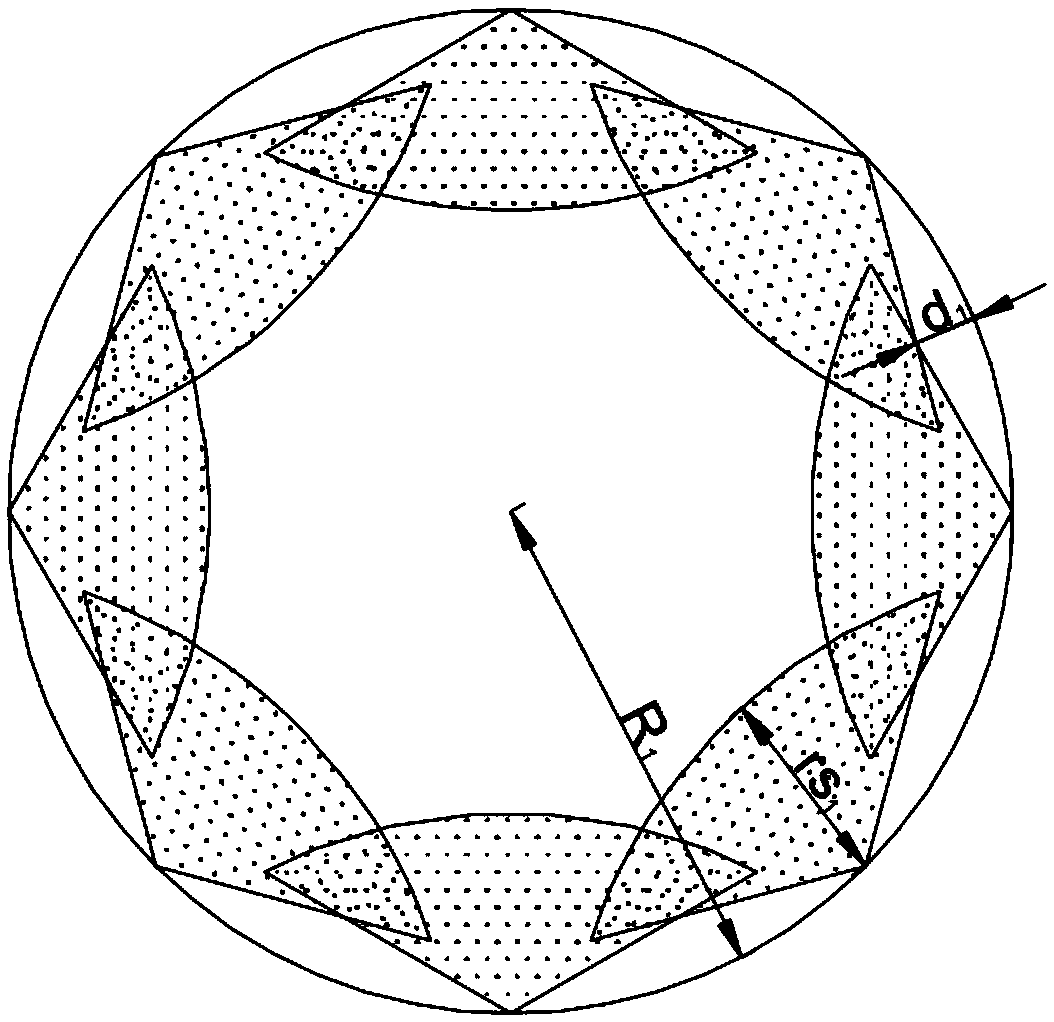

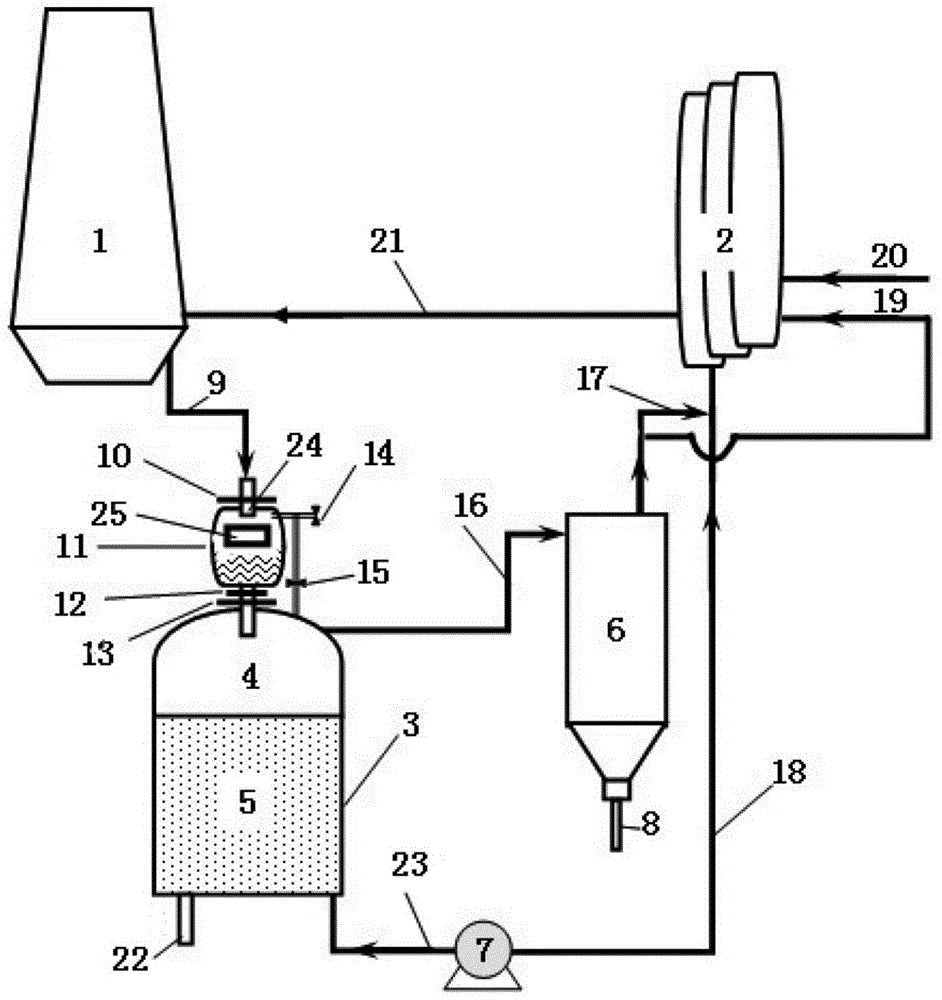

Vertical cooling and waste heat recovery furnace for sinters

ActiveCN103697707AReduce resistanceReduce power consumptionIncreasing energy efficiencyHandling discharged materialCold airFlue gas

The invention discloses a vertical cooling and waste heat recovery furnace for sinters, which comprises a feeding hopper and a discharge hopper, wherein the feeding hopper and the discharge hopper are respectively communicated with the top and the bottom of a cooling chamber; first and second air ducts are sequentially sleeved in the cooling chamber; the walls of the first and second air ducts are respectively provided with a plurality of air outlet holes; the top of the first air duct is provided with a cone distributor; the bottom of the second air duct is communicated with a cold air inlet pipe; the cooling chamber is provided with an inner sleeve; a plurality of vent holes are distributed in the wall of the inner sleeve; a hot air collecting cavity is formed between the inner sleeve and a housing of the cooling chamber; the upper part of the hot air collecting cavity is communicated with a hot waste gas exhaust pipe; and the bottom of the hot air collecting cavity is communicated with the discharge hopper. The invention provides a cooling system integrating sinter cooling with closed hot flue gas recovery and waste heat utilization; the vertical cooling and waste heat recovery furnace for the sinters operates under a negative pressure in the cooling process; emission of pollutants can be greatly reduced; the field environment is improved; and the heat recovery rate is improved.

Owner:铜陵市富鑫钢铁有限公司

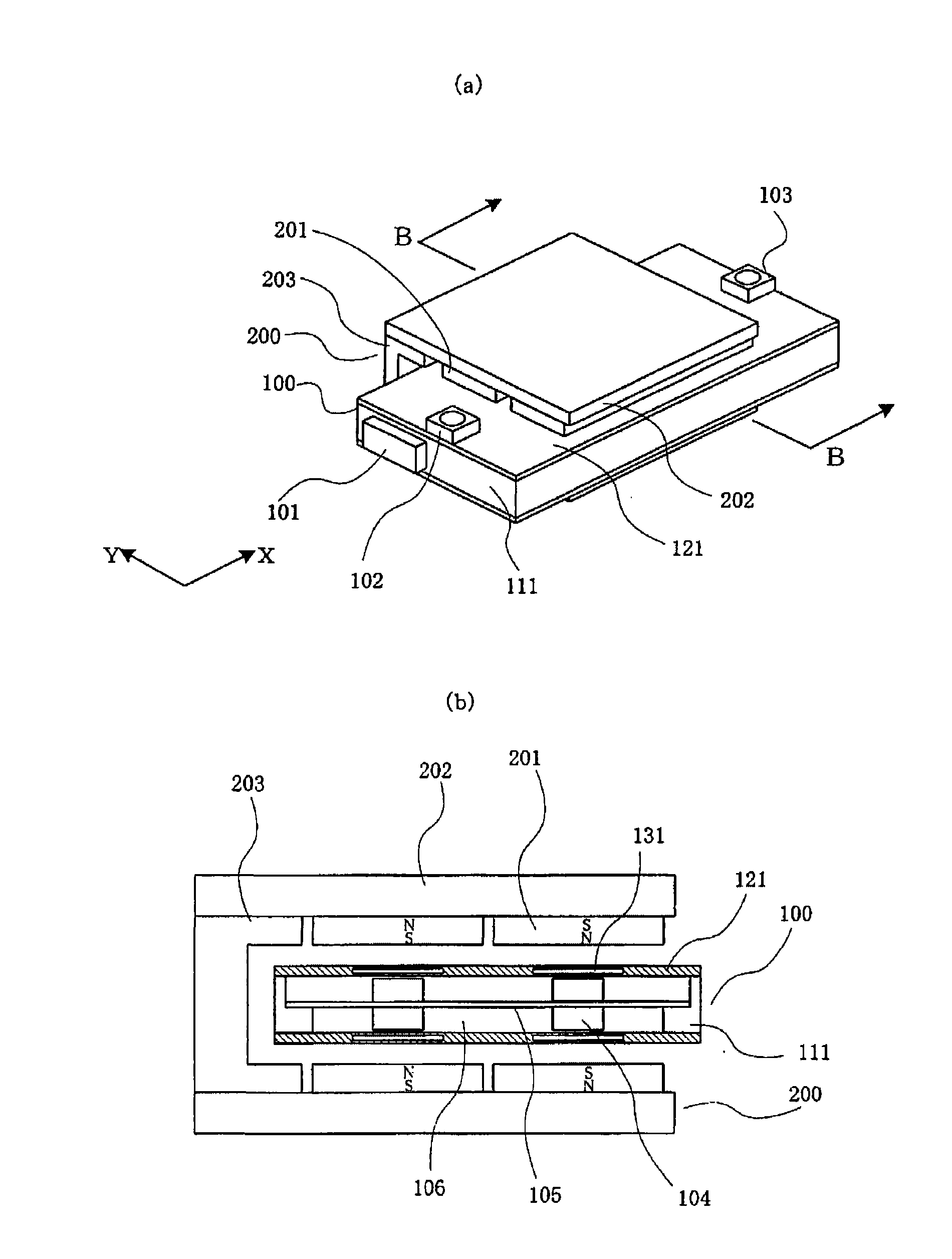

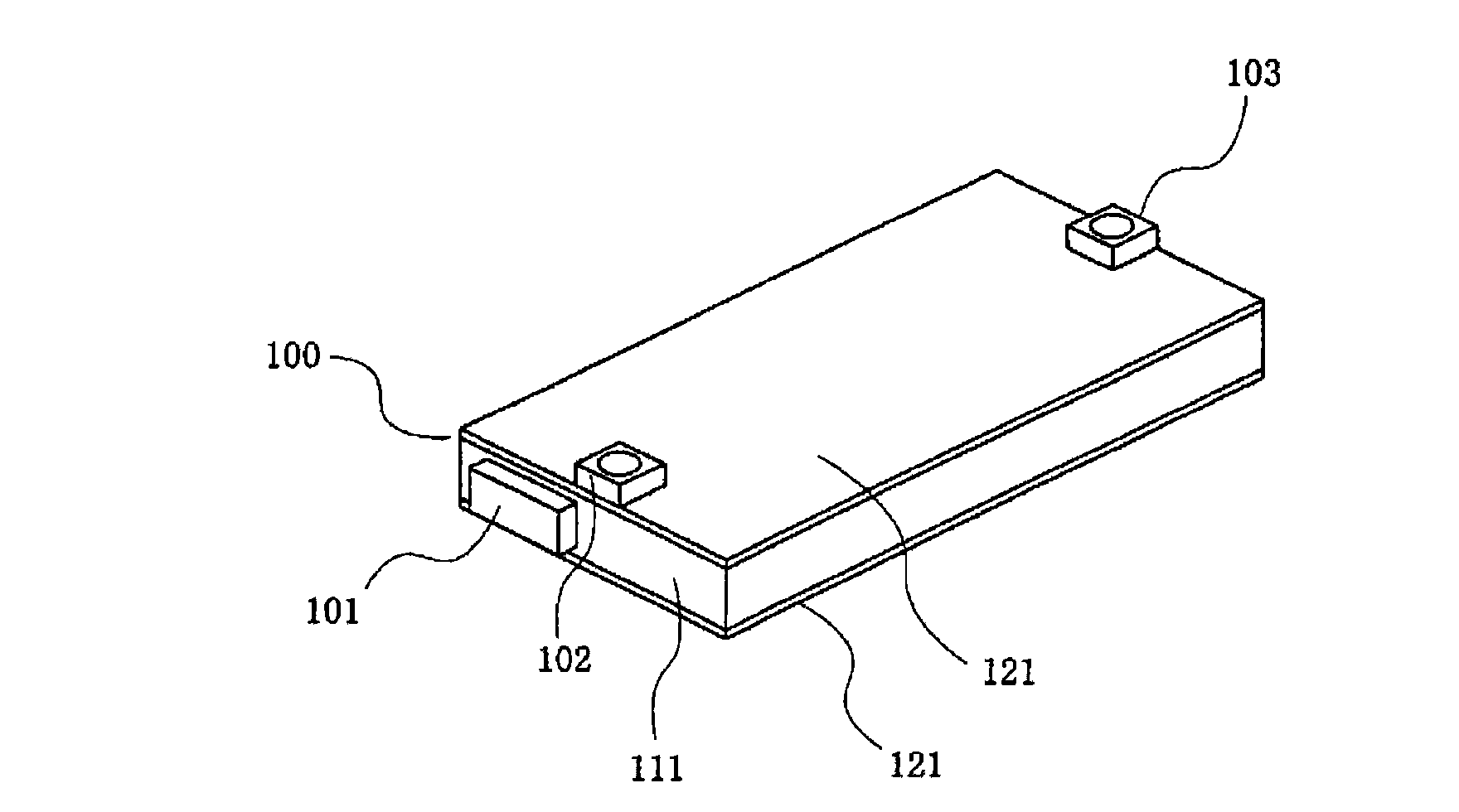

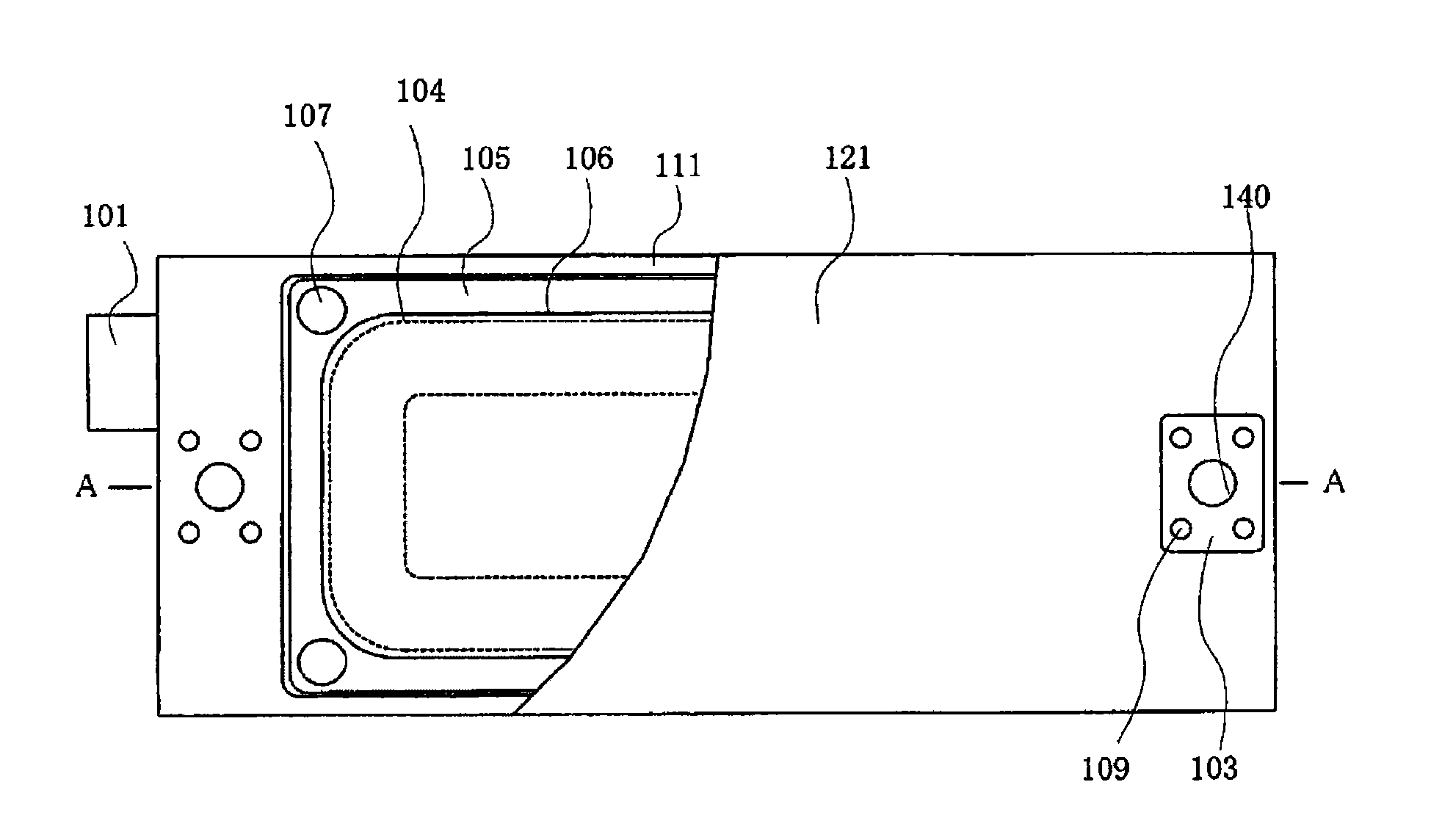

Canned linear motor armature and canned linear motor

InactiveCN101657956AEliminate insulation resistance reductionReduce temperature riseMagnetic circuitCooling/ventillation arrangementBrake forcePressure increase

A canned linear motor armature and a canned linear motor of water cooling type are provided. The insulation reliability of a canned linear motor armature is improved. The temperature rises of both the linear motor surface and the armature winding are reduced. Even if the coolant pressure increases, the can neither breaks nor deforms. The weight of the armature is lightened. The viscosity braking force is reduced. In the canned linear motor armature, the armature winding (104) is surrounded with a picture-frame-shaped case (111), both the openings of the case (111) are closed with flat can (121), and coolant passages (131) are provided inside the can (121) and on the top surface of the coil side of the armature winding (104).

Owner:YASKAWA DENKI KK

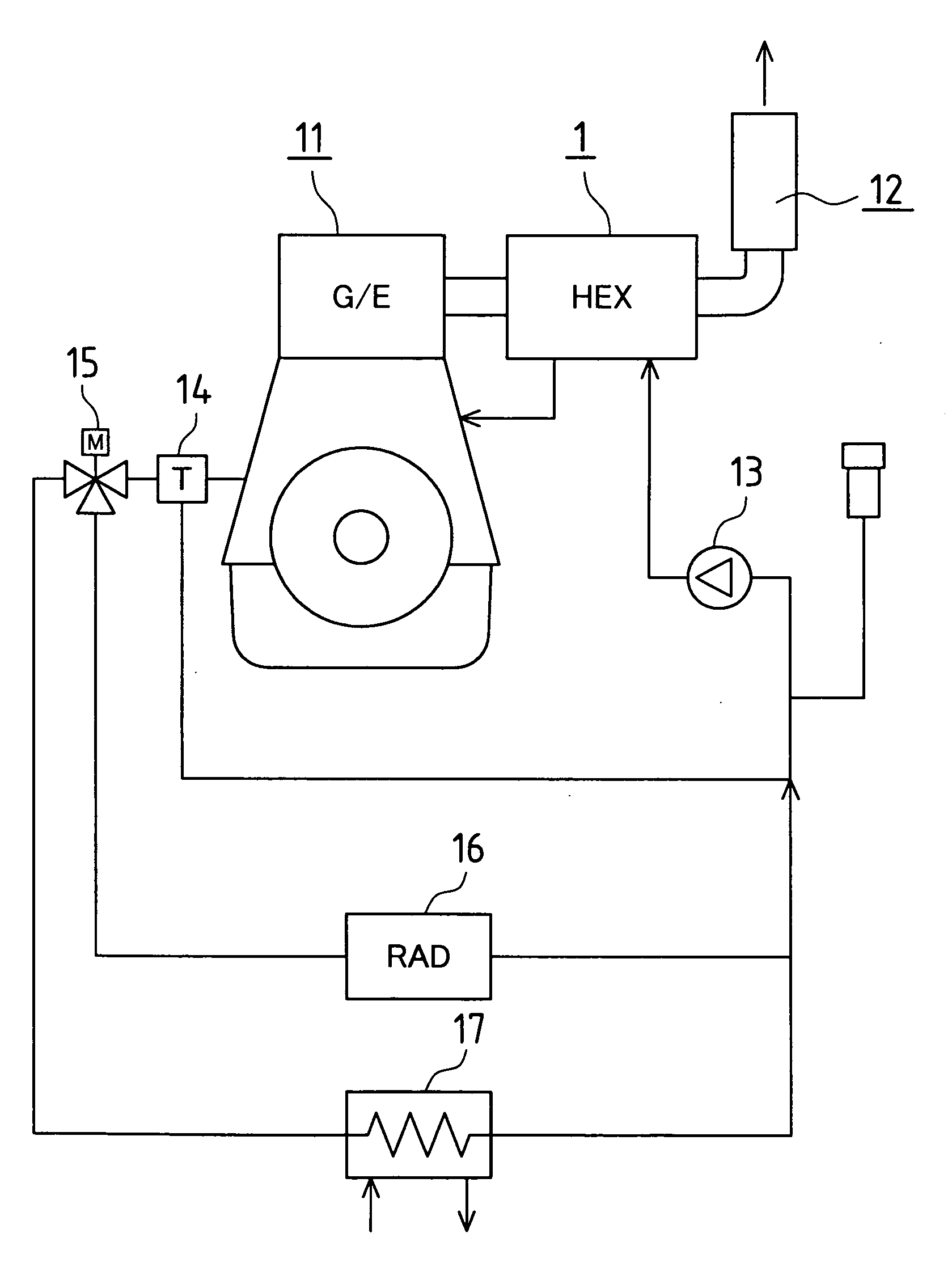

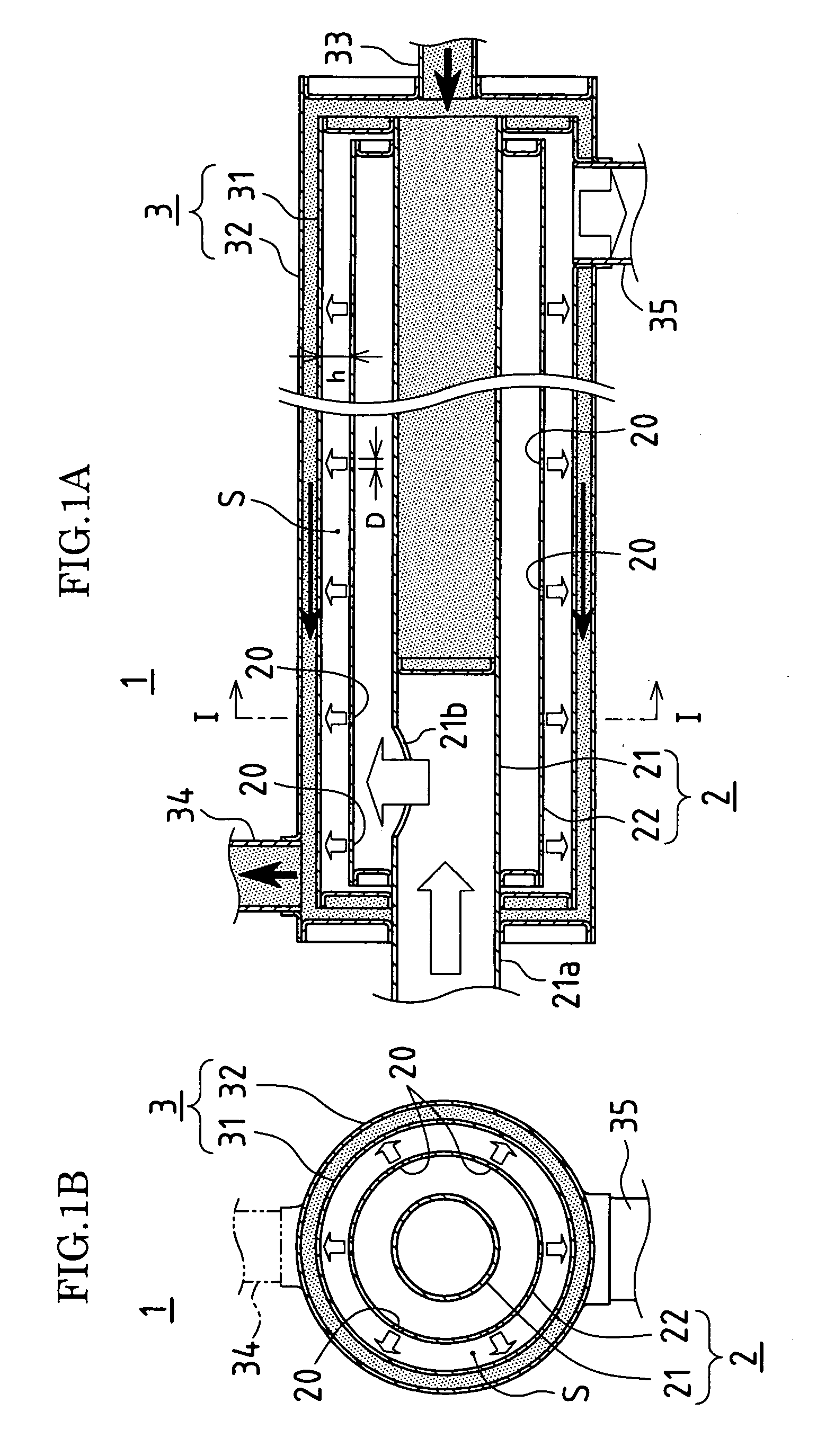

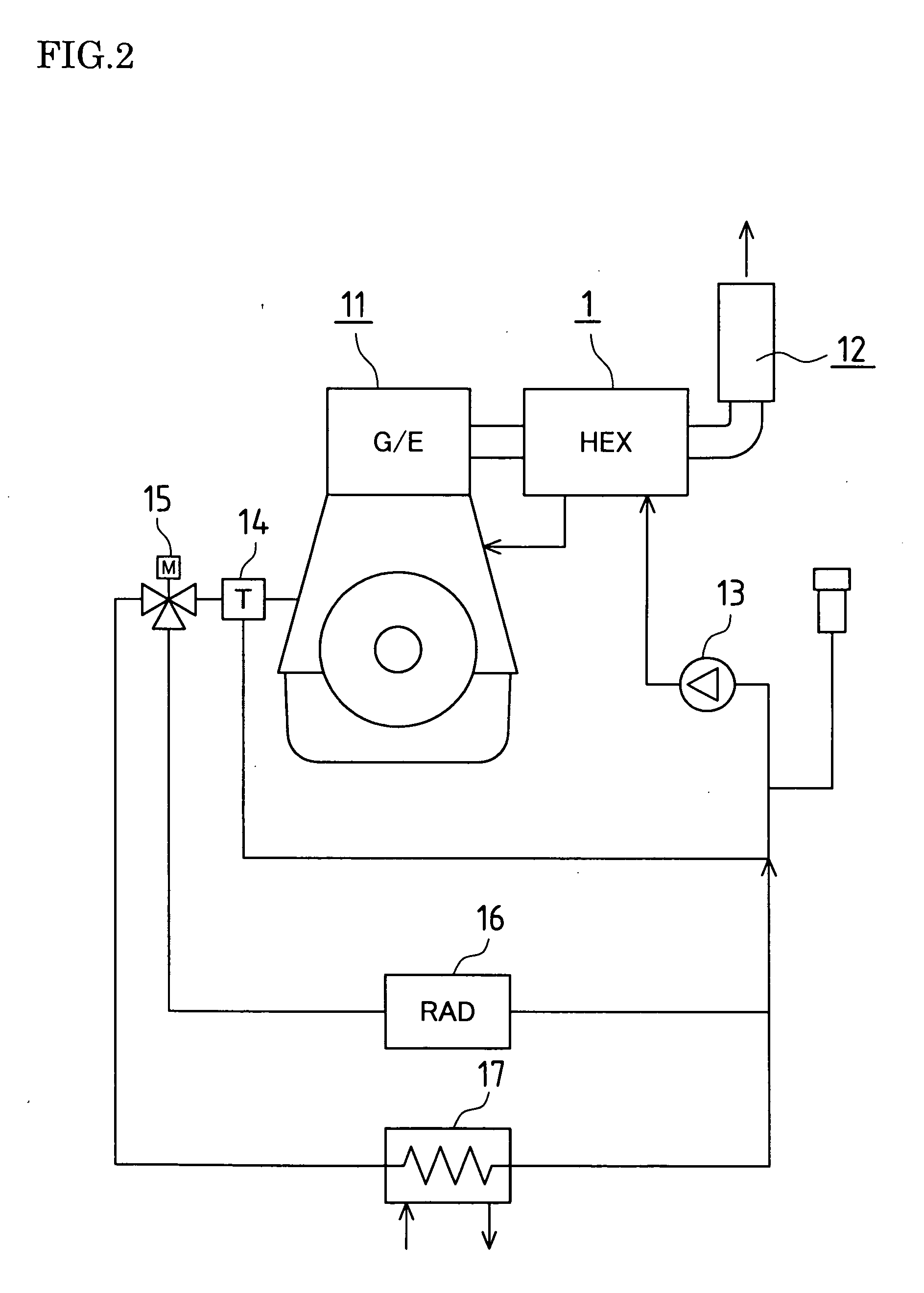

Engine exhaust heat recovery device, and energy supply apparatus using the same

InactiveUS20100205946A1Improve exhaust heat recovery rateReducing exhaust pressure lossInternal combustion piston enginesHeat recovery systemsExhaust fumesEnergy supply

[Problems] Provided is a configuration in which a member is not interposed between exhaust gas and a partition wall of an engine coolant passage, and the exhaust gas is caused to directly collide with the partition wall of the engine coolant passage, thus raising the gas flow velocity in a heat exchange part, which enables further improving the exhaust heat recovery rate.[Means for Solving Problems] An engine exhaust gas heat recovery device (1) recovers heat from engine exhaust gas by performing heat exchange between the engine exhaust gas and engine coolant. A plurality of spray holes (20) facing an inner cylinder tube (31) of a coolant passage (3) have been provided in an outer tube (22) of an exhaust gas inflow tube (2), and the exhaust gas is caused to directly collide with the inner cylinder tube (31) of the coolant passage (3). A minimum distance from each of the spray holes (20) to the inner cylinder tube (31) of the coolant passage (3) is in a range of 1.5 to 7 times the diameter of the spray holes. A relationship between a total opening area of the spray holes (20) and an exhaust gas flow rate is (total spray hole area / exhaust gas mass flow rate)=2.0 to 4.5 (cm2 / (kg / min)).

Owner:YANMAR CO LTD

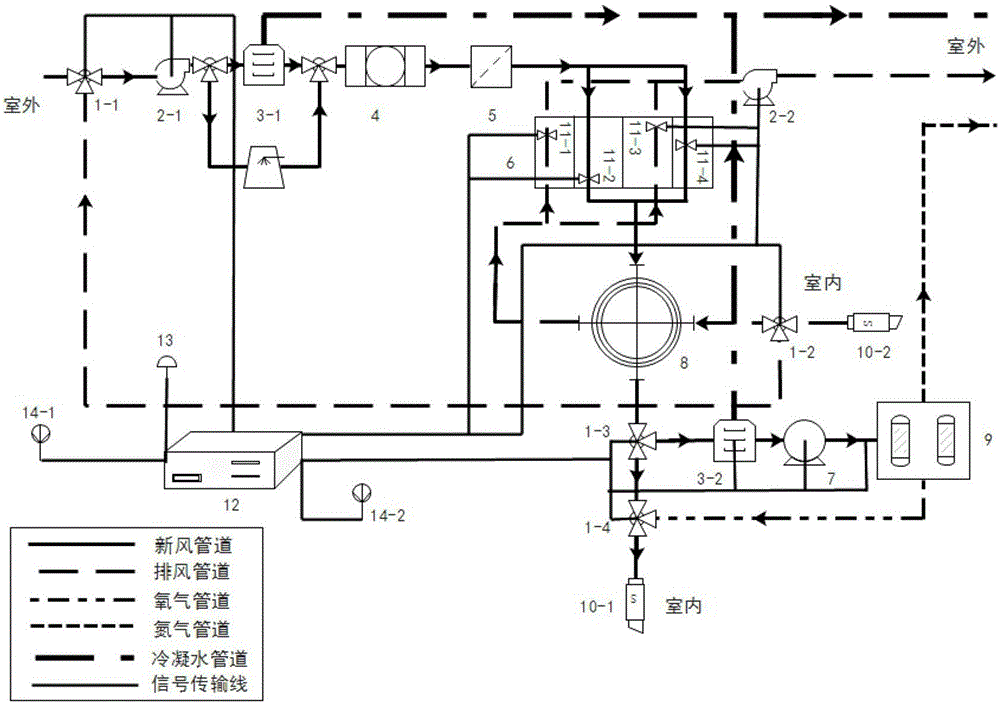

Fresh air integrated machine integrating multiple functions of air treatment, energy recovery and oxygenation

ActiveCN106196309AReduce loadSolve the problem of low energy recoveryEnergy recovery in ventilation and heatingMechanical apparatusAutomatic controlAir filter

The invention discloses a fresh air integrated machine integrating multiple functions of air treatment, energy recovery and oxygenation and belongs to the technical field of air purification and building ventilation and energy conversation. Based on a conventional independent fresh air system, problems that the comfort of the indoor environment is poor, the ventilating energy consumption is relatively great and the like are comprehensively solved by virtue of purification and dehumidification equipment, a phase change energy-storing material, devices such as a heat exchange device, a molecular sieve nitrogen and oxygen separator, and accessory valves thereof. The novel fresh air treatment device is divided into an air treatment module, an energy recovery module, an oxygenation module and an automatic control module and is mainly composed of driers, a high- and medium-efficiency air filter, an air purification device, a phase change energy-storing material device, the heat exchange device, the molecular sieve nitrogen and oxygen separator, a gas compressor, valves, silencers and the like. According to the integrated machine disclosed by the invention, in processes of adjusting the indoor thermal and humid environment and enhancing the air quality, the operating states of different module systems are controlled by monitoring and feedback by virtue of the automatic control module of the system, so that a good quality of the indoor environment is expected.

Owner:SHANDONG UNIV

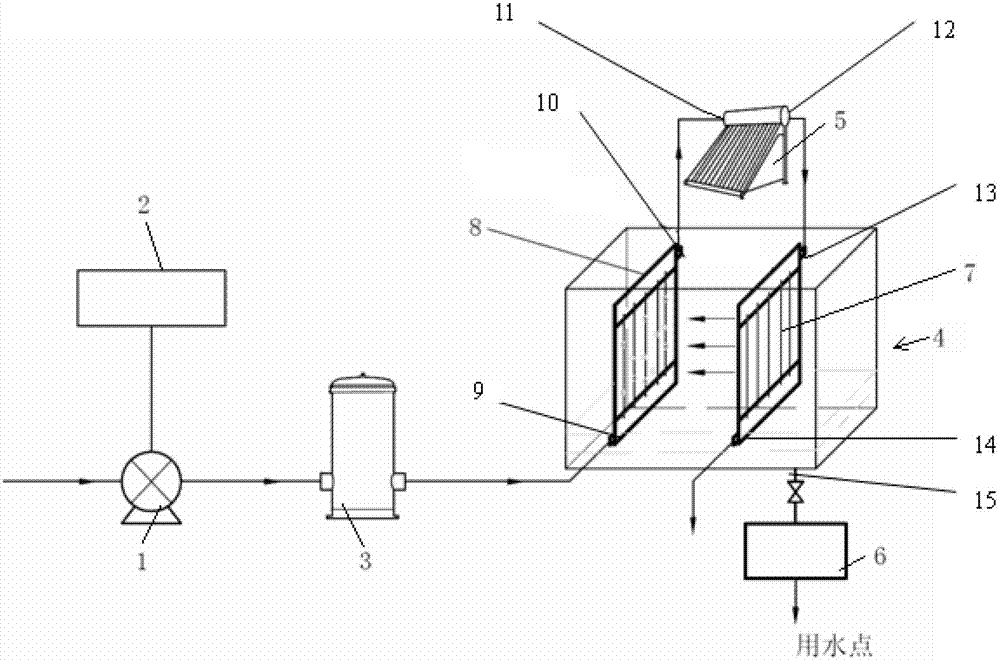

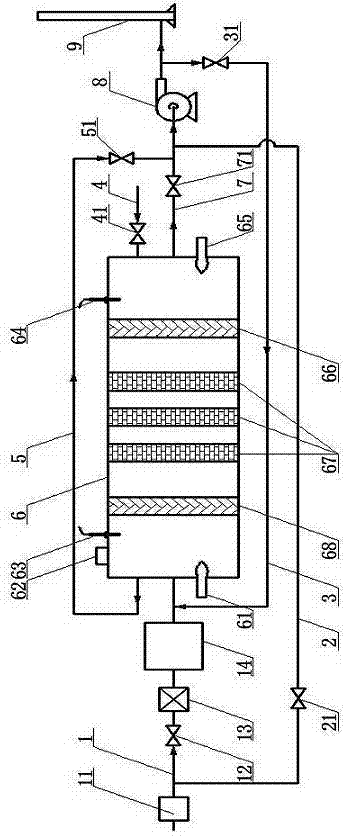

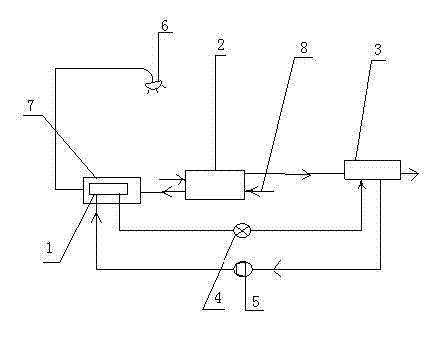

Solar membrane distillation seawater desalination plant for sea island

InactiveCN102826700AImprove heat recoveryNo electricity requiredSeawater treatmentMultistage water/sewage treatmentMembrane distillationElectric power

The invention discloses a solar membrane distillation seawater desalination plant for a sea island. The solar membrane distillation seawater desalination plant comprises a membrane module, a filter, a raw water pump, a solar heater, a solar thermoelectric system, a desalted water tank and pipelines used for connection of the above mentioned parts. The raw water pump is connected with an inlet of the filter; an outlet of the filter is connected with a cold seawater inlet of the membrane module; a cold seawater outlet of the membrane module is connected with a water inlet of the solar heater; an outlet of the solar heater is connected with a hot seawater inlet of the membrane module; and a water producing outlet at the bottom of the membrane module is connected with the desalted water tank. The solar membrane distillation seawater desalination plant for a sea island provided by the invention has the advantages of a high heat recovery rate, simple equipment, no need for electric power, low operation cost, etc.

Owner:ZHEJIANG DONGDA ENVIRONMENTAL ENG

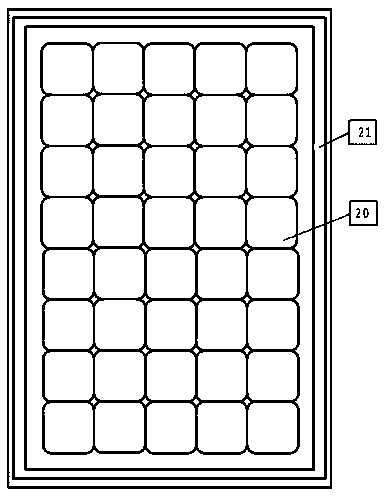

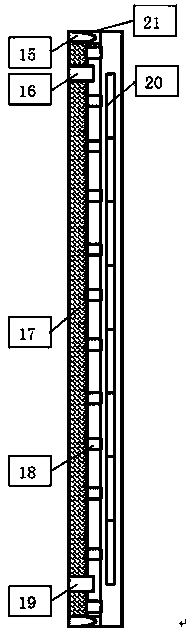

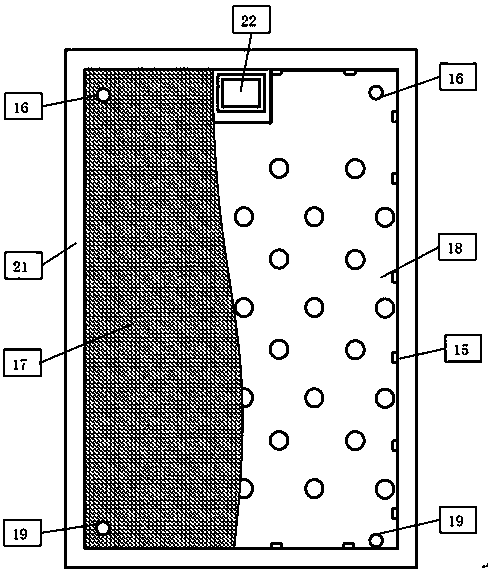

Solar photoelectric photo-thermal integrated assembly and solar combined heat and power generation system thereof

InactiveCN103594538AEliminate thermal contact resistanceGood hardnessPV power plantsEnergy industryCells panelCorrosion

The invention relates to a solar photoelectric photo-thermal integrated assembly and a solar combined heat and power generation system of the solar photoelectric photo-thermal integrated assembly. The solar photoelectric photo-thermal integrated assembly is characterized by comprising a photovoltaic cell panel provided with a metal outer frame, a metal sheet type heat exchanger and a heat-preservation material layer, wherein the metal sheet type heat exchanger and the heat-preservation material layer are sequentially arranged on the back surface of the photovoltaic cell panel in parallel and in an overlapped mode, and are rapidly fixed in the metal outer frame of the photovoltaic cell panel through a metal fixing clamp, and the standard photovoltaic cell panel can be rapidly modified into the photoelectric photo-thermal integrated assembly. The photoelectric photo-thermal integrated assembly has the advantages of being compact in structure, high in efficiency, small in pressure loss, light in weight, flexible to install, high in pressure bearing performance, resistant to corrosion, low in cost and the like, further reduces the initial investment and installation space of a medium and low temperature solar thermoelectric system, lowers the operation expenses of the system, and is suitable for civil and industrial occasions requiring for both heat and power.

Owner:SHANGHAI LVJIAN ENERGY TECH

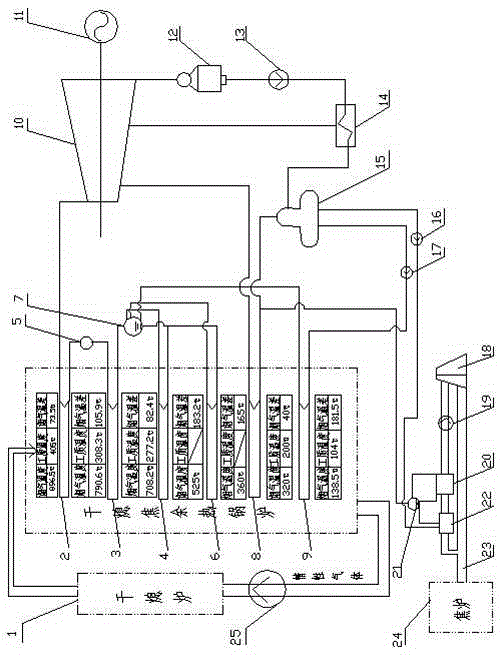

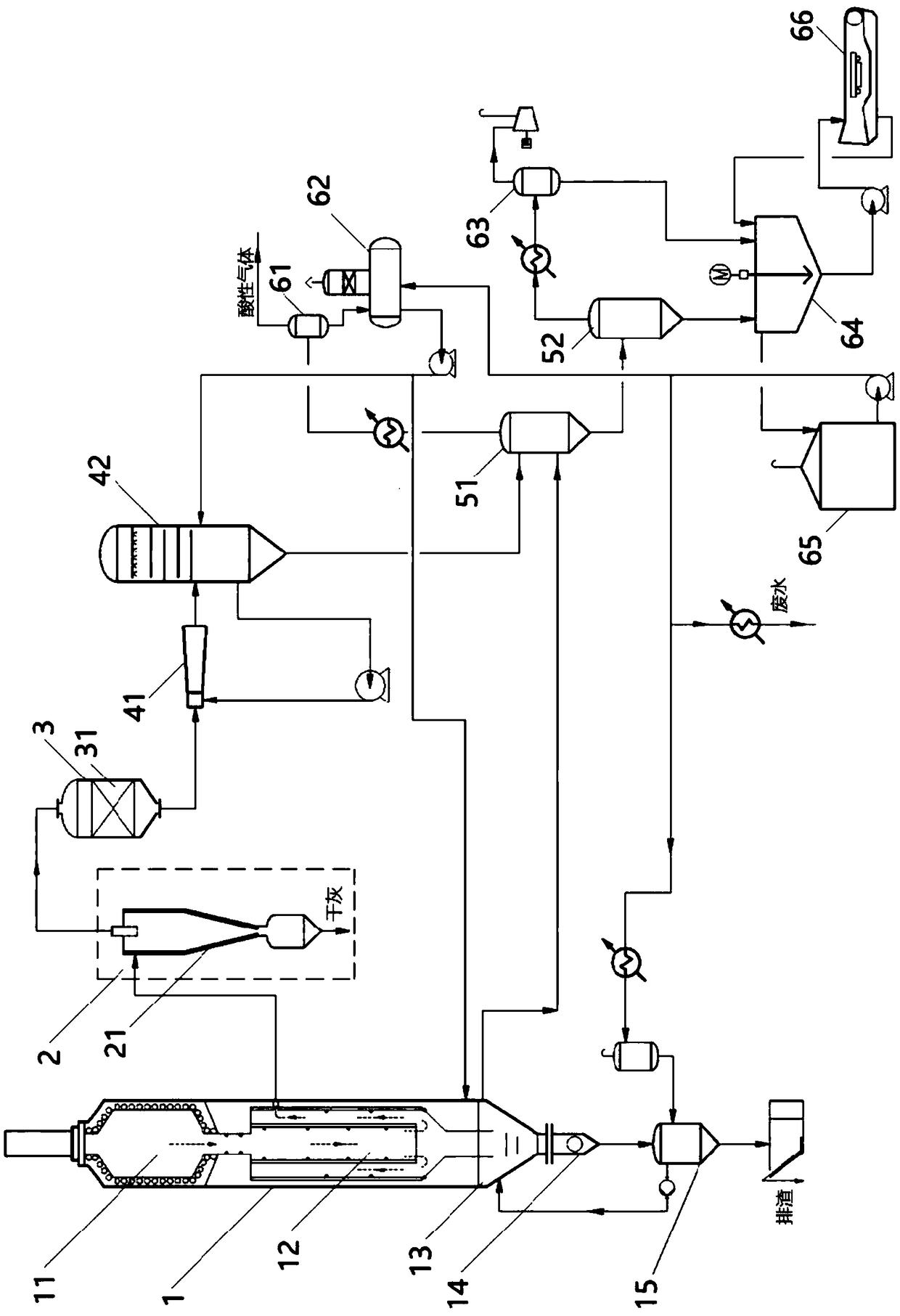

Coke oven flue-gas waste-heat and dry-quenching waste-heat coupled power generation system and coupled power generation method thereof

InactiveCN105275515ARealize high-value utilizationReduce wasteIncreasing energy efficiencySteam engine plantsDevice formMain channel

The invention relates to a coke oven flue-gas waste-heat and dry-quenching waste-heat coupled power generation system and a coupled power generation method thereof. The system comprises a dry-quenching waste-heat recycling device and the dry-quenching waste-heat recycling device comprises a dry-quenching furnace and a dry-quenching waste-heat boiler which are communicated with each other. A dry-quenching secondary superheater, a dry-quenching primary superheater, a first evaporator, a second evaporator, a coke oven flue-gas waste-heat superheater and a dry-quenching economizer are sequentially arranged in the dry-quenching waste-heat boiler. A coke oven flue-gas waste-heat recycling device comprises a coke oven. A coke oven flue-gas main channel is connected to the coke oven and sequentially connected with a coke oven flue-gas waste-heat economizer, a coke oven flue-gas waste-heat evaporator, a coke oven flue-gas draught fan and a coke oven flue-gas chimney. A steam turbine generator unit, the dry-quenching waste-heat recycling device and the coke oven flue-gas waste-heat recycling device form a loop through a condensing unit. According to the coke oven flue-gas waste-heat and dry-quenching waste-heat coupled power generation system and the coupled power generation method, coupled power generation is achieved in the manner that coking flue exhaust fume waste heat enters dry-quenching waste-heat power generation circulation in a coupled manner, and the purposes of efficient utilization of secondary energy and energy saving and emission reduction are achieved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Regenerative catalytic direct combustion system for treating VOCs waste gas

InactiveCN106855236AImprove processing efficiencyEasy to controlIncinerator apparatusCombustorFlue gas

The invention relates to a regenerative catalytic direct combustion system for treating VOCs waste gas. The system comprises a waste gas inlet pipe, a catalyst direct combustion chamber, a flue gas outlet pipe, an air inlet pipe, an air outlet pipe, a draft fan and an exhaust funnel. An anti-explosion door is installed at the top of the catalyst direct combustion chamber. One end of the catalyst direct combustion chamber is provided with a main burner, the other end of the catalyst direct combustion chamber is provided with an auxiliary burner. The air inlet pipe and the waste gas outlet pipe are inversely installed. A thermal couple and a catalyst layer are respectively installed at two sides in the catalyst direct combustion chamber. At least two layers of regenerative body are installed between catalyst layers. The regenerative catalytic direct combustion system for treating VOCs waste gas is reasonable in structure, good in energy-saving effect, low in investment and operation cost, and high in VOCs treatment efficiency, and therefore the system can be widely used in the field of VOCs waste gas treatment.

Owner:山东英派节能环保科技有限公司

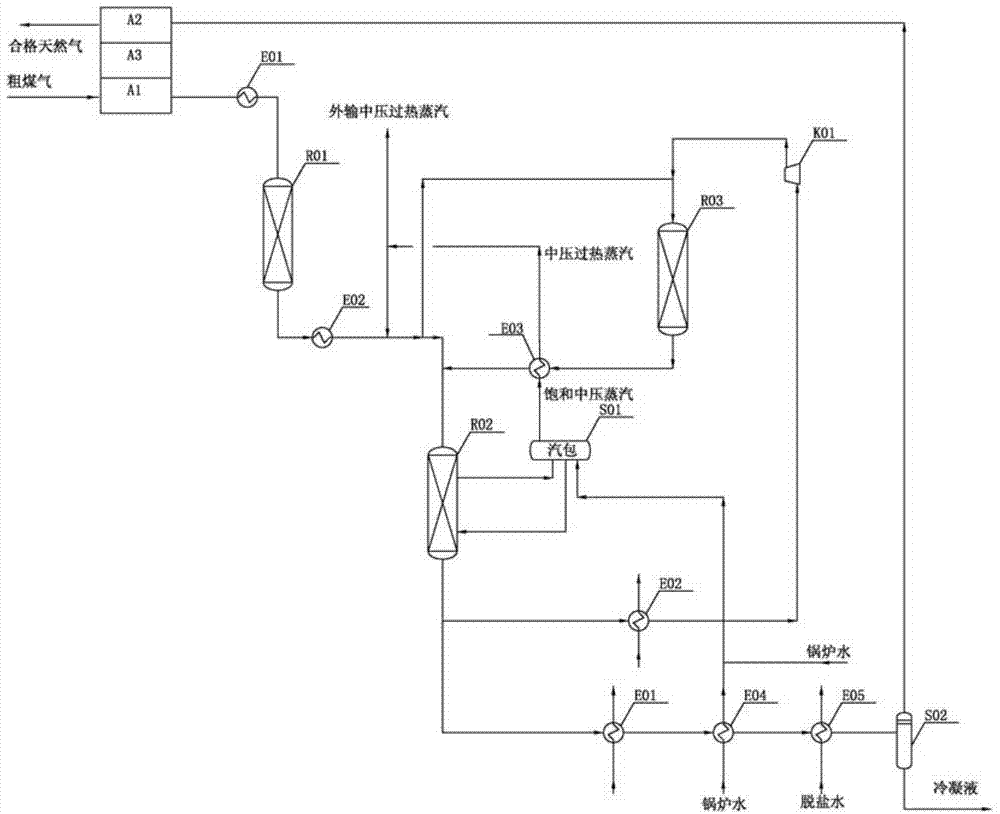

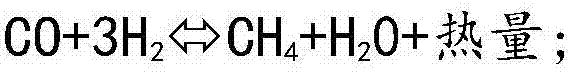

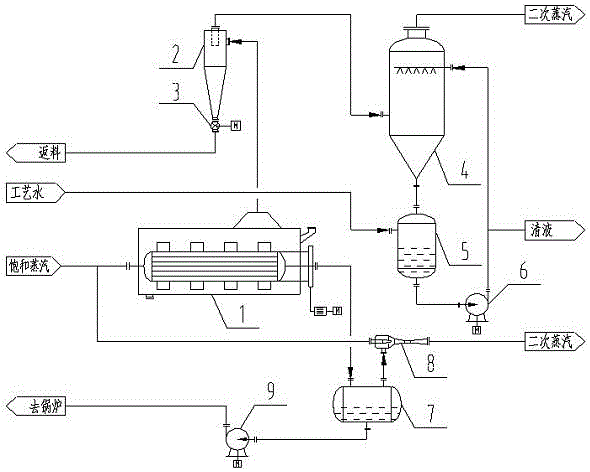

Synthetic natural gas prepared from one-step process coal and system thereof

ActiveCN104774663AThe process is simple and reliableImprove heat recoveryGaseous fuelsCombustible gas purificationThermal insulationMethanation

The invention discloses a synthetic natural gas prepared from one-step process coal and a system thereof. The synthetic natural gas is prepared by the following steps: H2S and other impurities are removed from normal-temperature crude coal gas to obtain purified gas; the purified gas is preheated, subjected to removal of sulfur and other impurities, and divided into two streams; the first purified gas stream enters a thermal-insulation methanation reactor to perform methanation reaction; the reaction gas from the thermal-insulation methanation reactor is cooled by a steam superheater, and sent into an isothermal methanation reactor together with the second purified gas stream; the reaction gas from the isothermal methanation reactor is divided into two streams; the first reaction gas stream is cooled, pressurized by a recycle gas compressor, and sent into the thermal-insulation methanation reactor together with the first purified gas stream; and the second reaction gas stream is cooled, subjected to condensate separation by a condensate separator, and sent into a second absorption tower of a low-temperature methanol washer to remove CO2 and water, thereby obtaining the synthetic natural gas. The method has the advantages of simple technique, brief process, and low device operation and investment cost, and can centrally recover heat energy and coproduce high-quality steam.

Owner:WUHUAN ENG

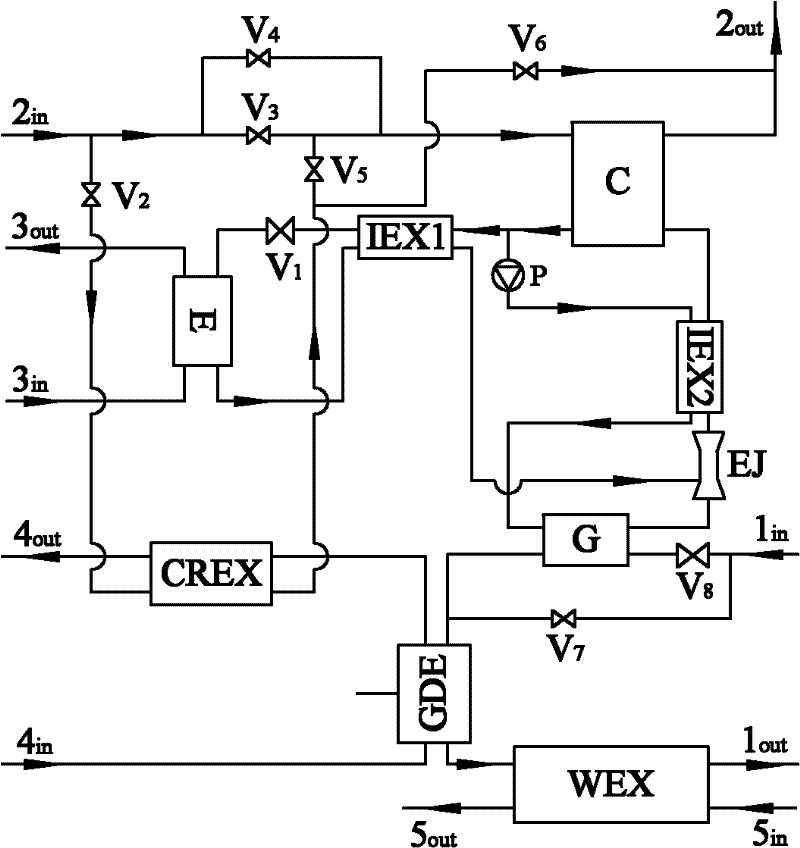

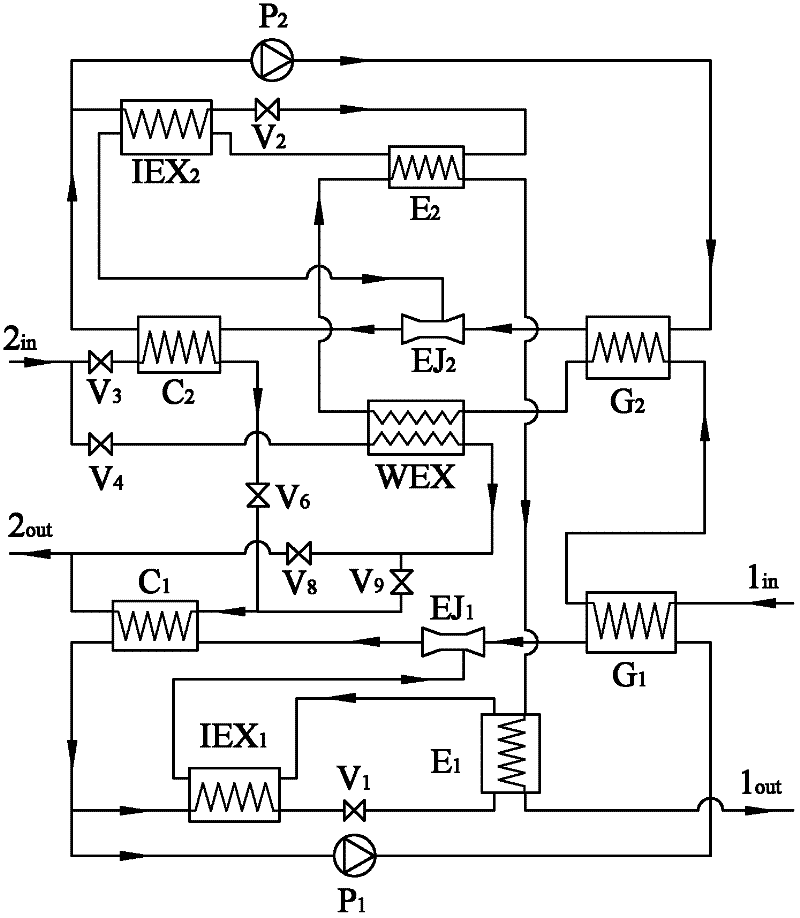

Multifunctional injection heat pump unit

InactiveCN102226601AReduce consumptionReduce peak-to-valley differenceHeat pumpsHeat recovery systemsThermal energyEngineering

The invention belongs to the technical field of energy sources and particularly relates to a multifunctional injection heat pump unit. The heat pump unit provided by the invention consists of an injection heat pump, a dehumidification solution regenerating system, a domestic hot water system, a valve and a connecting pipeline, and comprises a generator, a condenser, an evaporator, an injector, a pump, a heat regenerator, a solution generator, a solution cooler and a water-water heat exchanger; and the connecting pipeline is divided into a water system pipeline, a dehumidification solution system pipeline and a heat pump working medium system pipeline. The multifunctional injection heat pump unit provided by the invention can be used for recycling industrial waste heat, solar energy and the like, preparing chilled water and dehumidifying concentrated solution and hot water, improves the comprehensive utilization rate of heat and is beneficial to the reduction of the load peak and valley difference of a power grid in summer.

Owner:北京建筑工程学院

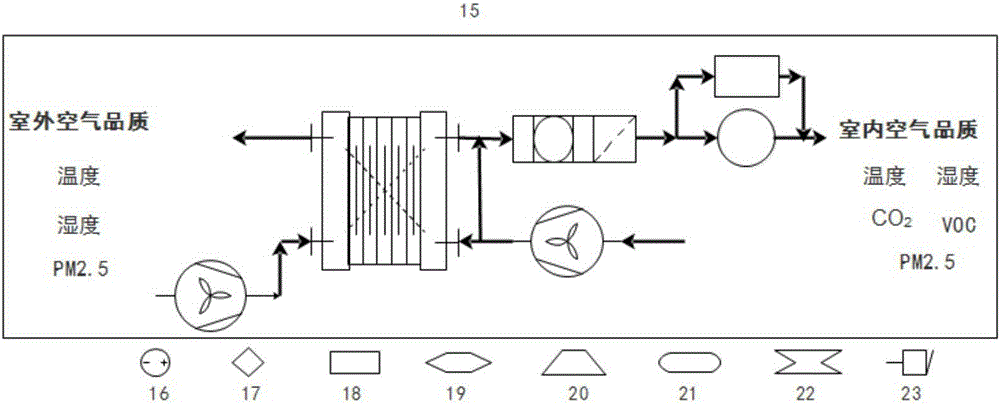

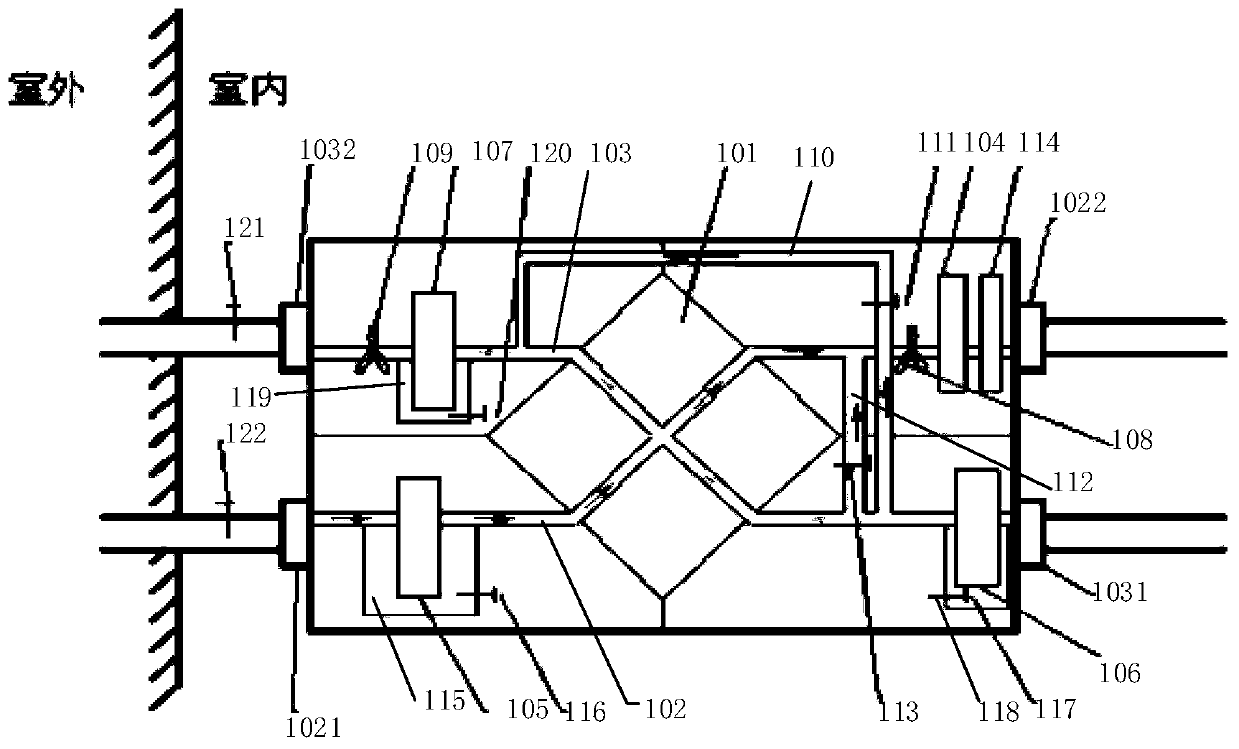

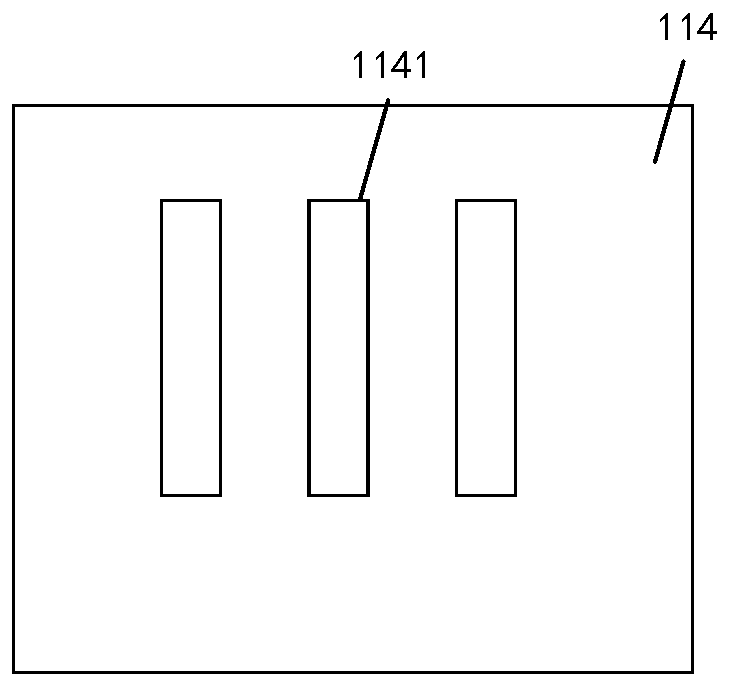

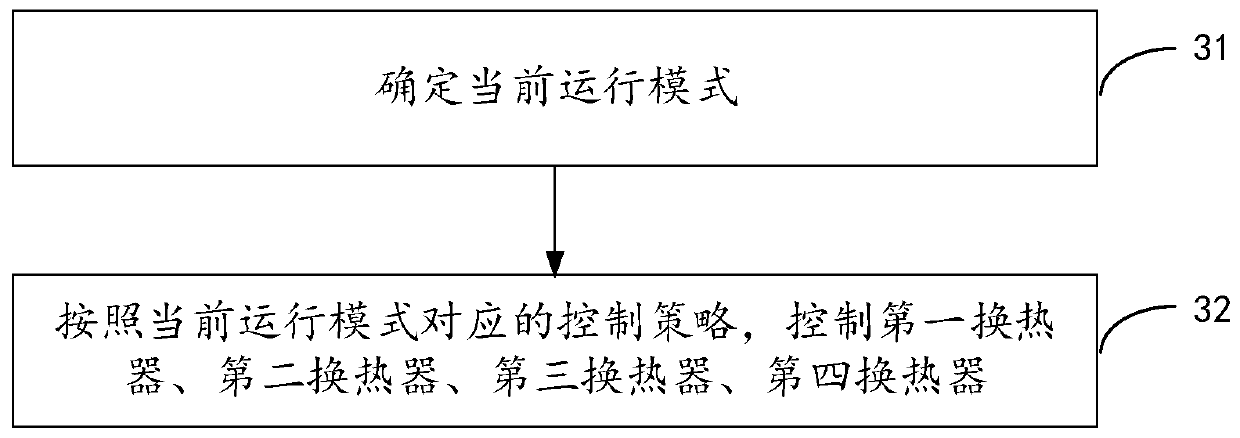

Air processing device and control method and device thereof

PendingCN110715364AMore heat recoveryImprove heat recoveryEnergy recovery in ventilation and heatingMechanical apparatusAir treatmentFresh air

The invention discloses an air processing device and a control method and device thereof. The air processing device comprises an air duct system and a coolant circulation system. The air duct system comprises a total heat exchange core, a fresh air duct and an air exhaust duct, wherein the fresh air duct penetrates through the total heat exchange core in a cross manner. The fresh air duct carriesout heat exchange through the total heat exchange core and the air exhaust duct. The fresh air duct comprises a fresh air inlet and a fresh air outlet. The air exhaust duct is provided with an exhaustair inlet and an exhaust air outlet. The coolant circulation system comprises a first heat exchanger, a second heat exchanger, a third heat exchanger and a fourth heat exchanger, wherein the first heat exchanger is arranged between the fresh air outlet and the total heat exchange core, the second heat exchanger is arranged between the fresh air inlet and the total heat exchange core, the third heat exchanger is arranged between the exhaust air inlet and the total heat exchange core, the fourth heat exchanger is arranged between the exhaust air outlet and the total heat exchange core, and thefirst heat exchanger and the second heat exchanger can carry out heat exchange with the fresh air duct, and the third heat exchanger and the fourth heat exchanger can carry out heat exchange with theair exhaust duct for heat recovery.

Owner:GREE ELECTRIC APPLIANCES INC

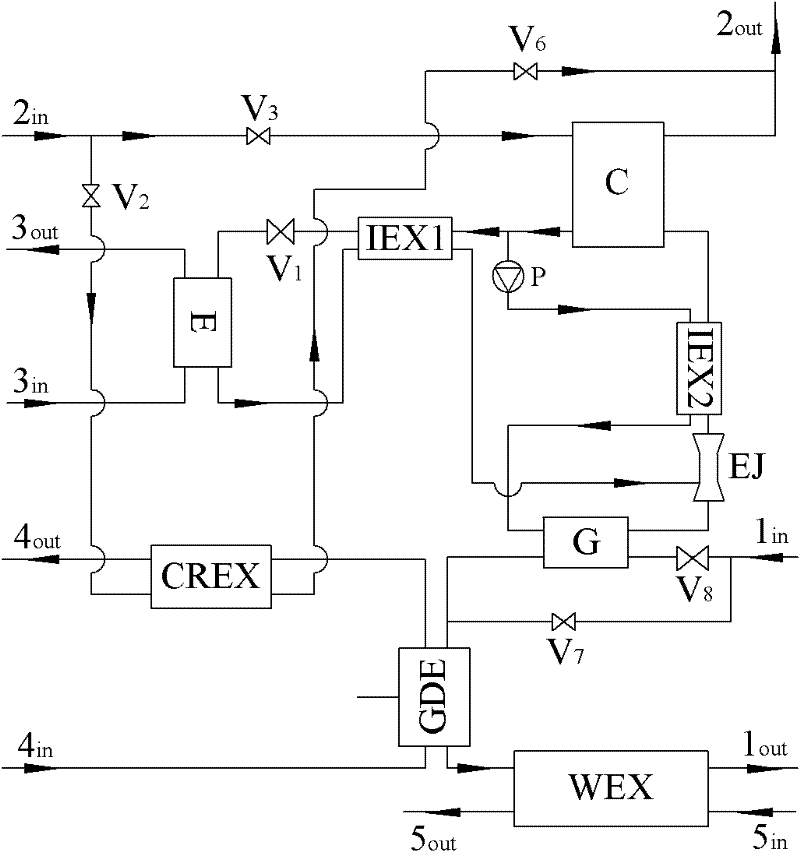

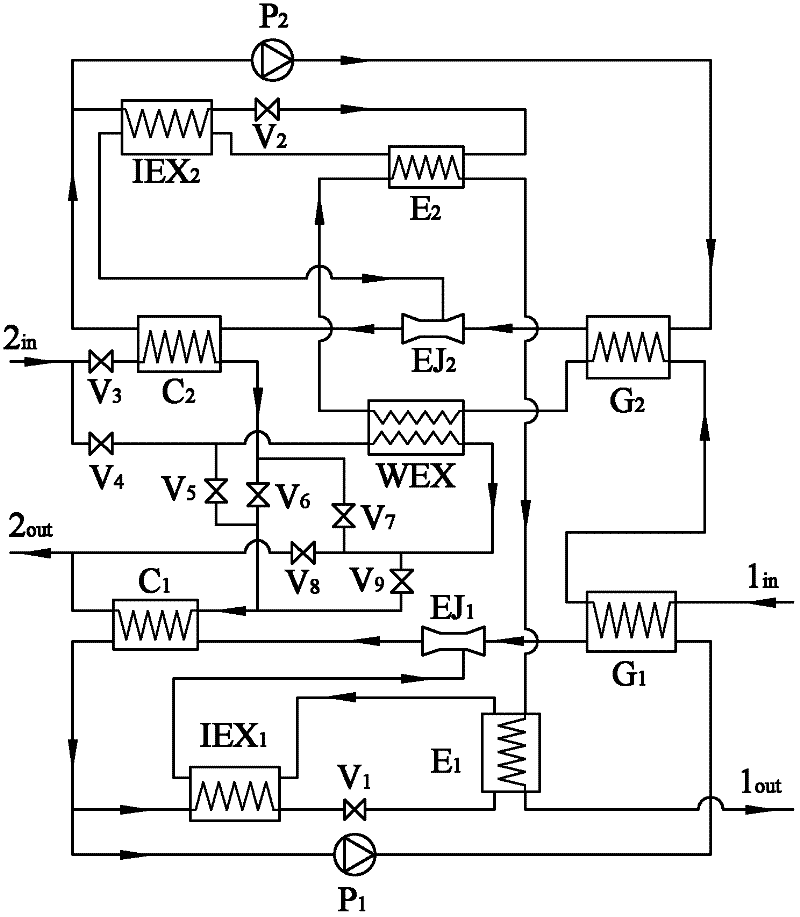

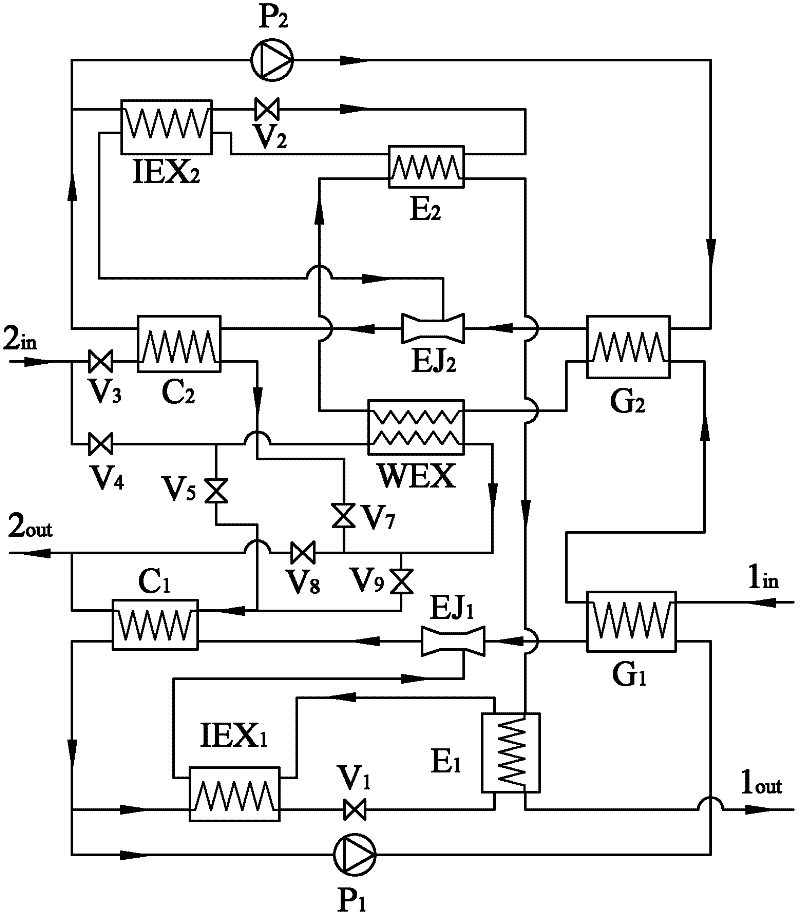

Two-stage injection heat pump type heat exchange unit

ActiveCN102226602AImprove delivery capacityImprove heat recoveryHeat pumpsEngineeringPlate fin heat exchanger

The invention relates to a two-stage injection heat pump type heat exchange unit, which belongs to the technical field of energy sources. The heat exchange unit provided by the invention comprises the accessories such as a two-stage injection heat pump, a water-water heat exchanger, a connecting pipeline, a valve and the like, wherein the water system of the connecting pipeline is divided into a primary side pipeline and a secondary side pipeline; the primary side pipeline adopts a series connection mode; the secondary side pipeline adopts a parallel connection, series connection or mixed connection mode. By means of an injection heat pump technique, the hot water heat of the primary side pipeline is utilized in a stepped mode; the backwater temperature of the primary side pipeline is greatly reduced; the backwater supply temperature difference of the primary side pipeline is increased; and the hot water heat transfer capability of the primary pipeline and the secondary pipeline is greatly enhanced. The two-stage injection heat pump type heat exchange unit provided by the invention can be used for recycling industrial waste heat, solar energy and the like to improve the waste heatrecycling rate and can be applied to the heat power station of a central heating system to improve the transmission capability of a primary heat network pipeline and reduce the irreversible loss in the heat exchange course.

Owner:北京华源泰盟节能设备有限公司

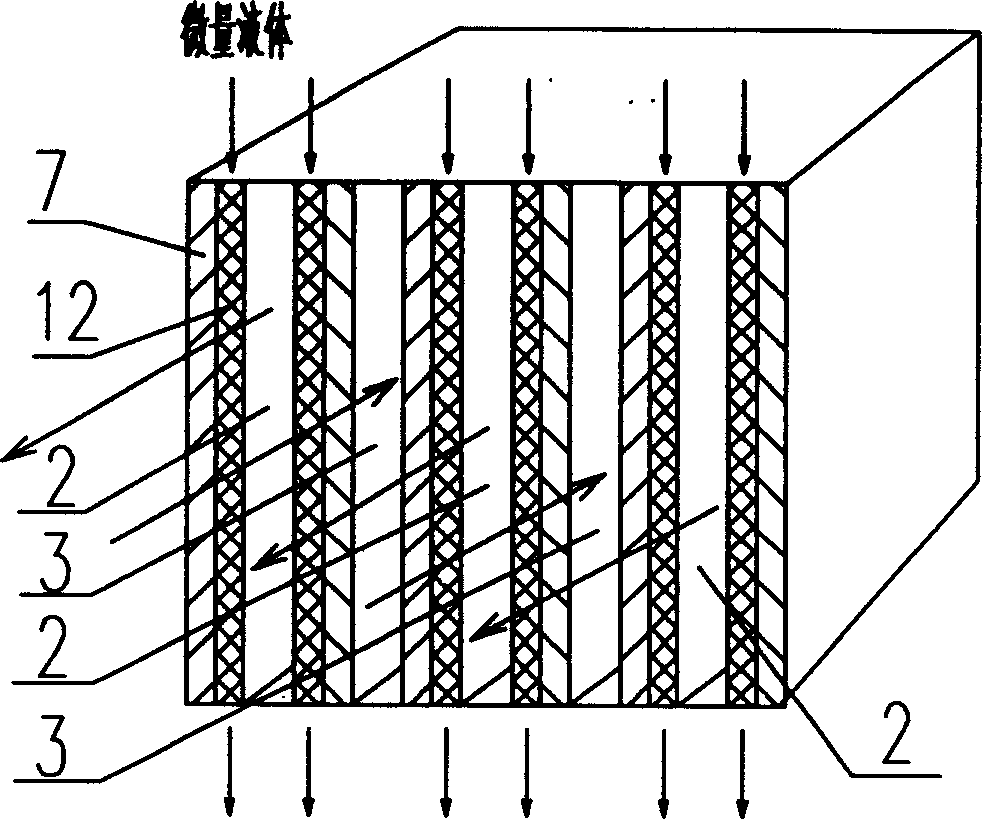

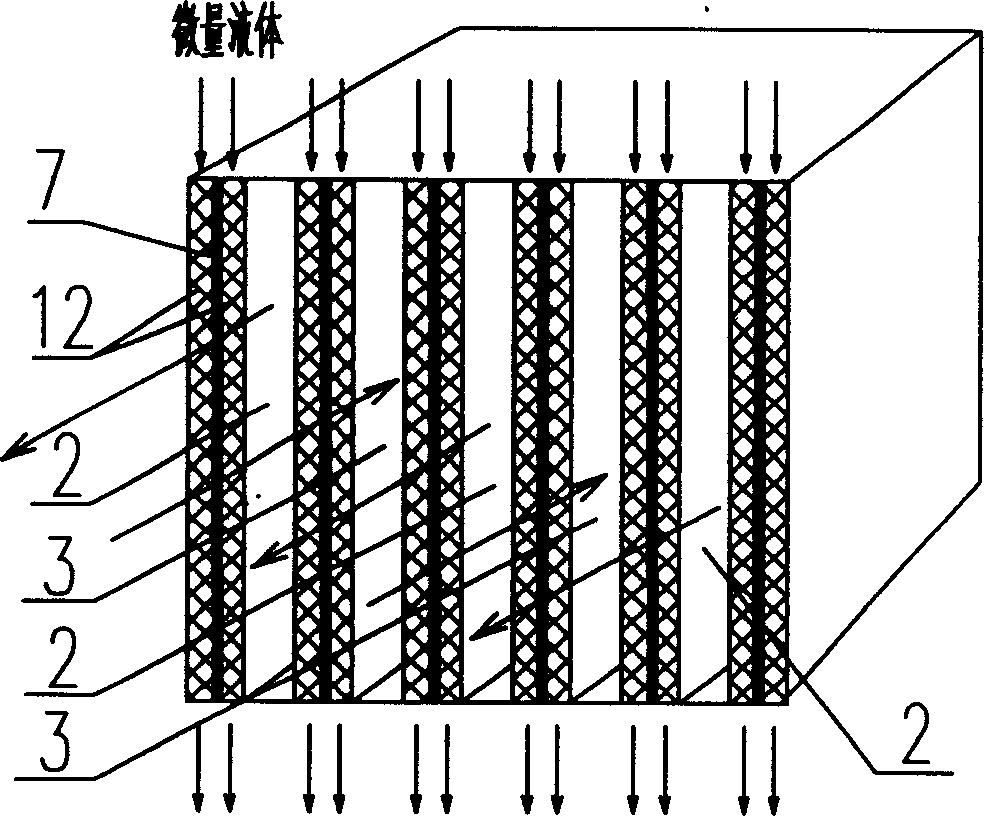

Fresh air heat recovery method and equipment

InactiveCN1687656AImprove the living environmentEvenly distributedDucting arrangementsLighting and heating apparatusRecovery methodAir treatment

The invention relates to the air treatment method and the device, especially to the new wind heat recycling method and its device. The method has the new air passage and the exhaust passage separated by the air passage plate; the liquid soakage layer of the said plate at the exhaust passage side; the minim liquid flows in or on the soakage layer when refrigeration to realize the heat exchange between the new air passage and the exhaust passage; the temperature difference between the new air passage and the exhaust passage realizes the heat exchange when heating. The device comprises the air passage wall, the new air intake, the new air outtake, the exhaust intake, the exhaust outtake, the new air passage and the exhaust passage, also the liquid intake, the liquid arranging structure connecting the liquid intake, and the soakage layer of the air passage plate at the side of the exhaust passage. The invention has high heat recycling ratio and wide utilization.

Owner:蒋国良

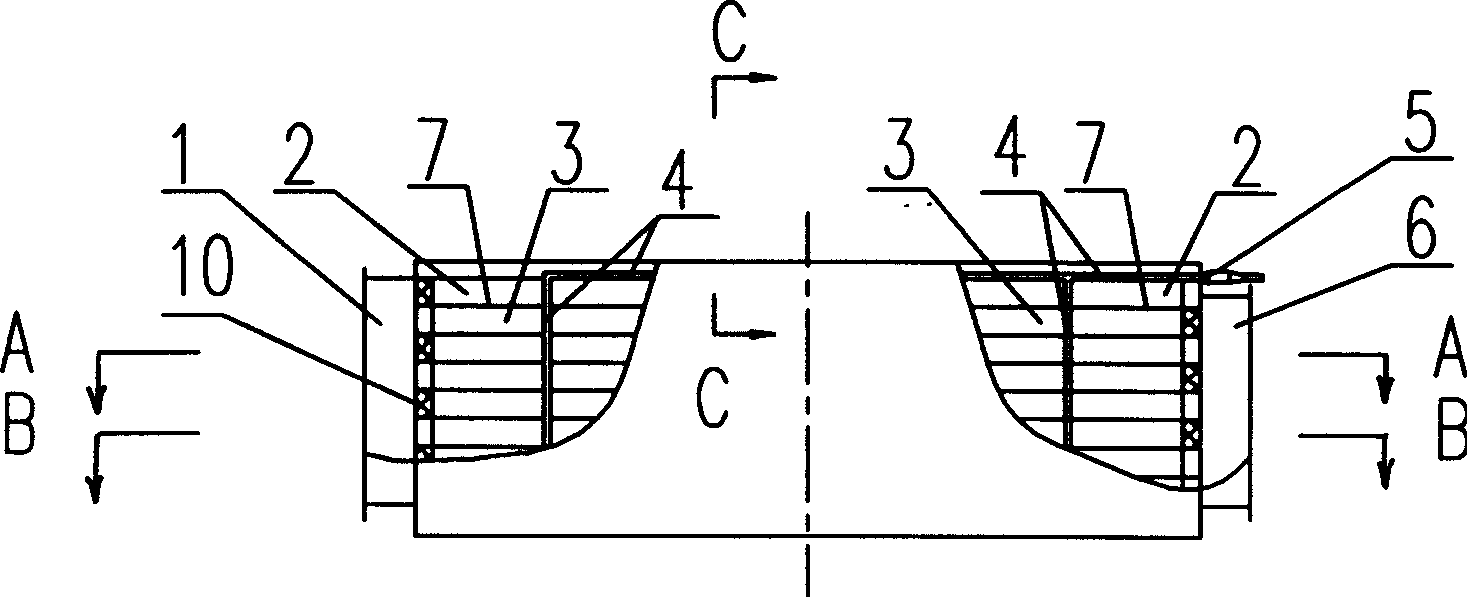

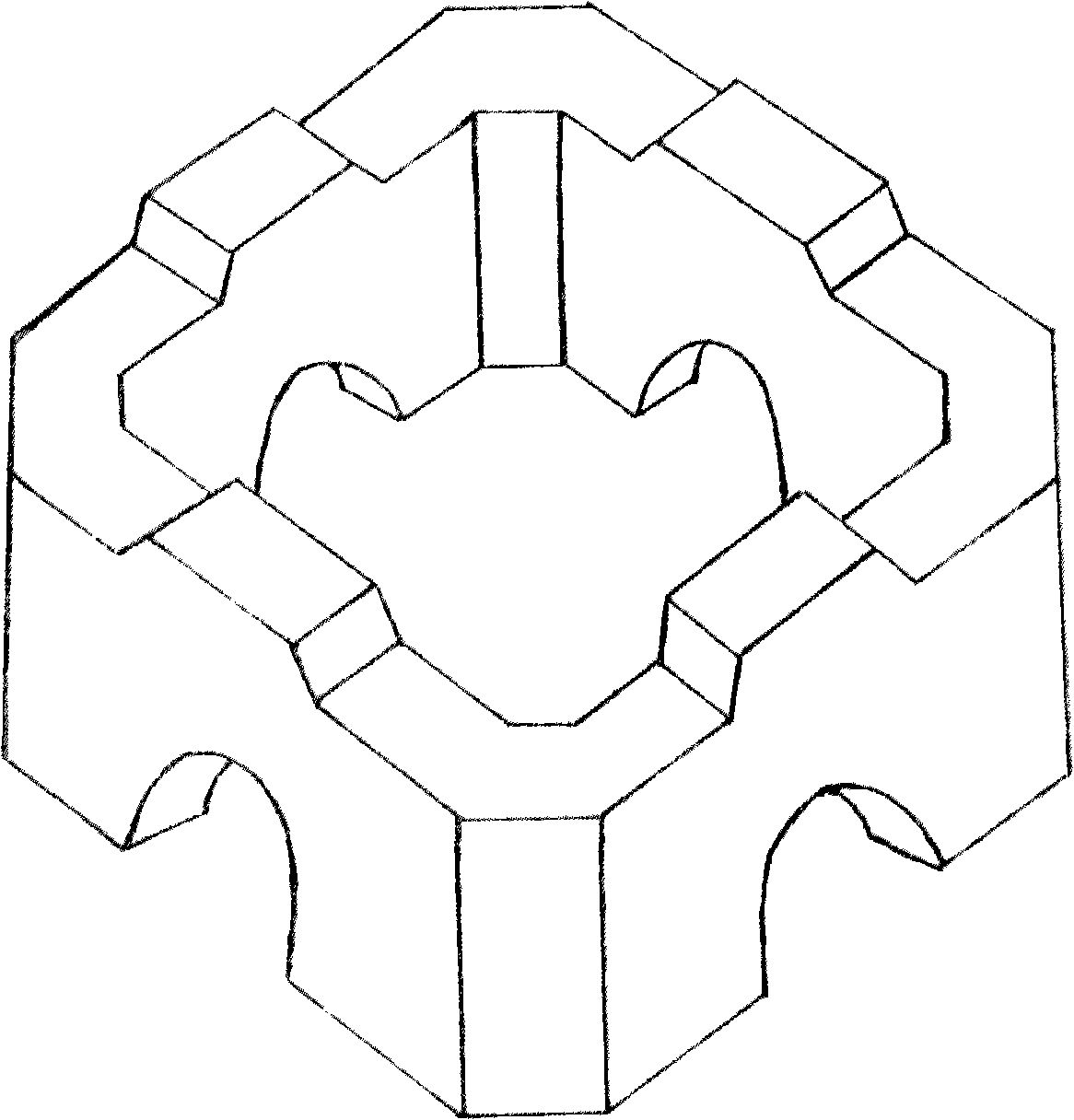

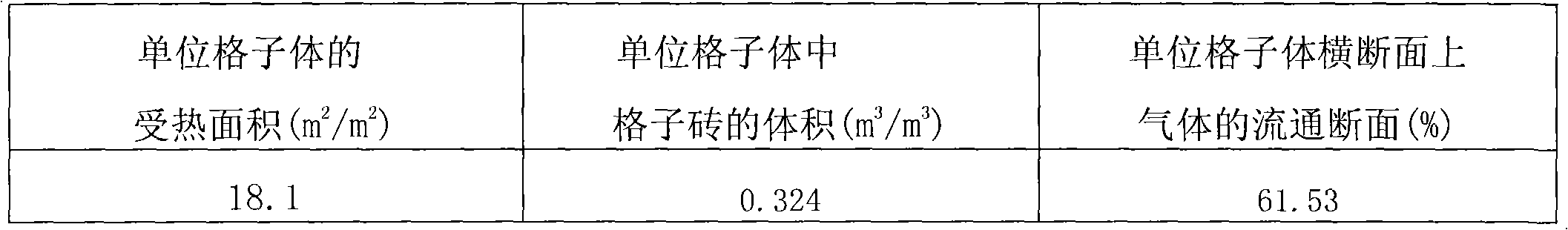

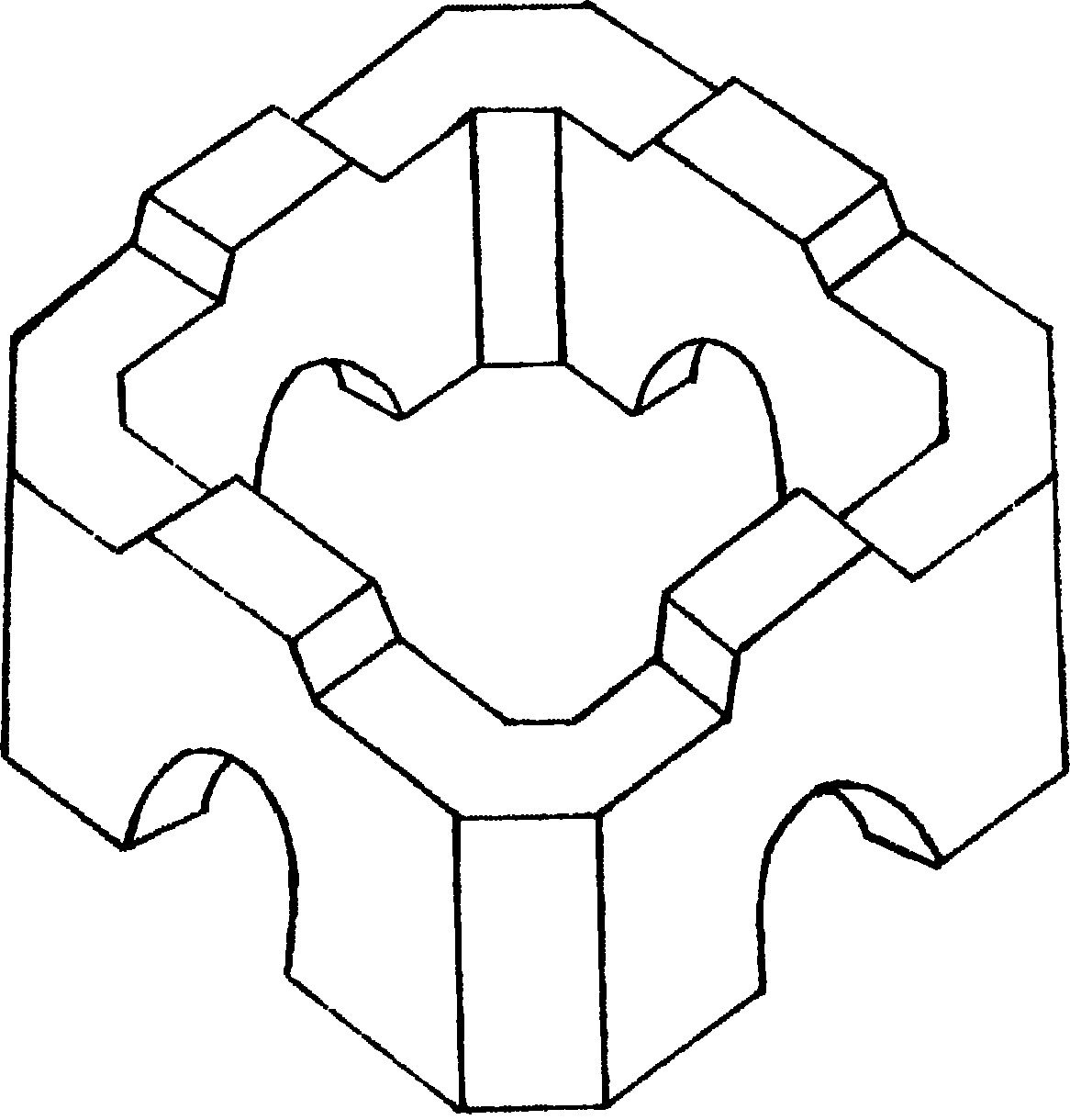

Fused cast alpha-beta alumina cylindrical brick and production method thereof

ActiveCN101891369ASmall side wall thicknessIncrease the heating areaGlass furnace apparatusGlass productionBrickLow voltage

The invention discloses a fused cast alpha-beta alumina cylindrical brick, wherein inner and outer ends at four corners of hollow cylinder wall are all chamfers, middle parts of upper and lower ends of four cylinder walls are provided with position-corresponding protrusions or recesses, the dimension ratio of the height of the protrusions to the depth of the recesses is 1:5, the formula of the brick includes 10-30% of recovered fused cast alpha-beta alumina clinker, and fused cast alpha-beta alumina brick raw material as the balance, which is homogeneous to the recovered clinker. The production method of the fused cast alpha-beta alumina cylindrical brick comprises the steps of: blending materials at first; feeding nitrogen in through the upper part of a hollow electrode, fusing the materials according to a low-voltage large-current fusing process in which the fusing voltage is 180 to 280V, the current is 4 to 9 thousands A and the constant conduction pressure of the nitrogen is 0.3 to 0.8MPa; then implementing casting formation, wherein the cast form adopts body clinker or magnesite integral sand mould, the weight ratio of mould sand to water glass is 90-100 : 6-10, the water glass modulus is 3.2 to 3.3, the casting temperature is 1900 to 2000 DEG C, and the casting speed is 180 to 200kg / min; annealing by using a silicon-aluminum hollow sphere as heat preservation medium after the casting, wherein the annealing speed is 0.053 to 0.060 DEG C / kg . h; and in the end, forming the cylindrical brick by means of cold working.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

Tube-type UHT high heat recovery rate hot water heat exchange system

PendingCN106865862AReduce consumptionReduce heat transfer areaMultistage water/sewage treatmentWater/sewage treatment by heatingThermodynamicsIce water

The invention relates to a tube-type UHT high heat recovery rate hot water heat exchange system. In a product pipe, a balance tank, a product pump, a degassing section, a heating section, a sterilization section, a heat recovery section, a tower water cooling section and an ice water cooling section are orderly arranged in the product pipe from an inlet to an outlet. A hot water pipe comprises a heat recovery section hot water circulation part and a sterilization hot water circulation part. The heat recovery section hot water circulation part orderly comprises a cooling hot water tank and a cooling hot water pump and the hot water orderly flows through a heat recovery section, a heating section and a degassing section and finally returns to the cooling hot water tank. The sterilization hot water circulation part orderly comprises a sterilization hot water tank, a sterilization hot water pump and a steam section and the hot water flows through the sterilization section and finally returns back to the sterilization hot water tank. Through a reasonable flow ratio of hot water to product, a high heat recovery rate is obtained.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

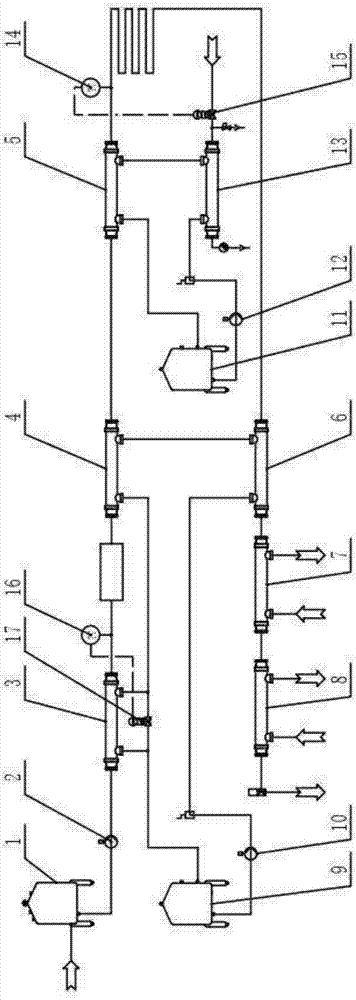

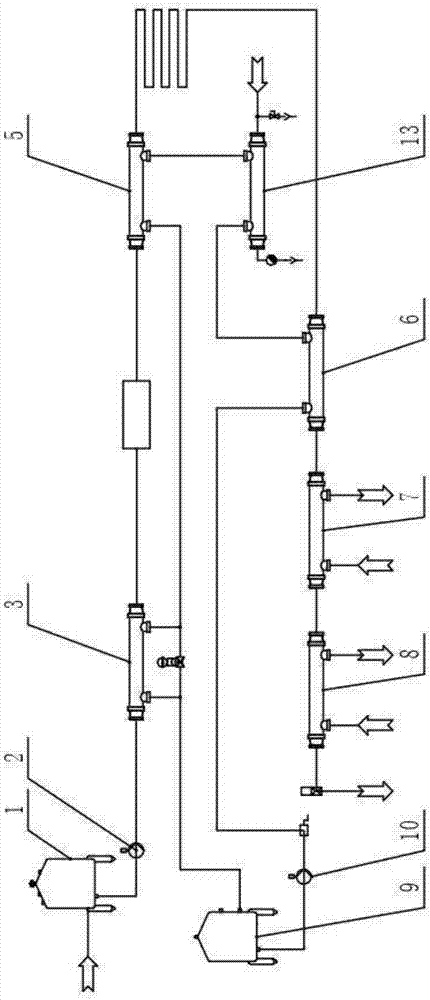

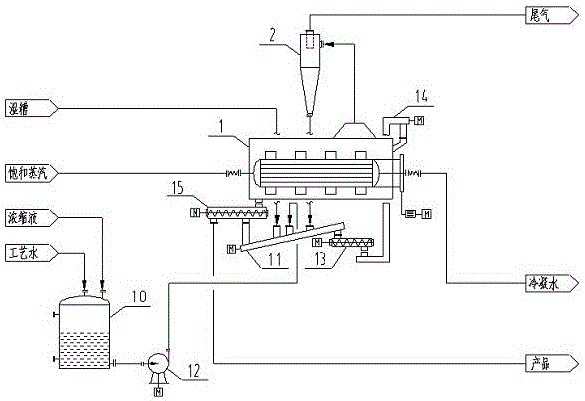

Method for vinasse tube bank type drying and exhaust gas and steam condensed liquid heat recycling

InactiveCN105865191AThe process is simple and reliableContinuous operationEnergy recuperation in distillationDrying solid materialsEnvironmental resistanceLiquid storage tank

The invention relates to a method for vinasse tube bank type drying and exhaust gas and steam condensed liquid heat recycling. The method comprises the following steps: (1), after centrifuging vinasse, obtaining a wet vinasse material and vinasse clear liquid, and after concentrating the vinasse clear liquid, feeding concentrated liquid into a concentrated liquid storage tank; (2), conveying the wet vinasse material and the concentrated liquid to a material return spiral conveyor, conveying the wet vinasse material and the concentrated liquid to a mixing spiral conveyor together, mixing, and after mixing uniformly, feeding the mixture into a tube bank type drying machine; (3), feeding saturated steam into the tube bank type drying machine, and heating and drying the material mixture in a reverse flow manner so as to obtain a dried material, exhaust gas and condensed water; (4), after separating the exhaust gas by a cyclone separator, obtaining a separated material and separated exhaust gas, feeding the separated material into the material return spiral conveyor, and cyclically utilizing the separated material; (5), feeding the separated exhaust gas into a sprinkling tower, washing the exhaust gas, and separately producing secondary steam A and washing water left after heat exchange; and (6), feeding the condensed water into a condensed water flash evaporation tank, carrying out flash evaporation on the condensed water, and separately producing secondary steam B and condensed liquid. The method is simple and reliable, is continuous in running, saves energy, reduces consumption and is safe and environment-friendly.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION +1

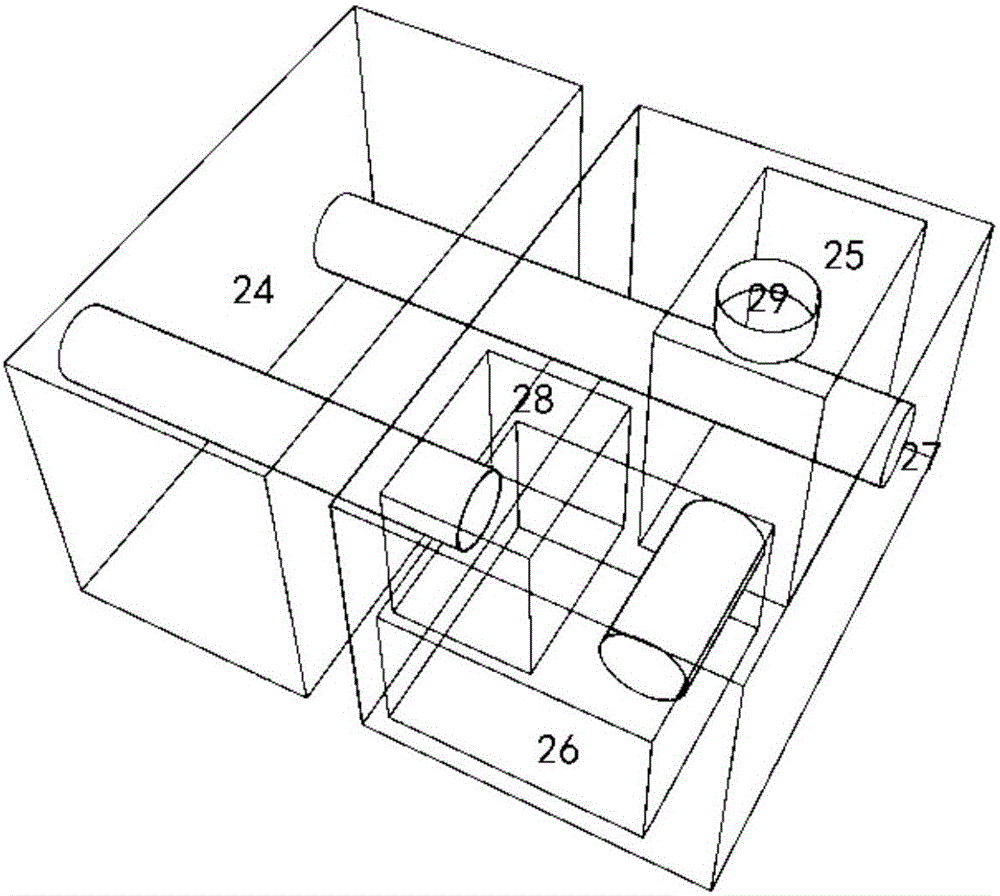

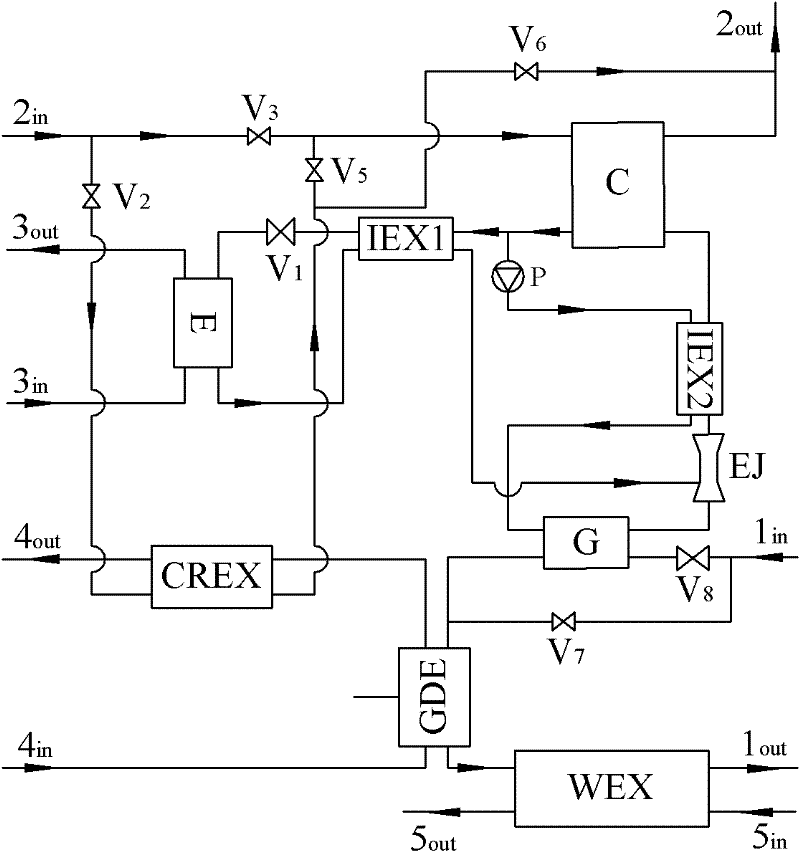

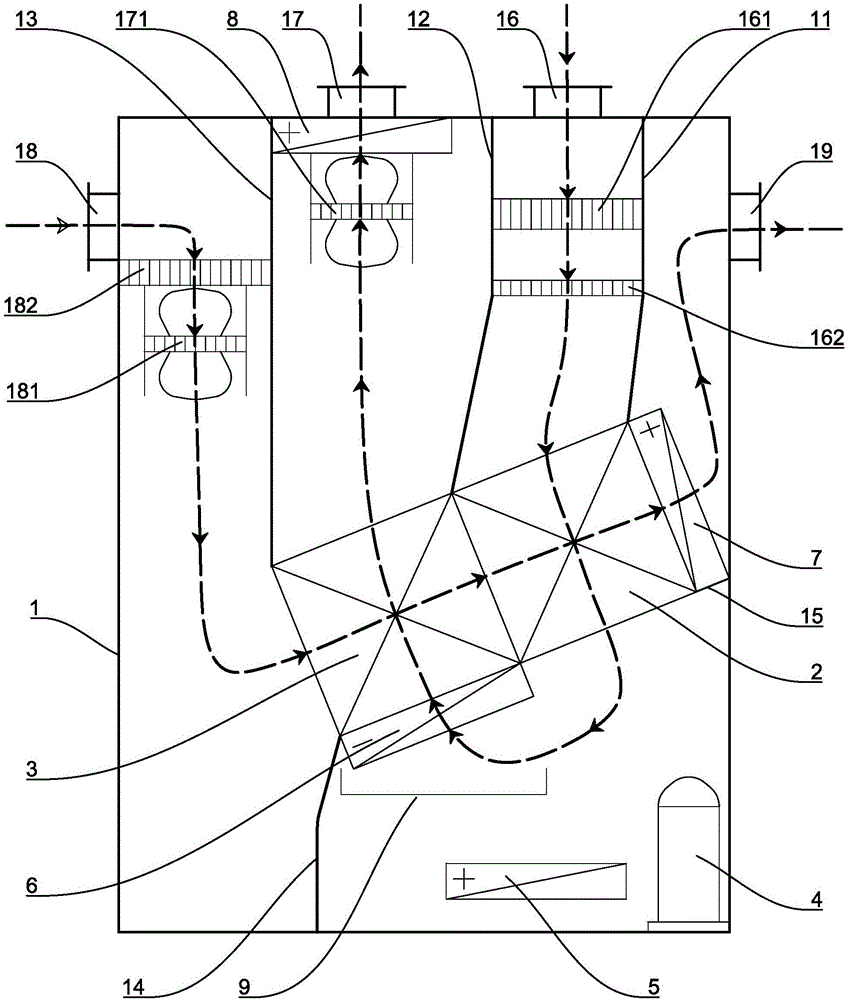

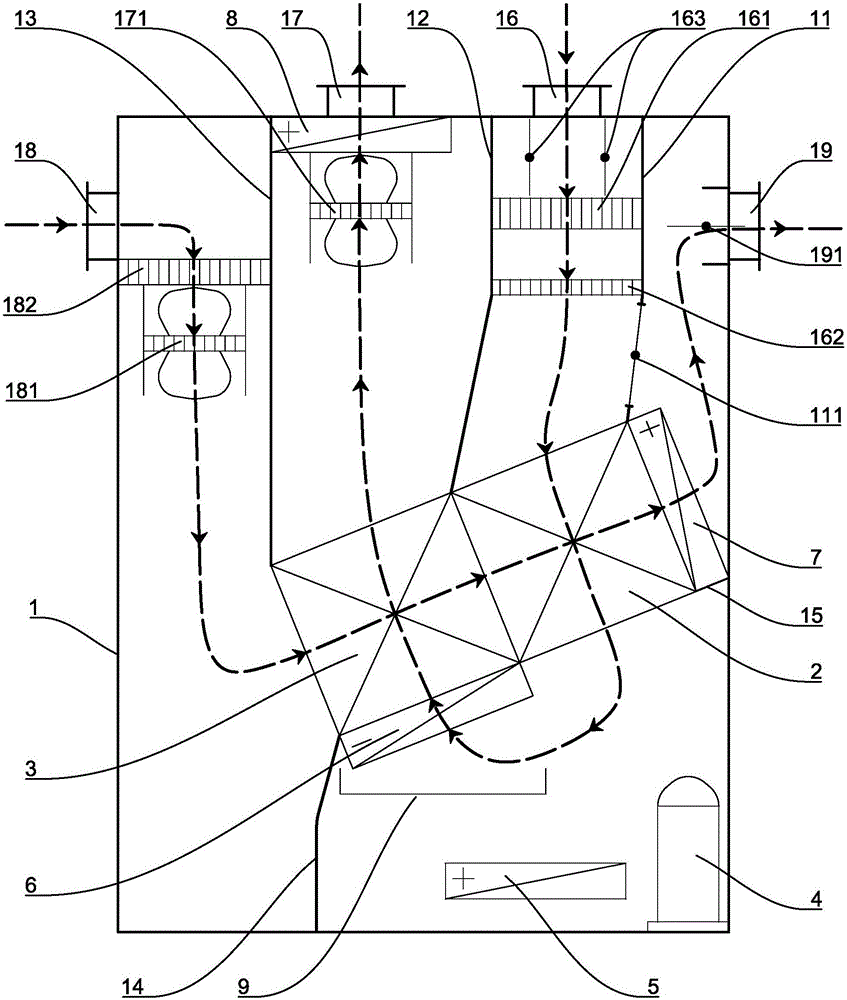

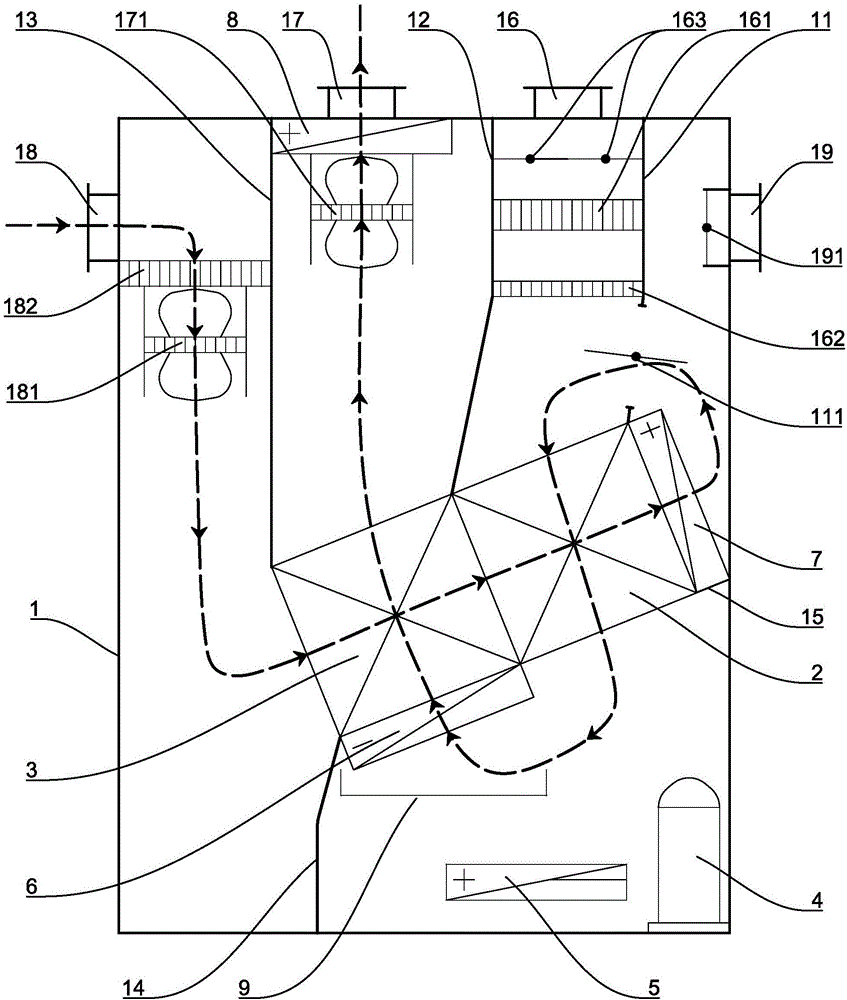

Fresh air handling unit with internal circulation and heat recovery

ActiveCN106839354ASimple structureImprove heat recoveryEnergy recovery in ventilation and heatingMechanical apparatusBusiness efficiencyFresh air

The invention relates to a fresh air handling unit with internal circulation and heat recovery. The fresh air handling unit comprises a shell, a first plate heat exchanger, a second plate heat exchanger, a compressor, a water-cooling condenser and an evaporator, the first plate heat exchanger and the second plate heat exchanger are arranged side by side, a first partitioning plate is arranged between the upper side of the right end of the first plate heat exchanger and the top wall of the shell, a second partitioning plate is arranged between the connecting position of the first plate heat exchanger and the second plate heat exchanger and the top wall of the shell, a third partitioning plate is arranged between the upper side of the left end of the second plate heat exchanger and the top wall of the shell, a fourth partitioning plate is arranged between the lower side of the left end of the second plate heat exchanger and the bottom wall of the shell, and a fifth partitioning plate is arranged between the lower side of the right end of the first plate heat exchanger and the right wall of the shell. A fresh air port and an air delivery port are formed in the top wall of the shell, an air-returning port and an air-discharging port are formed in the left side wall and right side wall of the shell, and the evaporator is arranged on the lower side of the second plate heat exchanger side by side. The fresh air handling unit has the advantages of being simple in structure and high in heat recovery rate and energy efficiency ratio, and can achieve intelligent control and low-energy-consumption operation.

Owner:HUNDRED TECH CO LTD

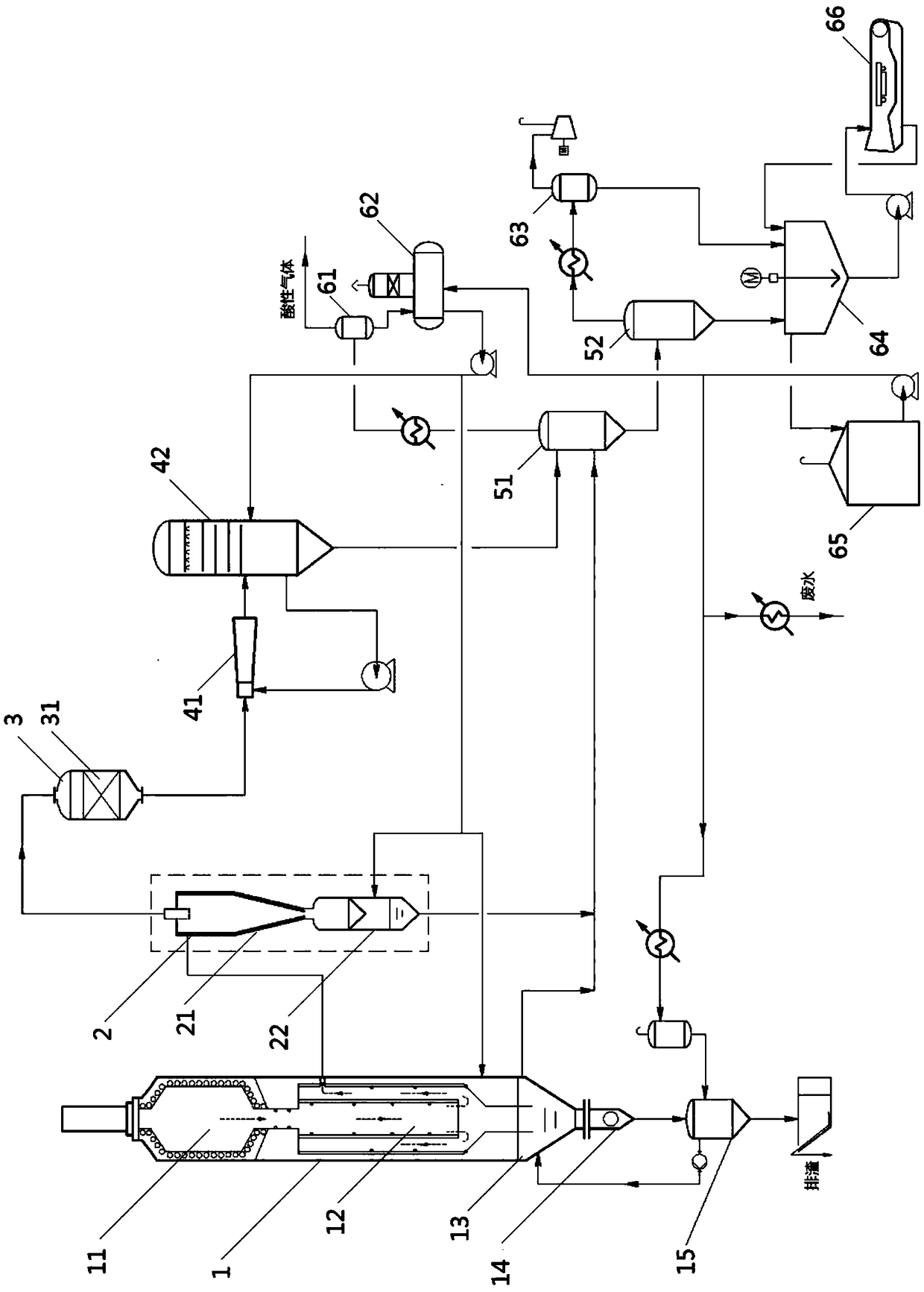

Gasification system and process for high-efficiency recovery of heat energy via wet ash cooling method

PendingCN108913208AImprove heat recovery efficiencyIncrease productionChemical industryGasification processes detailsScrubberDistillation

The invention provides a gasification system for high-efficiency recovery of heat energy via a wet ash cooling method. The gasification system comprises: a gasification furnace, wherein an injection device is arranged on a heat exchange surface in a radiant heat exchange chamber of the gasification furnace, thereby forming a low-temperature zone close to the heat exchange surface and a core high-temperature zone located at the side, away from the heat exchange surface, of the low-temperature zone; a gas-solid separation and wet ash cooling device, which is configured to communicate with the synthesis gas outlet of the gasification furnace; a convection heat exchange device, which is used for recycling the sensible heat of synthesis gas and produces power steam; a gas scrubbing equipment, which comprises a venturi scrubber and a scrubbing tower in series connection; and a black water treatment system, which comprises a primary flash distillation unit and a secondary flash distillation unit in series connection. The invention also provides a gasification process for high-efficiency recovery of heat energy. According to the invention, the radiant heat exchange chamber using a border area temperature control technology can ensure the safety of heat exchange tubes, higher heat recovery efficiency under high radiation intensity, higher saturated steam yield and smaller equipment size.

Owner:BEIJING AEROSPACE MWAY TECH CO LTD

Method for stepwise cooling cement clinker

The invention provides a method for stepwise cooling a cement clinker. The method is characterized by comprising steps of (1) first-stage quick cooling; (2) clinker crushing; and (3) second-stage conventional cooling. The cooling method comprises first-stage cooling and second-stage cooling, and the cooling volume of the two cooling stages can be controlled independently, so that the stability of the system is improved, and air mixing among air openings can be avoided; air entering a first-stage cooler is subjected to heat exchange to form high-temperature hot air which is completely used for supplying secondary and tertiary air for a system, wherein the average temperature after the secondary air and the tertiary air are mixed can be more than 1050 DEG C, so that the heat recovery efficiency of the cooler can be over 85 percent; a crushing step is executed before second-stage cooling, so that the contact area of the clinker and cooling air in a second-stage cooler can be increased, the air entering the second-stage cooler is only 0.6-0.8Nm<3> / kg.cl, and the air volume is remarkably reduced; furthermore, the temperature of formed hot air is remarkably increased, so that caloric content in the clinker is recycled as much as possible; and the total cooling air volume in the two cooling stages can be controlled under 1.5Nm<3> / kg.cl, and the total air volume is remarkably reduced.

Owner:SINOMA TECH & EQUIP GRP

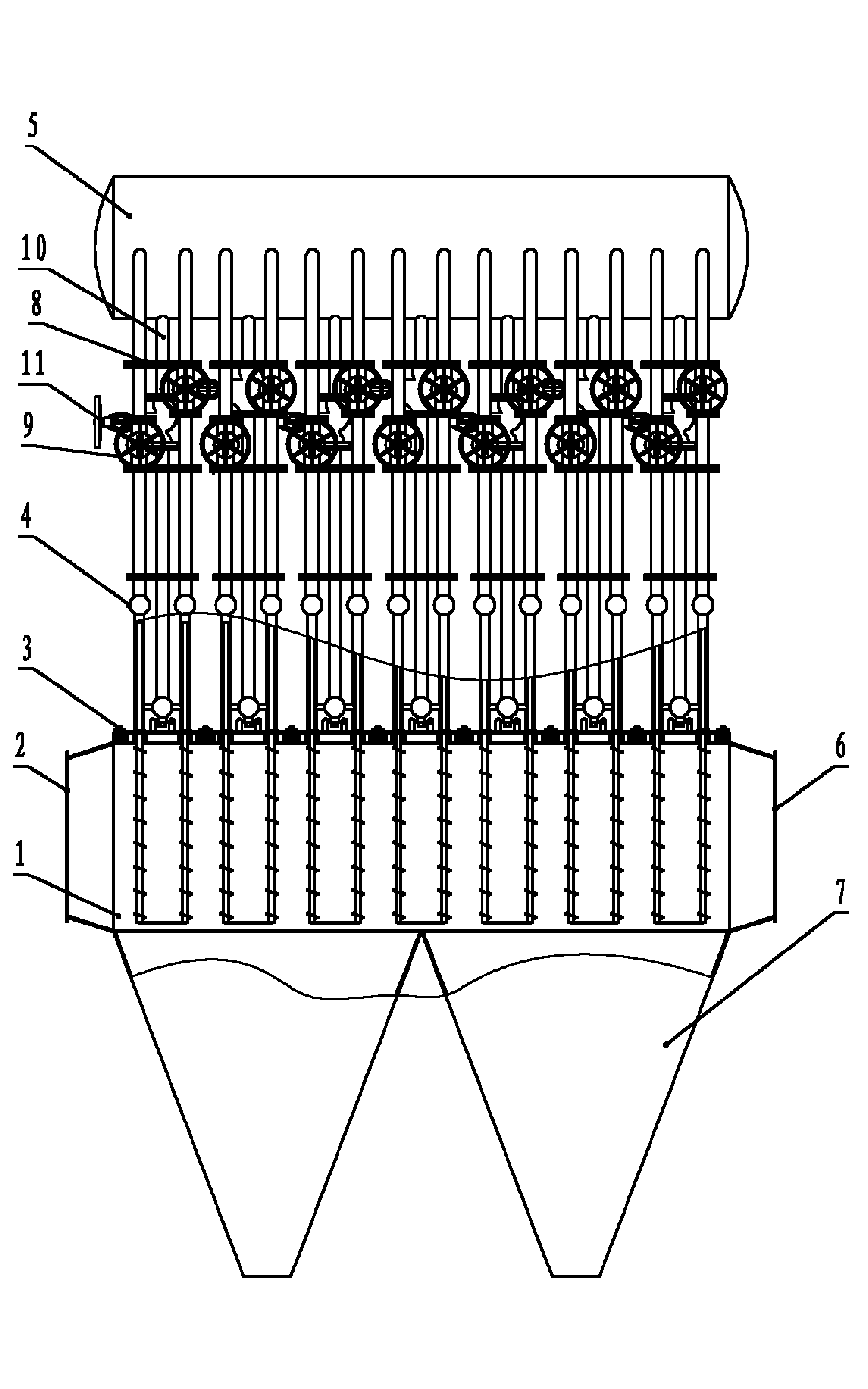

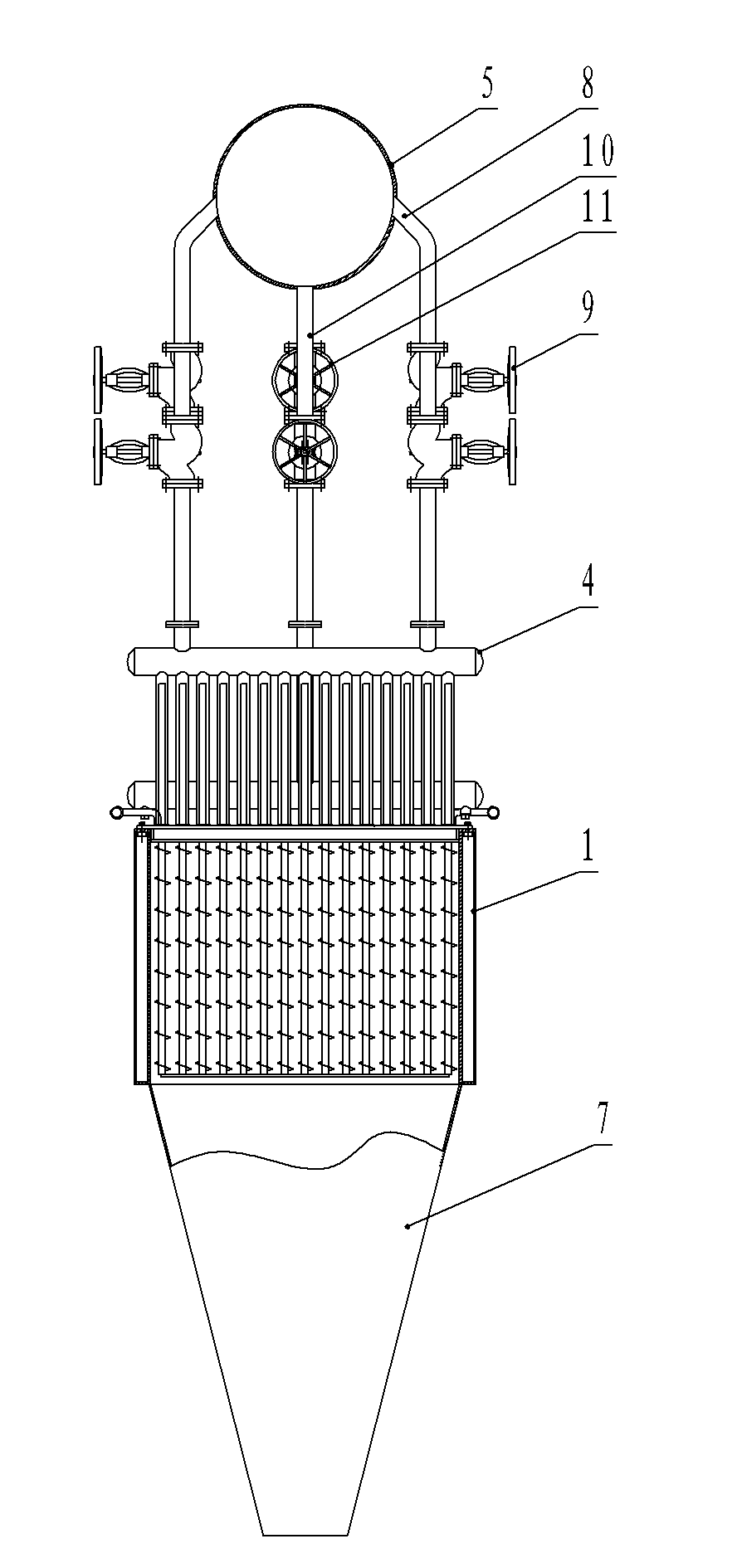

Assembly type heat-pipe steam generator of kiln furnace

InactiveCN102128439AImprove adaptabilitySolve the problem of poor adaptability to fluctuations in working conditionsEnergy industryIncreasing energy efficiencyFlue gasEngineering

The invention discloses an assembly type heat-pipe steam generator of a kiln furnace; a plurality of groups of heat-pipe heat-exchanging assemblies are installed in a smoke box; each group of heat-pipe heat-exchanging assemblies is formed by fixedly connecting a movable top plate of the smoke box as well as a plurality of heat pipes and sleeve assemblies which penetrate on the movable top plate; and each sleeve assembly is formed by connecting sleeves enclosed on the upper part of the heat pipes on the movable top plate; the upper parts of the sleeves are communicated with a steam dome through a connecting pipeline and a gas valve; and the lower parts of the sleeves are communicated with water outlets at the lower part of the steam dome through a connecting pipeline and a water valve. In comparison with the prior art, the assembly type heat-pipe steam generator disclosed by the invention is capable of solving the problems that the traditional heat-pipe steam generator is difficult to repair and replace and has poor adaptability to the fluctuant working conditions of the kiln furnace and high maintenance cost, and is beneficial to improvement of the reliability of the heat-pipe steam generator as well as standardization and normalization of design, production, installation, use, maintenance and other aspects of flue gas waste heat recovery for the kiln furnaces.

Owner:GUANGXI ZHIYUAN ENERGY SAVING & ENVIRONMENTAL PROTECTION EQUIP

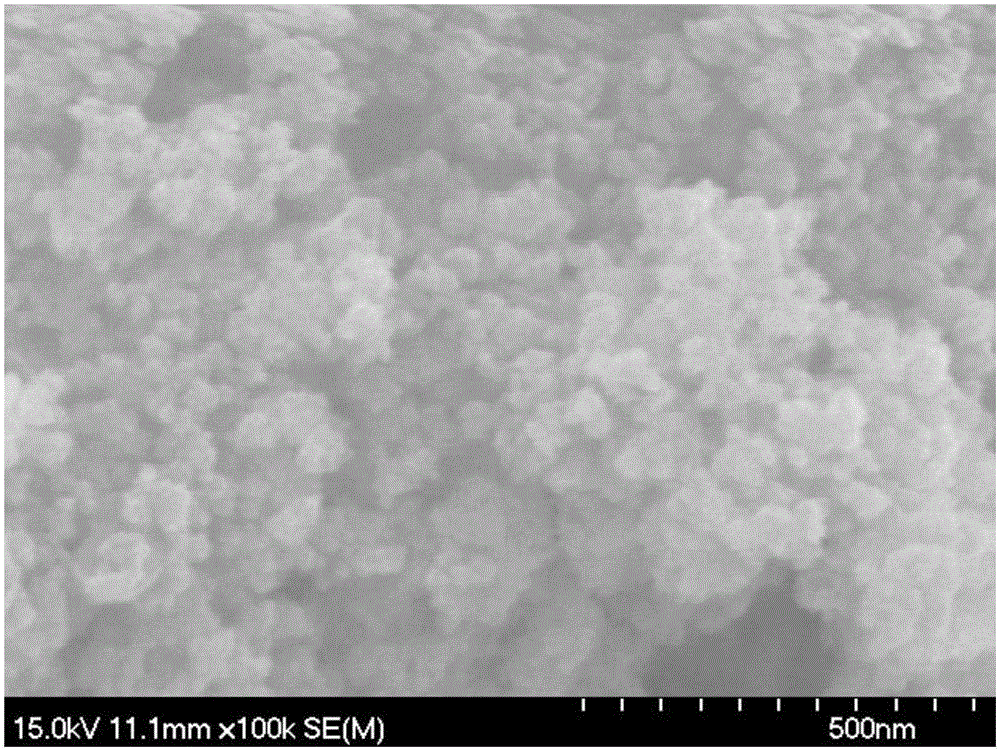

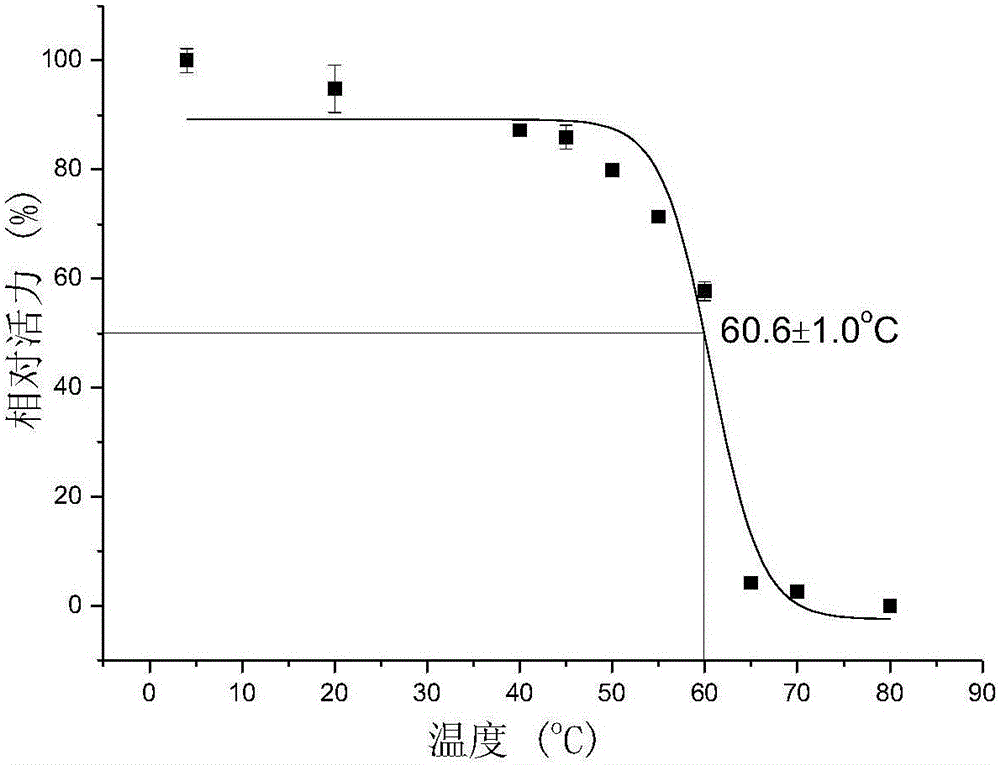

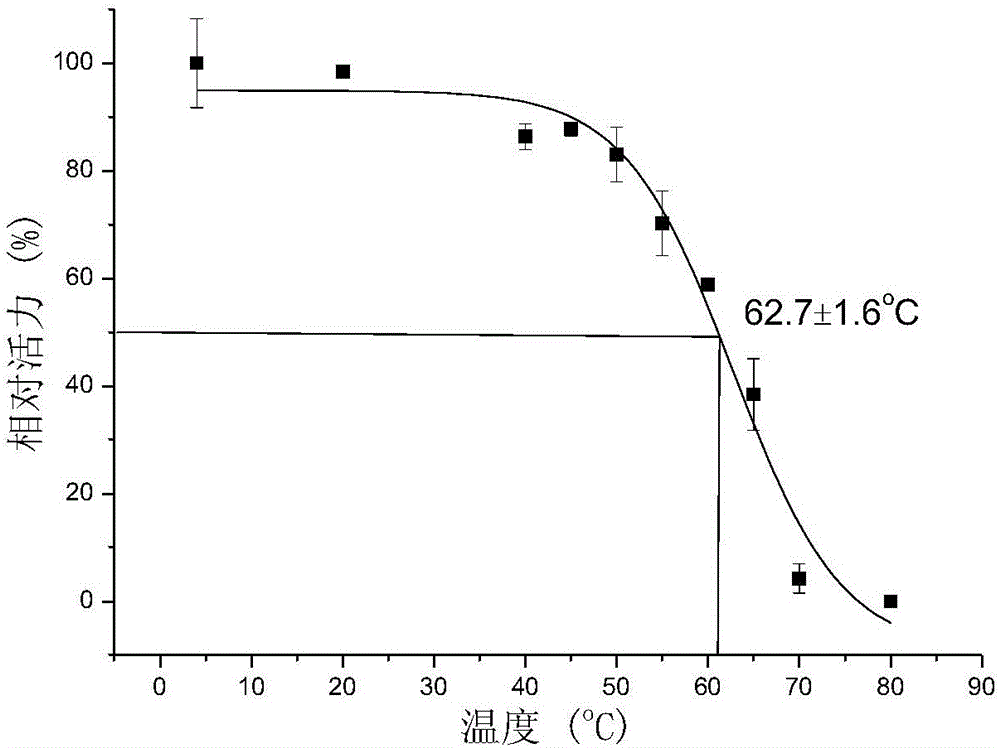

Carboxyl magnetic bead immobilized glutamic acid decarboxylase and preparation method and application thereof

ActiveCN105907742AImprove thermal stabilityImprove heat recoveryMicroorganism based processesFermentationMagnetic beadGlutamate decarboxylase

The invention discloses carboxyl magnetic bead immobilized glutamic acid decarboxylase and a preparation method and application thereof. According to the carboxyl magnetic bead immobilized glutamic acid decarboxylase, carboxyl magnetic beads are adopted as a carrier, glutamic acid decarboxylase is fixed to the surface of the carboxyl magnetic beads through coupling of amidogen and carboxyl, and the base sequence of encoding genes of the glutamic acid decarboxylase is shown as SEQ ID NO.1. The preparation method comprises the following steps that 1, the glutamic acid decarboxylase and the carboxyl magnetic beads are provided; 2, the glutamic acid decarboxylase and the activated carboxyl magnetic beads are mixed, and after the reaction is completed, the carboxyl magnetic bead immobilized glutamic acid decarboxylase is obtained through separation. The carboxyl magnetic bead immobilized glutamic acid decarboxylase has the advantages of being easy to separate, capable of being repeatedly recycled, high in thermal stability, high in operation stability and the like. Compared with free enzymes, half-inactivation temperature of the carboxyl magnetic bead immobilized glutamic acid decarboxylase is improved by 2.1 DEG C, and after 10 times of repeated catalyzing, the activity is still kept at 90.42%.

Owner:上海邦成生物工程有限公司

Thermal recovery system with improved thermal efficiency and thermoelectric combined production system equipped with the thermal recovery system

ActiveCN102345850AEnsure complete combustionReduce lossesMachines/enginesSteam generation plantsCombustion chamberCogeneration

The invention provides a thermal recovery system with improved thermal efficiency and a thermoelectric combined production system equipped with the thermal recovery system. A combustion apparatus includes a cylindrical combustion chamber surrounded by an inner wall. A cooling chamber comprises an intermediate wall spaced from the inner wall. Cooling water flows in and out lower and upper sides of the intermediate wall, to cool the inner wall by the cooling water that flows into a space formed between the inner and intermediate walls of the cooling chamber. A lateral combustion air supply chamber comprises an outer wall spaced from an outer side of the intermediate wall. Combustion air is supplied at an upper side of the outer wall to thereby make the air in a tangential direction with respect to the cylindrical outer wall turn and fall in a space formed between the intermediate wall and the outer wall, so that the combustion air is supplied to the combustion chamber via an opened lower portion of the lateral combustion air supply chamber.

Owner:创意能源控股有限公司

Gasification system and technology for efficient heat recovery

PendingCN108795500AImprove heat recoveryEnsure safetyChemical industryGasification processes detailsThermal energyDistillation

The invention provides a gasification system for efficient heat recovery. The system comprises a gasification furnace, gas-solid separation and ash cooling equipment, a convective heat exchange device, gas scrubbing equipment and a black water treatment system, wherein a spraying device is arranged on a heat transfer surface in a radiation heat transfer chamber of the gasification furnace, so as to form a lower temperature zone close to the heat transfer surface and a core high temperature zone on one side, far from the heat transfer surface, of the lower temperature zone; the gas-solid separation and ash cooling equipment is communicated with a synthesis gas outlet of the gasification furnace; the convective heat exchange is used for recycling sensible heat of synthesis gas and producingpower steam; the gas scrubbing equipment comprises a venturi scrubber and a scrubbing tower which are connected in series; the black water treatment system comprises a primary flash distillation device and a secondary flash distillation device. The invention further provides a gasification technology for efficient heat recovery. The scheme adopts a radiation heat exchange chamber adopting a borderland temperature control technology, not only guarantees the safety of a heat exchange tube, but also guarantee high heat recovery efficiency, higher yield of saturated steam and smaller equipment volume under high radiation intensity.

Owner:BEIJING AEROSPACE MWAY TECH CO LTD

Two-stage bathing wastewater recovery device

InactiveCN102865662AImprove heat recoveryTo achieve the purpose of preparing bath waterFluid heatersDevice formWastewater

The invention discloses a two-stage bathing wastewater recovery device. An input port I of a heat exchanger is connected with a water collection tank containing bathing wastewater, an output port I of the heat exchanger is connected with an input port IV of an evaporator, an output port IV of the evaporator is connected with a drain outlet, a condenser is mounted in a heat collection case, and the evaporator, a compressor, the condenser and a throttling device form a two-stage heat extraction pipeline. The two-stage bathing wastewater recovery device is high in heat recovery rate, is efficient and energy-saving, safe and reliable, and can be used for houses, units, bath centers and the like.

Owner:泰安阿拉斯佳空调有限公司

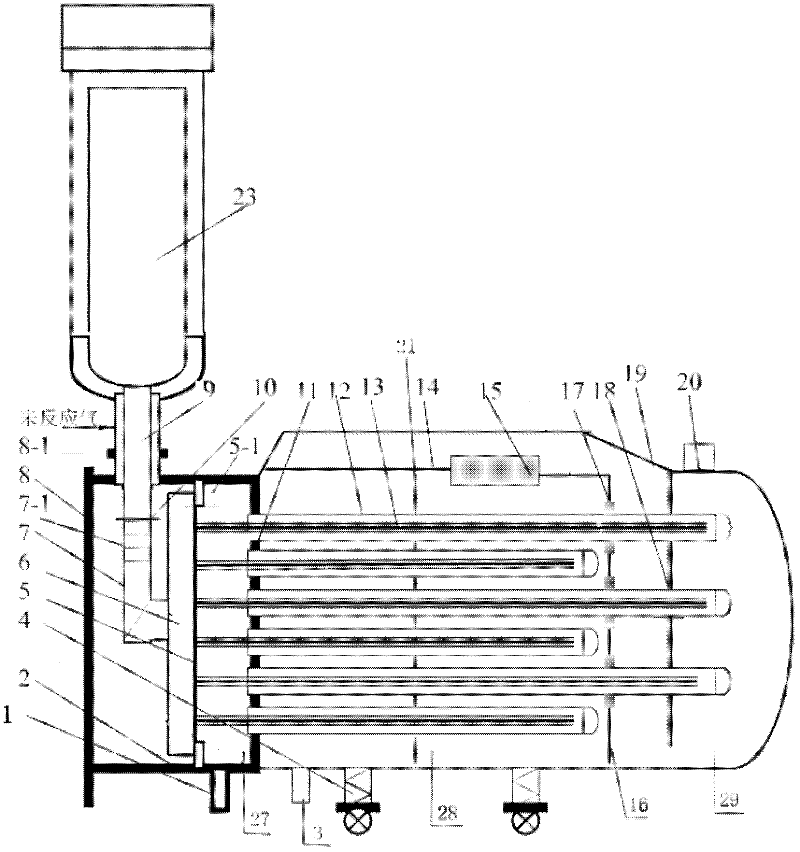

A reactor waste heat boiler steam superheater three-in-one device

InactiveCN102261638AAvoid deformationReduce areaExothermal chemical reaction heat productionSteam generation plantsCold airTemperature stress

A reactor waste heat boiler steam superheater three-in-one device is a chemical high-temperature reaction heat recovery and utilization device; it includes a high-pressure cylinder, a saturation section and a superheating section in the waste heat boiler shell. The saturated section has a water inlet, and the superheated section has a superheated steam outlet; the saturated section and the superheated section are connected through a demister wire mesh, and there is a gas distribution box and a cold air chamber in the high-pressure cylinder at one end of the waste heat boiler shell, and the reaction hot gas enters the three sets through the gas distribution box. After the tube is cooled, it gathers at the outlet of the cold air chamber; the longer three sleeves pass through the saturated section and extend to the superheated section, and the three shorter sleeves are located in the saturated section; one end of the outer sleeve is welded to the thick tube plate at the end of the high pressure section; through a special structure to avoid The temperature difference of the same tube plate will cause temperature difference stress and cause deformation and damage; the device can significantly save valuable materials and investment, and can improve heat recovery rate.

Owner:HUNAN ANCHUN ADVANCED TECH

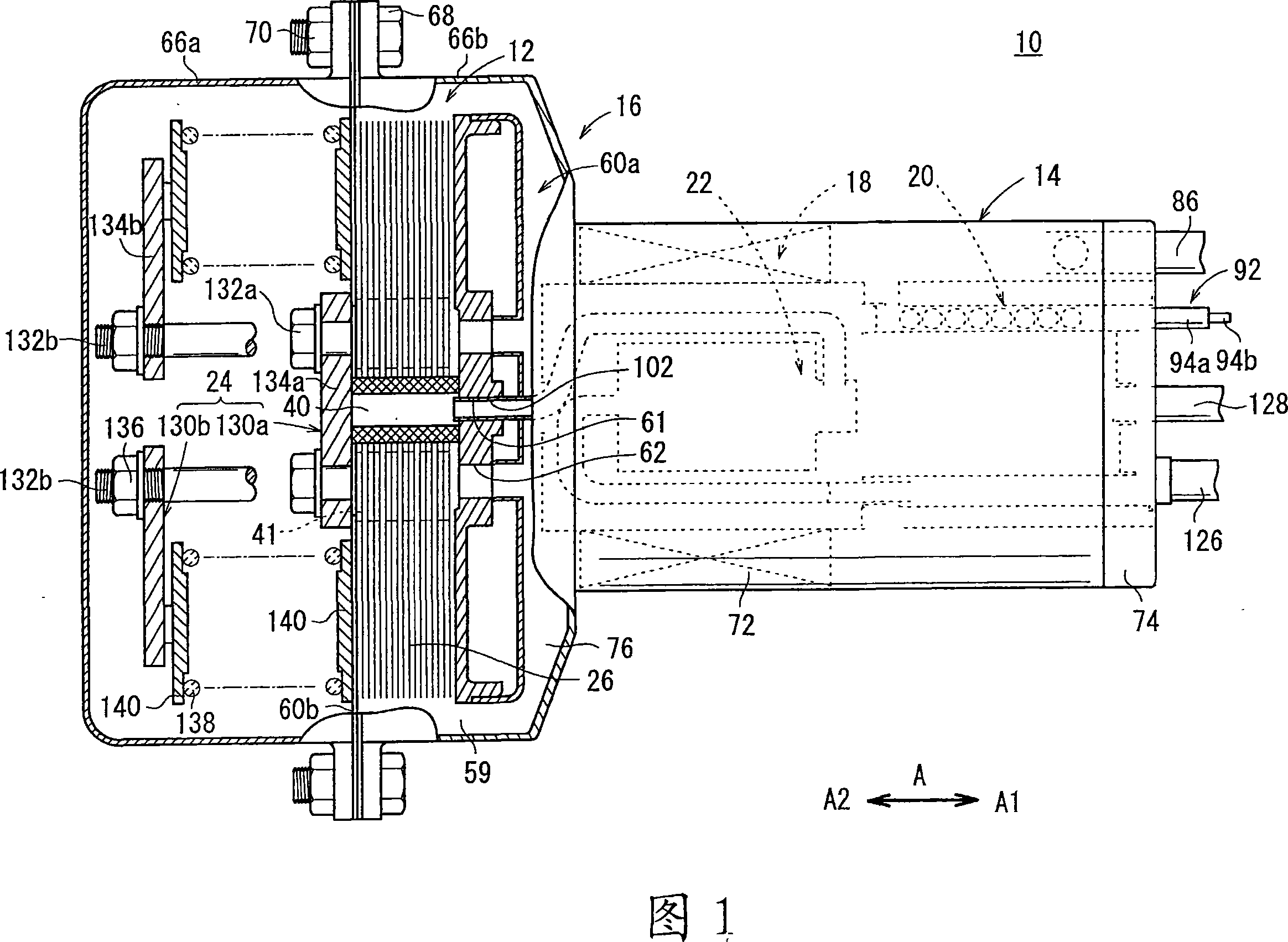

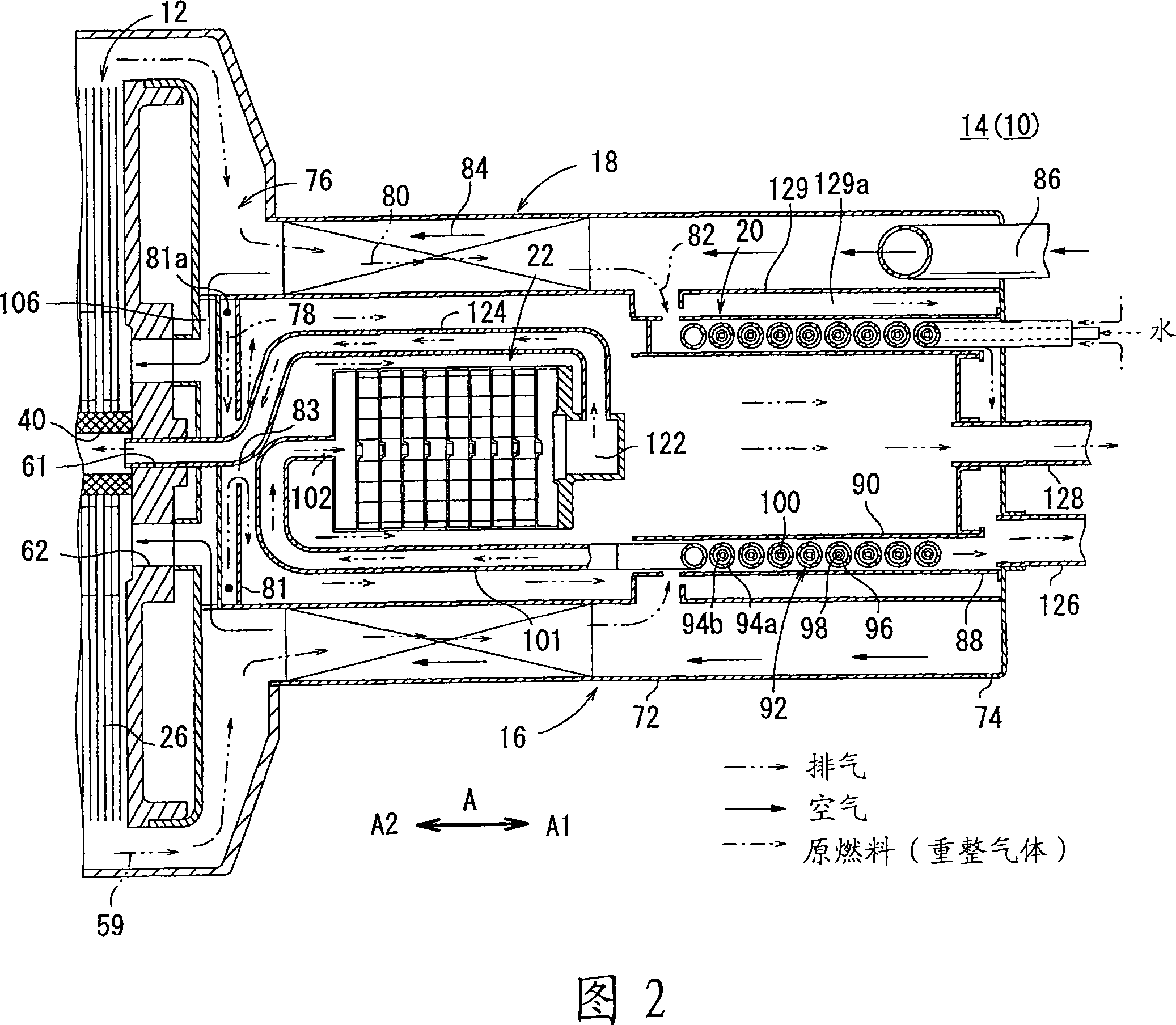

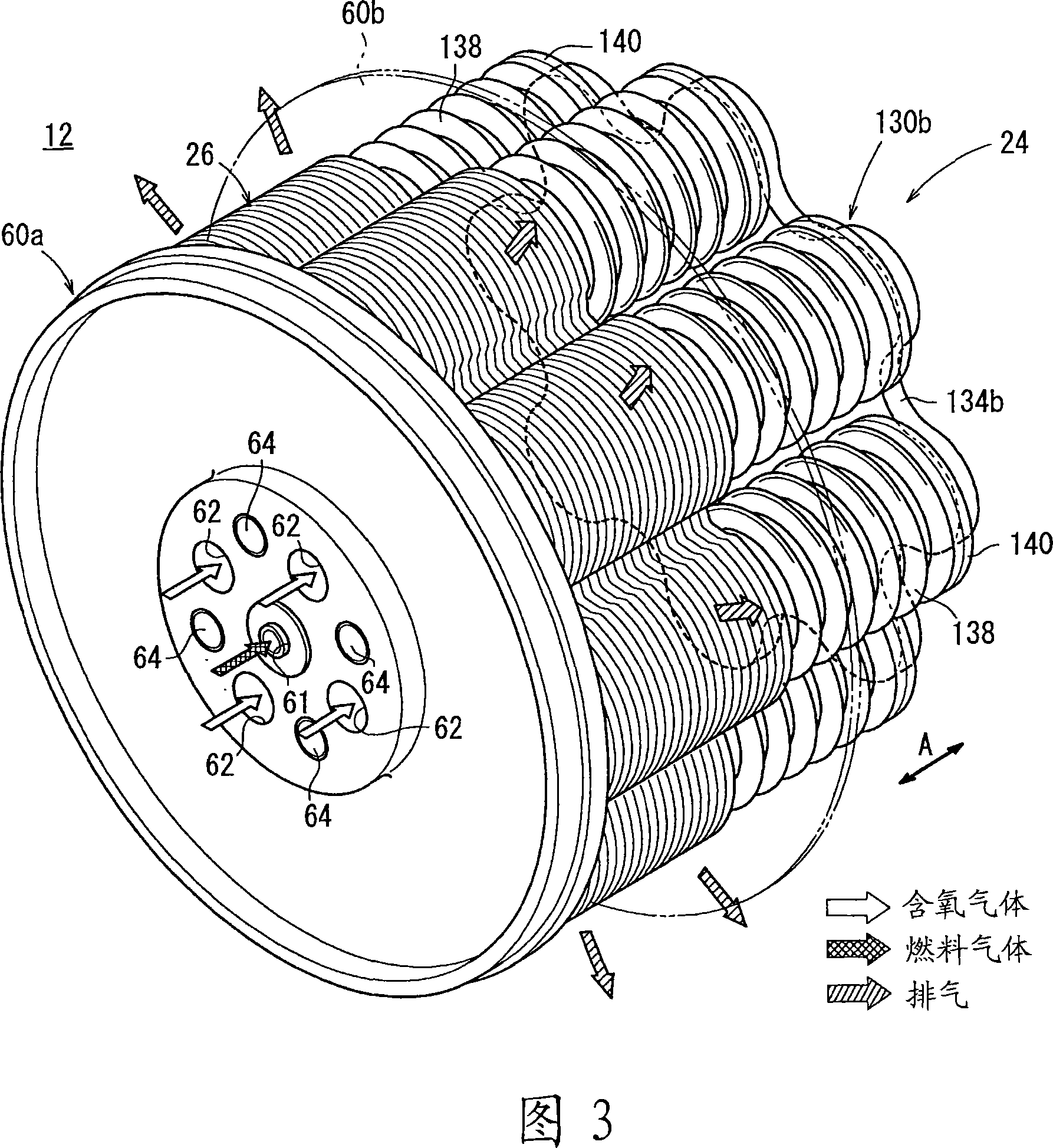

Fuel cell system

A fluid unit includes a heat exchanger, an evaporator, and a reformer. The fluid unit is provided in a third case unit. In the third case unit, an exhaust gas channel as a passage of an exhaust gas is provided. The exhaust gas channel includes a first channel for supplying the exhaust gas to the reformer, a second channel for supplying the exhaust gas to the heat exchanger, and a third channel connected to the downstream side of the second channel for supplying the exhaust gas to the evaporator. The exhaust gas supplied to the evaporator has the lower temperature due to the heat exchange in the heat exchanger.

Owner:HONDA MOTOR CO LTD

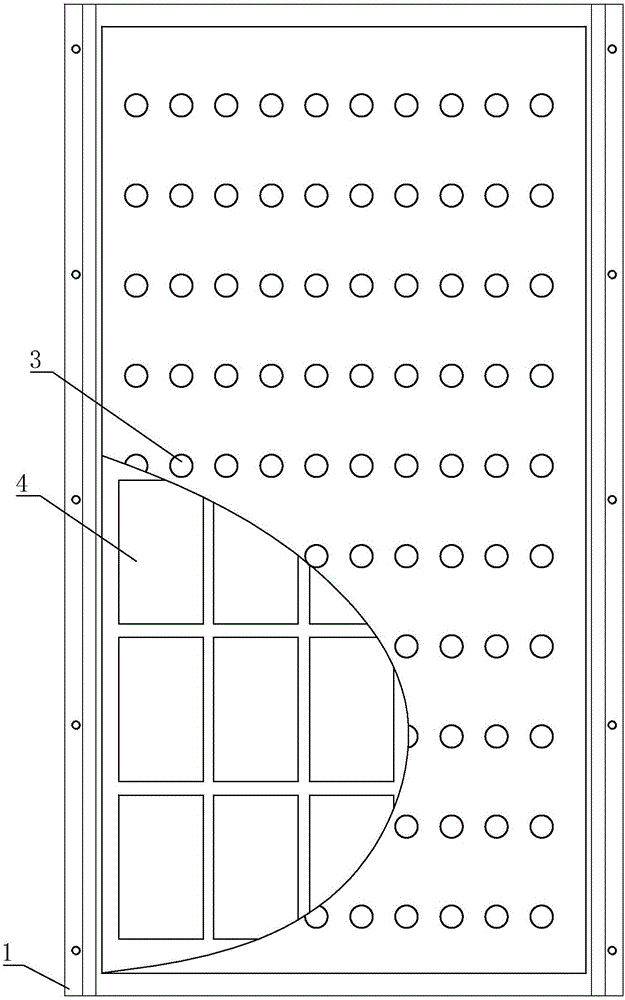

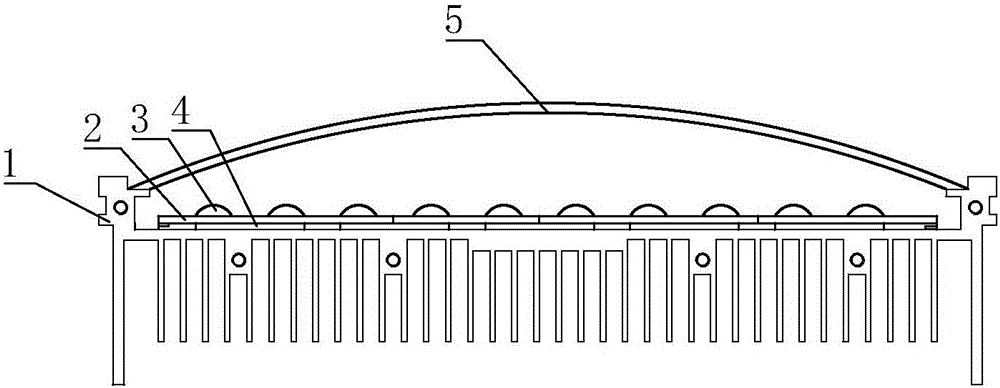

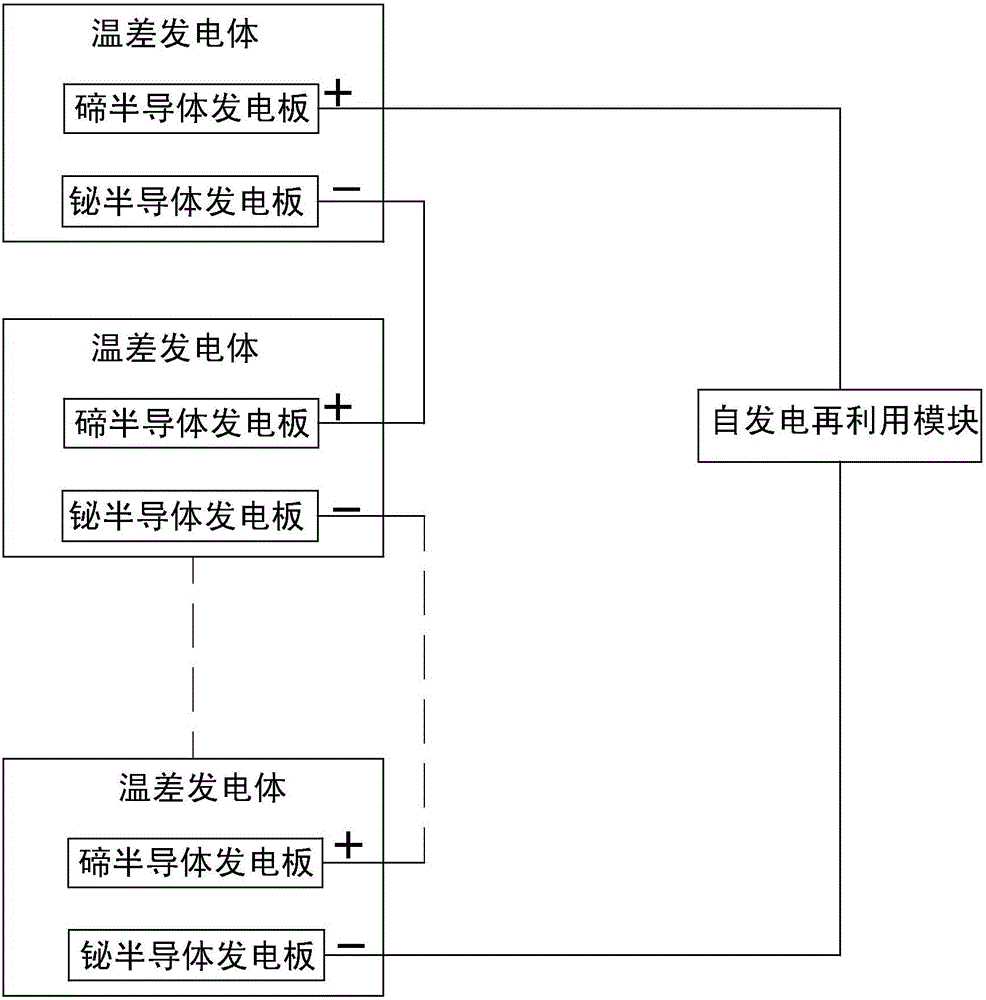

Self-generating LED lamp and application thereof

InactiveCN105782890AImprove cooling effectGuaranteed service lifeElectrical apparatusLighting heating/cooling arrangementsEngineeringAluminum substrate

The invention discloses a self-generating LED lamp and application thereof. The self-generating LED lamp comprises a heat radiator, an LED drive circuit, thermoelectric power generating bodies and a self-generating recycle module, wherein each thermoelectric power generating body comprises a heat power generating plate and a cold power generating plate; the heat power generating plates are in contact with an aluminum substrate; the cold power generating plates are in contact with the heat radiator; after the contact, heat energy generated from luminescence of LED light sources is transferred to the hot power generating plates of the thermoelectric power generating bodies; as the cold power generating plates are in contact with the heat radiator, a Seebeck effect is generated between the hot power generating plates and the cold power generating plates of the thermoelectric power generating bodies, and an electric field is generated between the hot power generating plates and the cold power generating plates to form electromotive force; then, both the hot power generating plates and the cold power generating plates are electrically connected with the self-generating recycle module to form a loop, so as to fulfill the purpose of energy conservation; and part of the heat energy can be recovered by the thermoelectric power generating bodies, so that the heat radiating effect is excellent and the service life of the LED light sources is guaranteed. According to the main application of the self-generating LED lamp, voltage between the hot power generating plates and the cold power generating plates is utilized for operation, and power generated by the self-generating LED lamp can be widely utilized.

Owner:WEIFANG MINGRUI OPTOELECTRONICS TECH

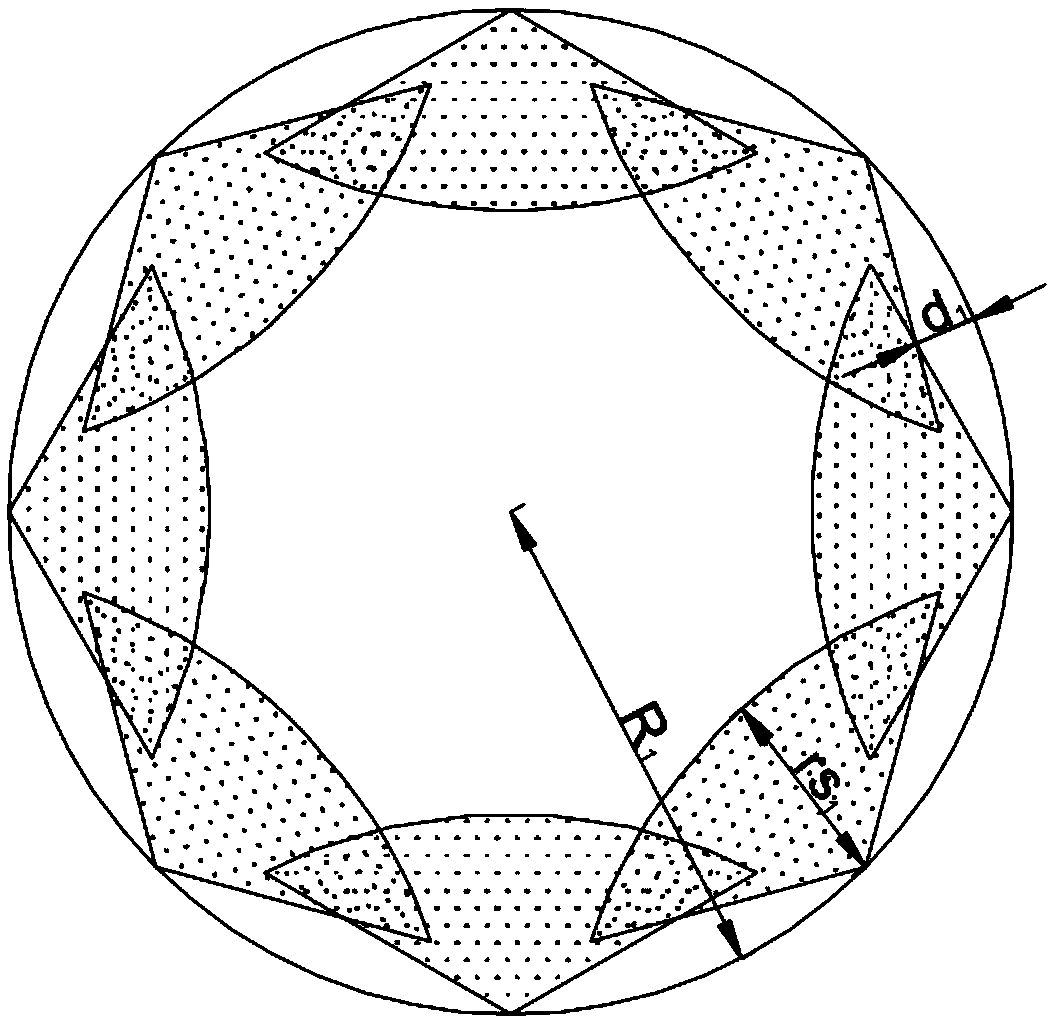

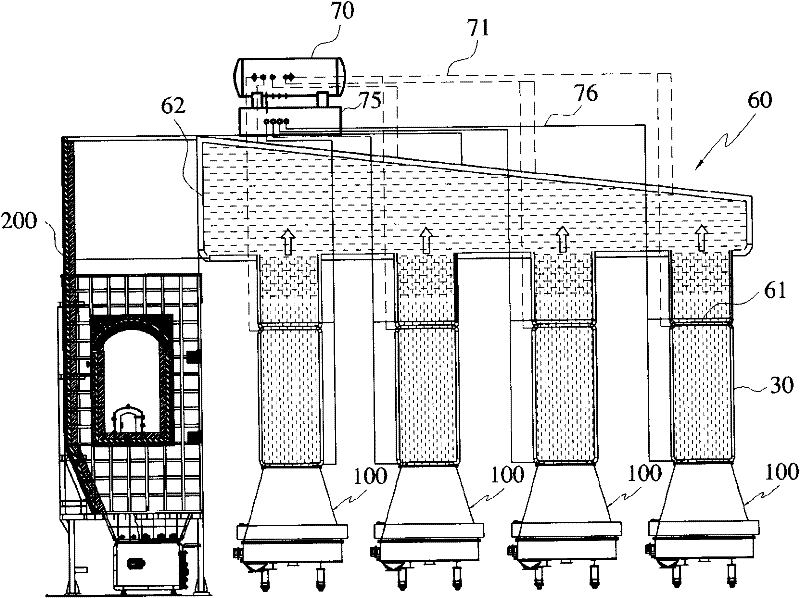

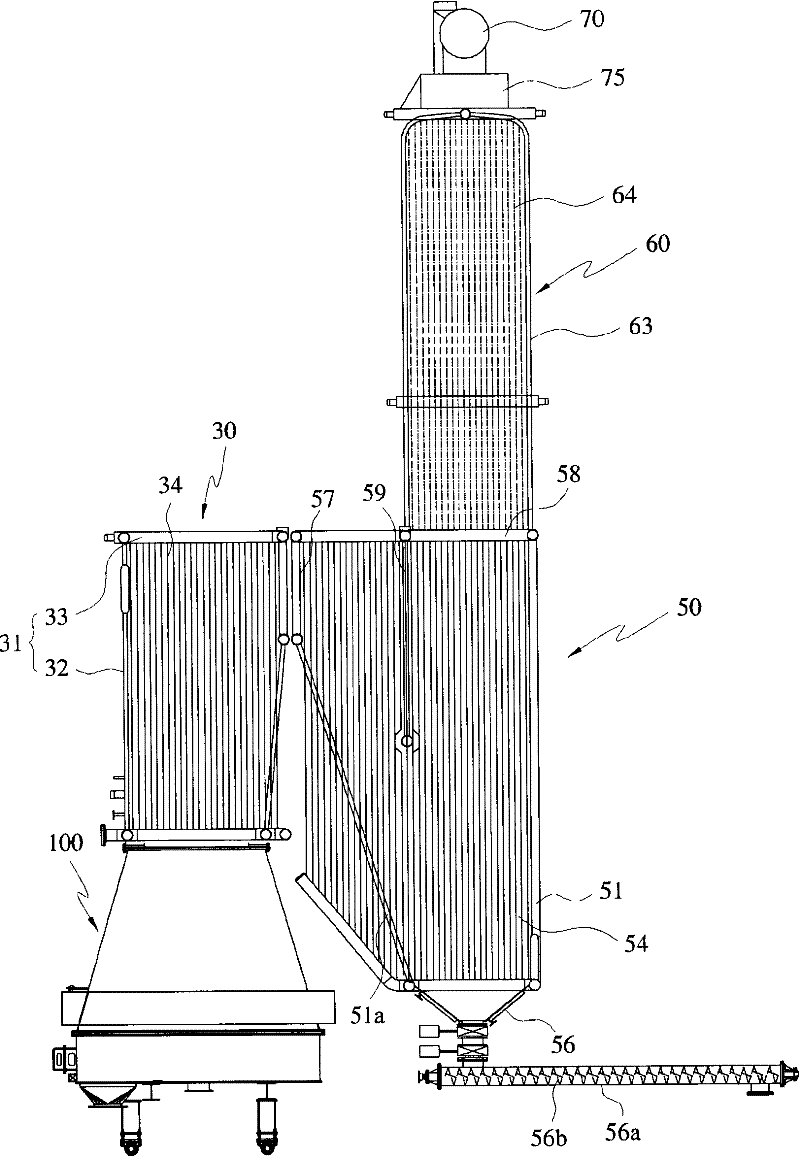

Device for recovering waste heat of blast furnace slag by dry granulation and method for recovering waste heat of blast furnace slag

ActiveCN105112577BImprove heat recoveryHigh heat recovery in the blast furnace processIncreasing energy efficiencyRecycling and recovery technologiesRecovery methodHeat losses

Provided is a device and method for dry granulation recovery of blast furnace slag waste heat, which belongs to the technical field of metallurgical slag heat energy recovery. The device is installed between the blast furnace and the hot blast furnace and consists of a granulating kiln used for dry granulation of blast furnace slag and its accessory piping devices as well as a matching dust collector. Among them, the granulating kiln and its ancillary pipeline devices include: blower, slag introduction tank, upper sealing valve, slag storage tank, sliding water port, lower sealing valve, relief valve, pressure equalizing valve, granulating kiln gas output pipeline, low-temperature granulation Slag discharge pipe, granulating kiln cold air pipe, slag nozzle pipe and granulator. The granulating kiln body is equipped with a granulating area and a heat exchange area. This device can fully recover the latent heat of solidification of molten slag and the sensible heat of high-temperature slag particles. In addition, the hot air generated by waste heat recovery is directly supplied to the blast furnace hot blast stove, which has the advantages of short material transportation distance, low process heat loss, high heat recovery rate, basically no secondary power consumption, and low additional investment.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com