A reactor waste heat boiler steam superheater three-in-one device

A waste heat boiler and reactor technology, which is applied to steam superheating, steam generating devices, heating devices, etc., can solve the problems of large temperature difference between tube sheets, large thermal stress, deformation and damage, etc., so as to improve the heat recovery rate and reduce the floor space. , The effect of convenient inspection and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

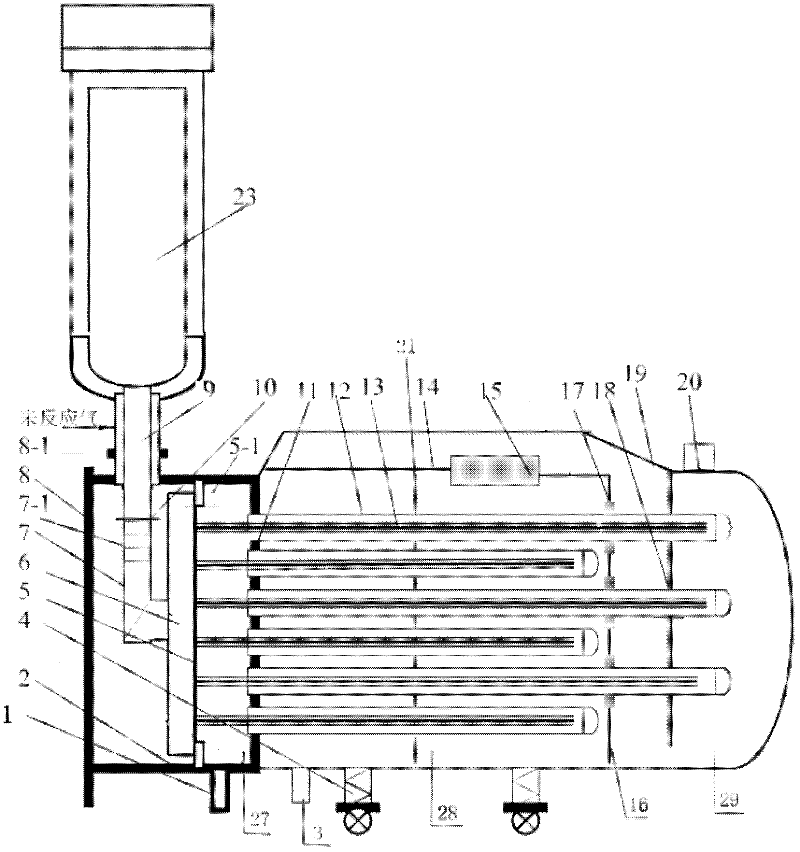

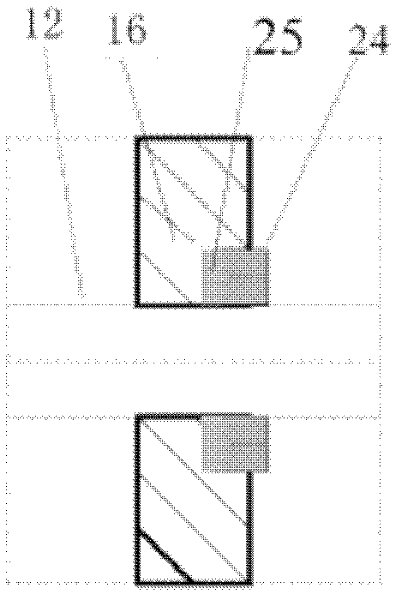

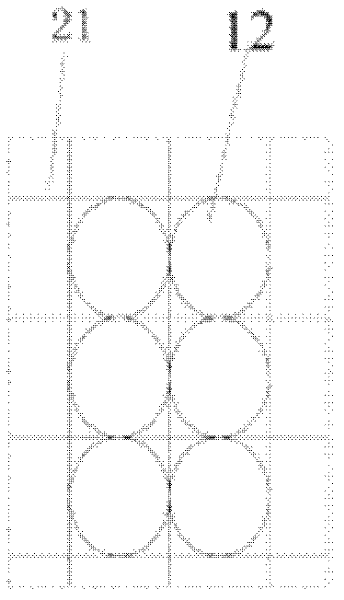

[0036] Embodiment 1: as figure 1As shown, the reactor waste heat boiler steam superheater three-in-one device includes a reactor 23 and a waste heat boiler shell 19; one end of the waste heat boiler shell 19 is provided with a high-pressure section, and the high-pressure section includes a high-pressure flange at the outer end The high-pressure cylinder 2 of the cover 8, the other end of the high-pressure cylinder 2 is a thick tube plate 11 adjacent to the shell 19 of the waste heat boiler; The gas distribution box cover on one side communicates with the cavity of the gas distribution box 6, and the other end of the connecting pipe 7 communicates with the reaction gas outlet of the reactor 23, and the other side of the gas distribution box 6 is a thin tube sheet 5; the thin tube sheet 5 and the thick tube plate 11 at the other end of the high-pressure cylinder 2, the cavity of the high-pressure cylinder is a cold air chamber 27, and the cold air chamber 27 is provided with a r...

Embodiment 2

[0045] Embodiment 2: The structure of the device is the same as in Embodiment 1. It is used in the ammonia synthesis industry. The outlet gas temperature of the synthesis tower (reactor 23) is 455-460 ° C. It enters the gas distribution box 6 from the high-pressure end of the device of the present invention, and turns to enter the interior. Double casing 13, such as figure 1 Shown from left to right, turn to the right end, enter outer sleeve 12, in this outer sleeve as figure 1 Shown from right to left, arrive at the cold air chamber 27 at the left end, the temperature drops to 270~280°C, and then send out the device from the gas outlet 1 at the lower end of the cold air chamber 27.

[0046] The preheated desalted water enters the waste heat boiler (saturated section 28) from the water inlet 3, and is heated to generate saturated steam with a pressure of 3.9-5.0Mpa and a temperature of 250-265°C, which rises through the defoaming screen 15 and enters the right-hand overheating...

Embodiment 3

[0050] Embodiment 3: The device structure is the same as that in Embodiment 1. It is used in the ammonia synthesis industry. The outlet gas temperature of the synthesis tower (reactor 23) is 370-395 ° C. It enters the gas distribution box 6 from the high-pressure end of the device of the present invention, and turns to enter the interior. Double casing 13, such as figure 1 Shown from left to right, turn to the right end, enter outer sleeve 12, in this outer sleeve as figure 1 Shown from right to left, enter the cold air chamber 27 at the left end, the temperature drops to ~270°C, and then send out the device from the gas outlet 1 at the lower end of the cold air chamber 27.

[0051] The preheated desalted water enters the waste heat boiler (saturated section 28) from the water inlet 3, and is heated to generate saturated steam with a pressure of 3.9Mpa and a temperature of 250°C, which rises through the defoaming screen 15 and enters the overheating section 29 at the right end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com