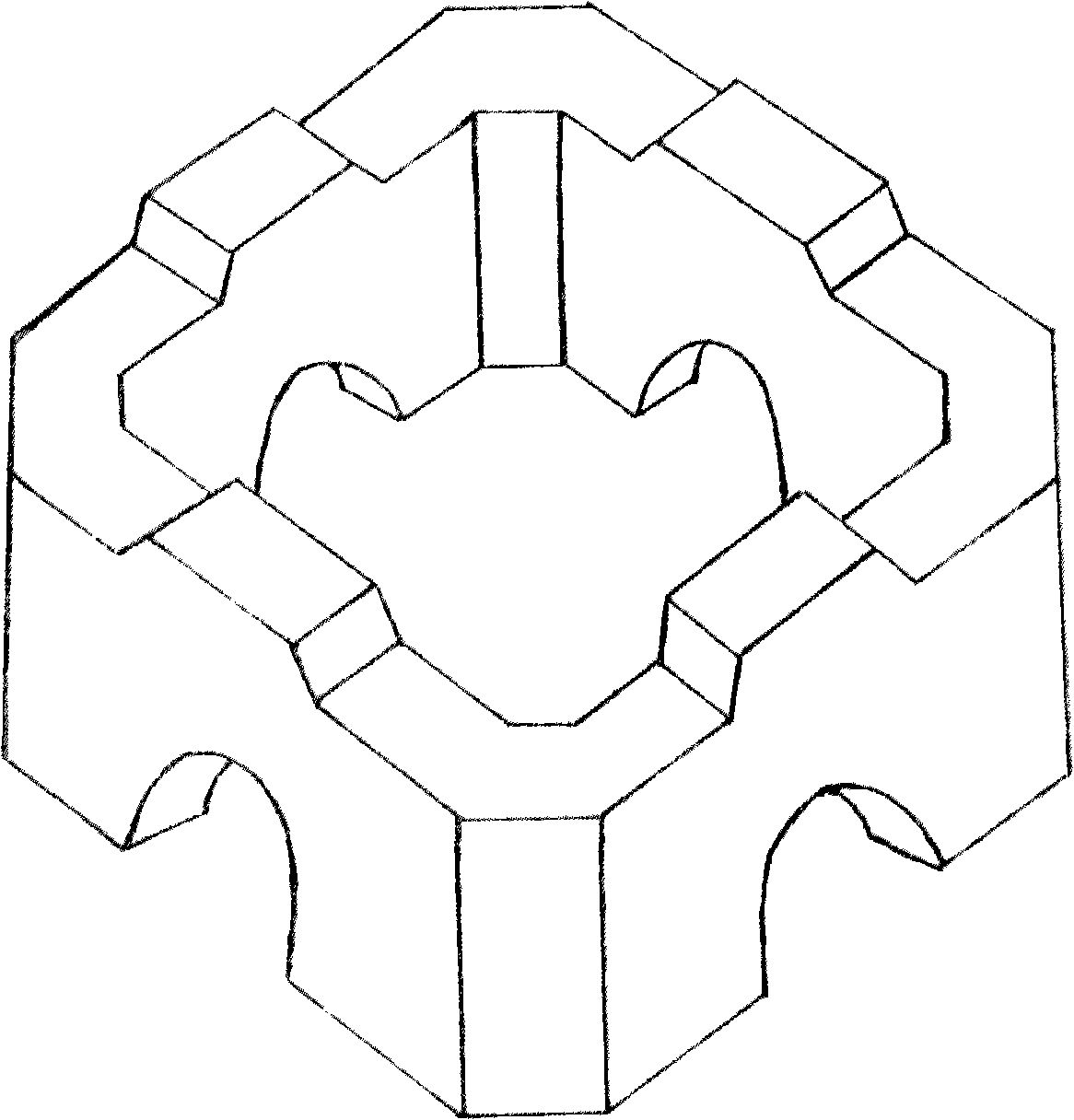

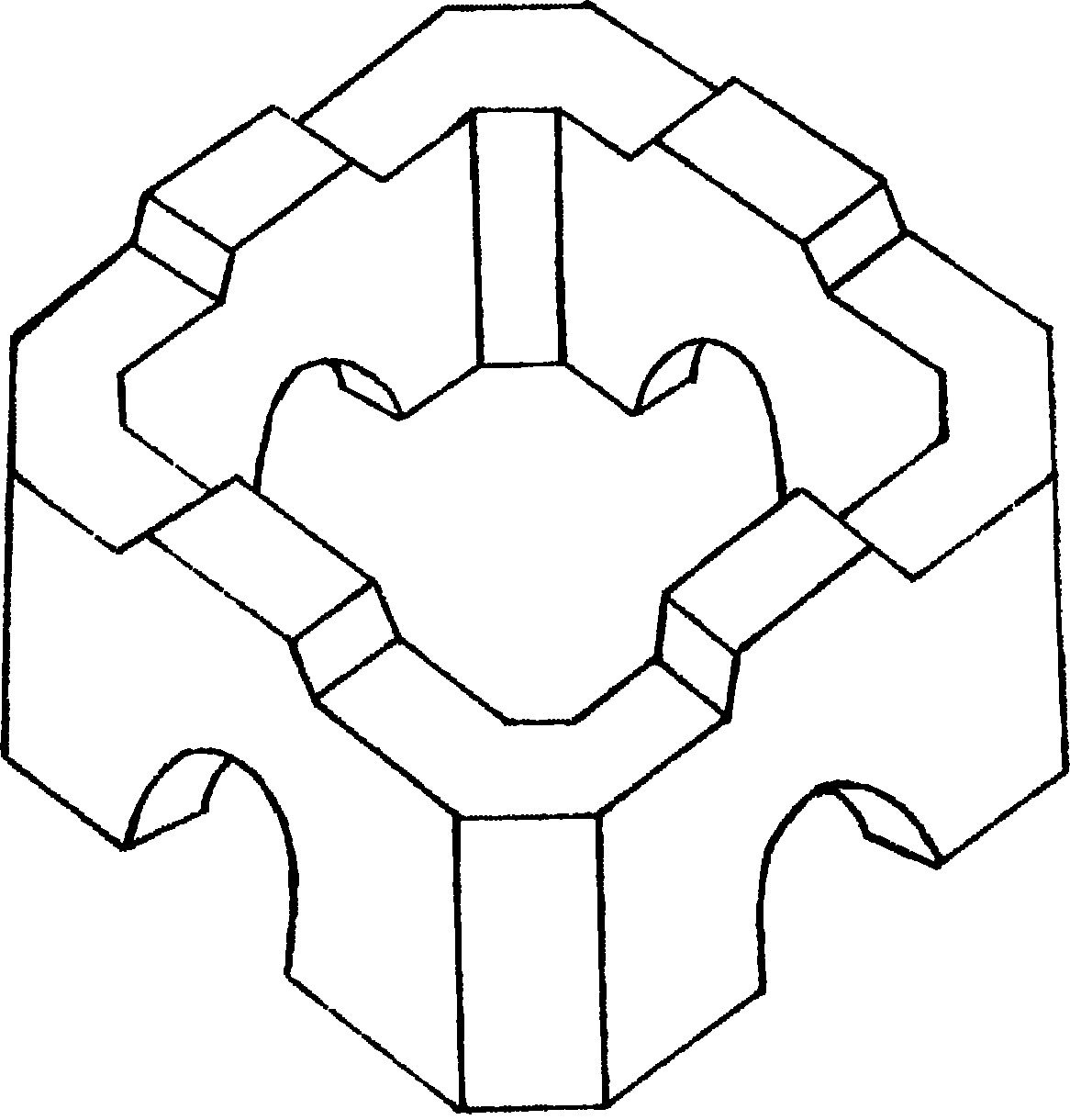

Fused cast alpha-beta alumina cylindrical brick and production method thereof

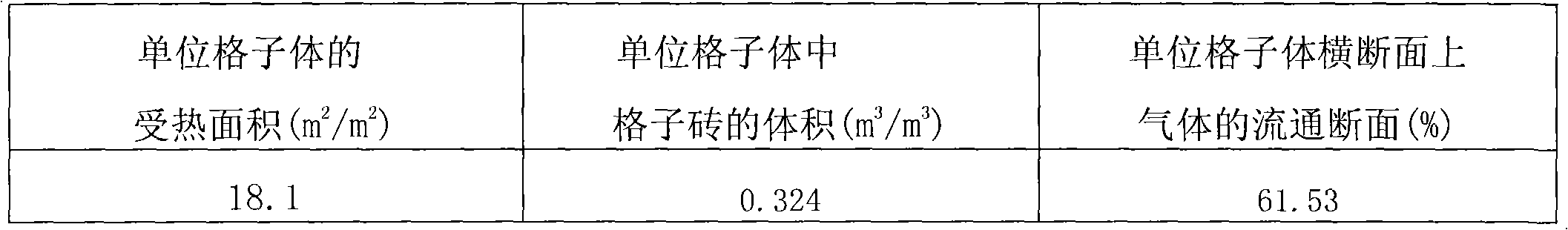

A β-alumina, cylindrical brick technology, applied in the field of refractory materials, can solve the problems of low glass phase content, product cracking, low yield, etc., to achieve good corrosion resistance and thermal shock resistance, high temperature resistance and resistance to deterioration. The effect of strong performance and large heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Ingredients: The raw material composition contains 15% recycled clinker, and the balance is raw material of fused cast α-β alumina brick formula with the same material as the clinker, that is, industrial alumina 81.25%, additives: fine quartz sand 0.85%, sodium carbonate 2.90%.

[0023] The preparation process includes batching, mixing, electric furnace melting, cooling annealing and cold working.

[0024] The molding sand is mixed evenly with a self-controlled high-speed mixer, put into the wooden model, and after vibration molding, the vent hole is drilled, and the commercially available high-temperature release agent is applied to make a complete model with a high-strength binder.

[0025] Electric furnace melting: The mixed ingredients are melted in a three-phase electric arc furnace with a hollow electrode, the melting voltage is 237V, the melting current is 5000-5600A, and the nitrogen pressure continuously connected from the hollow electrode is 0.4mpa.

[0026] ...

Embodiment 2

[0043] Ingredients: The raw material composition contains 30% recycled clinker, and the balance is the raw material of the fused cast α-β alumina brick formula with the same material as the clinker, that is, industrial alumina 66.64%, additives: fine quartz sand 0.70%, sodium carbonate 2.66%.

[0044]Electric furnace melting: The mixed ingredients are melted in a three-phase electric arc furnace with a hollow electrode, the melting voltage is 246V, the melting current is 5800-6500A, and the nitrogen pressure continuously connected from the hollow electrode is 0.6mpa.

[0045] Casting:

[0046] The casting temperature is 2000°C, and the casting speed is 195kg / min.

[0047] The casting mold uses magnesia as a whole sand mold. Its weight ratio is magnesia:water glass=100:8, and the modulus of water glass is 3.29.

[0048] Annealing process: use silicon-aluminum hollow balls as insulation medium;

[0049] The temperature drop rate in the annealing process was 0.054°C / kg·h.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com