Lightweight bicycle wheel rim and method for producing it

一种自行车、轮缘的技术,应用在轻质高性能车轮及其制造领域,能够解决重量损失、降低轮子旋转惯量特性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

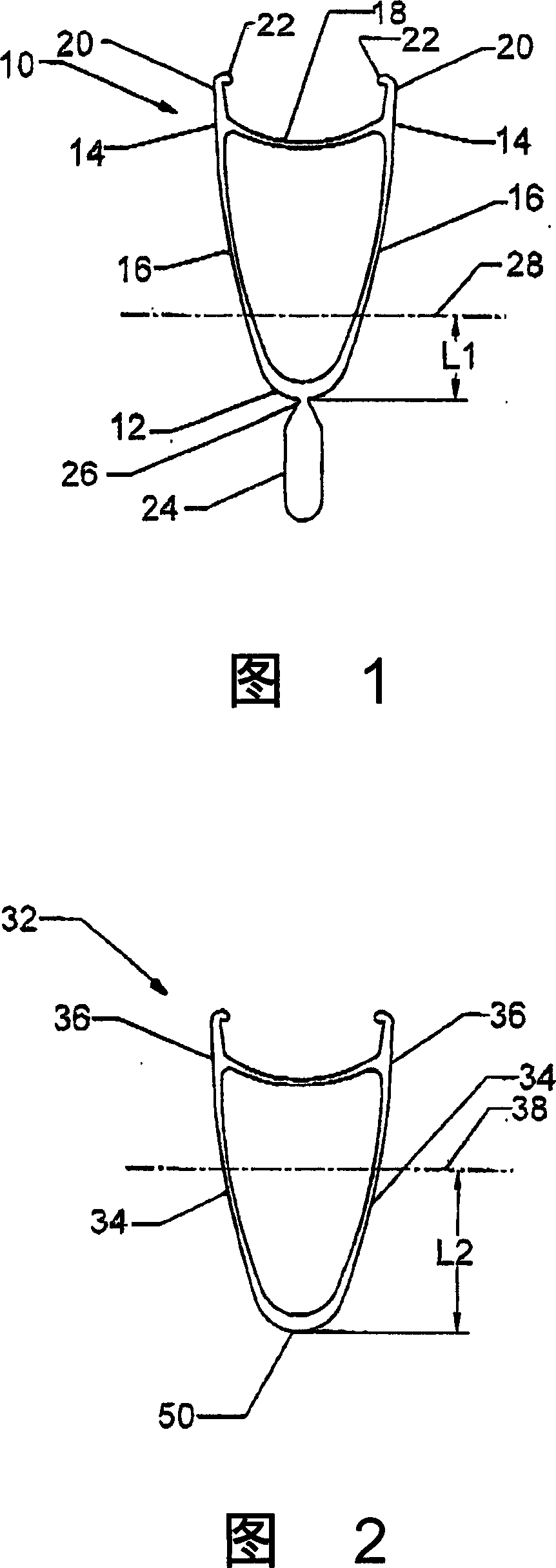

[0020] Referring to FIG. 1, the linear extrusion indicated at 10 includes a rim base or spoke base 12, opposing braking surfaces 14 and opposing side walls 16 extending between the spoke bases 12 and braking surfaces 14. A transverse edge 18 extends between the two upper parts of the extrusion 10 , close to the braking surface 14 . A bead 20 extends upwardly from the transverse rim 18 and terminates in a bead hook 22 . The crimp tab 24 is engaged on the spoke base 12 by a thin neck 26 . Line 28 at a distance L1 from the bottom of spoke base 12 represents the neutral center of bending of extrusion 10; that is, when a length of extrusion 10 made of a typical rim alloy is rolled into a rim shape, line 28 and the transverse Portions of the sidewall 16 between the edges 18 are compressed under tension, and those portions of the sidewall further away from the transverse edges 18 are compressed and subjected to twisting. The sidewall 16 (eg extruded) has the thickness required for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com