Tube-type UHT high heat recovery rate hot water heat exchange system

A heat exchange system and recovery rate technology, applied in heating water/sewage treatment, water/sewage multi-stage treatment, degassed water/sewage treatment, etc. Area increase and other issues, to achieve the effect of maintaining flavor, shortening time under high temperature, and reducing heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

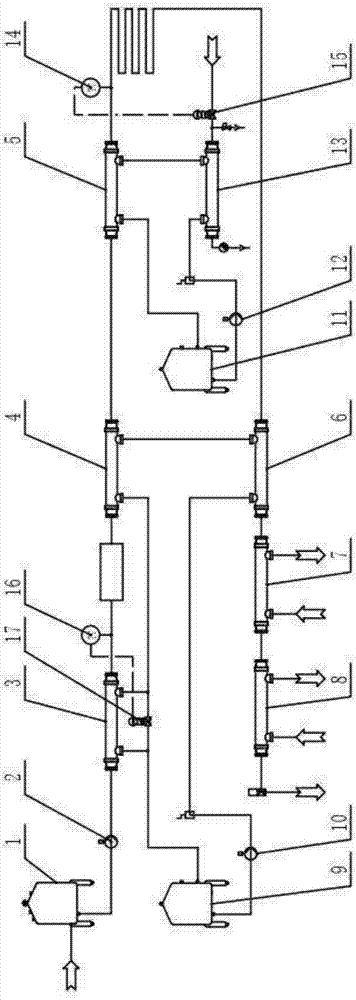

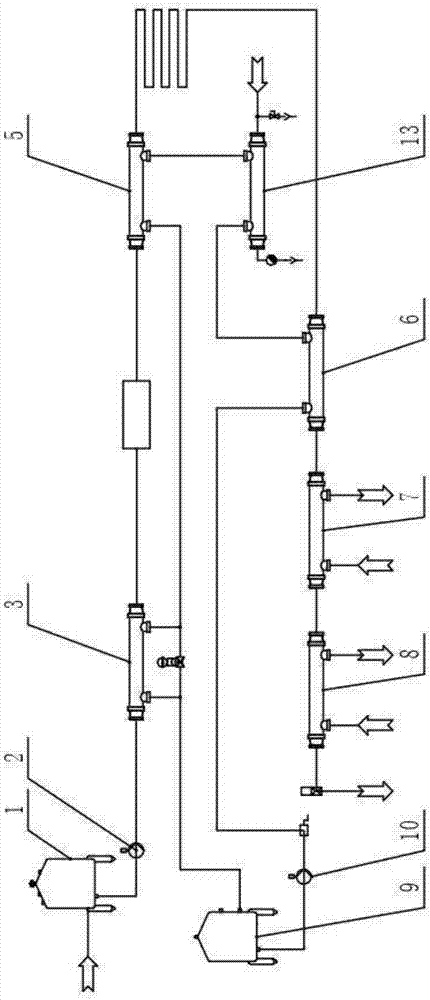

[0017] A tubular UHT hot water heat exchange system with high heat recovery rate according to the present invention will be further described in detail through specific examples below.

[0018] Such as figure 1 As shown, a tubular UHT hot water heat exchange system with high heat recovery rate includes a balance tank 1, a product pump 2, a degassing section 3, a heating section 4, and a sterilization section 5 in the product pipeline from the inlet to the outlet. Heat recovery section 6, tower water cooling section 7 and ice water cooling section 8, the hot water pipeline includes the hot water circulation part of the heat recovery section and the sterilizing hot water circulation part, and the hot water circulation part of the heat recovery section includes the cooling hot water tank 9 in turn , the cooling hot water pump 10, flows through the heat recovery section 6, flows through the heating section 4, flows through the degassing section 3, and finally returns to the cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com