Patents

Literature

95results about How to "Facilitates heat recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

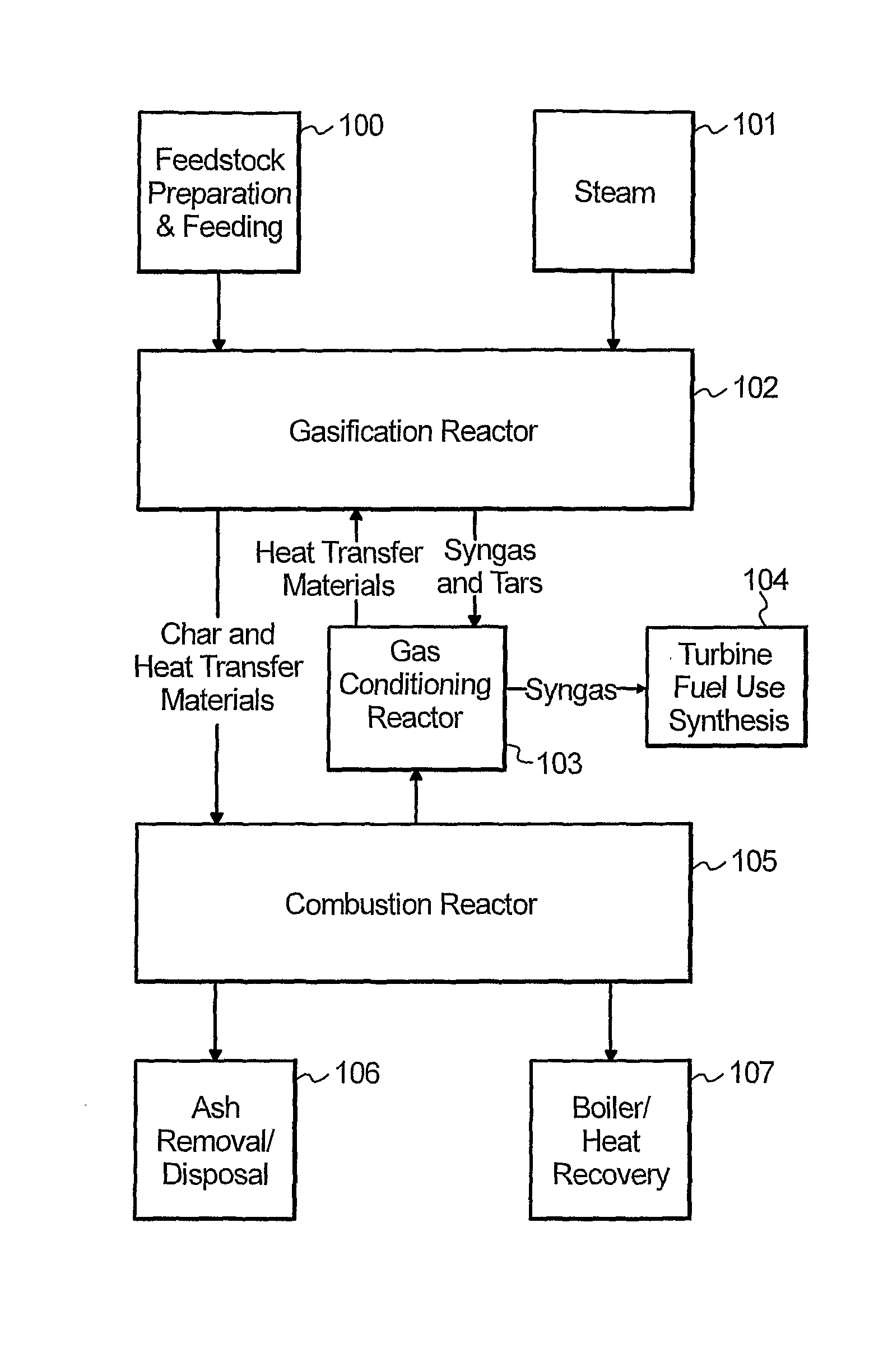

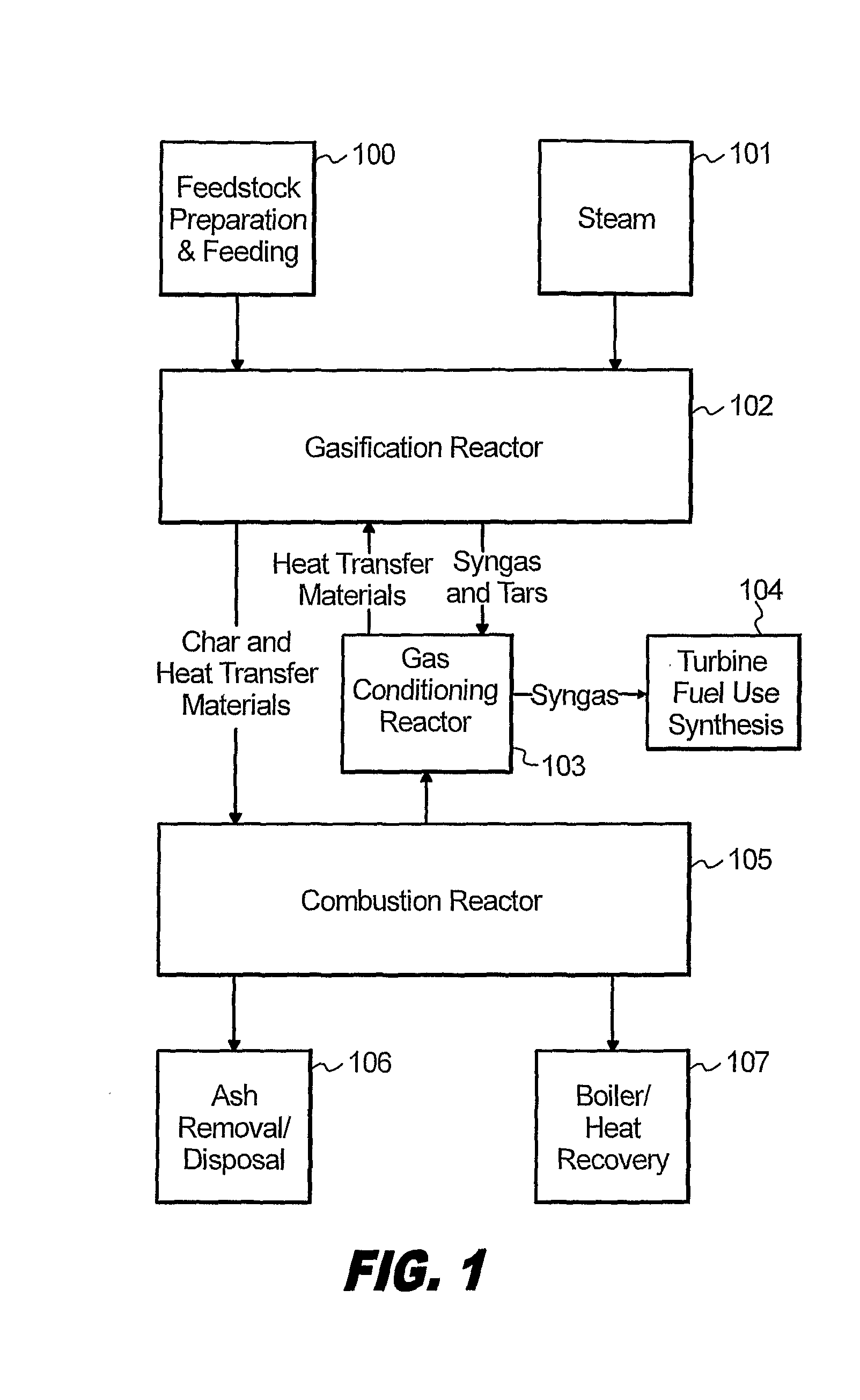

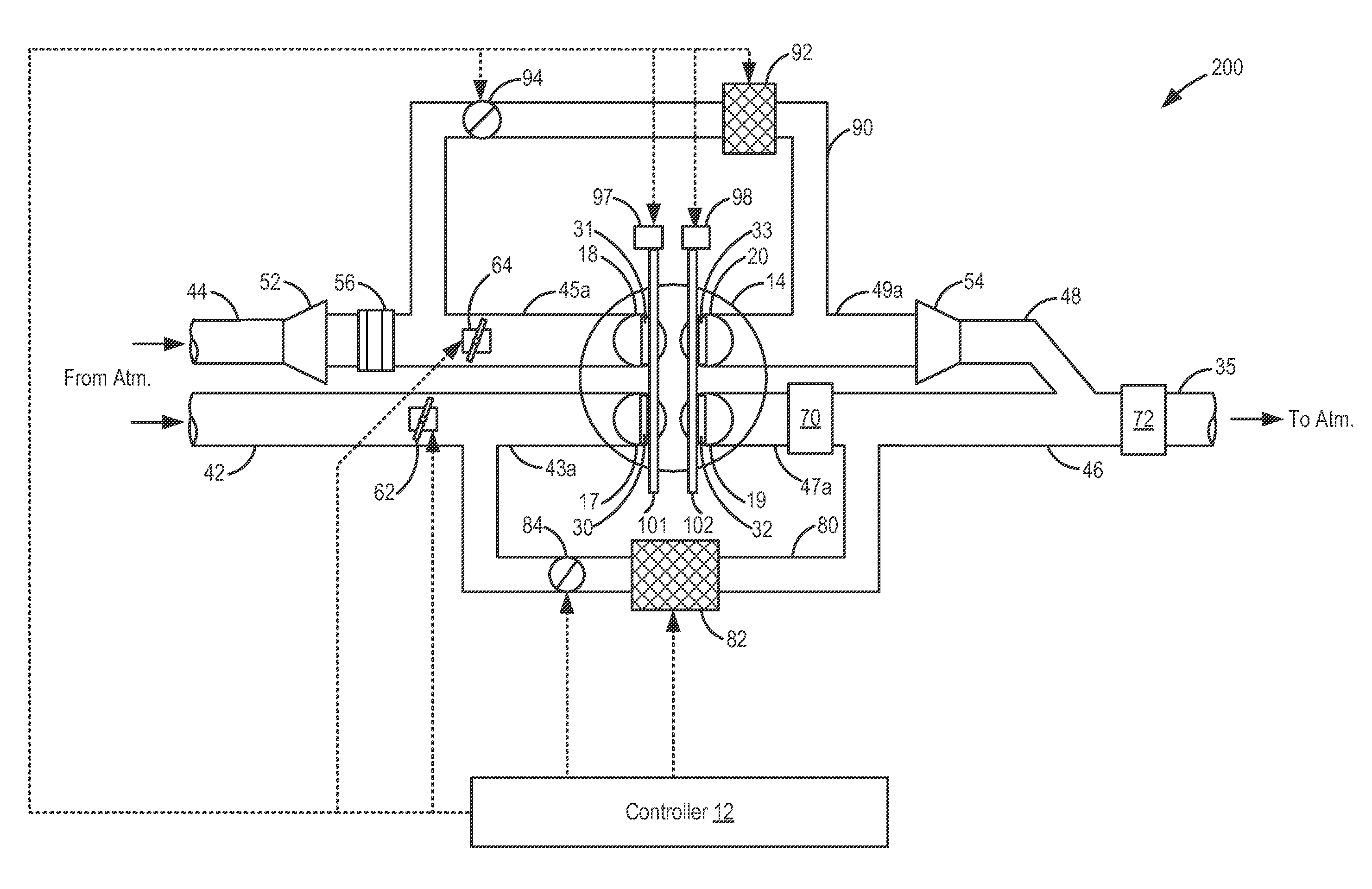

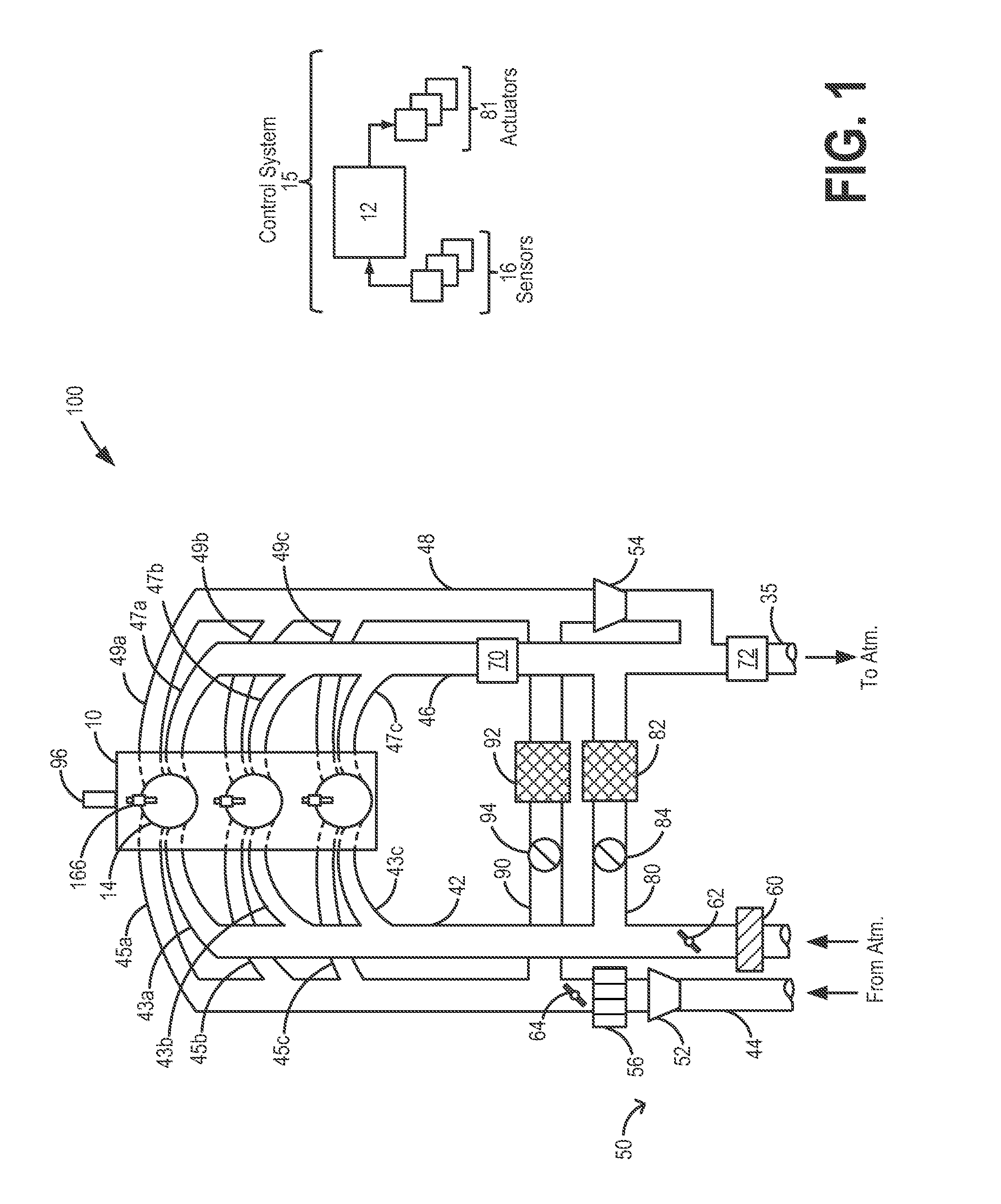

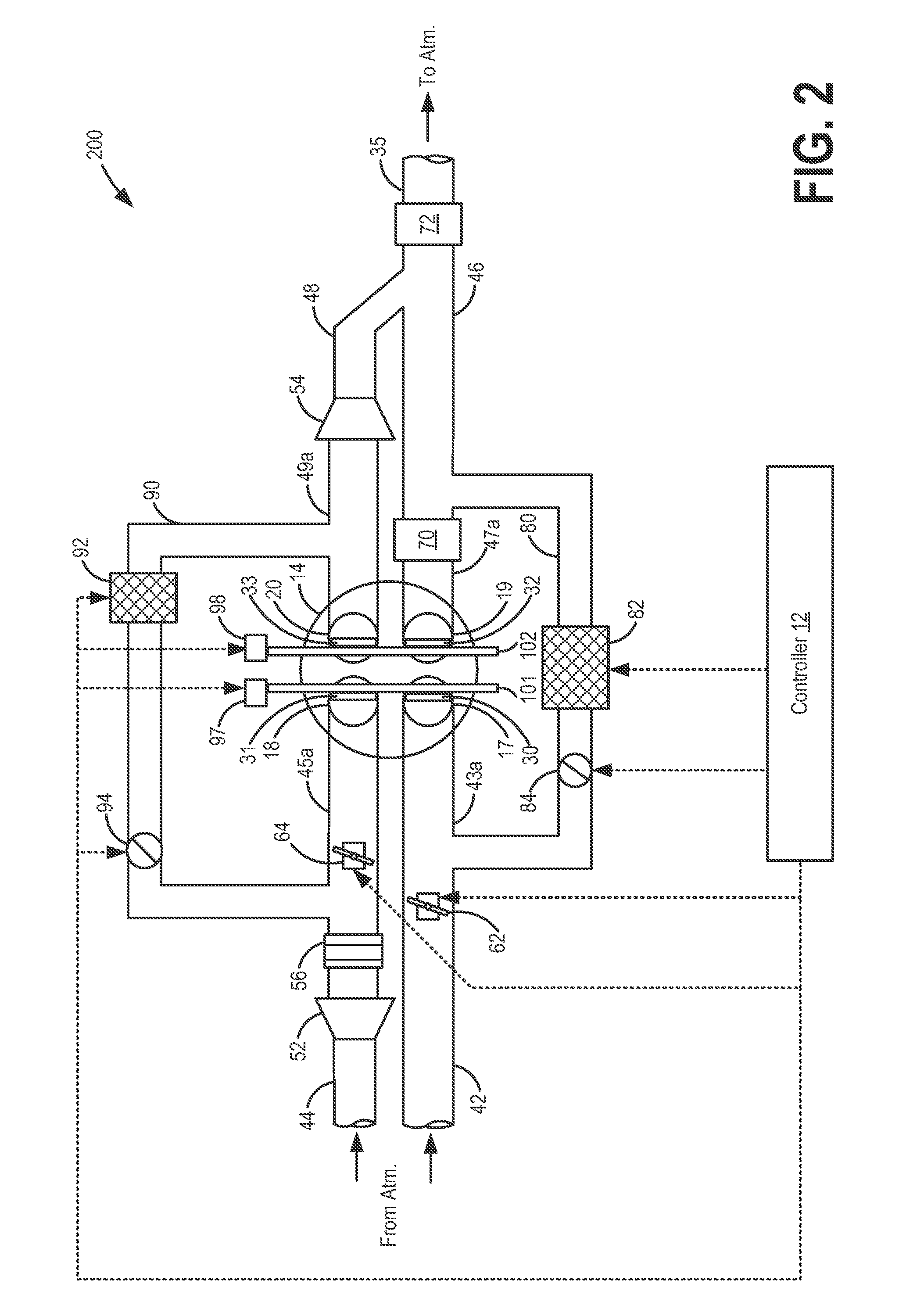

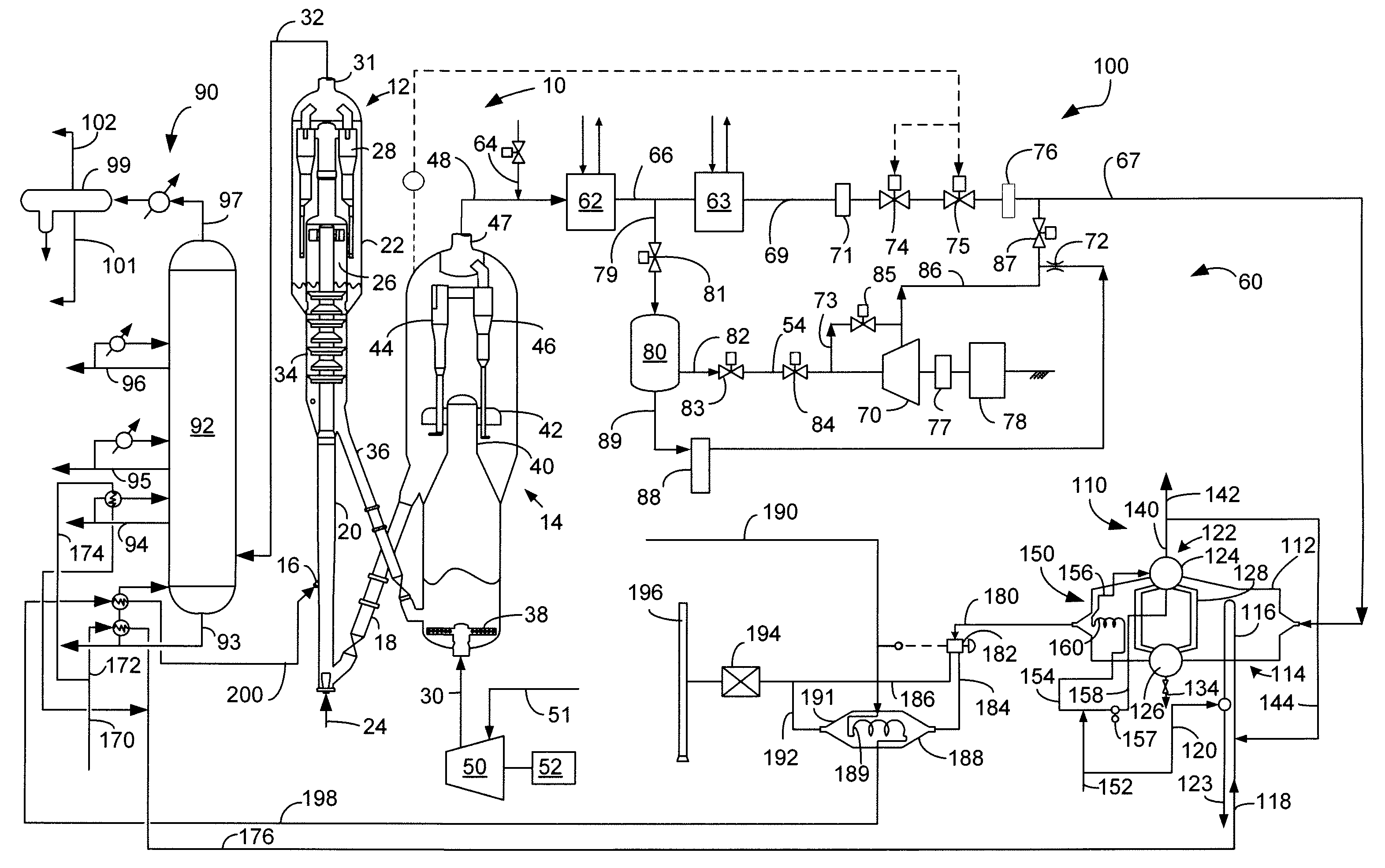

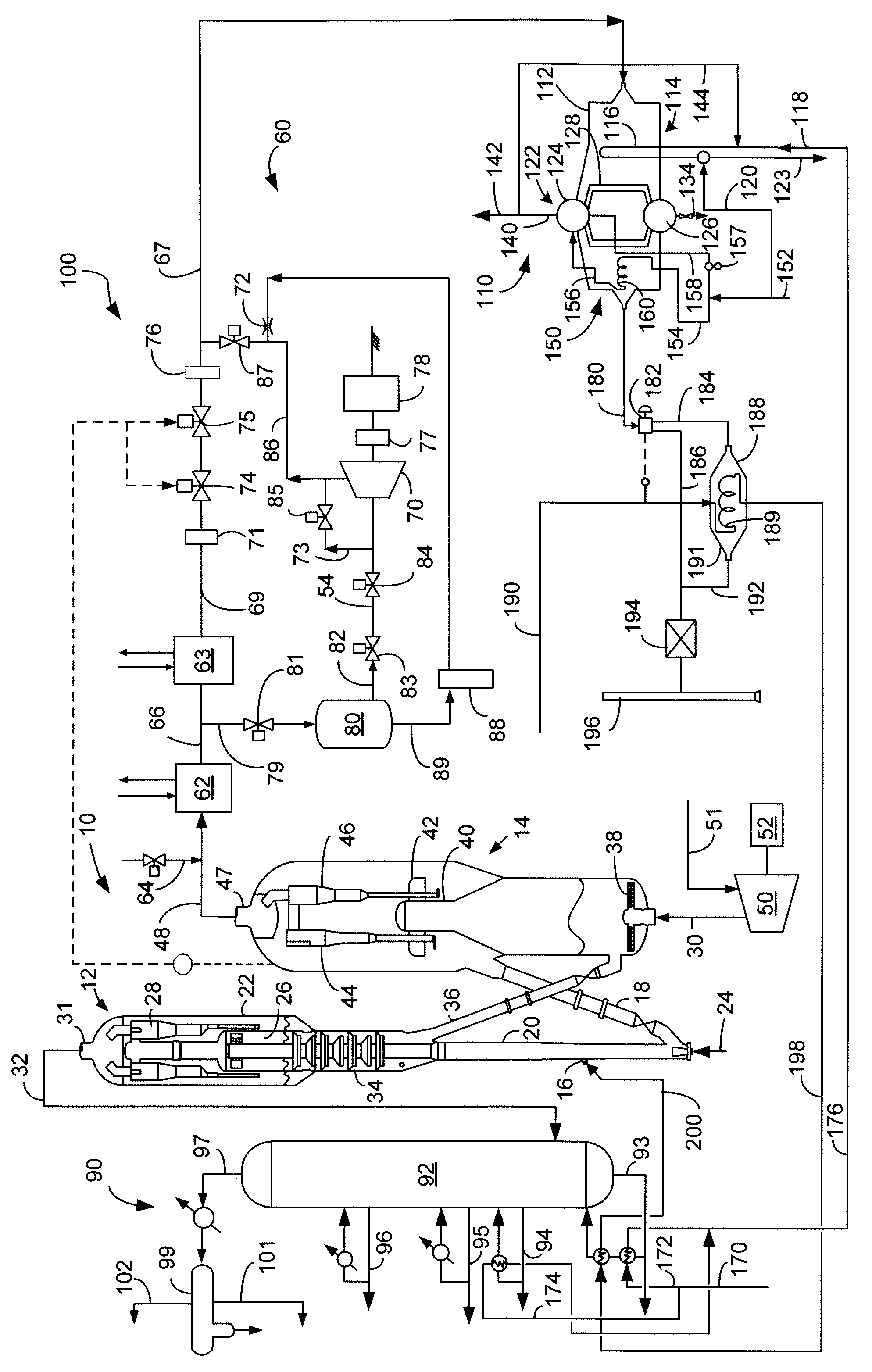

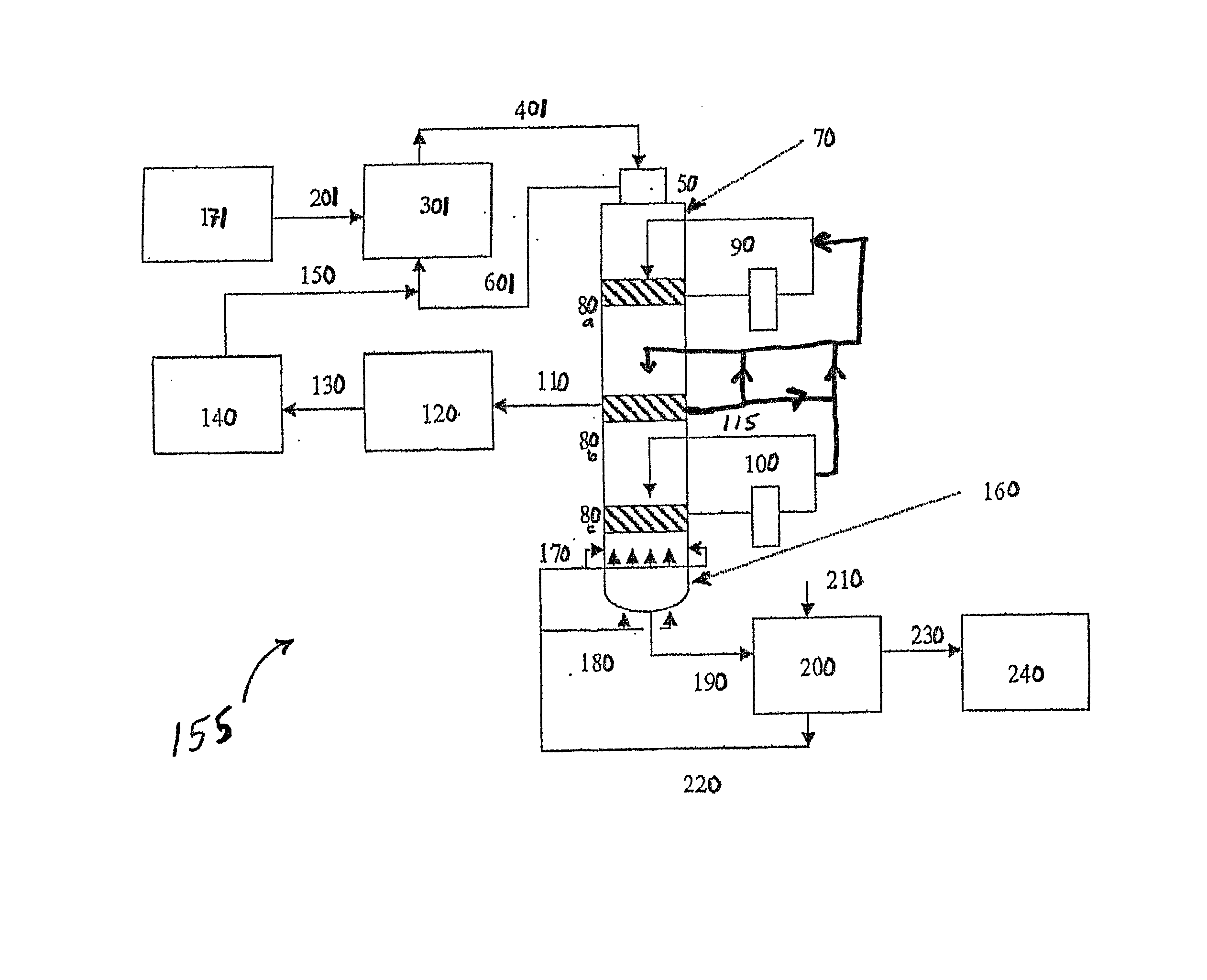

Process and System for Gasification with In-Situ Tar Removal

ActiveUS20080244976A1Simplifying downstream heat recoveryIncreased hydrogenCombustible gas catalytic treatmentCombustible gas thermal treatmentHeat carrierTar

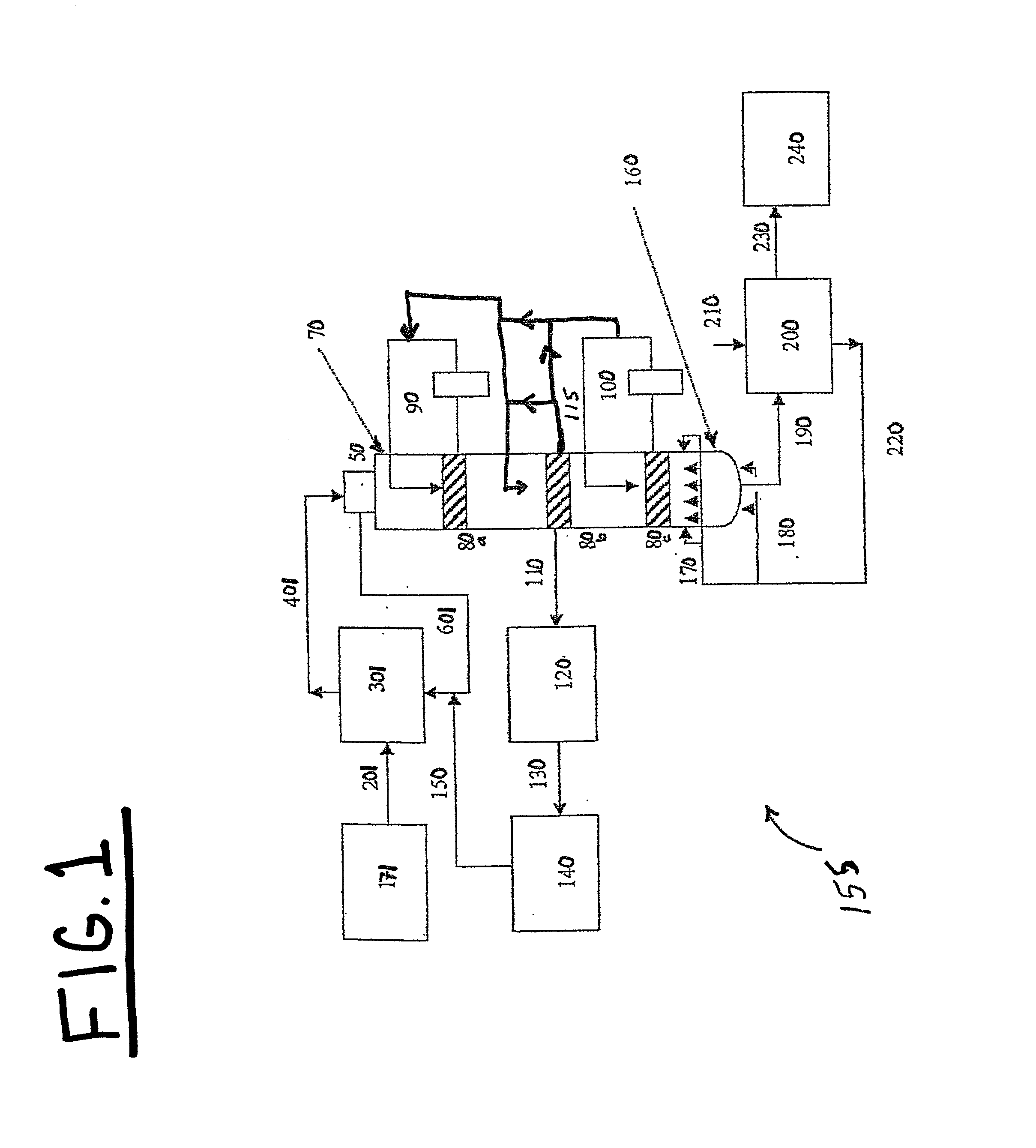

The present invention relates to a process and system for gasifying biomass or other carbonaceous feedstocks in an indirectly heated gasifier and provides a method for the elimination of condensable organic materials (tars) from the resulting product gas with an integrated tar removal step. More specifically, this tar removal step utilizes the circulating heat carrier to crack the organics and produce additional product gas. As a benefit of the above process, and because the heat carrier circulates through alternating steam and oxidizing zones in the process, deactivation of the cracking reactions is eliminated.

Owner:TAYLOR BIOMASS ENERGY

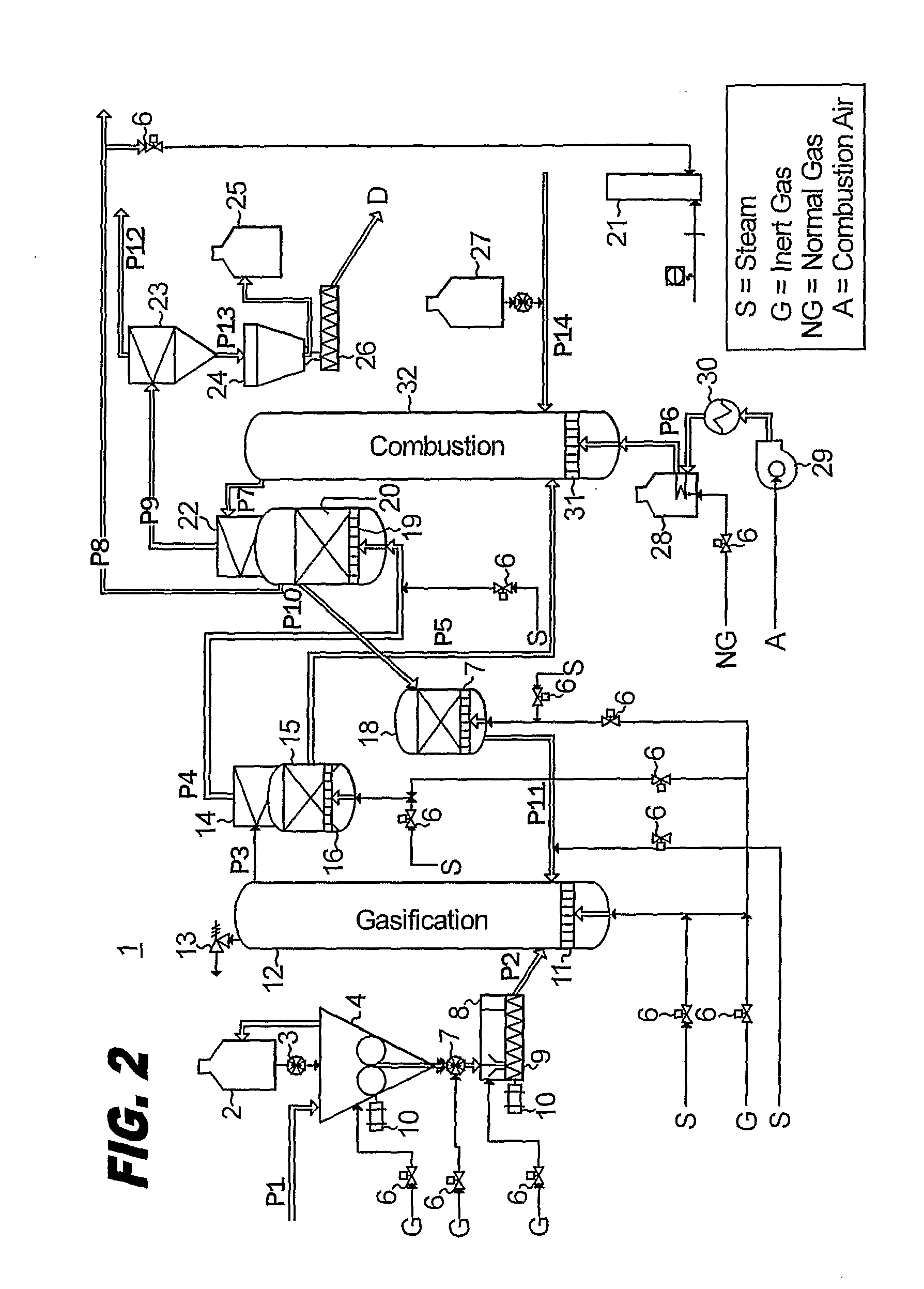

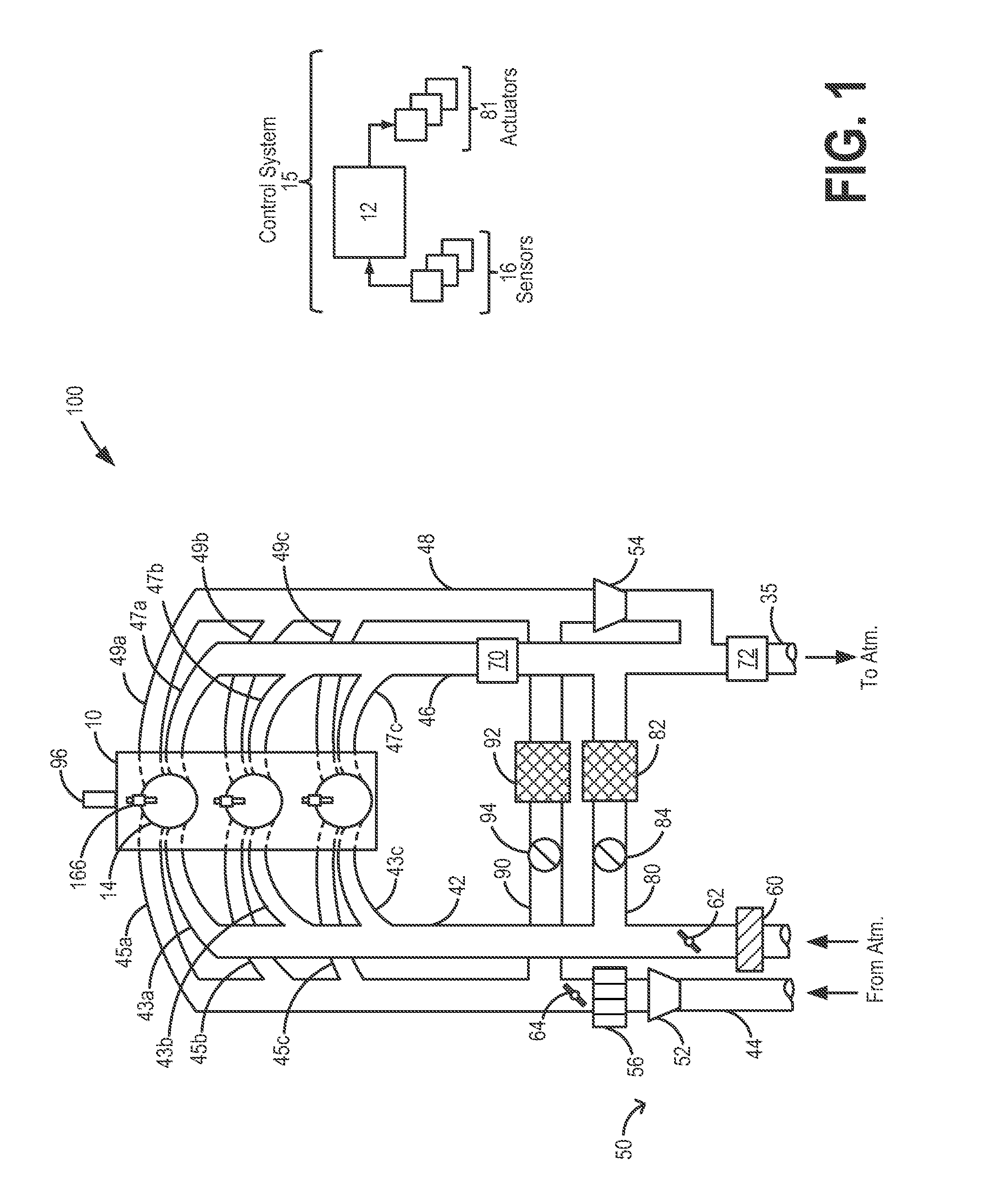

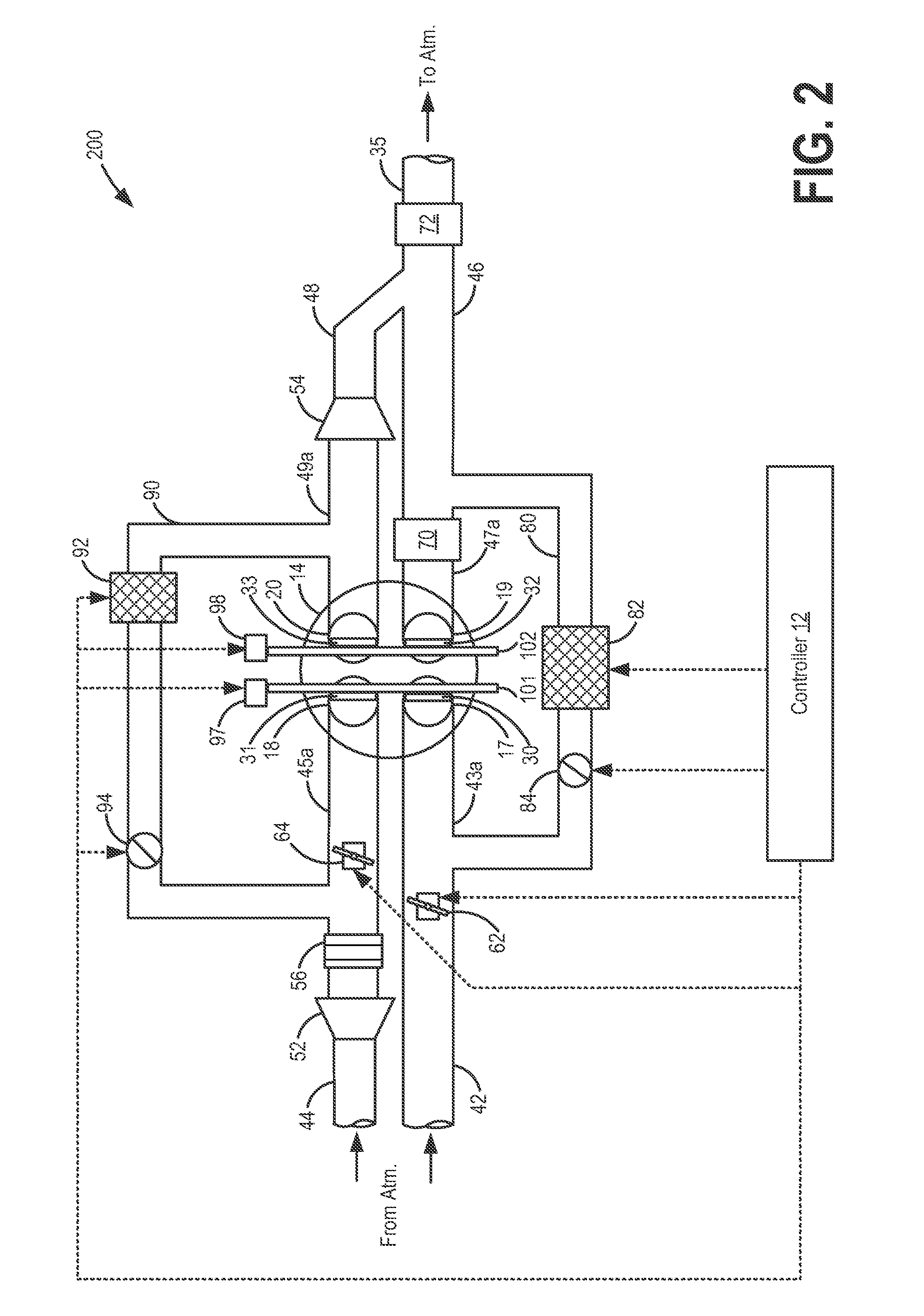

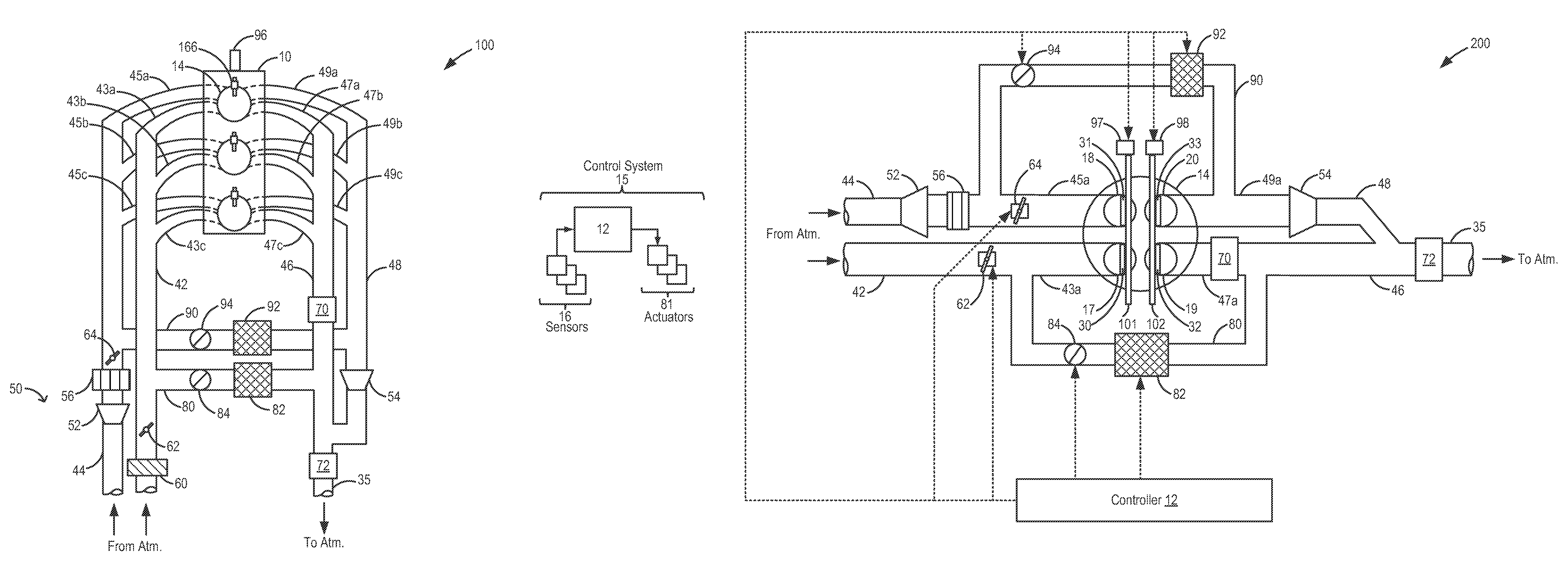

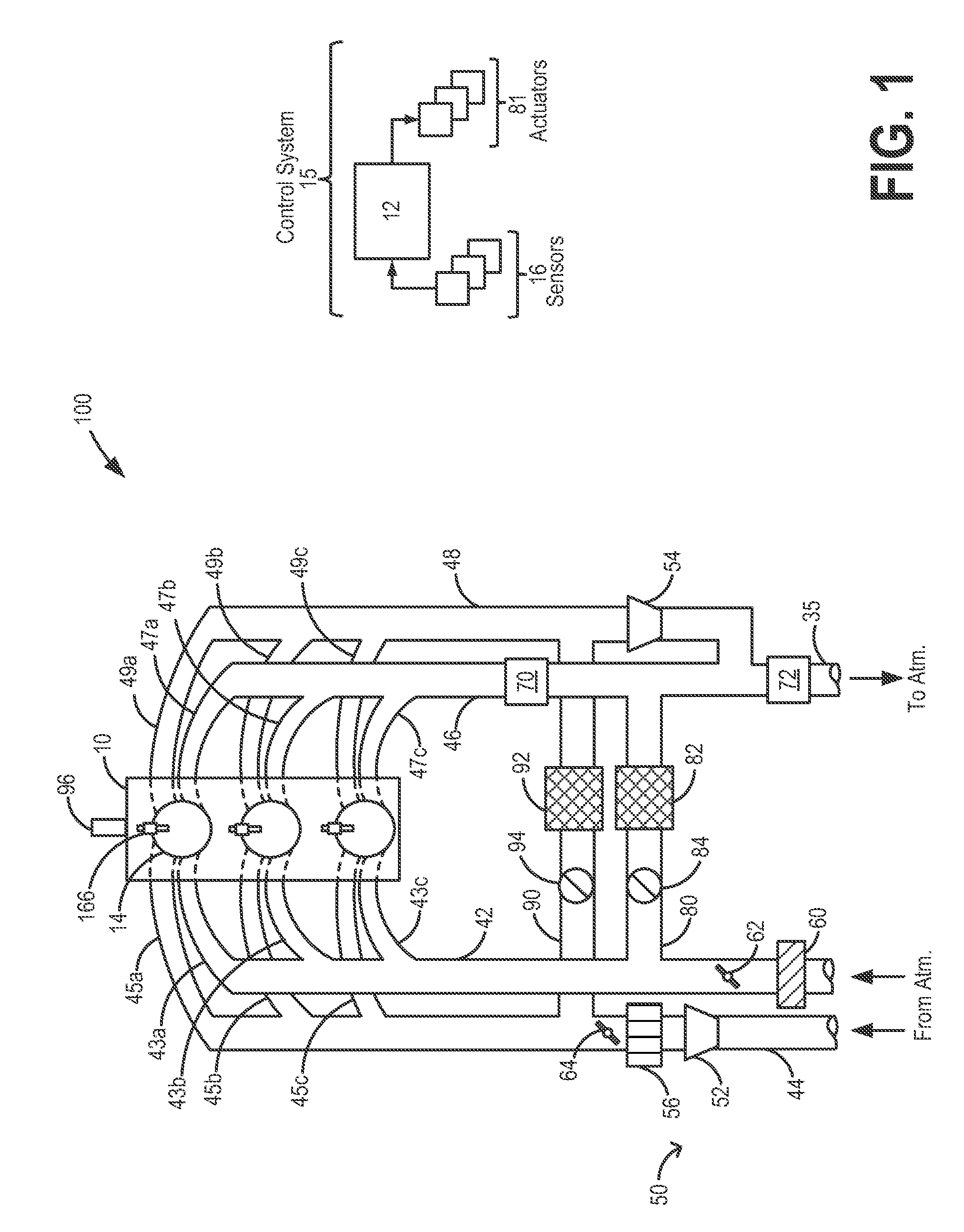

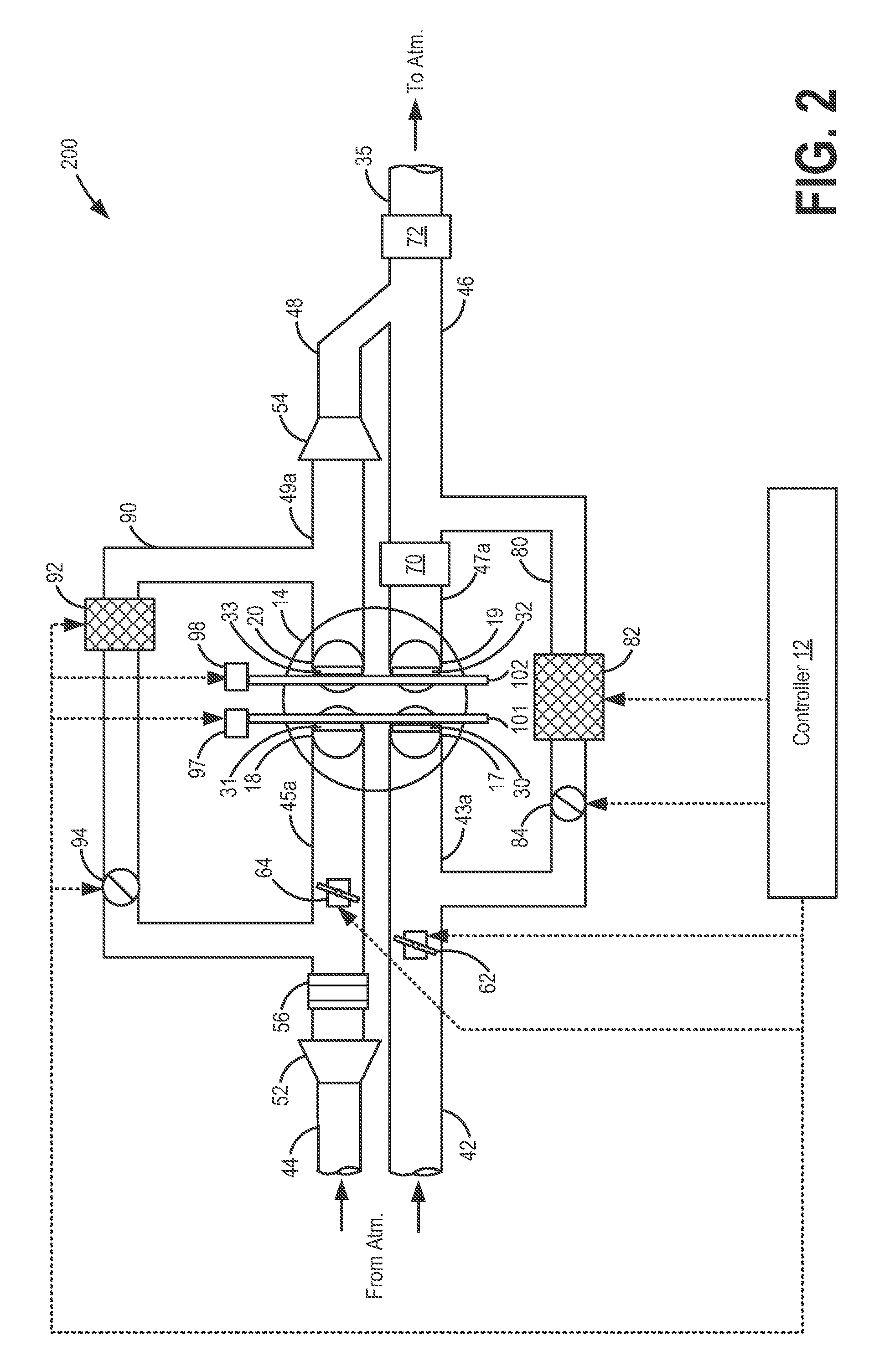

Method and system for a turbocharged engine

InactiveUS8701409B2Reduce exhaust emissionsImprove fuel economyValve arrangementsElectrical controlEngine cycleAutomotive engineering

Methods and systems are provided for a boosted engine having a split intake system coupled to a split exhaust system. Aircharges of differing composition, pressure, and temperature may be delivered to the engine through the split intake system at different points of an engine cycle. In this way, boost and EGR benefits may be extended.

Owner:FORD GLOBAL TECH LLC

Method and system for a turbocharged engine

ActiveUS8479511B2Without compromising boost performanceBoosted airchargeValve arrangementsElectrical controlEngine cycleAutomotive engineering

Methods and systems are provided for a boosted engine having a split intake system coupled to a split exhaust system. Aircharges of differing composition, pressure, and temperature may be delivered to the engine through the split intake system at different points of an engine cycle. In this way, boost and EGR benefits may be extended.

Owner:FORD GLOBAL TECH LLC

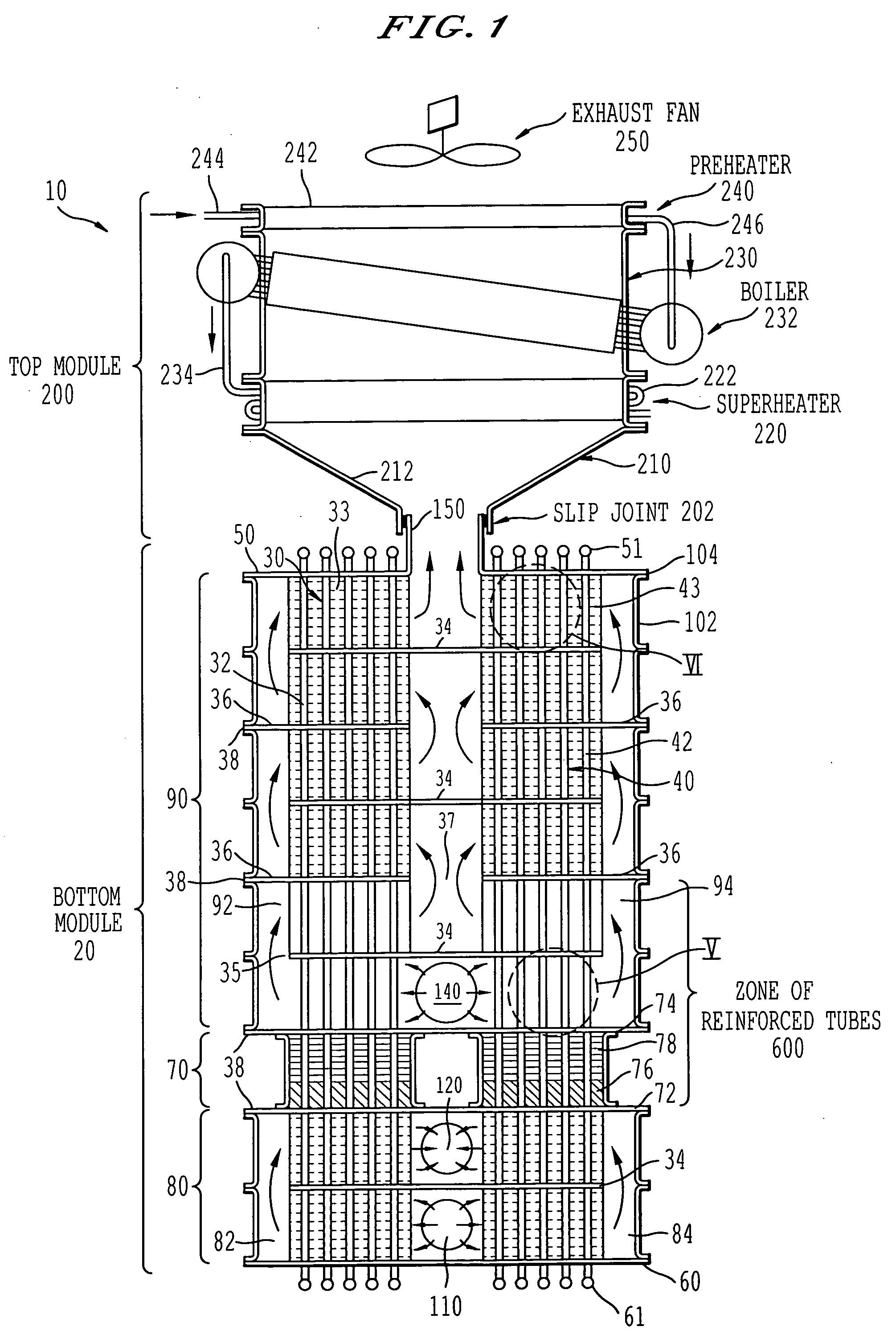

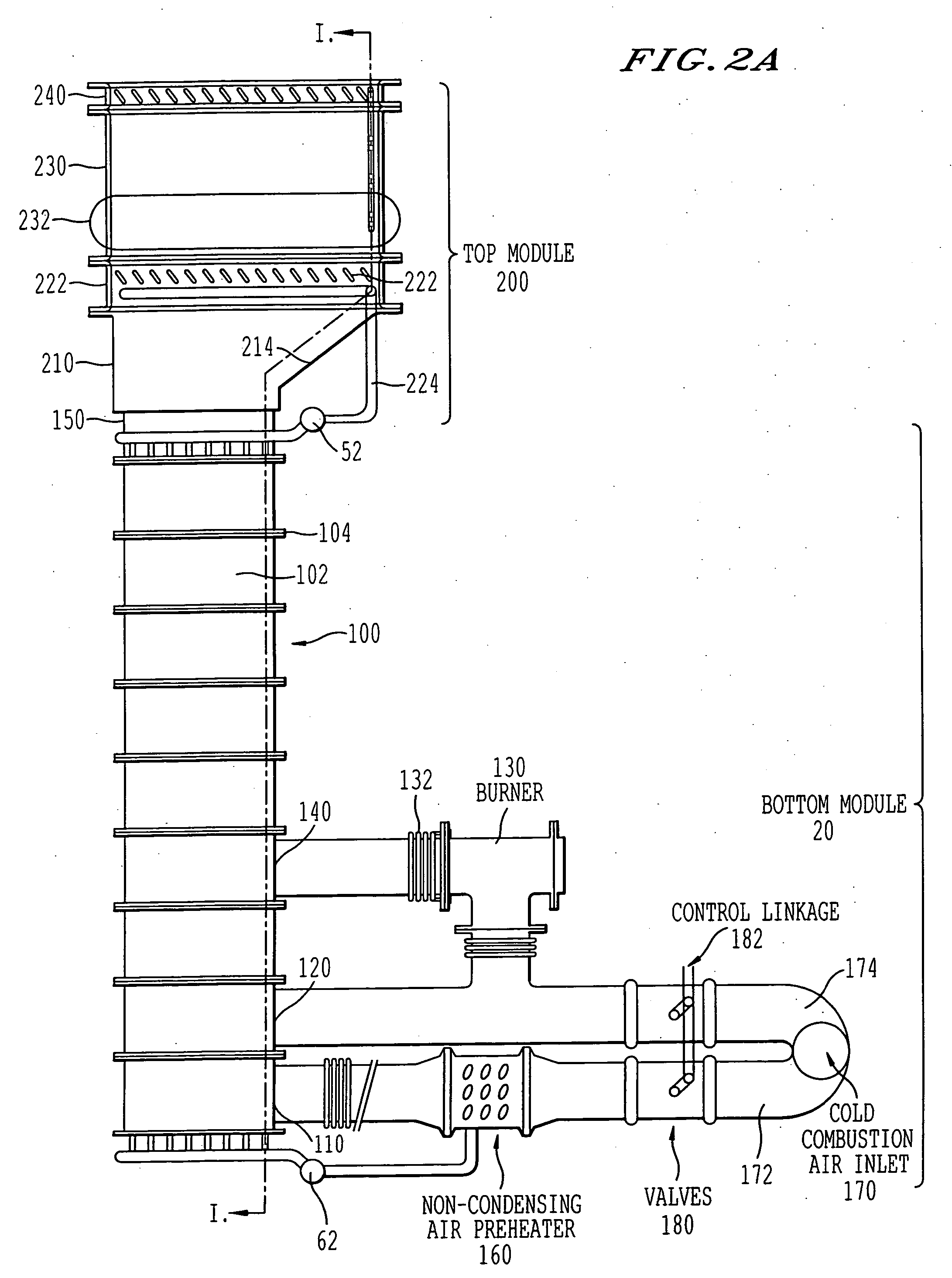

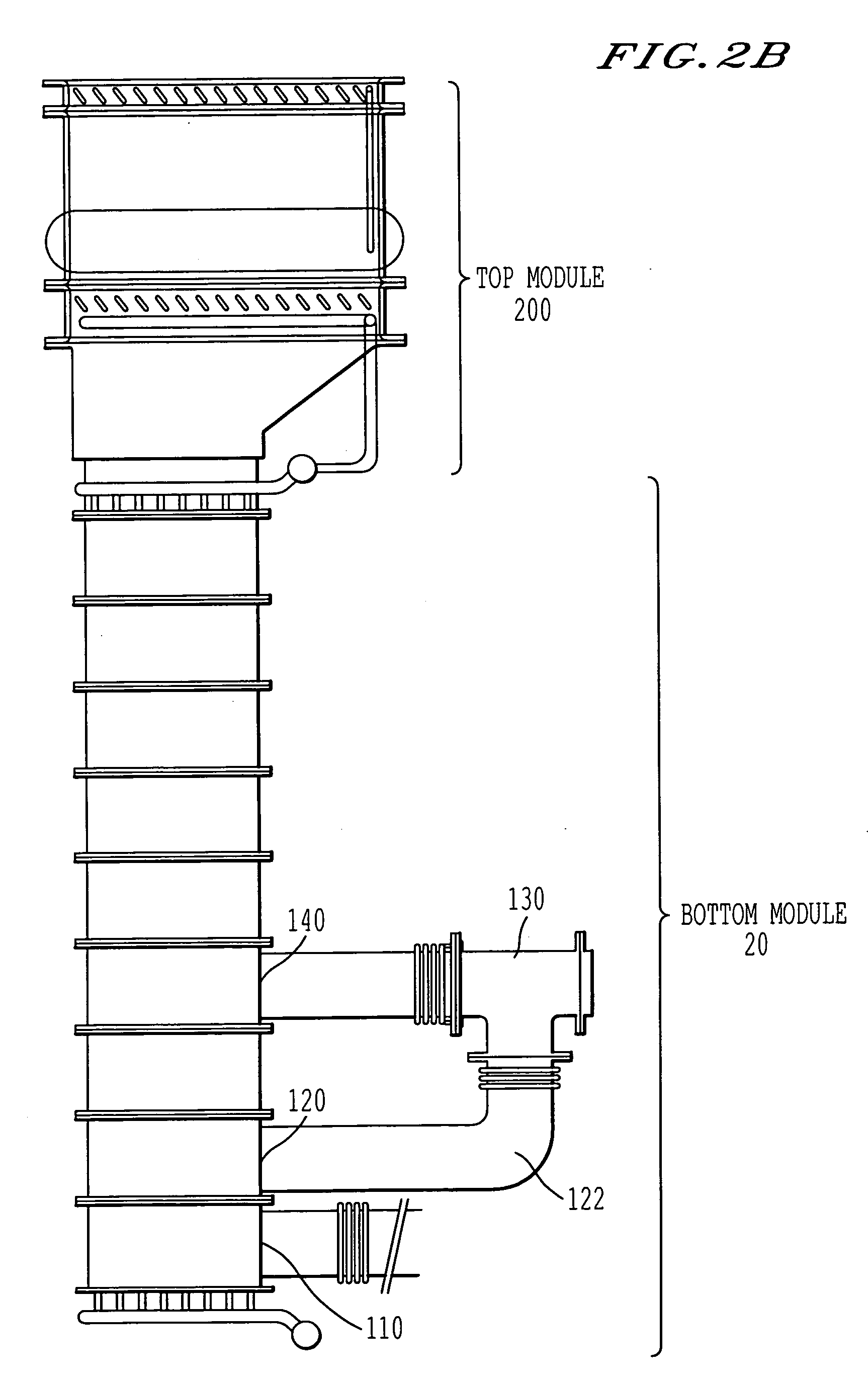

Heat exchanger having plural tubular arrays

InactiveUS20050194120A1Reduce pressureFacilitate accurate dynamic controlHydrogenReinforcing meansEngineeringHeat exchanger

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Method and device for recovering energy

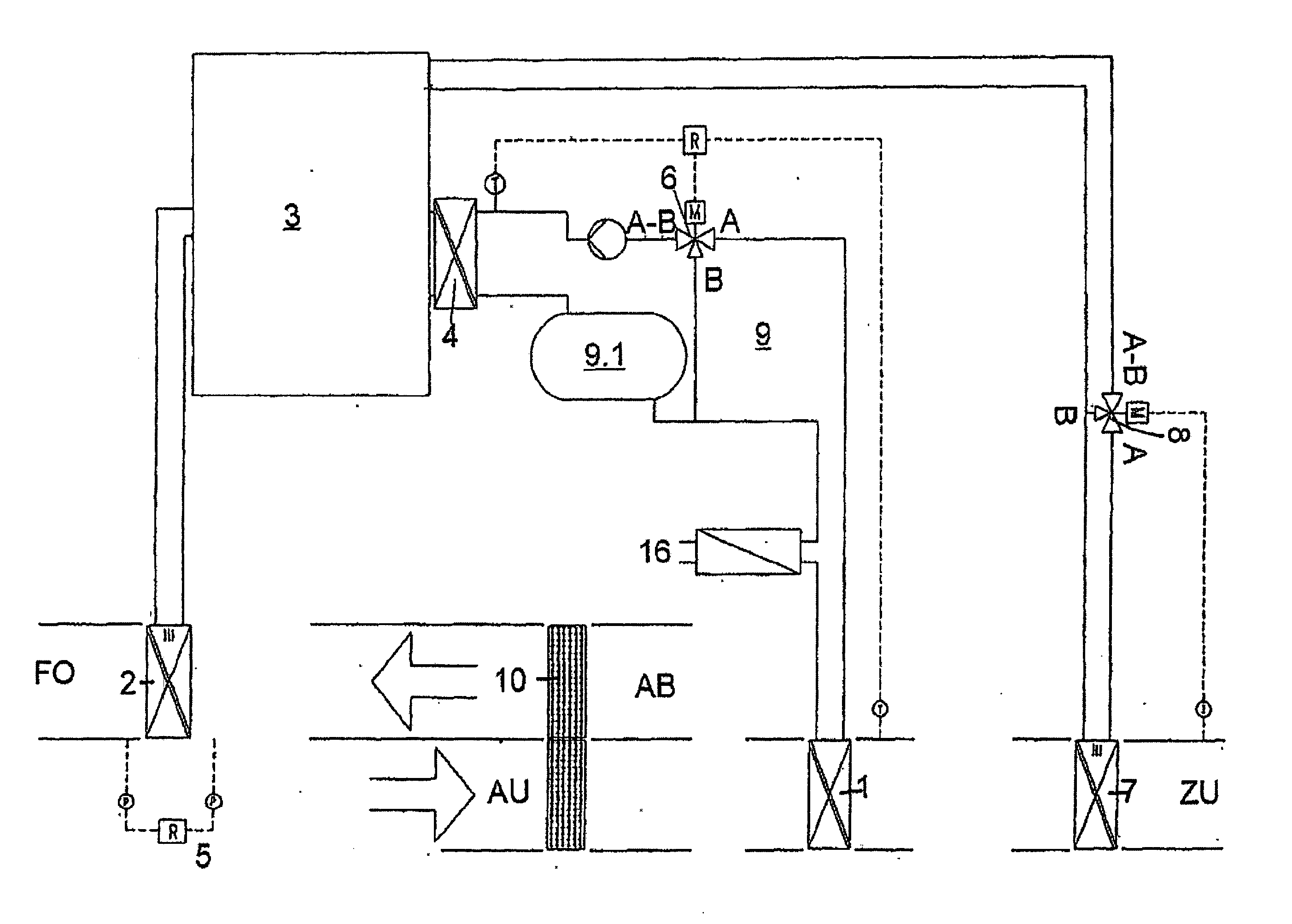

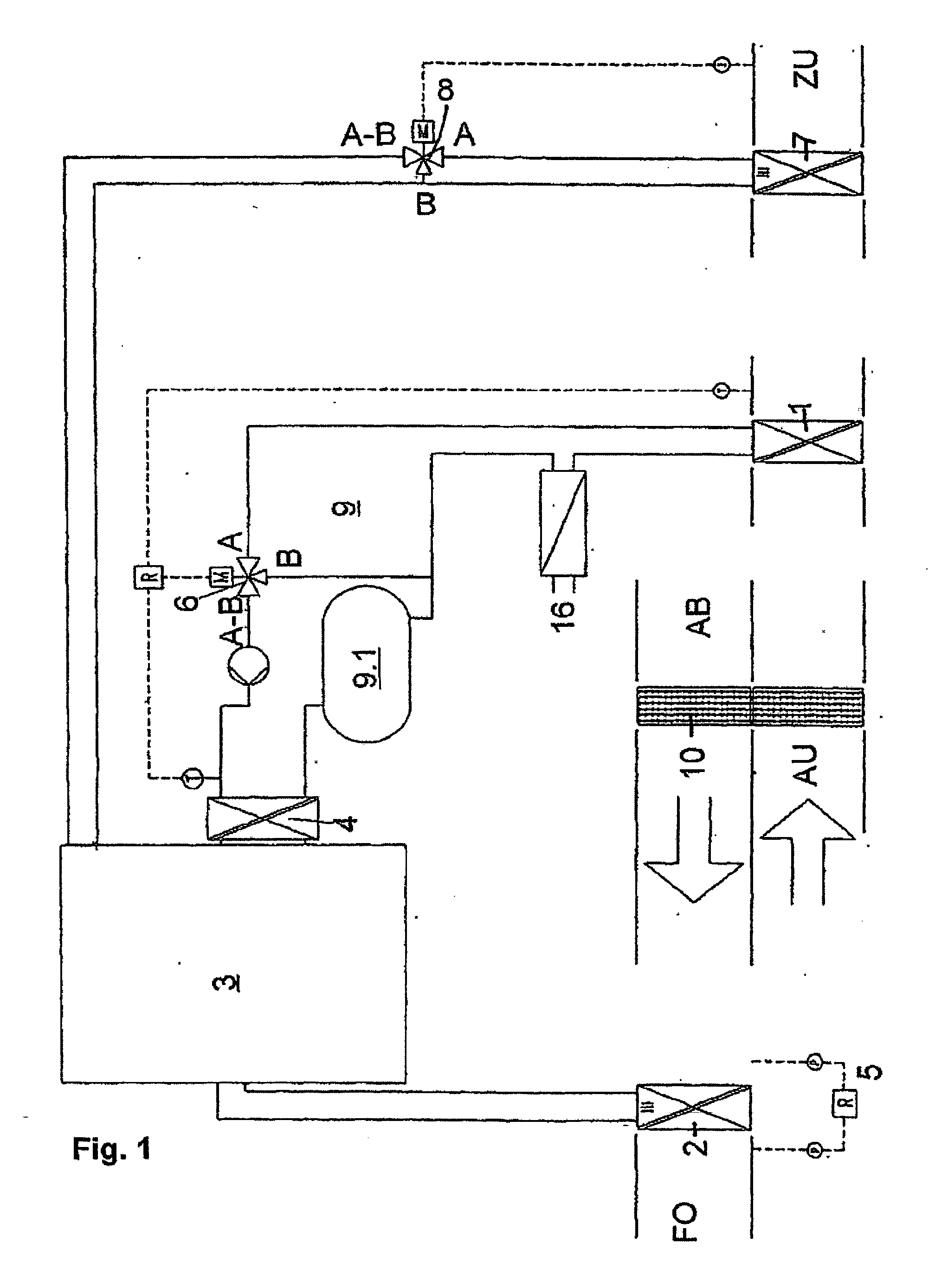

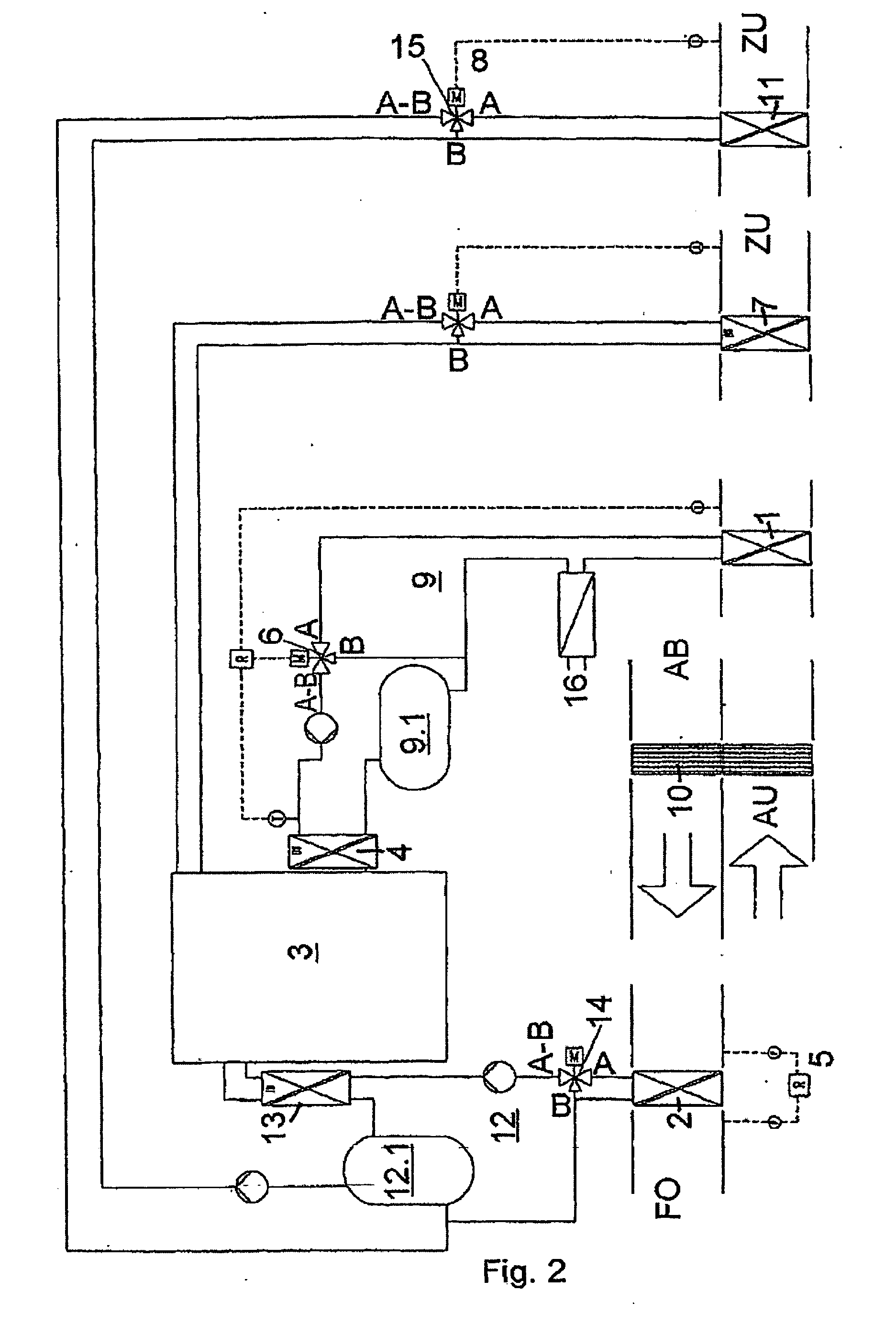

InactiveUS20070095519A1Large heat recoveryRemove more energyEnergy recovery in ventilation and heatingHeat recovery systemsThermal energyAir volume

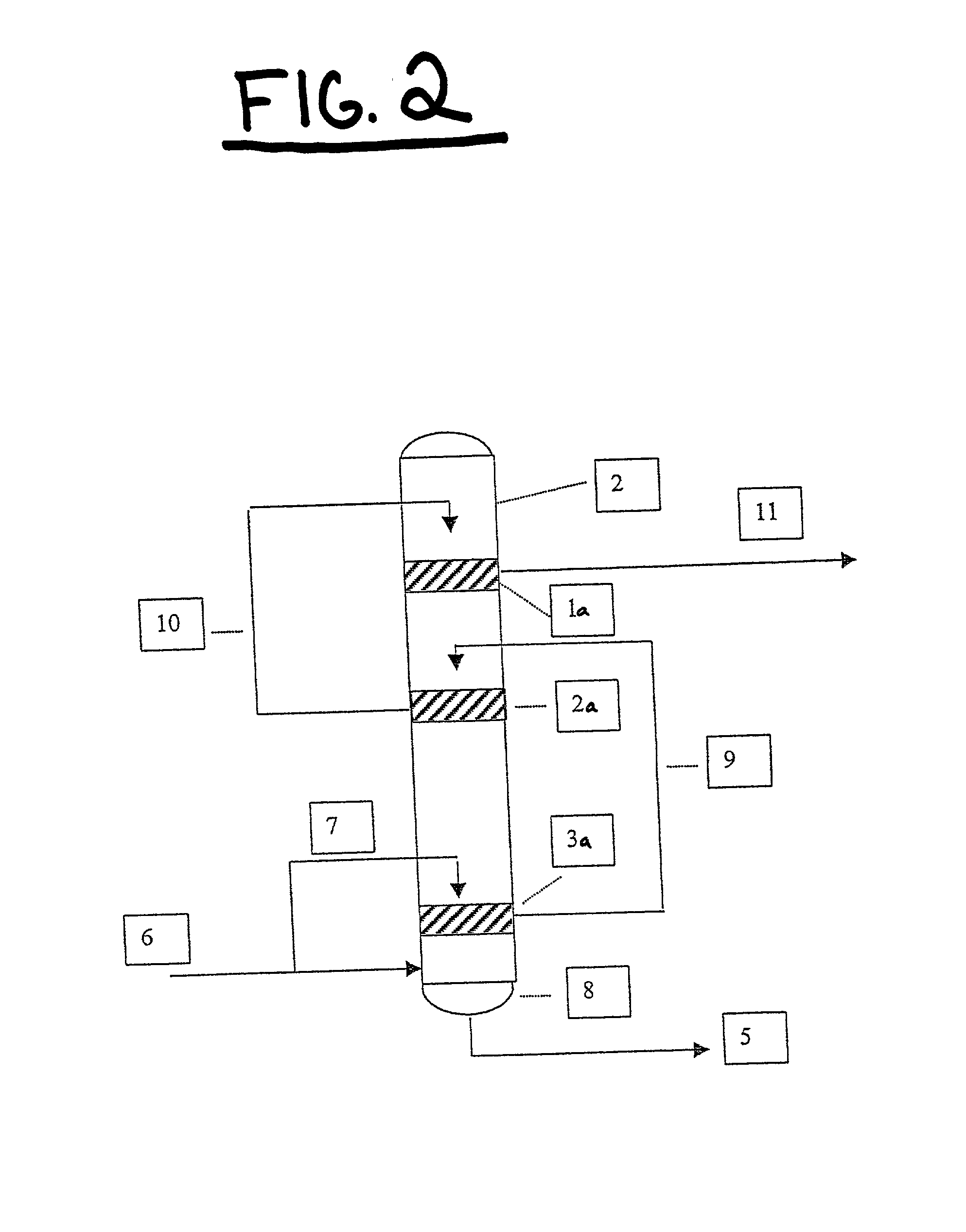

Existing energy recovery systems are used in the fields of air conditioning and ventilation for recovering energy from the outgoing air or external air. Subsequent to an energy recovery system (10), additional thermal energy is extracted from a used air volume flow AB, which is coming from an air-conditioned room, by another system, which consists of a heat pump (3), a heat exchanger (1), another heat exchanger (2), an accumulator circuit (9), an energy accumulator (9.1), and of a mixing valve (6). The associated supply air volume flow ZU is, when heating, additionally heated by the heat pump (3) by means of thermal energy from the used air volume flow AB. This results in increasing the energy yield from the used air volume flow AB. The temperature of the supply air is regulated. When cooling, the supply air volume flow ZU is cooled to the desired supply air temperature.

Owner:HOMBUCHER HEINZ DIETER

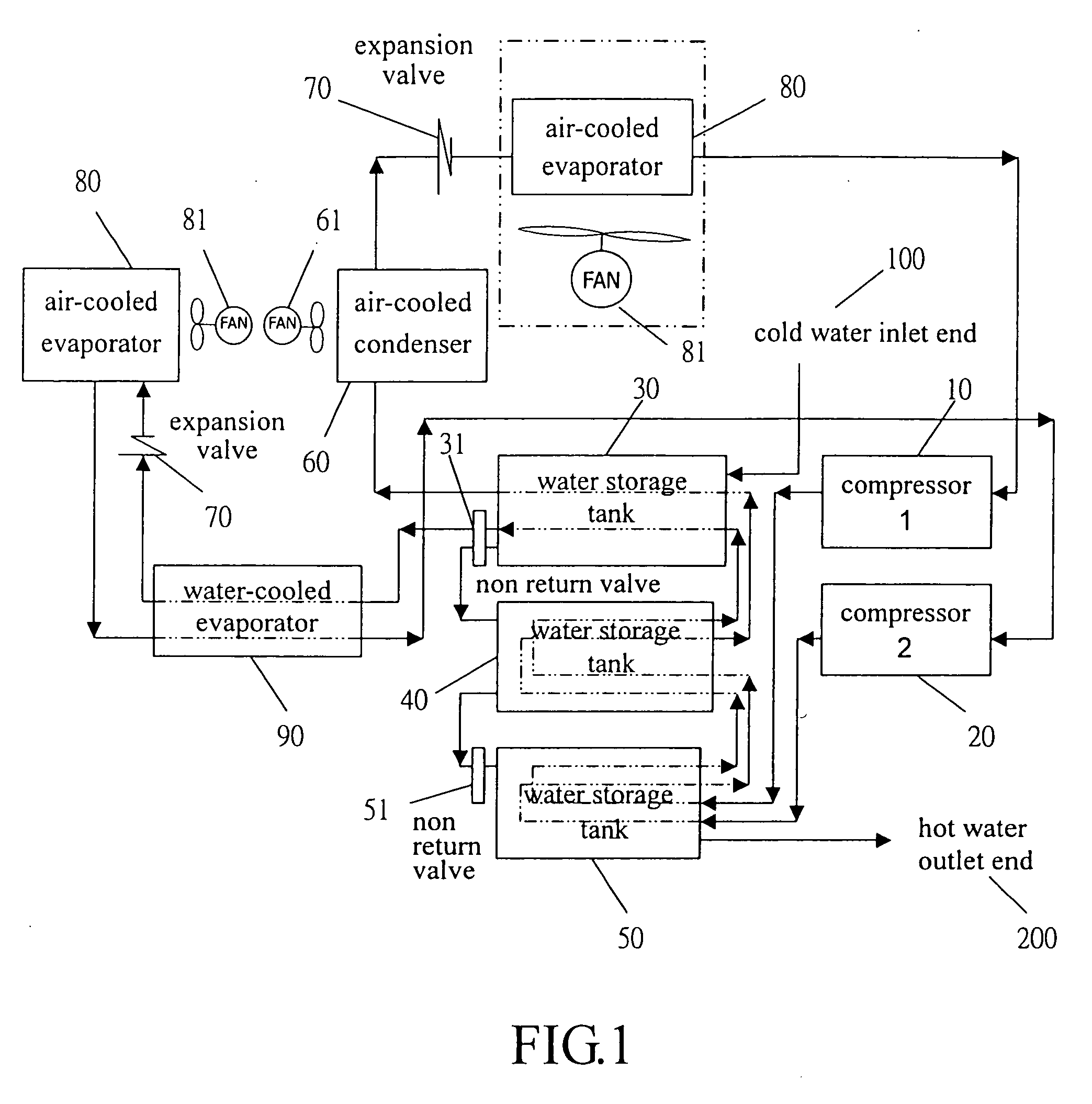

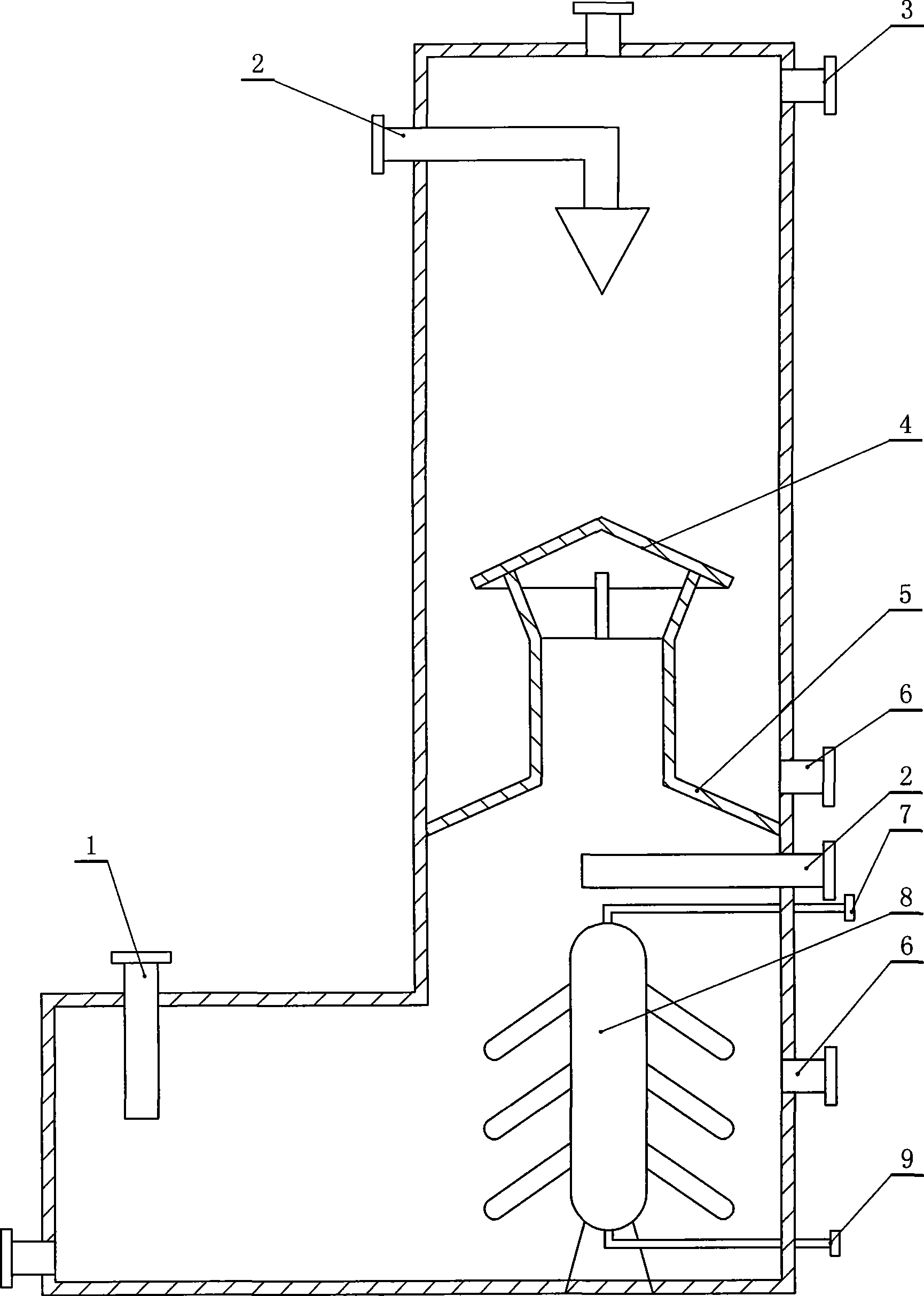

Heating and heat recovery unit for an air conditioning system

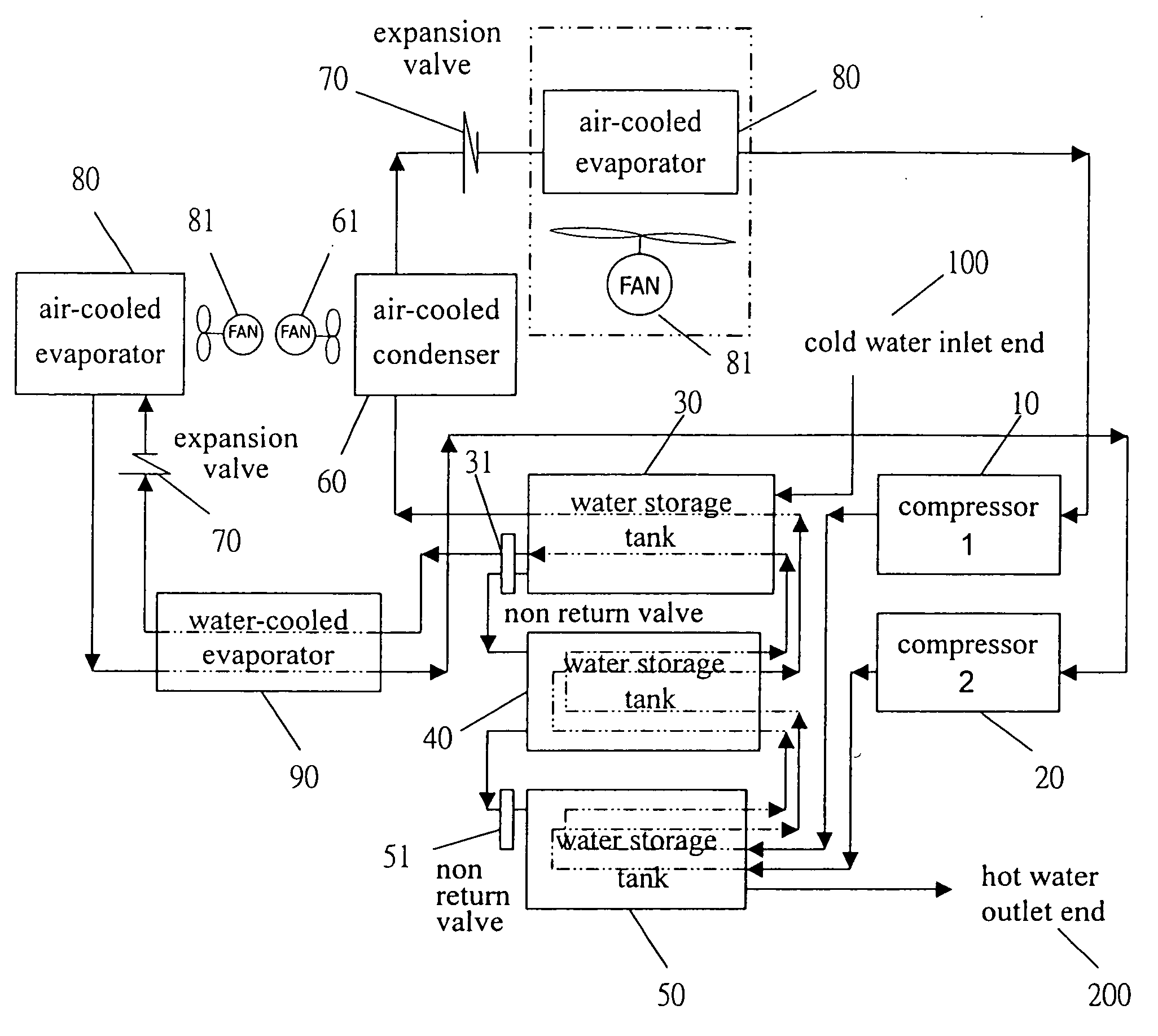

InactiveUS20100000709A1Facilitates heat recoveryImprove efficiencyCentral heating with accumulated heatHeat storage plantsWater storage tankEngineering

A heating and heat recovery unit for an air conditioning system, which is assembled from compressors, several insulated water storage tanks, an air-cooled condenser, expansion valves, air-cooled evaporators and a water-cooled evaporator. The compressors are suitable for various types of air conditioning systems and refrigerant heat pump water heater systems. The installed water storage tanks are arranged according to size, from the largest at the top down to the smallest at the bottom. A high-temperature and high-pressure refrigerant from the compressors is first input into the smallest tank, and after passing through to the largest tank, it is then passed on to the expansion valve and the evaporator. A configuration of cold water pipes is provided for input into the largest tank through to the smallest tank 50, and output therefrom. Hence, the heat exchange flow process consists of heating of cold water after entering from a cold water inlet end, and heating the water before output at a hot water outlet end, moreover, each of the tanks can be independently heated to raise the temperature thereof.

Owner:CHANG TSUNG CHE

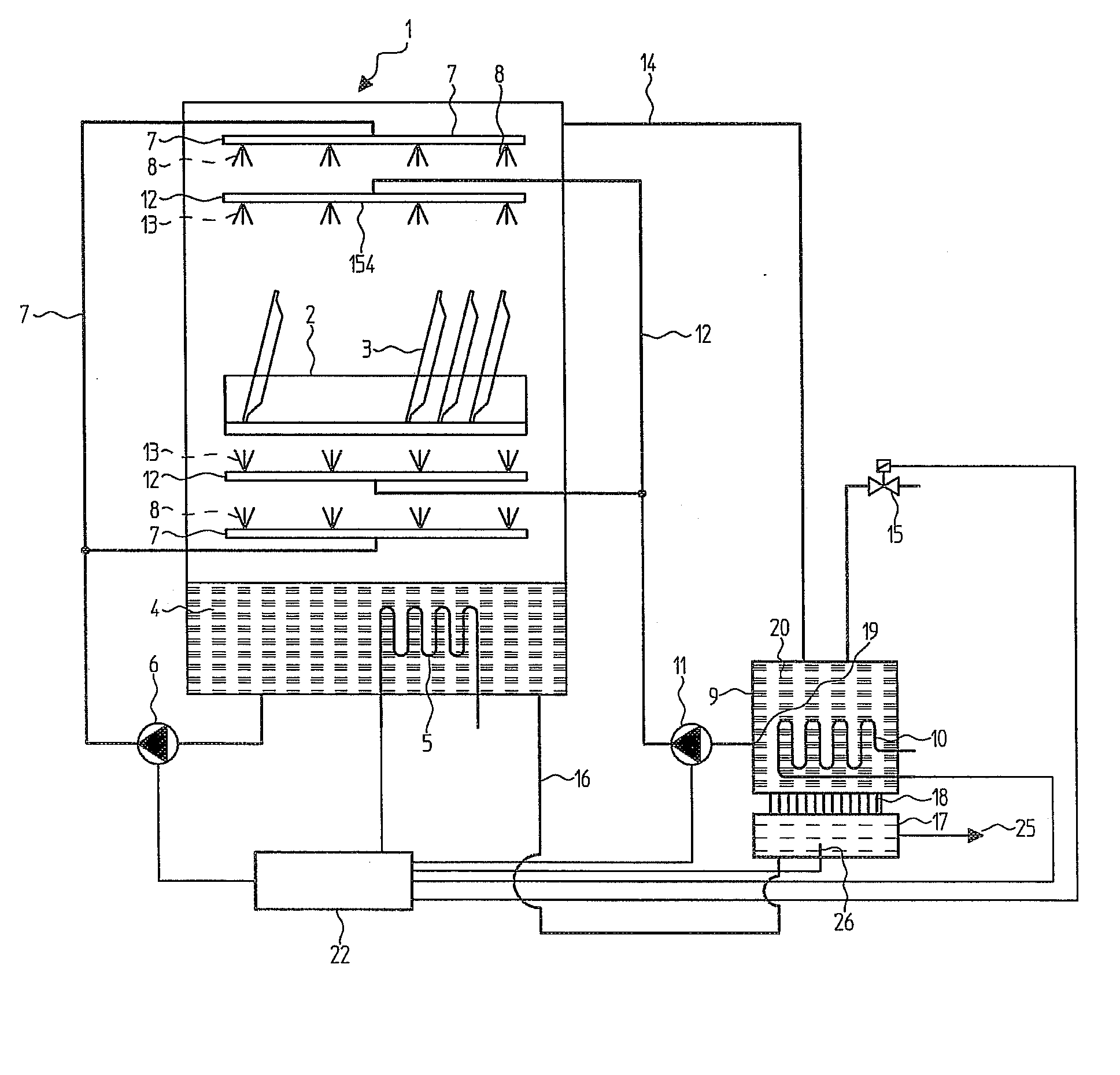

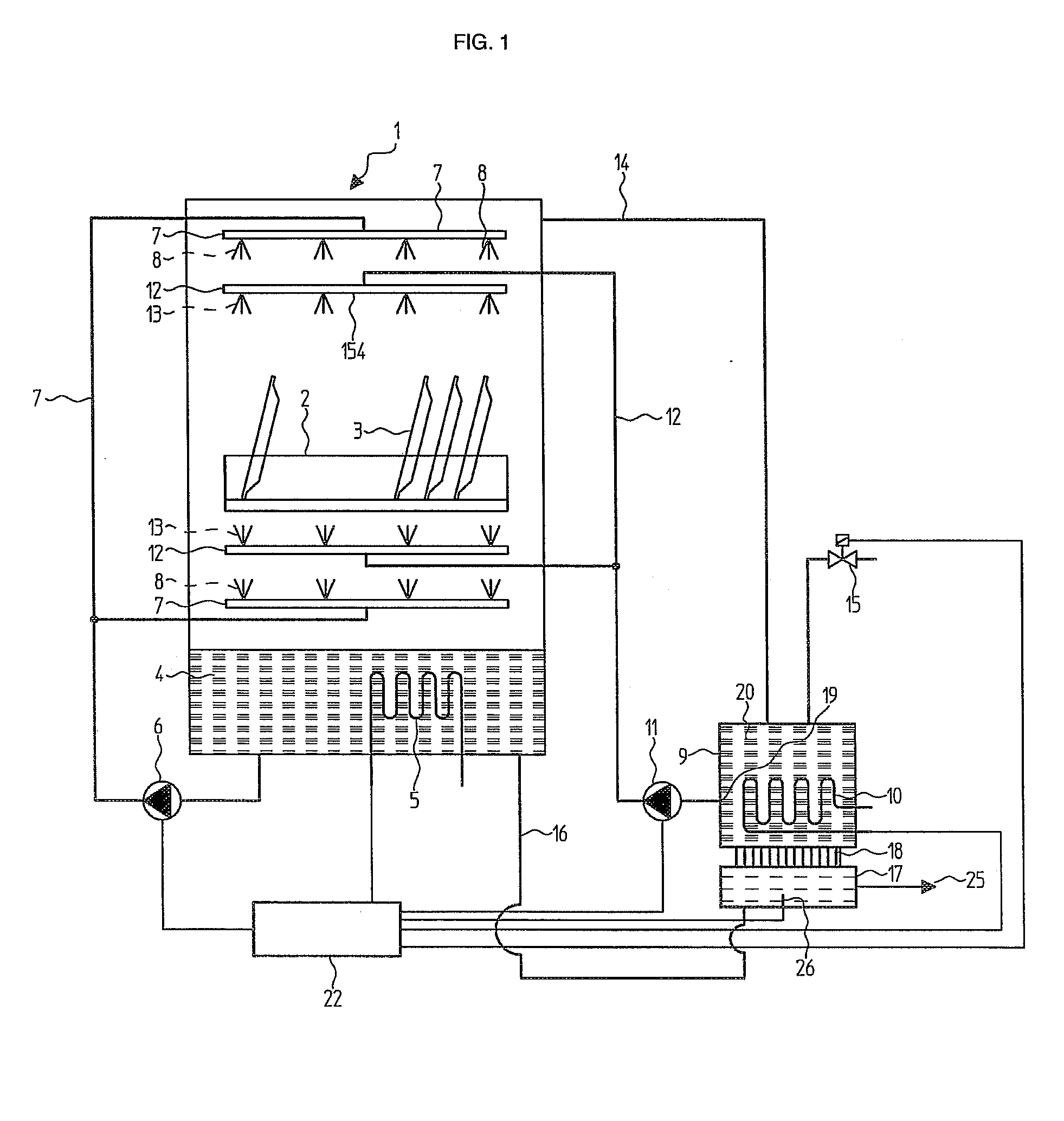

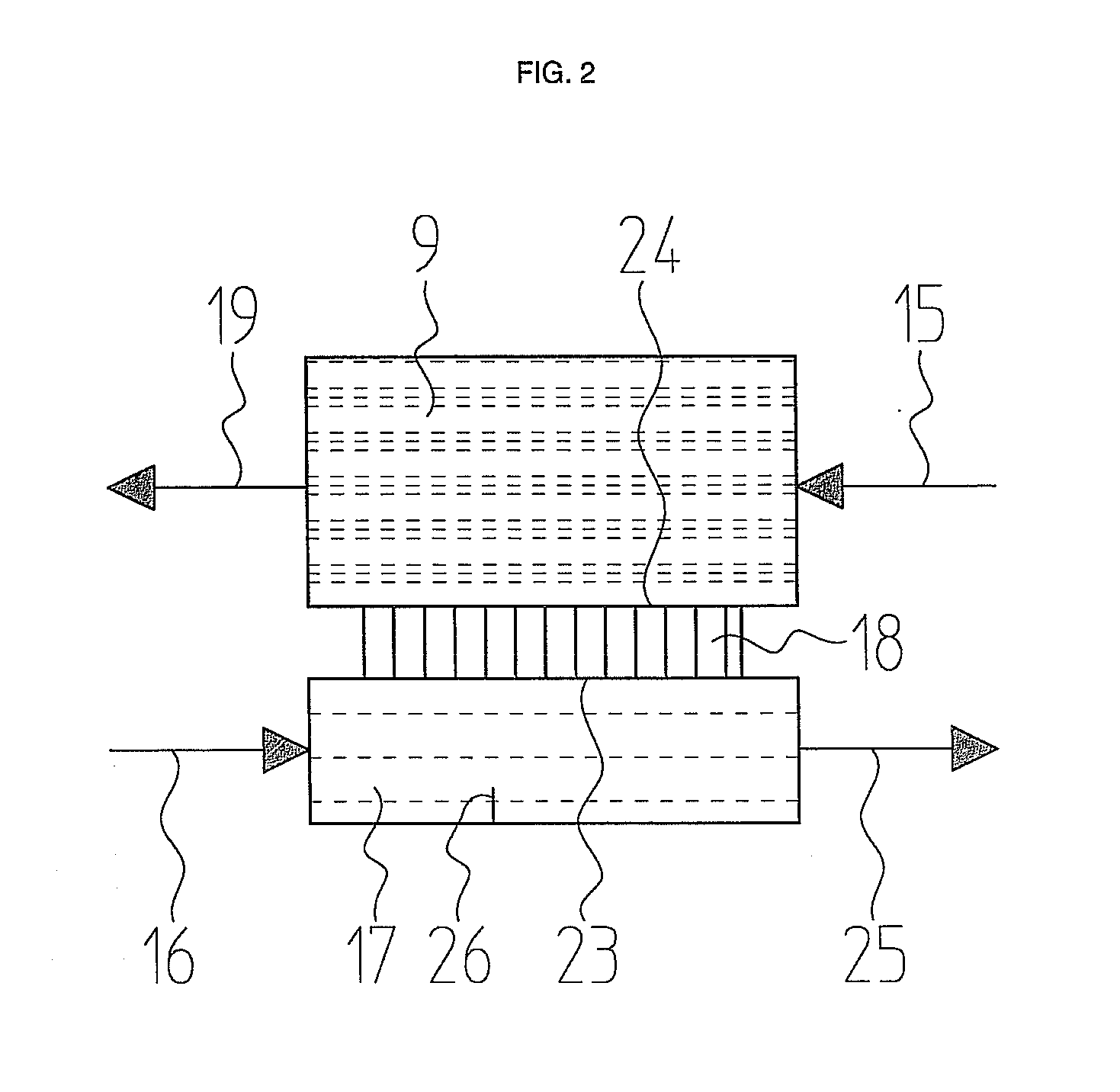

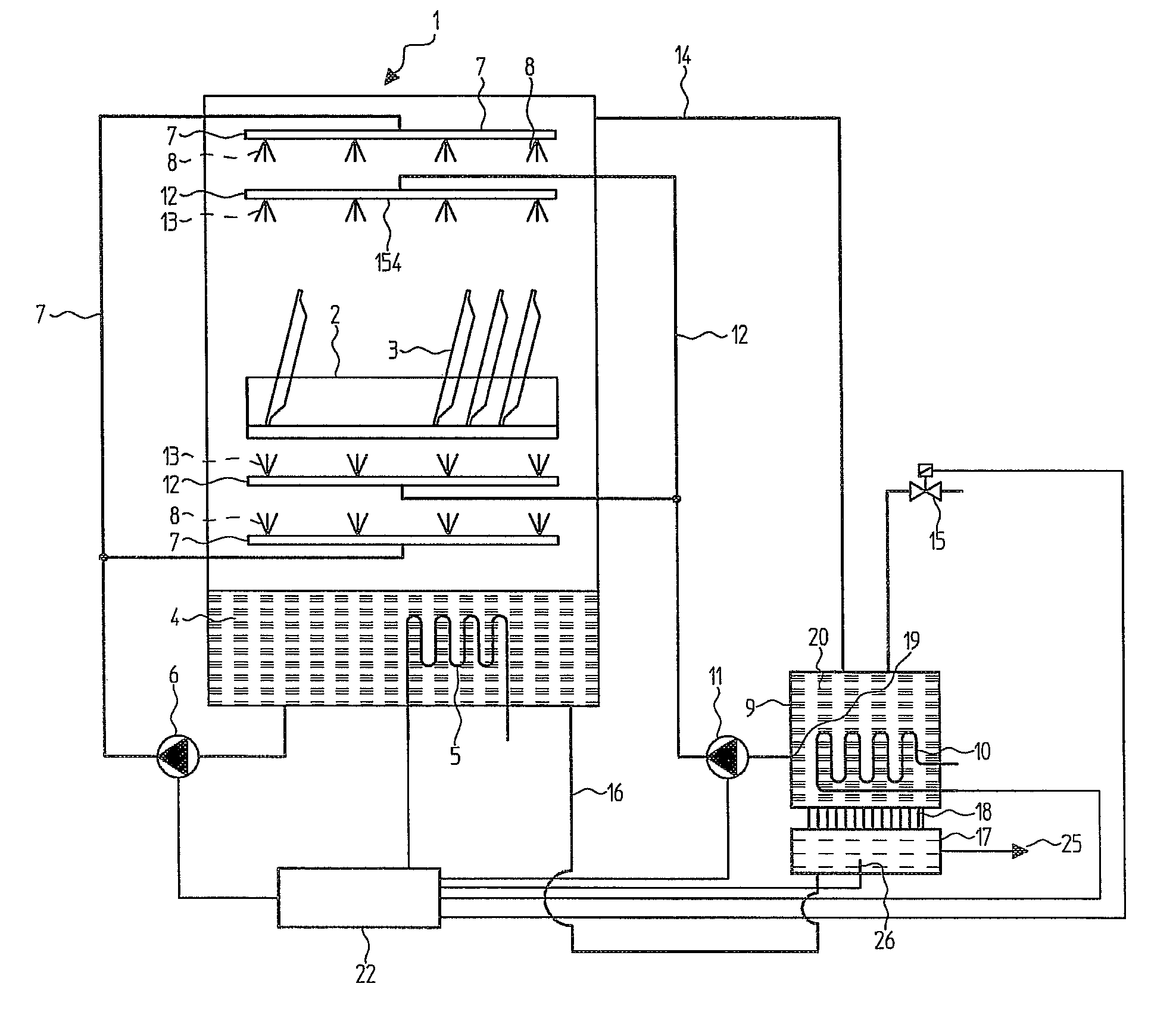

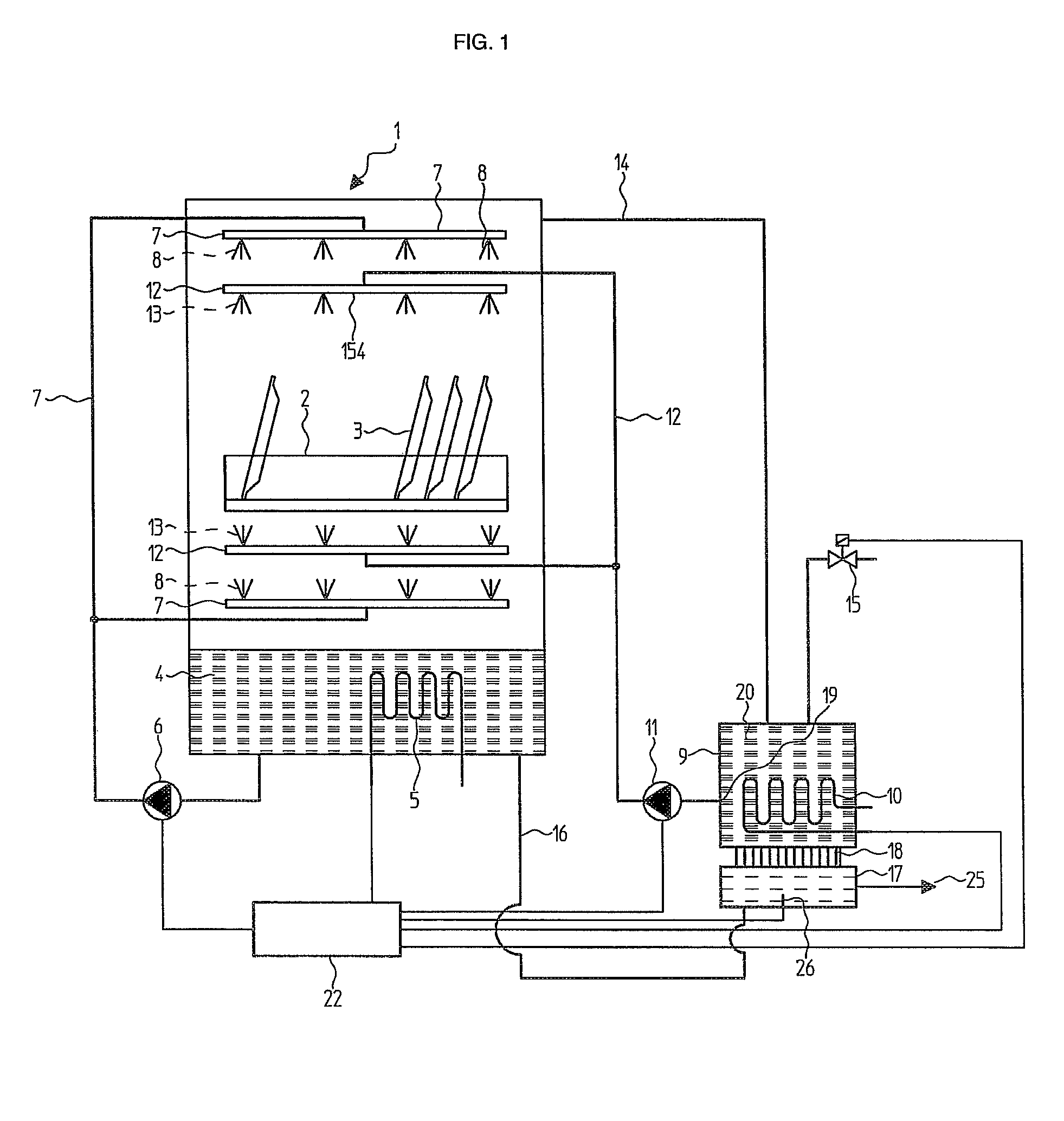

Batch dishwasher with waste water heat recovery

ActiveUS20090242005A1Facilitates heat recoveryTableware washing/rinsing machine detailsAutomatic washing/rinsing machine detectionHeat exchangerWastewater

A cleaning machine, in particular a batch dishwasher, comprising an individual cleaning chamber in which the items to be cleaned are accommodated, a pump which circulates washing liquid within the cleaning chamber, and a further pump which delivers fresh water, and also a boiler which stores and heats fresh water, wherein the boiler has an associated heat exchanger by means of which heat is indirectly or directly transferred from waste water which is stored in a reservoir to the fresh water which is stored in the boiler.

Owner:MEIKO MASCHENBAU

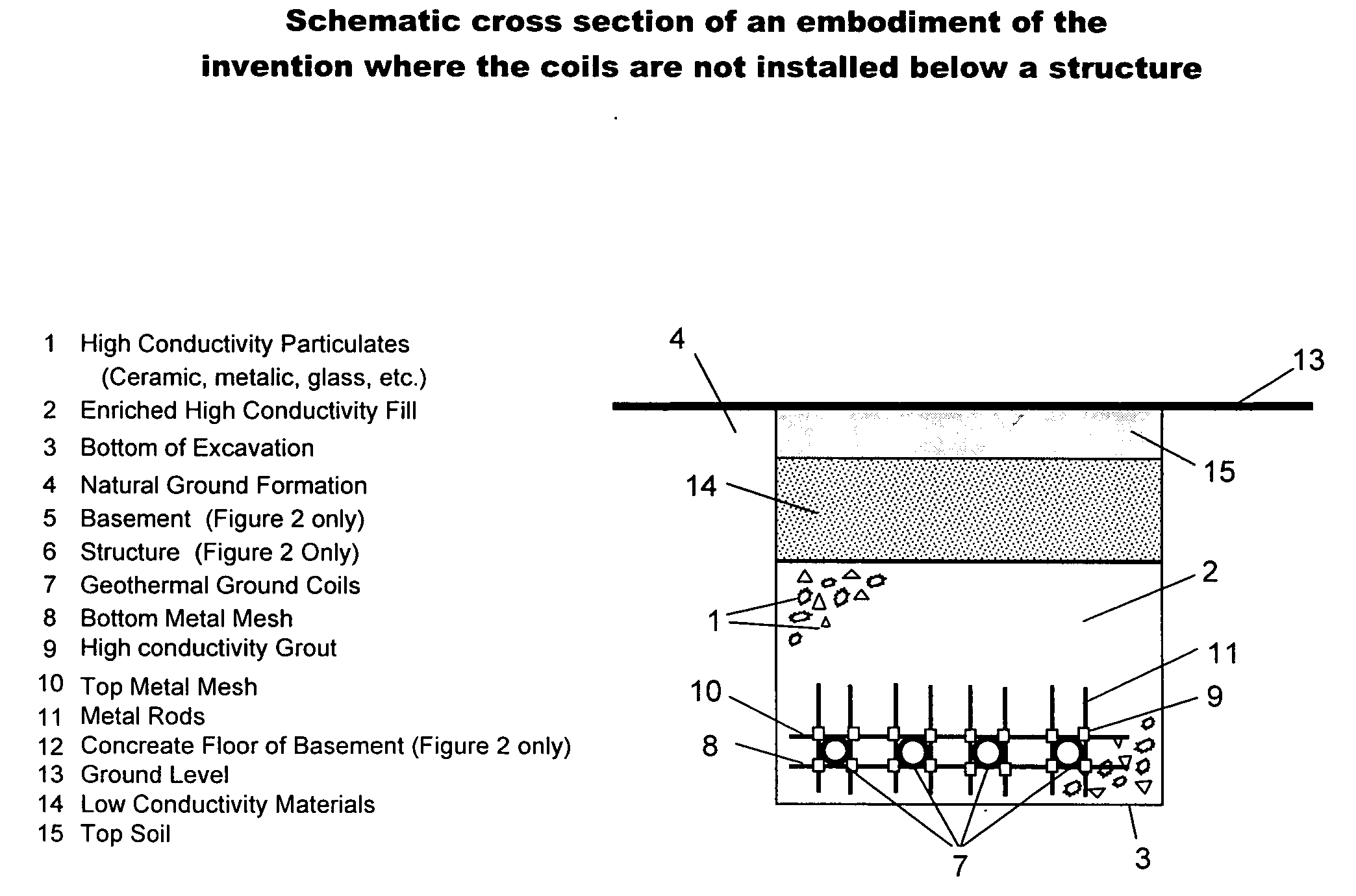

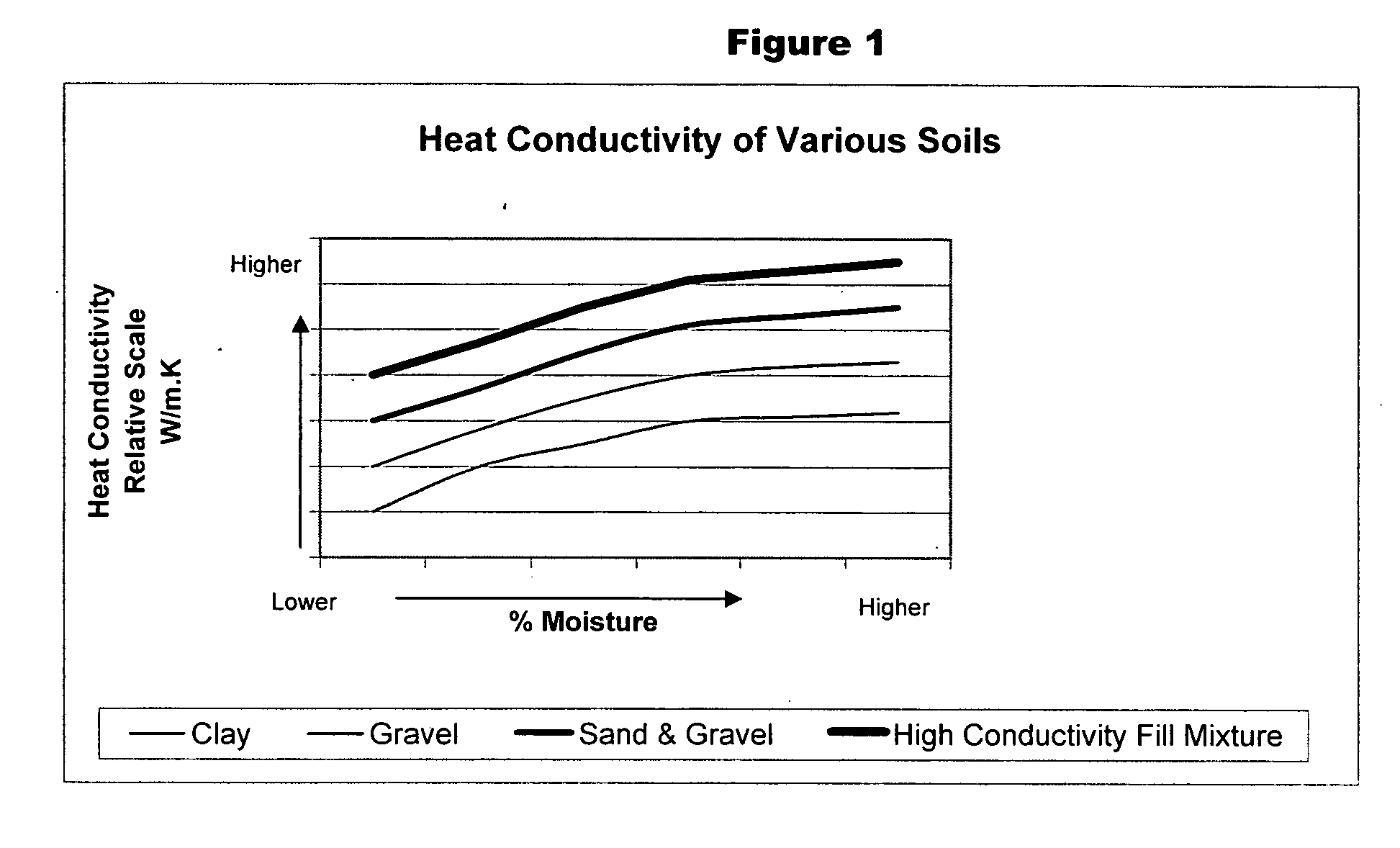

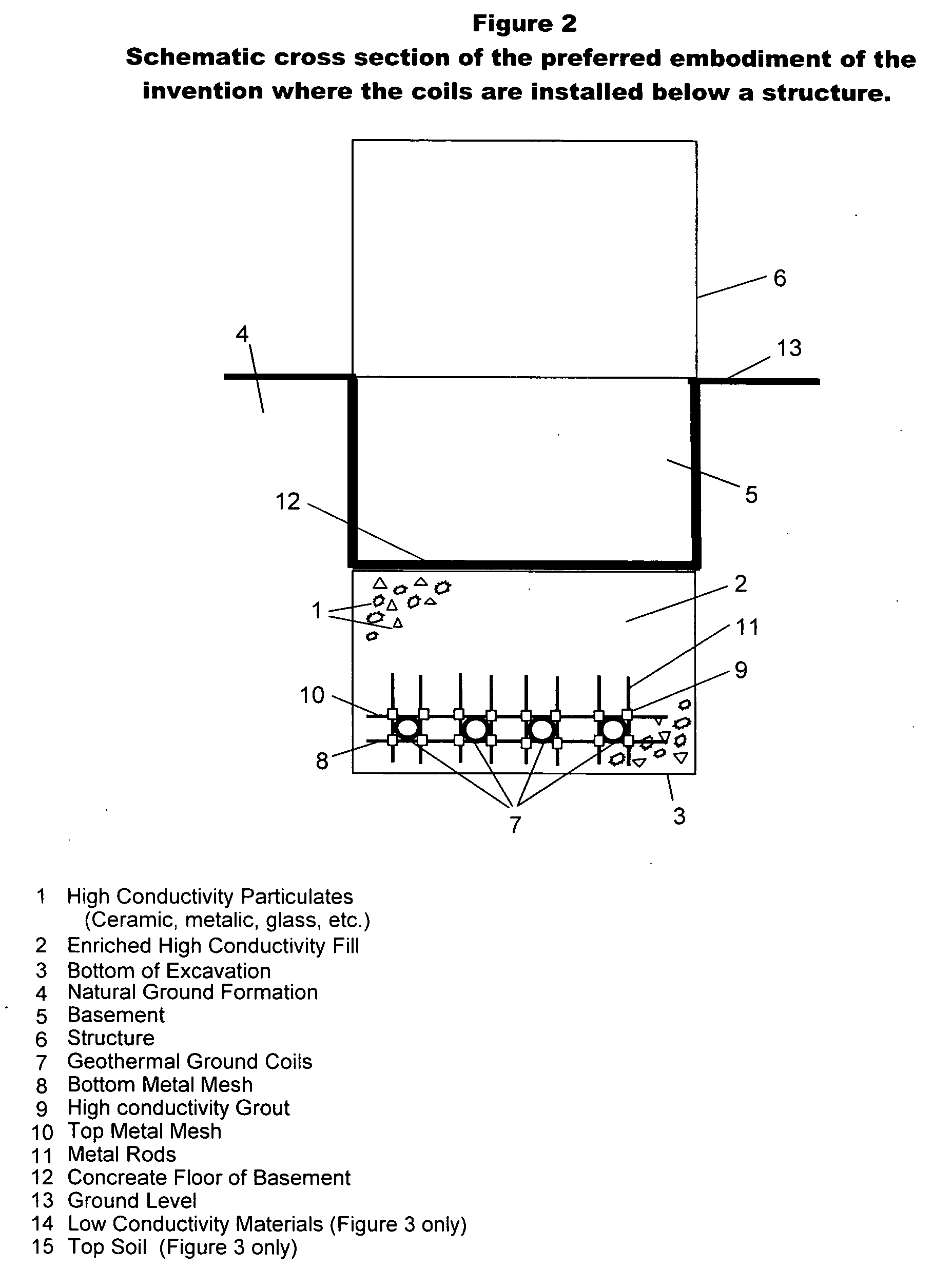

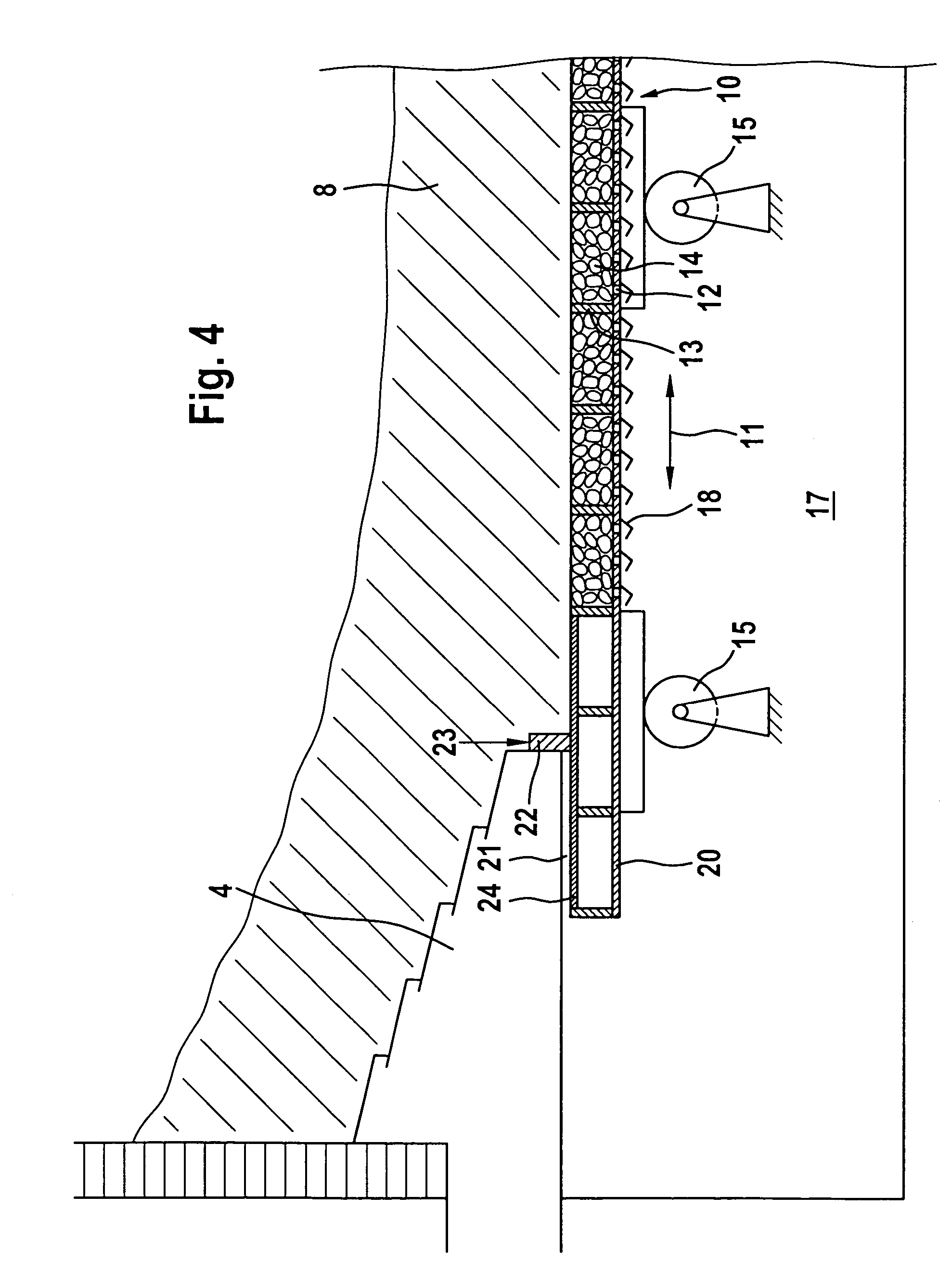

Enriched high conductivity geothermal fill and method for installation

InactiveUS20060249276A1Increase heatReduce installation costsOther heat production devicesGeothermal energy generationParticulatesMetallurgy

A geothermal fill material composed of one or more high heat conductivity materials alone or in combination to produce a fill that can be used to cover and encapsulate geothermal ground coils to improve heat transfer between the ground and the fluid inside the coils and to improve the rate of heat recovery of the fill in contact and in the vicinity of the coils. These materials can be in the form of particulates, rods or wire mesh and in any combination. Further enhancements are to cover this high conductivity material with low conductivity materials near the surface of the ground or to install the coils in a ground coil field below a structure in order to reduce ground heat loss to the atmosphere in the winter and to reduce heat gain from the atmosphere in the summer.

Owner:SPADAFORA PAUL F +2

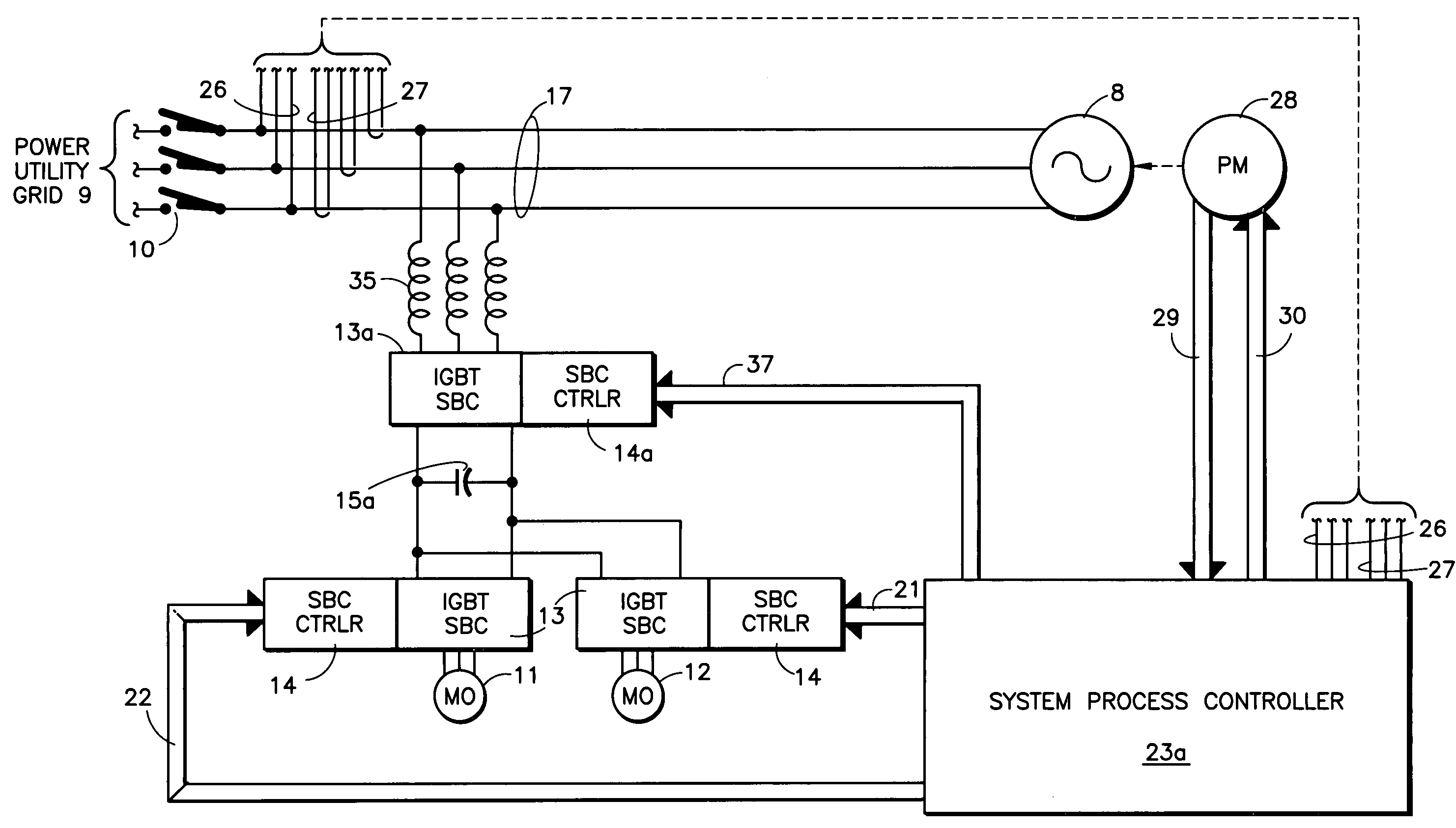

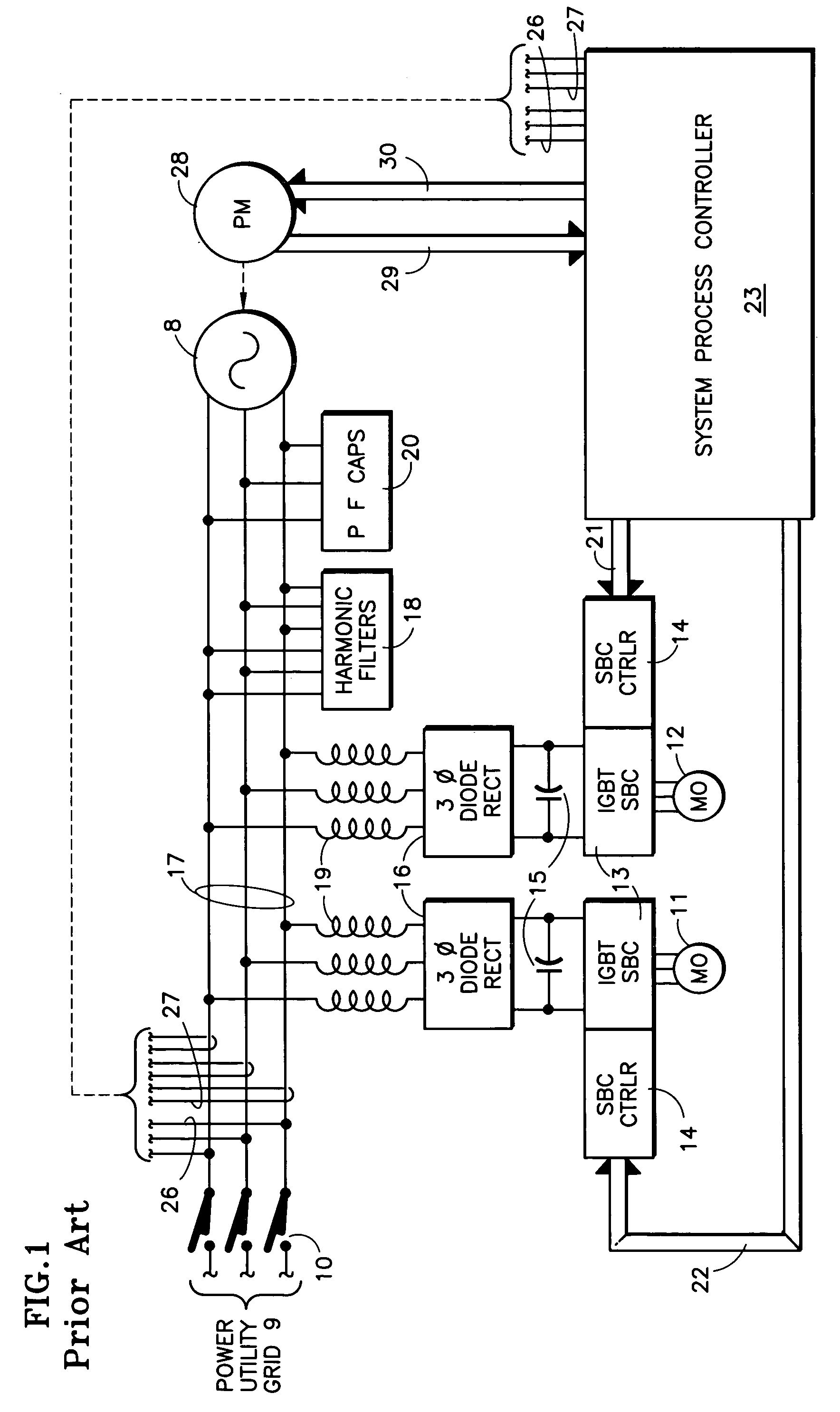

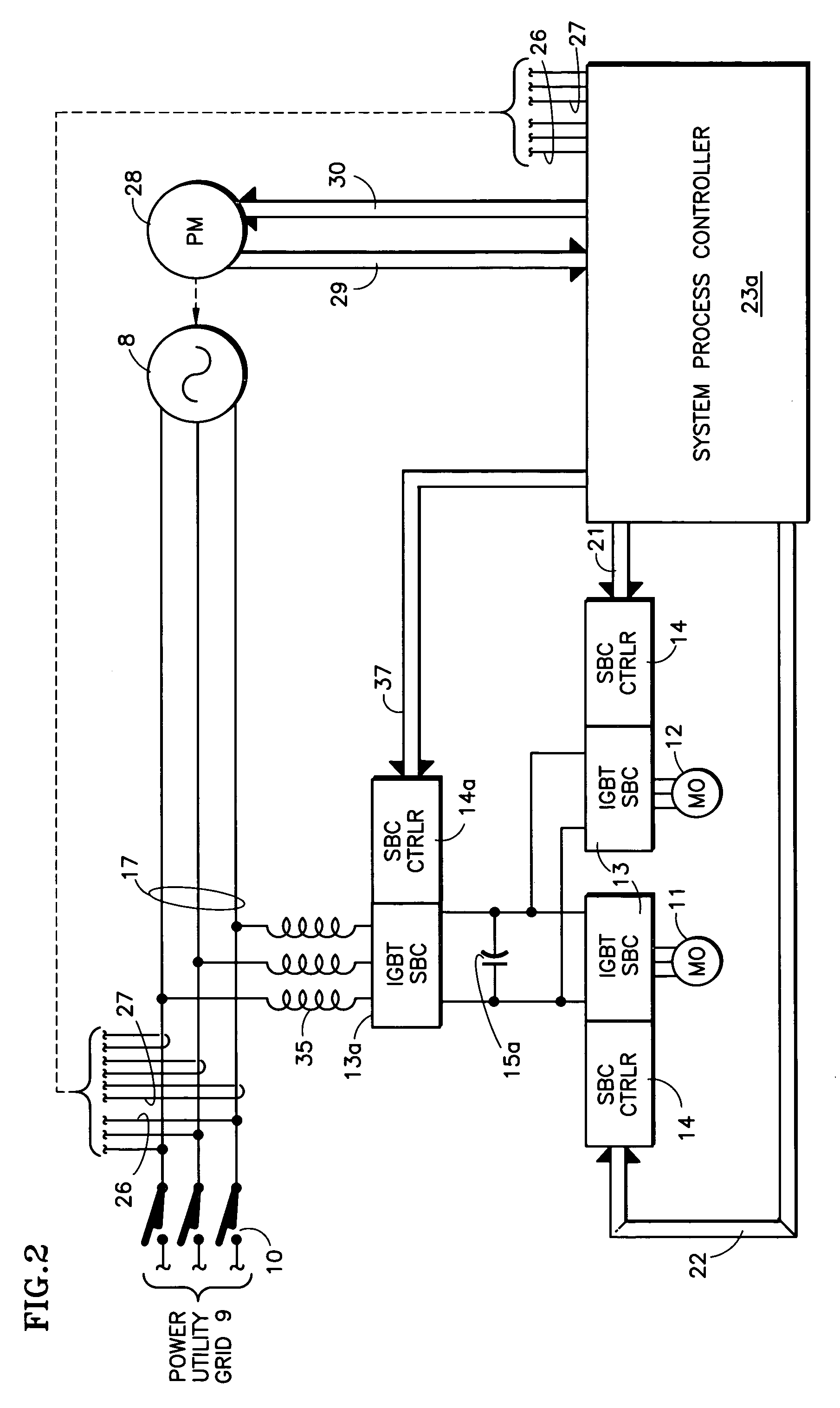

Quality power from induction generator feeding variable speed motors

InactiveUS7038329B1Without degrade qualityImprove heat recoveryBoards/switchyards circuit arrangementsAC motor controlDynamoPower grid

A prime mover (28) in a heat recovery system drives an induction generator (8) which feeds power to a utility grid (9) through a breaker (10) but also powers a load including auxiliary induction motors (11, 12). To provide acceptable waveform and power factor, the auxiliary equipment is driven through IGBT switched bridge converters (13) by DC voltage (15) generated by an IGBT switched bridge converter (13a), instead of three-phase diode rectifiers (16). The switched bridge converter controller (14a) is responsive to a system process controller (23a) which causes the switched bridge controller (13a) to be driven in response to the voltage (26) and current (27) on the generator bus (17). This eliminates the need for harmonic filters (18) and power factor capacitors (20) while improving the quality of the power generated. The controller (23a) trips the breaker if the voltage, frequency or power factor is out of limits.

Owner:UNITED TECH CORP

Method and system for a turbocharged engine

InactiveUS20120023934A1Reduce exhaust emissionsImprove fuel economyElectrical controlInternal combustion piston enginesEngineeringEngine cycle

Methods and systems are provided for a boosted engine having a split intake system coupled to a split exhaust system. Aircharges of differing composition, pressure, and temperature may be delivered to the engine through the split intake system at different points of an engine cycle. In this way, boost and EGR benefits may be extended.

Owner:FORD GLOBAL TECH LLC

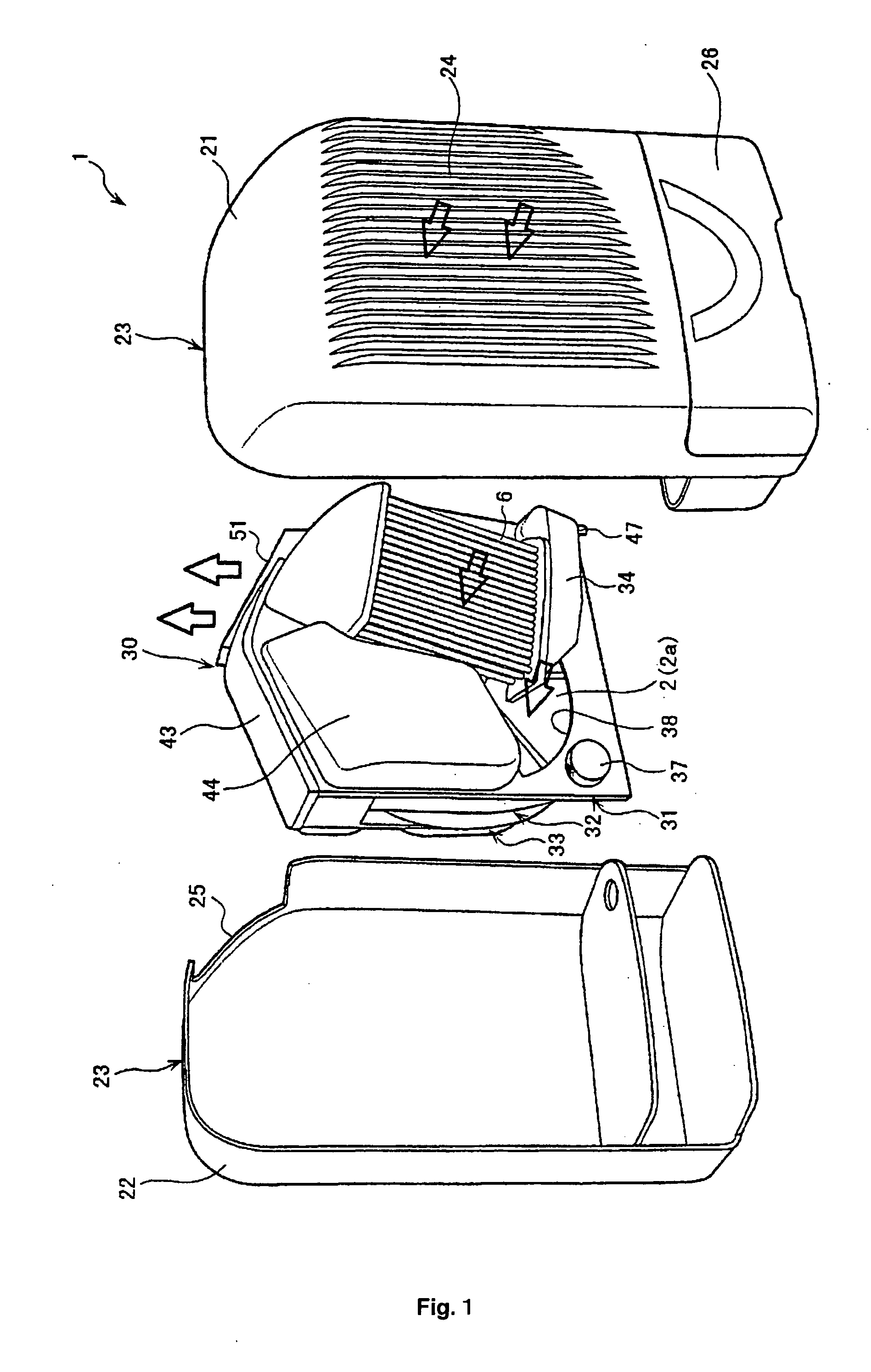

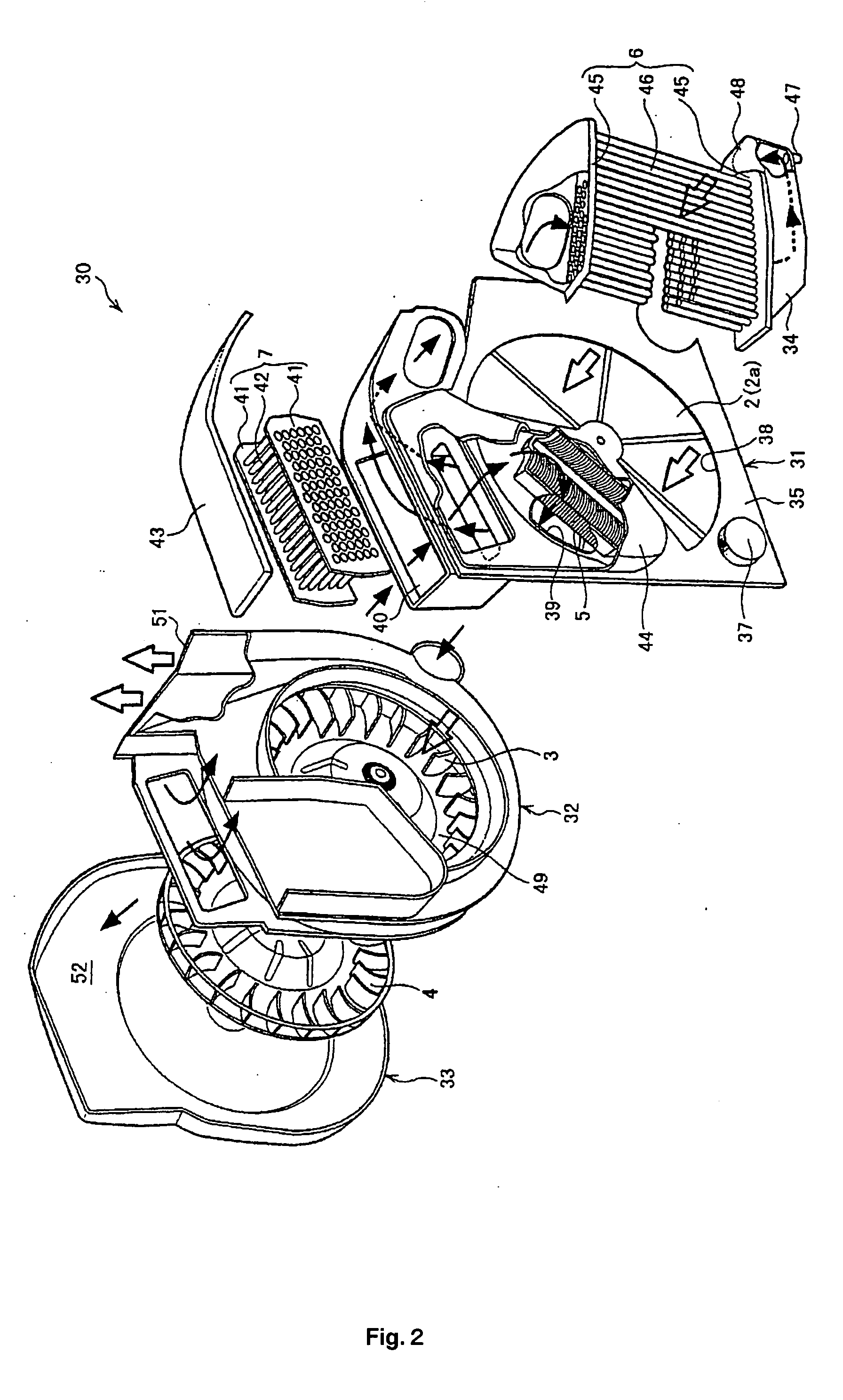

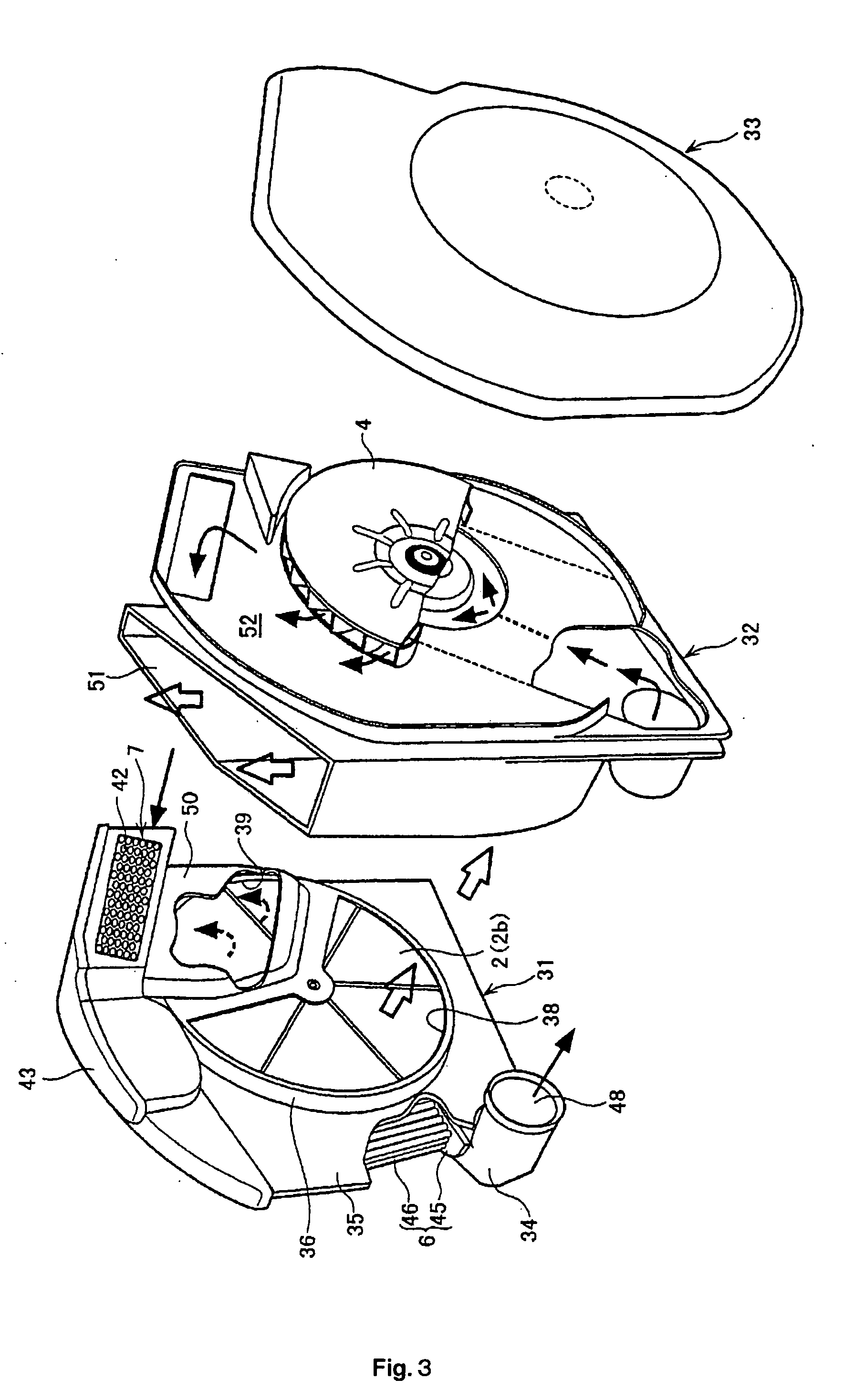

Dehumidifier

InactiveUS20060015974A1Reduce power consumptionAmount of dehumidification per a power consumption can be promotedAir treatment detailsNuclear energy generationEngineeringMechanical engineering

A dehumidifier by which the rate of heat recovery by the heat exchanger for recovering heat can be increased, the power consumption of the heater can be decreased, and by which the amount of dehumidification per a power consumption can be promoted, is disclosed. The dehumidifier 1 comprises a rotor case 31 harboring a dehumidification rotor 2 rotatably and drivably mounted therein, having an opening for dehumidification 38 through which air to be dehumidified passes, and having an opening for regeneration 39 through which air for regeneration passes; a heater 5 for heating the air for regeneration before passing through the opening for regeneration; a heat exchanger for recovering heat 7 which transfers heat of the air for regeneration passing through the second passage section to the air for regeneration passing through the first passage section; a dehumidification passage X harboring a dehumidification fan 3; and a regeneration passage Y harboring a regeneration fan 4. The direction of rotation of the dehumidification rotor 2 is set such that the air for regeneration which passed through posterior area C of the dehumidification rotor flows into downstream portion in the second passage section, and that the air for regeneration which passed through anterior area H of the dehumidification rotor flows into upstream portion in the second passage section.

Owner:AMBIENT CORPORATION

Copper-based powder dispersion ceramic as well as preparation method and application thereof

InactiveCN103667772AStrong impact pressureHigh mechanical strengthBraking membersCopperUltimate tensile strength

The invention relates to copper-based powder dispersion ceramic as well as a preparation method and application thereof, and relates to the field of ceramic materials. The copper-based powder dispersion ceramic is prepared from an anti-abrasion constituent element as one of the raw materials, wherein the anti-abrasion constituent element comprises the following components by mass percent of all the raw materials: 1-5 percent of diamond powder and 1-5 percent of titanium diboride powder. The copper-based powder dispersion ceramic is high in impact pressure resistance, high in mechanical intensity, high in friction and abrasion resistance, long in service life, high in heat dissipation property and heat recovery property, high in high-temperature and low-temperature resistance, high in acid, alkaline, oil, water and the like corrosion resistance and the like.

Owner:刘伟

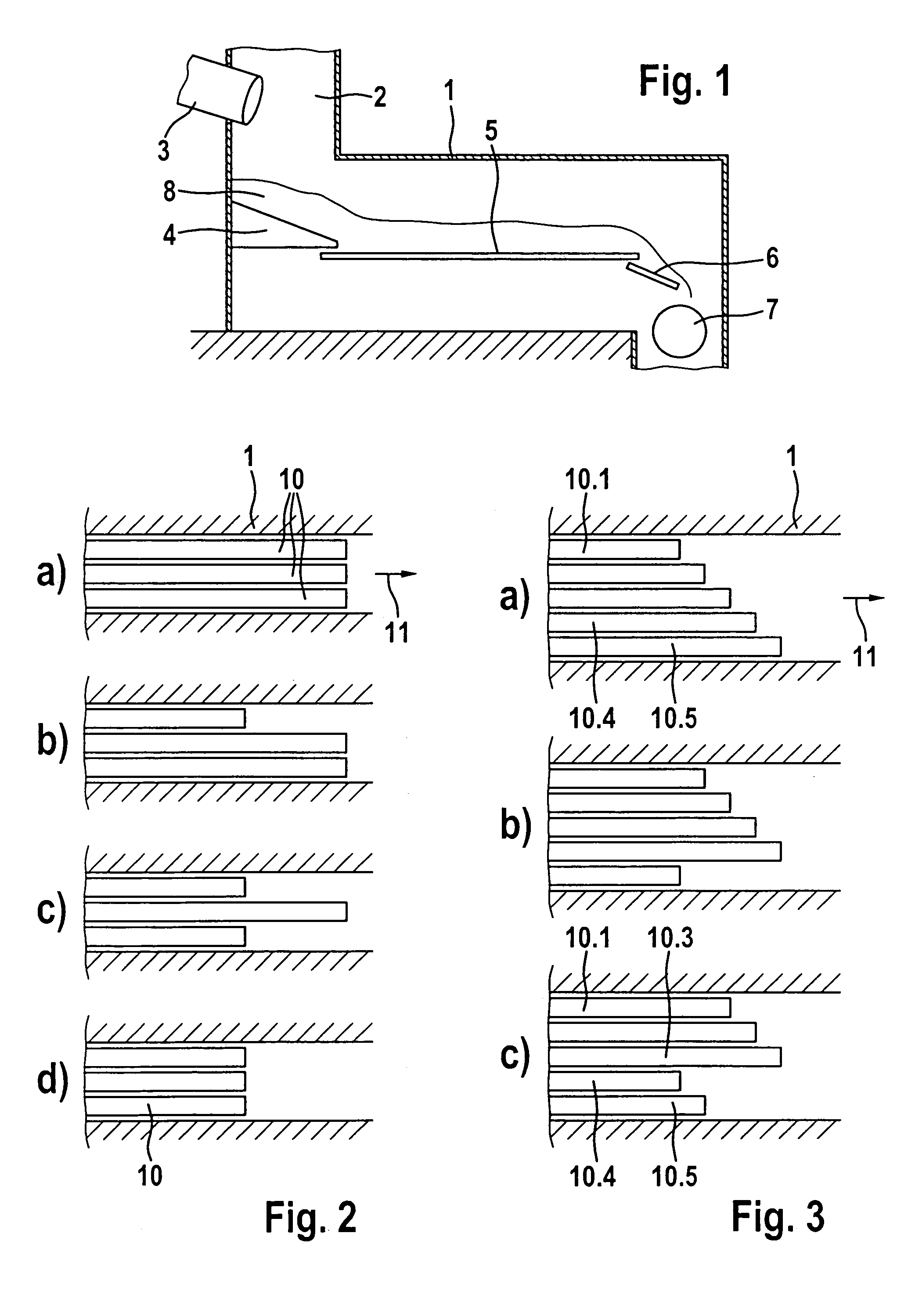

Method and apparatus for treating a layer of bulk material

InactiveUS7114612B2Facilitates heat recoveryNo energy lossConveyorsRotary drum furnacesBattenAirflow

The invention includes a method and apparatus for treating, in particular cooling, a layer of bulk material by means of a stream of gas passed through it on a grate. The grate includes a plurality of elongated planks which extend in a conveying direction and are driven in advancing and return strokes in the conveying direction in such a manner that at least two adjacent planks are moved forward simultaneously and are moved back non-simultaneously. Since the material located on a plank which is being moved back is prevented from completely following the plank moving back by the friction generated with the material located above the adjacent planks or with the wall, the conveying effect in the conveying direction outweighs the conveying effect in the opposite direction.

Owner:CLAUDIUS PETERS PROJECTS

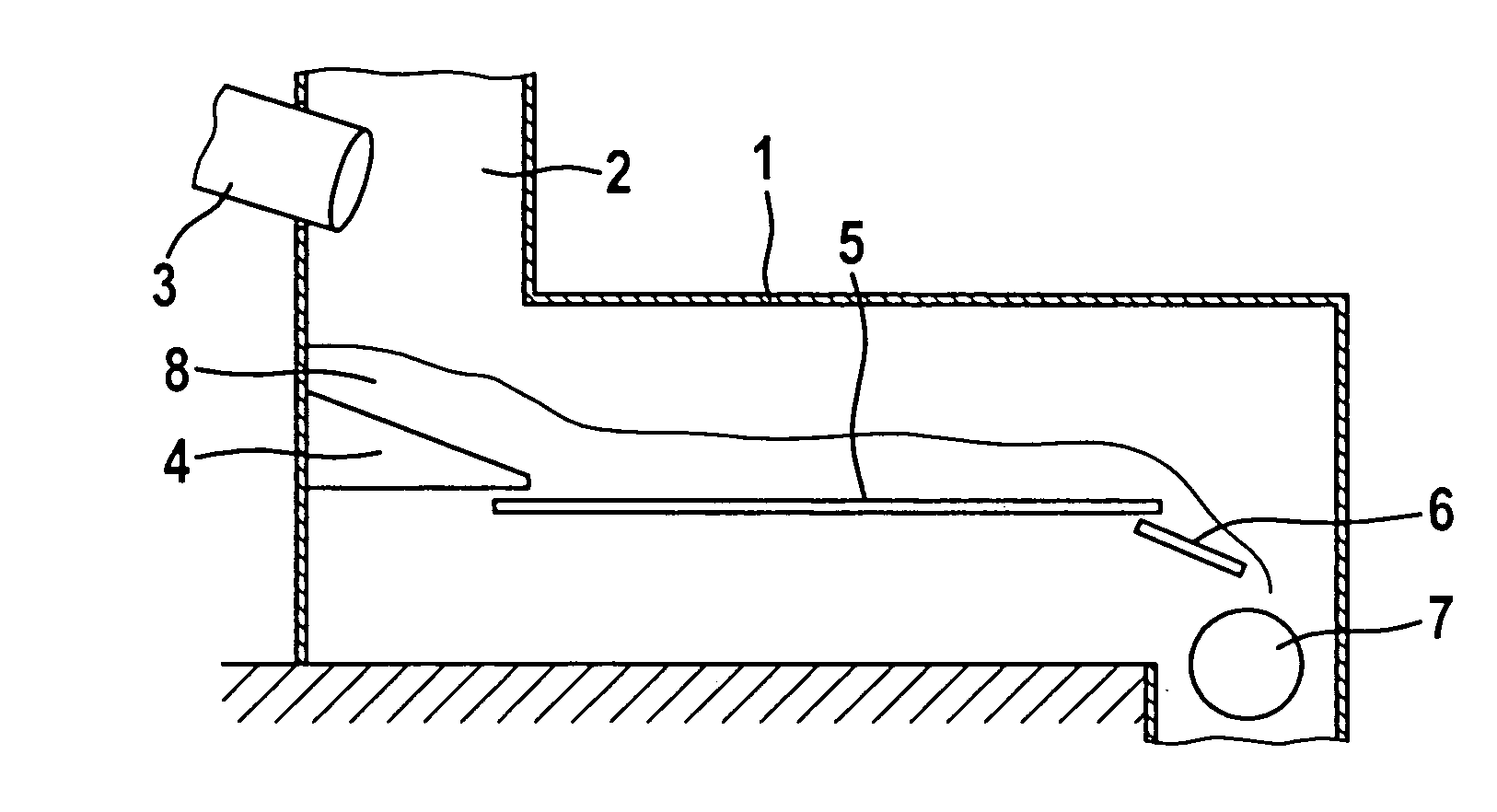

SNCR (Selective Non-catalytic Reduction) denitration device and denitration method

InactiveCN103349898AImprove efficiencyLess investmentDispersed particle separationTemperature controlNuclear engineering

The invention relates to an SNCR (Selective Non-catalytic Reduction) denitration device and a denitration method adopting the device. The device includes a denitration reactor (1), a fuel jetting control device (2), a temperature control device (3), a reducing agent jetting device (4), a denitration reactor outlet flue (5), a denitration reactor inlet flue (6) and a fuel system controller (8), wherein the fuel jetting control device (2), the temperature control device (3), the reducing agent jetting device (4), the denitration reactor outlet flue (5) and the denitration reactor inlet flue (6) are all mounted on the denitration reactor (1); the fuel jetting control device (2) is connected with the temperature control device (3) through a fuel system controller (9). The denitration method provided by the invention is realized through adopting the denitration device provided by the invention. The device provided by the invention has the advantages of high efficiency, low investment and excellent heat recovery benefit.

Owner:张蕊

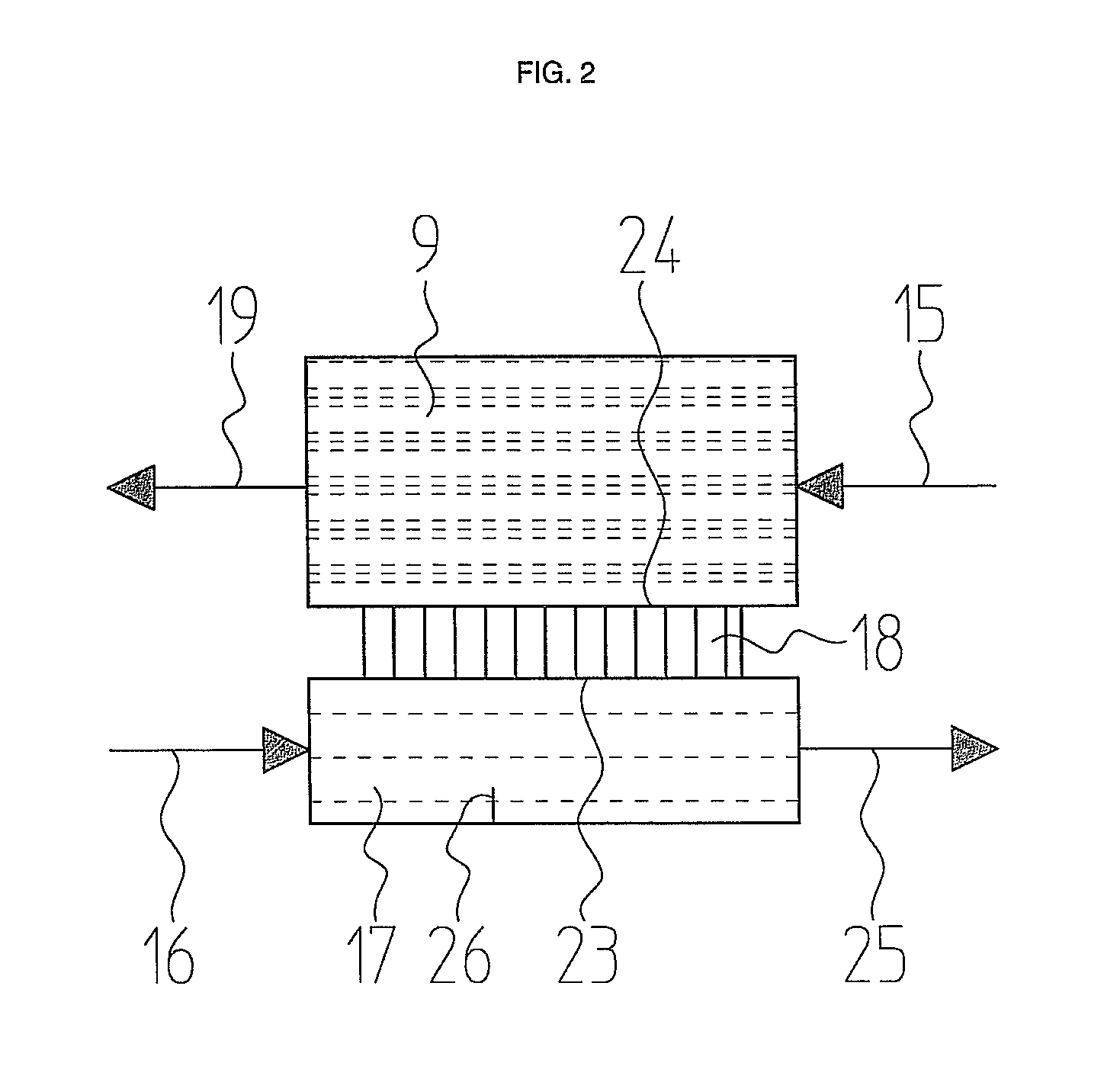

Greenhouse

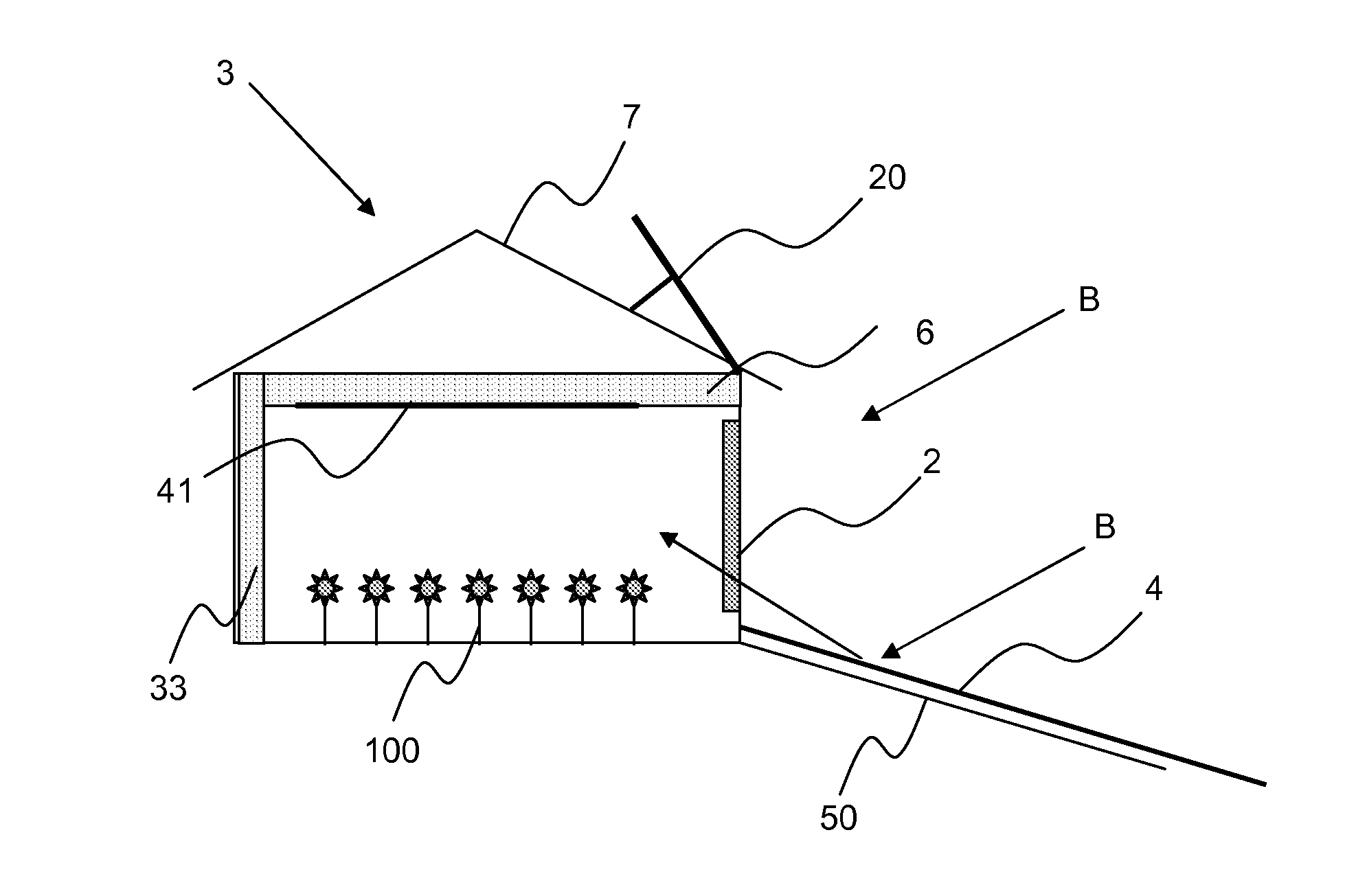

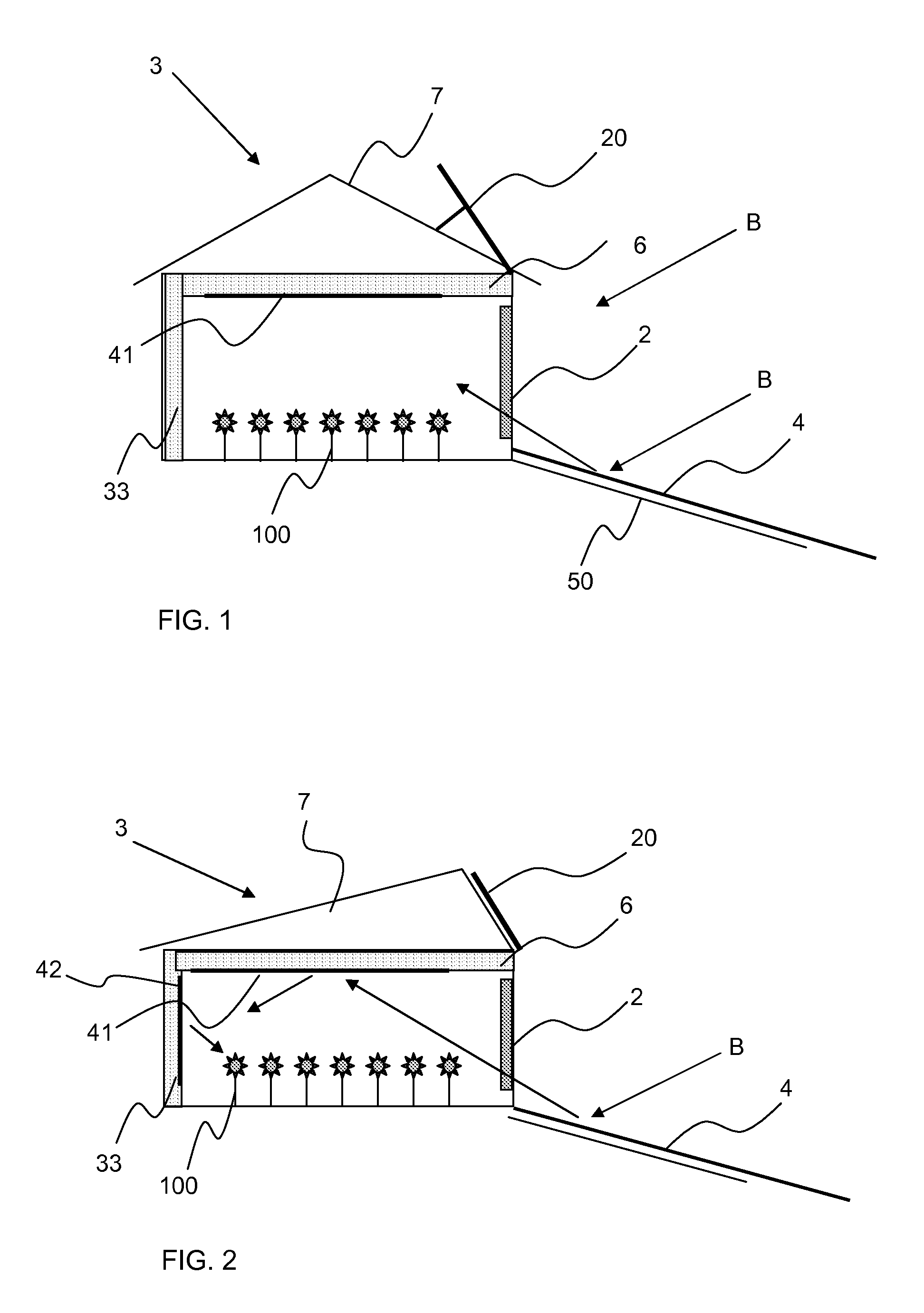

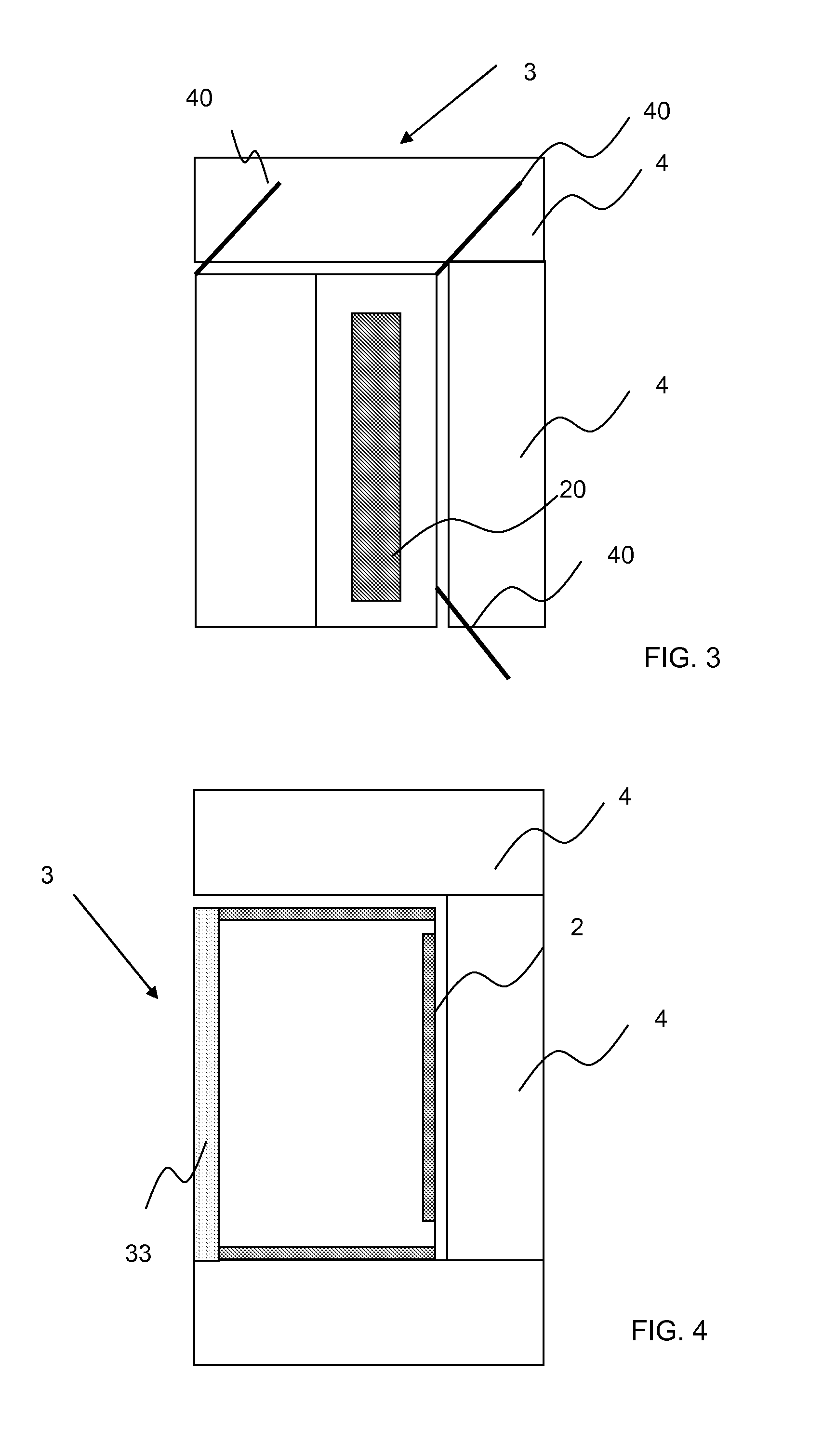

ActiveUS20110167716A1Save energyFacilitates heat recoverySolar heating energySolar heat devicesGreenhouseEngineering

The present invention relates to a greenhouse comprising outside walls provided with translucent surfaces (2) such that light may be received into the greenhouse (3) from at least two geographical directions, a roof structure (7) and a roof (6) provided with an insulating material portion. The invention is characterized in that the outside walls, in connection with the translucent surfaces (2), are provided with a light reflecting yard structure which resides below the translucent surfaces (2), above a ground surface (50), and extending away from the outside wall. The greenhouse (3) may further comprise vertically positioned light reflecting surface elements (40) and light reflecting shade elements (44) movable in a direction parallel with the transparent surfaces (2).

Owner:MYNTTI ASKO

Nitric acid production technology with double-pressurized method

InactiveCN105366653AIncrease profitImprove absorption rateEnergy inputNitric acidHigh concentrationPlatinum

The invention discloses a nitric acid production technology with a double-pressurized method. The technology includes the steps of: (1) mixing of raw materials; (2) operation of an ammoxidation reaction; (3) thermal recovery and cooling; (4) absorption; (5) bleaching; and (6) treatment of tail gas. The production technology is reasonable and simple, and has high ammonia utilization rate, low platinum consumption, high absorptivity, high concentration of finished acid, and low content of NOx in the tail gas. Moreover, the production technology avoids wasting of energy resources, is suitable for promotion in various nitric acid manufactures, and has good thermal recovery so that the steam is more than self-sufficient.

Owner:蒋小华

Apparatus for Feed Preheating with Flue Gas Cooler

ActiveUS20100239475A1Simple materialReduce riskCatalytic crackingMilk preservationFlue gasHigh pressure

Hydrocarbon feed to a catalytic reactor can be heat exchanged with flue gas from a catalyst regenerator. This innovation enables recovery of more energy from flue gas thus resulting in a lower flue gas discharge temperature. As a result, other hot hydrocarbon streams conventionally used to preheat hydrocarbon feed can now be used to generate more high pressure steam.

Owner:UOP LLC

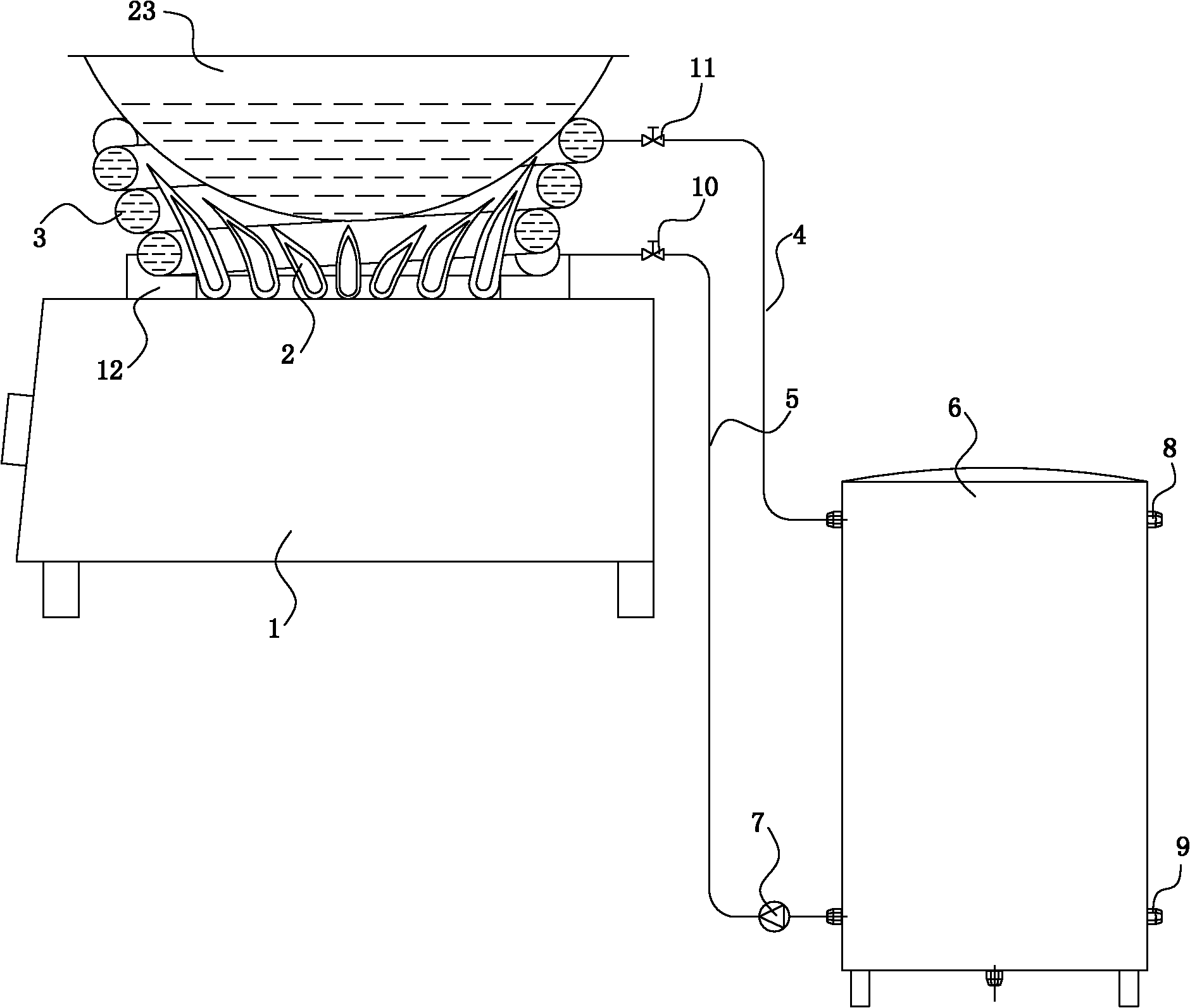

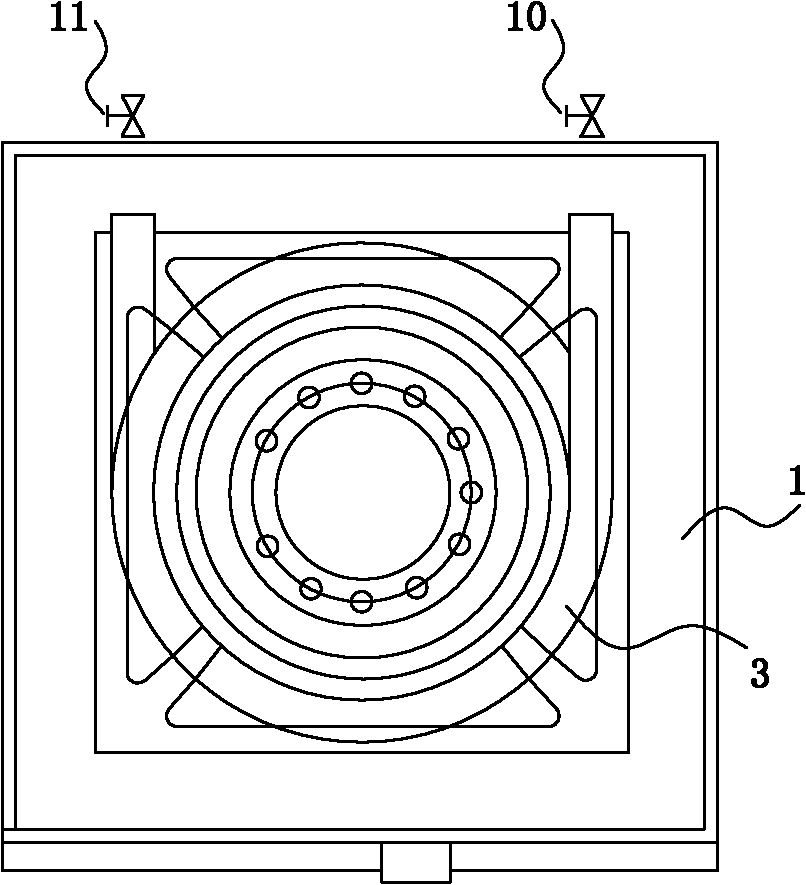

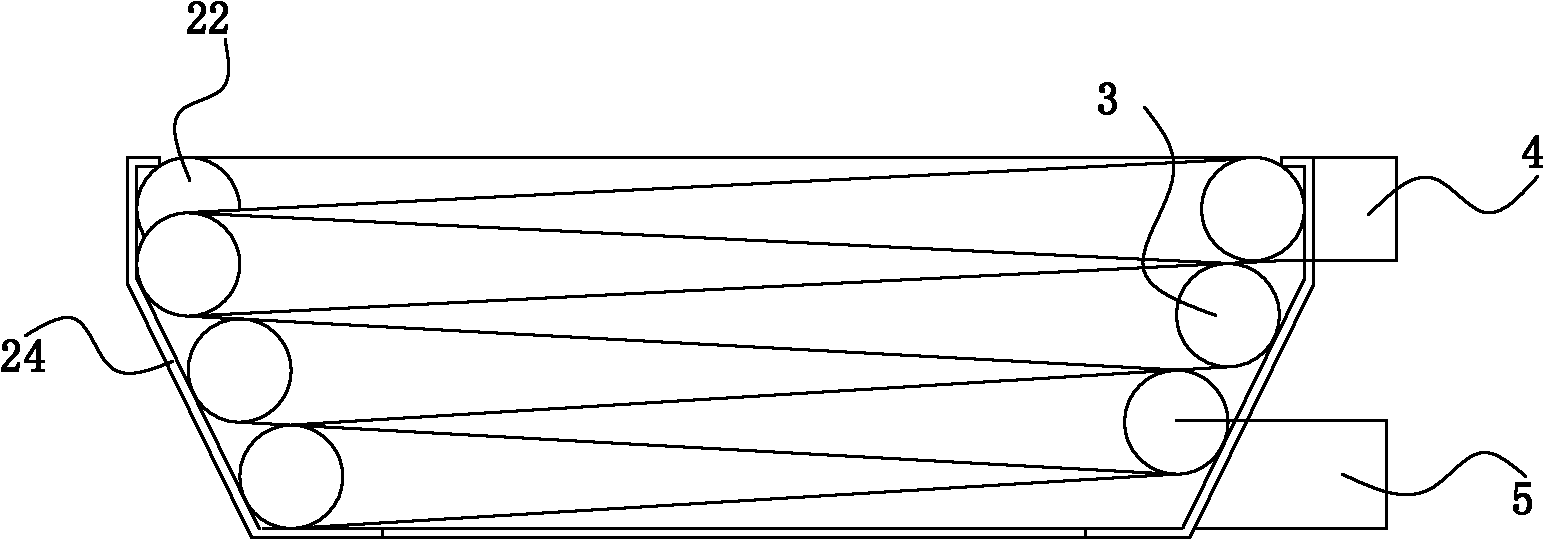

Heat recovery system of gas cooker

InactiveCN102102879AImprove the effect of environmental protection and energy savingImprove comfortLighting and heating apparatusWater heating stoves/rangesProcess engineeringCooker

The invention discloses a heat recovery system of a gas cooker, comprising the gas cooker, a heat recovery exchanger, a hot water outlet pipe, a water return pipe and a hot water storage tank. A fire hole is arranged above the gas cooker, the heat recovery exchanger is arranged at the periphery of the fire hole, two ends of the heat recovery exchanger are communicated with the hot water storage tank respectively through the hot water outlet pipe and the water return pipe to form a heat recovery pipeline, and a water pump, a water feeding hole and a hot water outlet are arranged on the heat recovery pipeline. By virtue of the heat recovery system of the gas cooker, heat energy in a home can be recycled, more hot water can be provided for home life, and the comfortableness of the home life is further improved.

Owner:苏宇贵

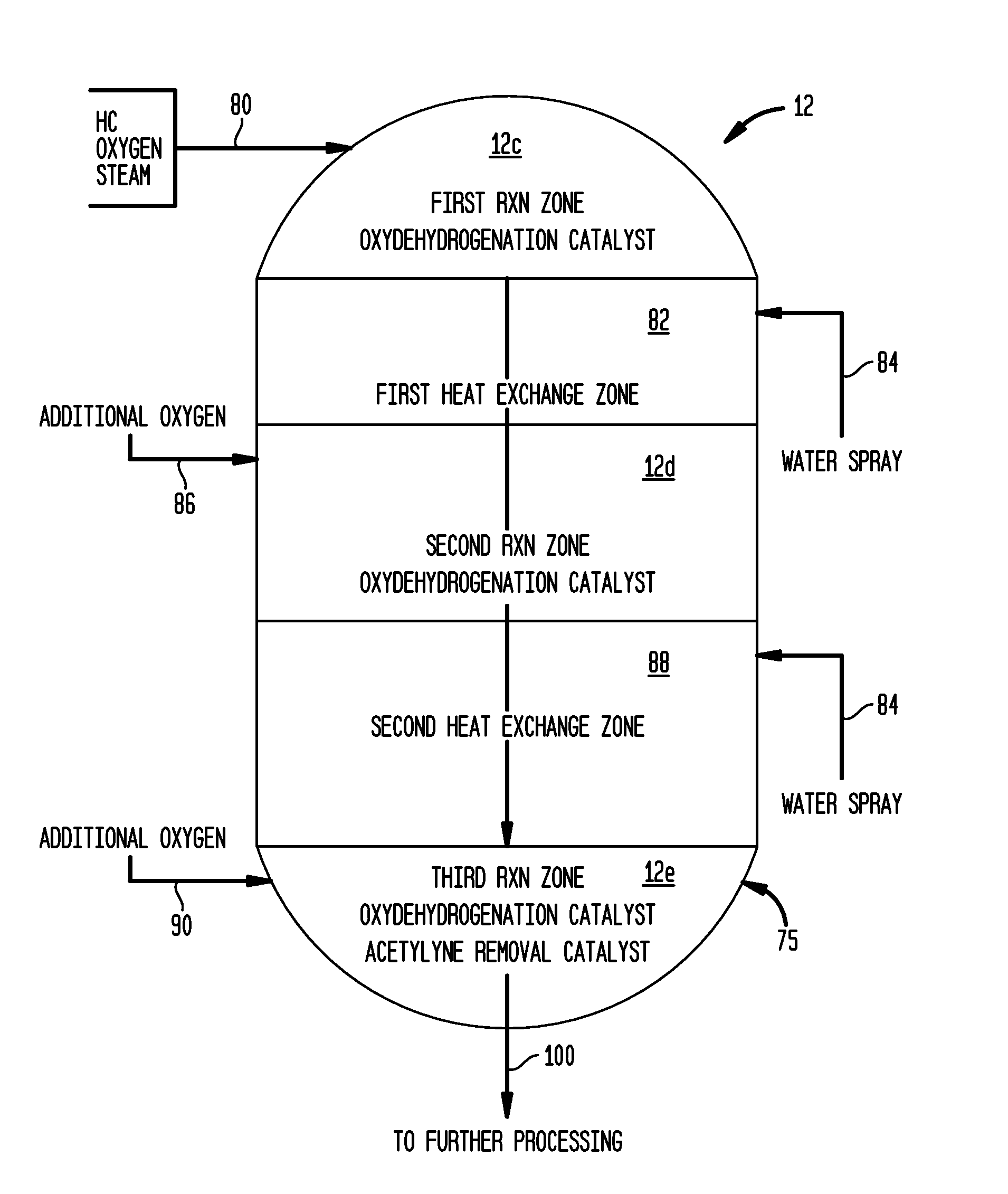

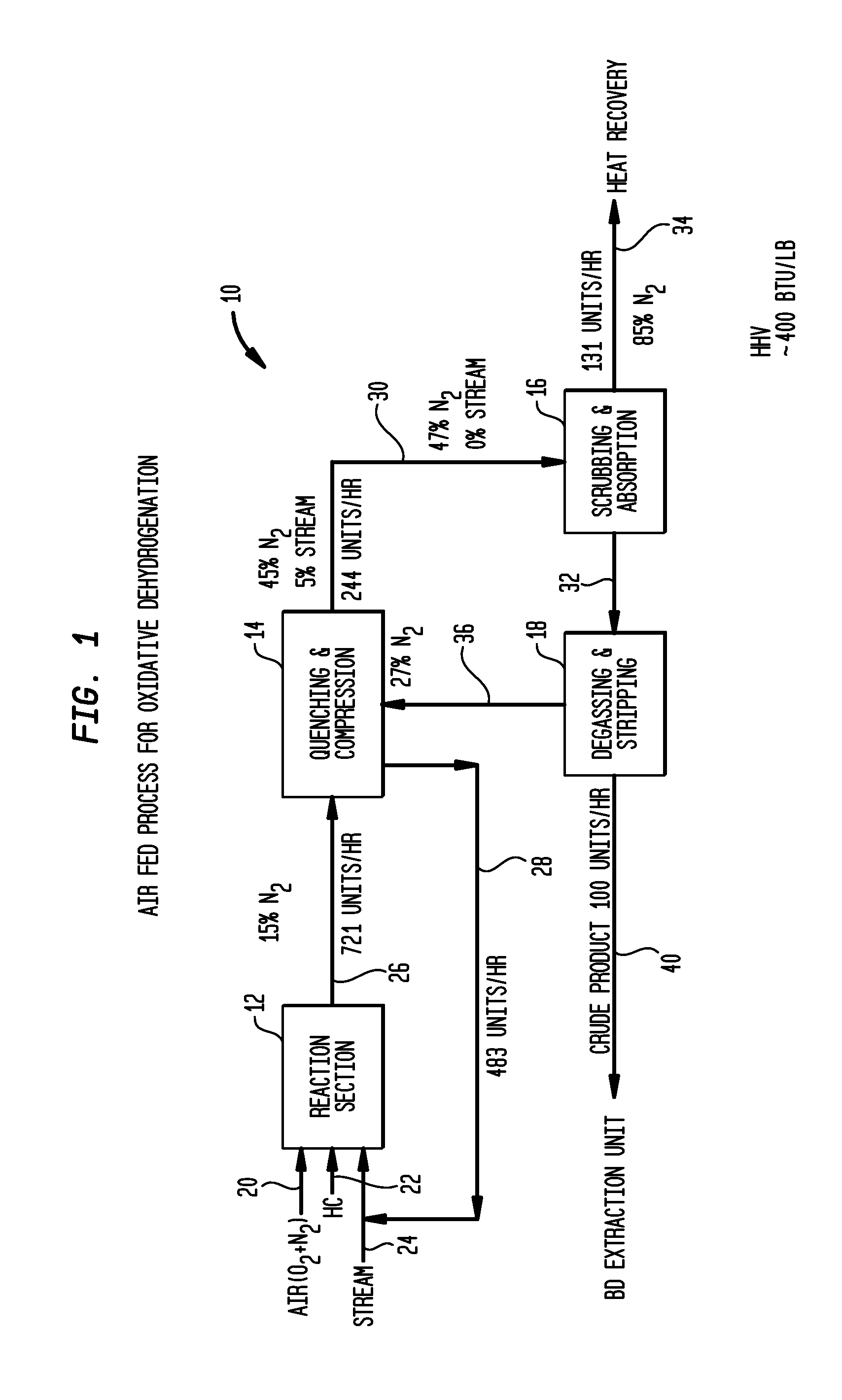

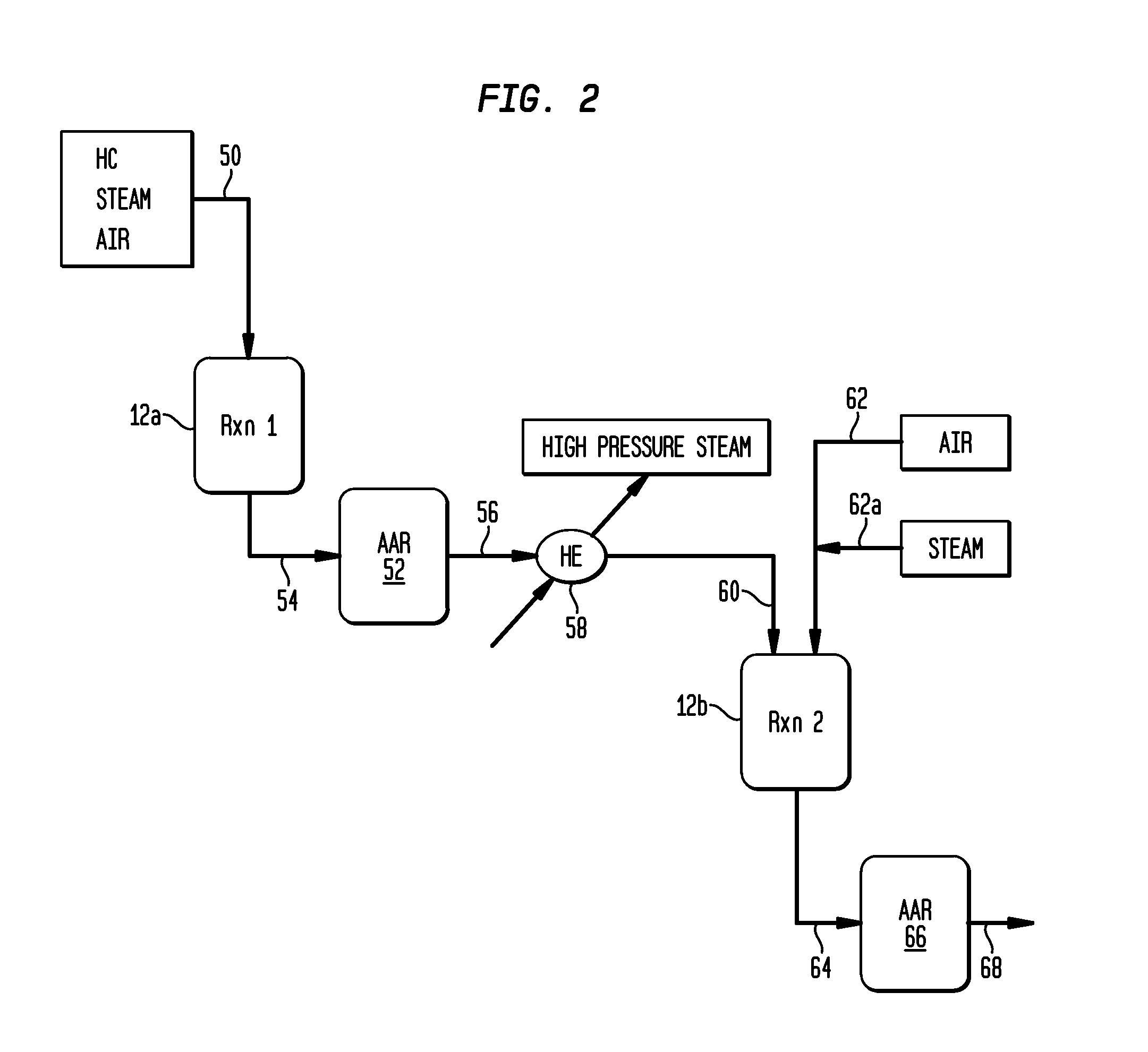

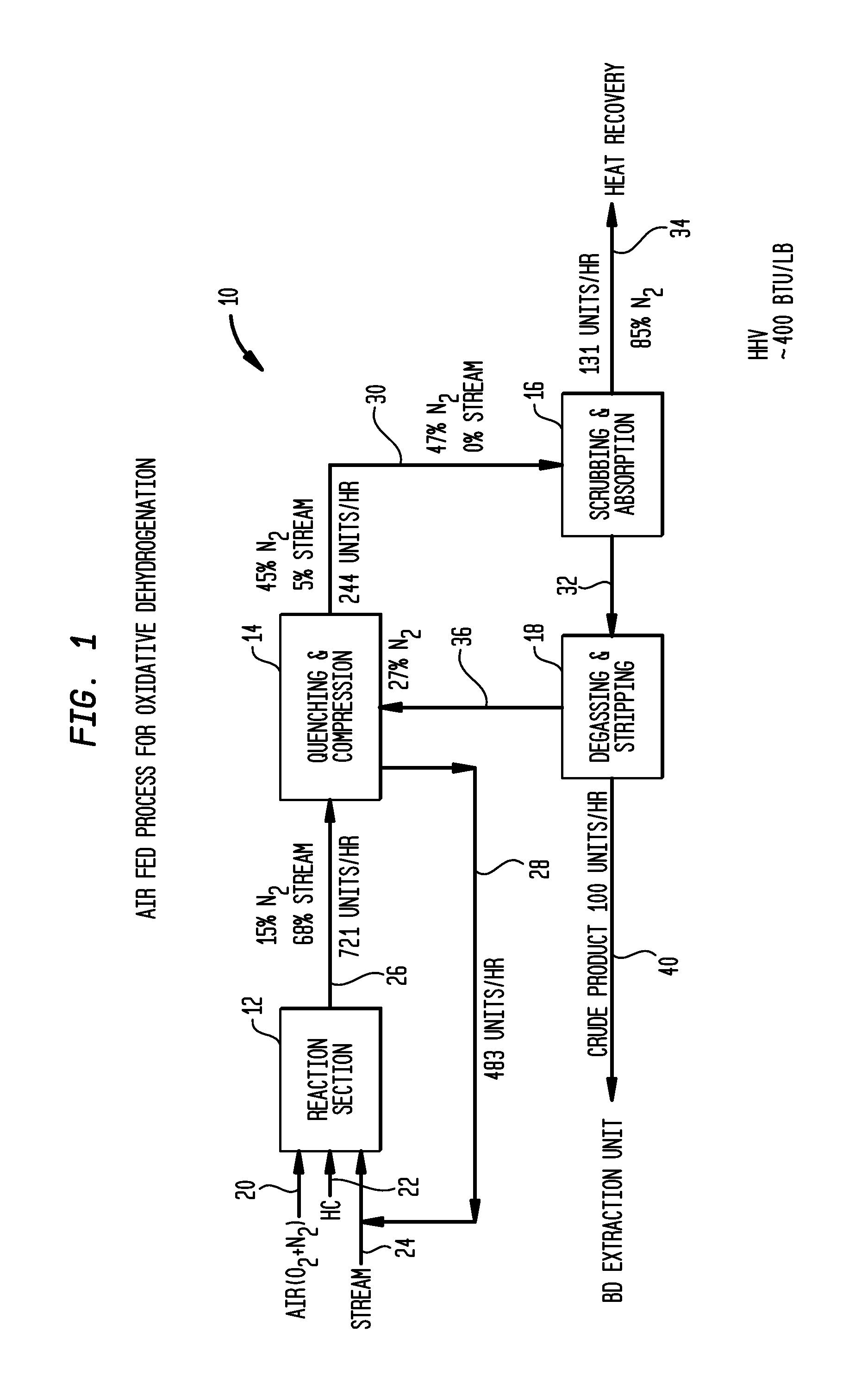

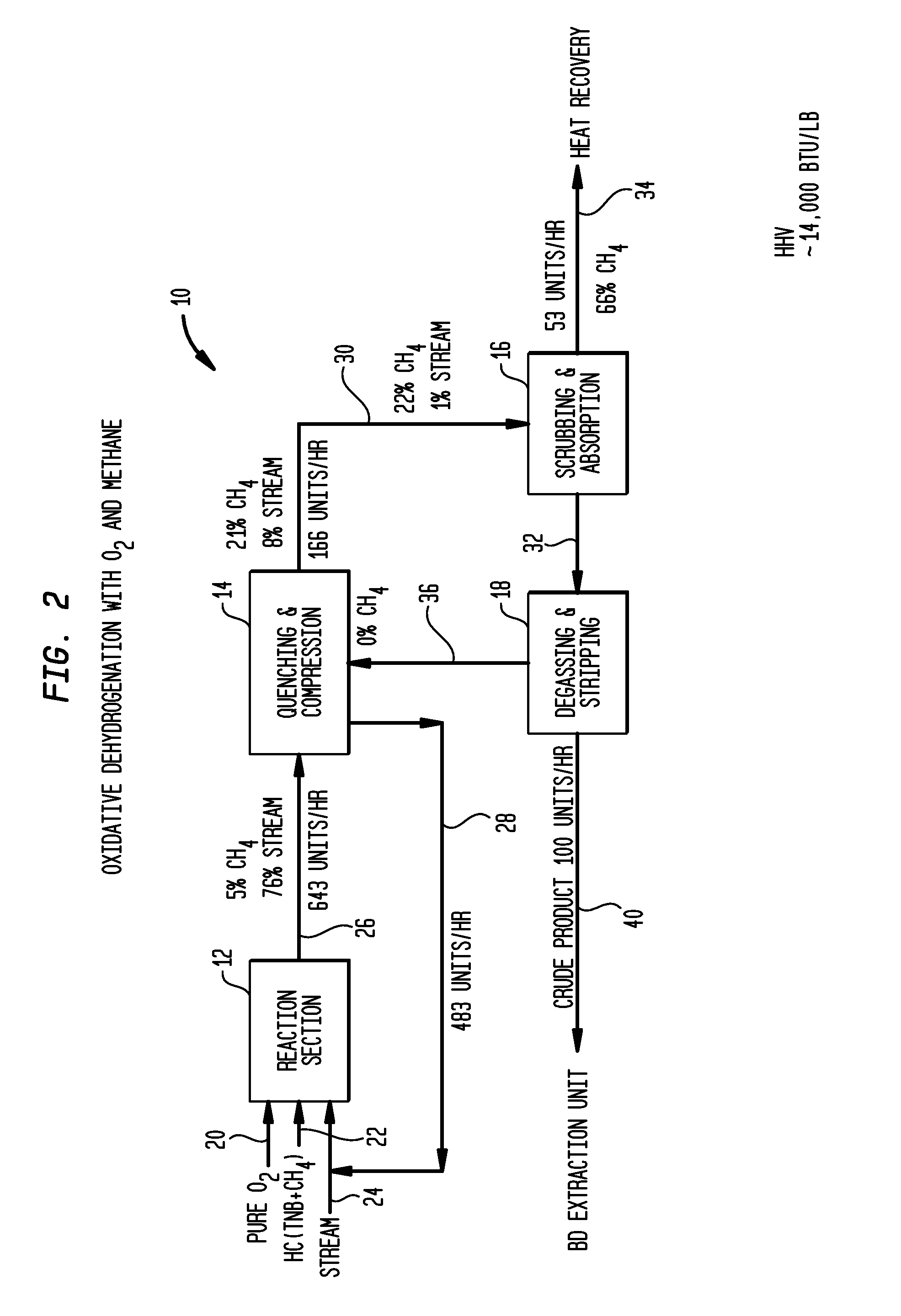

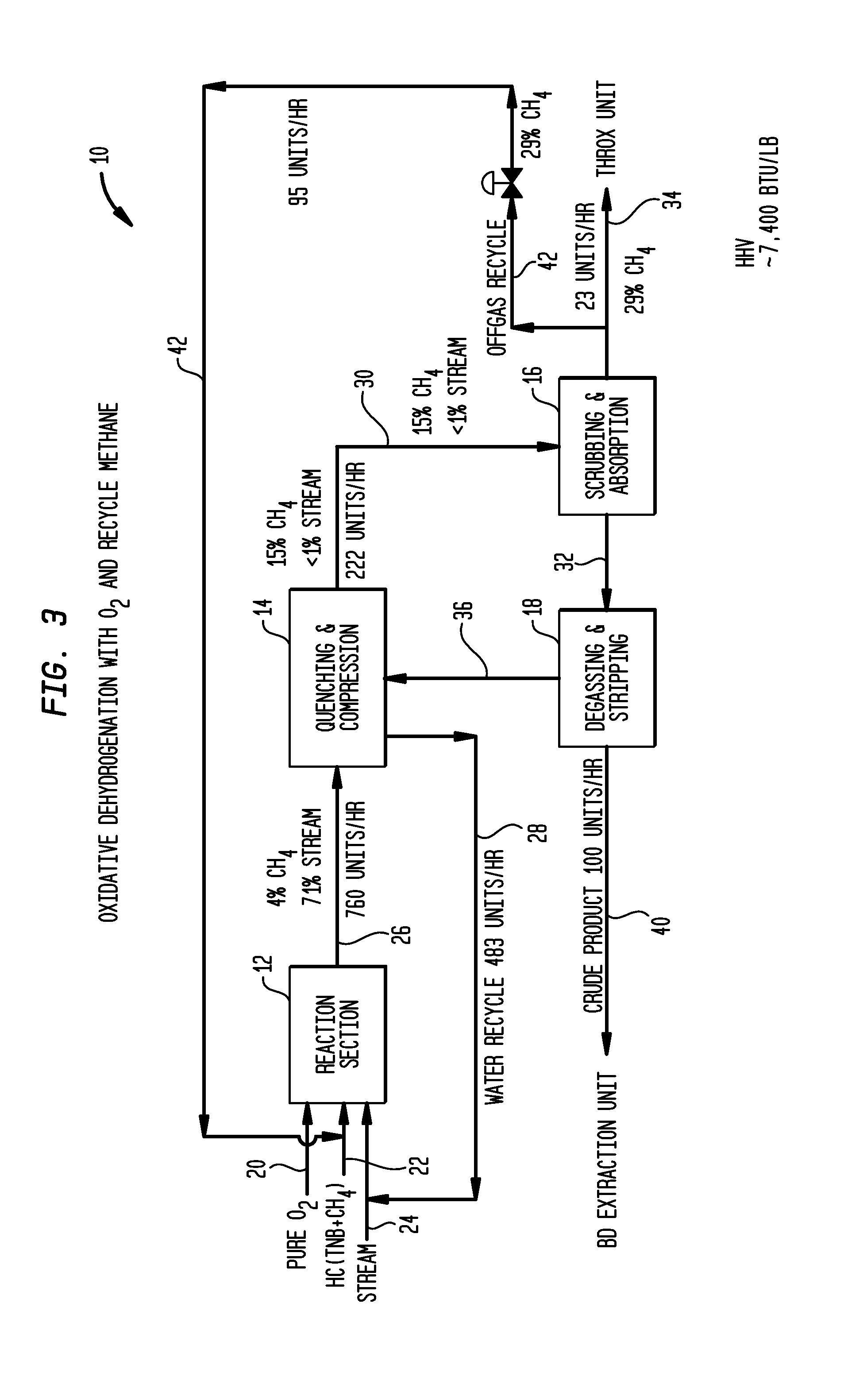

Multi-Stage Oxidative Dehydrogenation Process with Inter-Stage Cooling

ActiveUS20160023963A1Reduce usageReduces associated energyHydrocarbon by hydrogenationChemical industryButeneDehydrogenation

A method of oxidatively dehydrogenating a dehydrogenation reactant includes providing a first gaseous feed stream to a first adiabatic, catalytic reaction zone with less than a stoichiometric amount of oxygen and superheated steam, oxidatively dehydrogenating dehydrogenation reactant in said first adiabatic, catalytic reaction zone and subsequently cooling the effluent, adding additional oxygen and reacting the effluent stream in at least one subsequent adiabatic reaction zone. The deydrogenation system enables higher conversion and yield per pass and in some cases greatly reduces steam usage and energy costs. In a preferred integrated process, ethylene is converted to n-butene which is then oxidatively dehydrogenated to butadiene.

Owner:TPC GROUP

Process and configuration for providing external upflow/internal downflow in a continuous digester

InactiveUS20020129911A1Facilitates heat recoveryImprove washing efficiencyDigestersPulping with inorganic basesCellulose pulpHigh elevation

A continuous digester configuration and process for continuously cooking and digesting cellulosic material and producing cellulosic pulp is disclosed. The digester configuration comprises a plurality of jump-stage recirculations located along the length of a continuous digester vessel, wherein each of the jump-stage recirculations moves extracted liquor from one elevation of the digester vessel and re-introduces the liquor at a higher elevation in the vessel to maintain an internal liquor downflow substantially throughout the entire digester vessel. The process for continuously cooking and digesting cellulosic material comprises maintaining an internal concurrent liquor downflow substantially throughout the continuous digester vessel, wherein the internal liquor downflow does not exceed 400 gallons per ton of b.d. wood feed.

Owner:GLENS FALLS GROUP

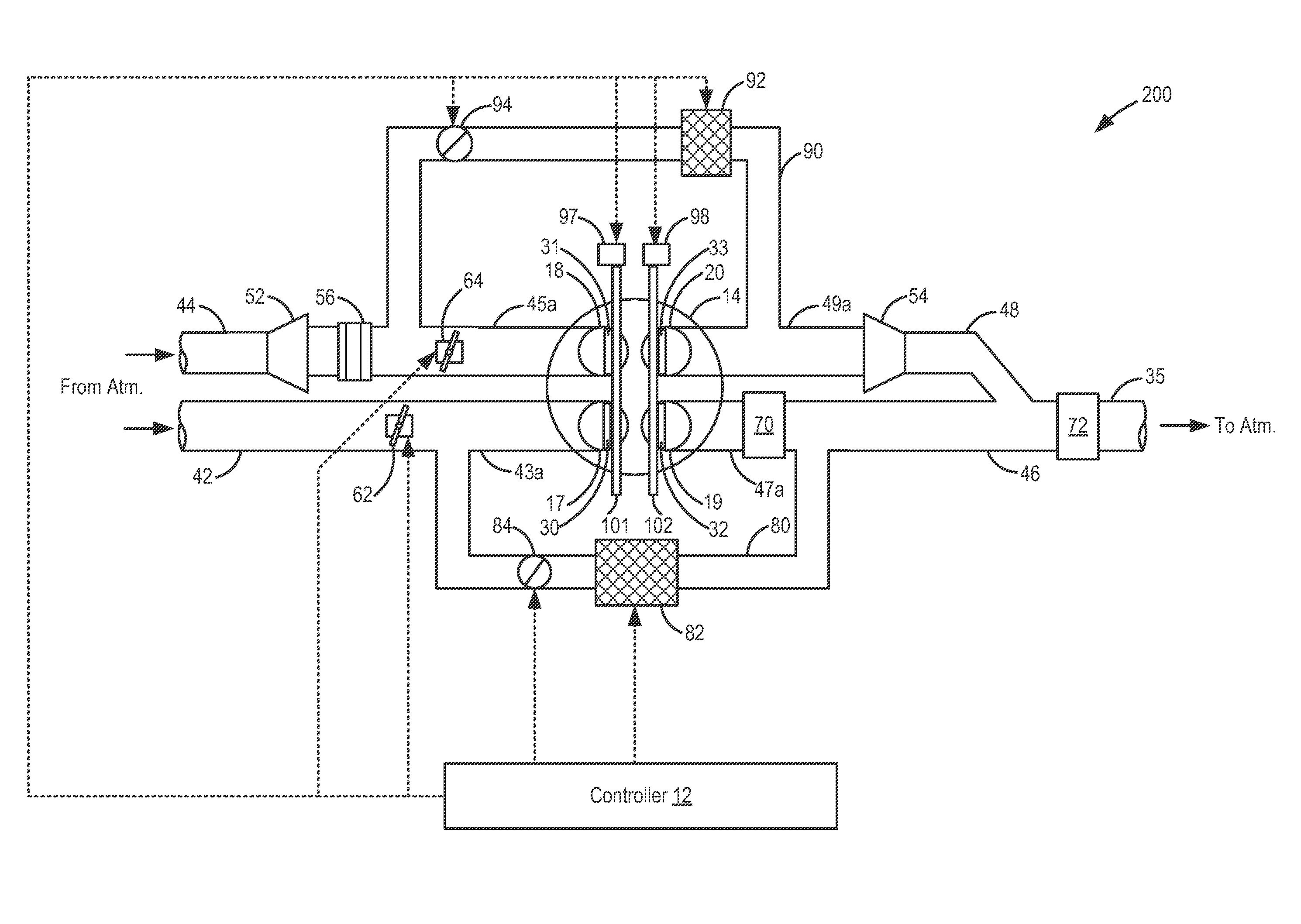

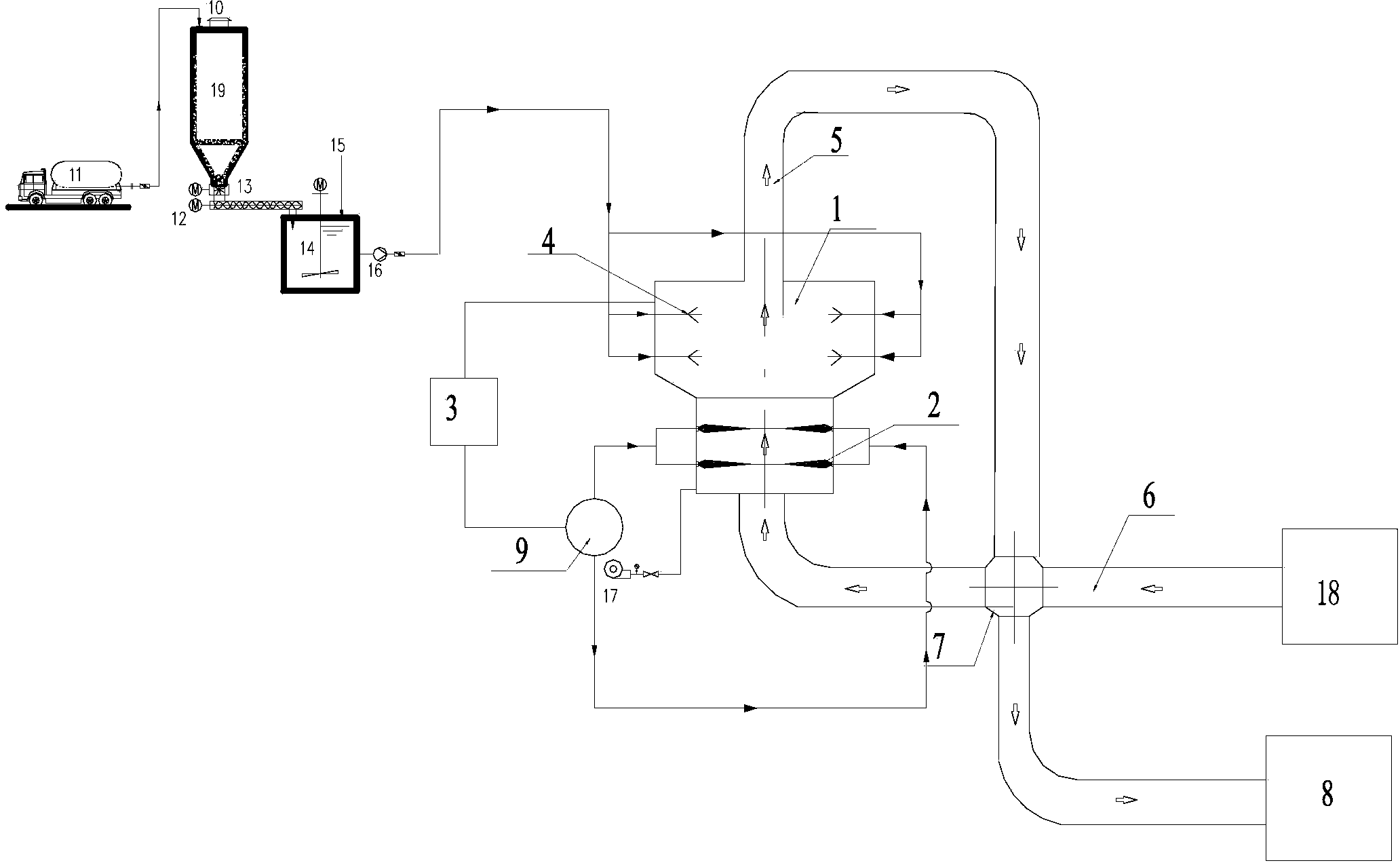

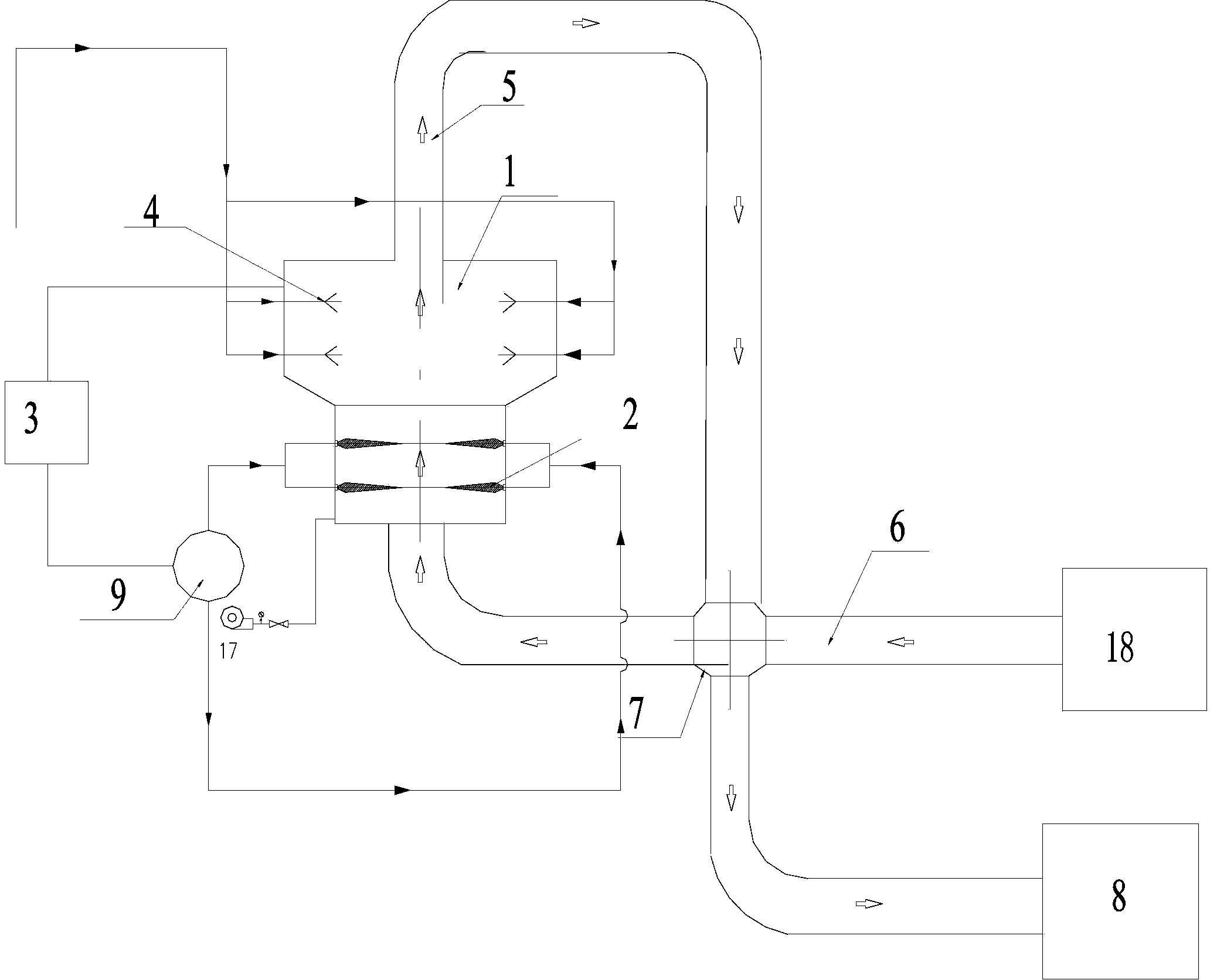

Self-regenerative integrated device for synergetic oxidation of low-concentration gas and ventilation gas in coal mine

ActiveUS20160136575A1Easy to operateEasy maintenanceGas treatmentExhaust apparatusProportional controlEngineering

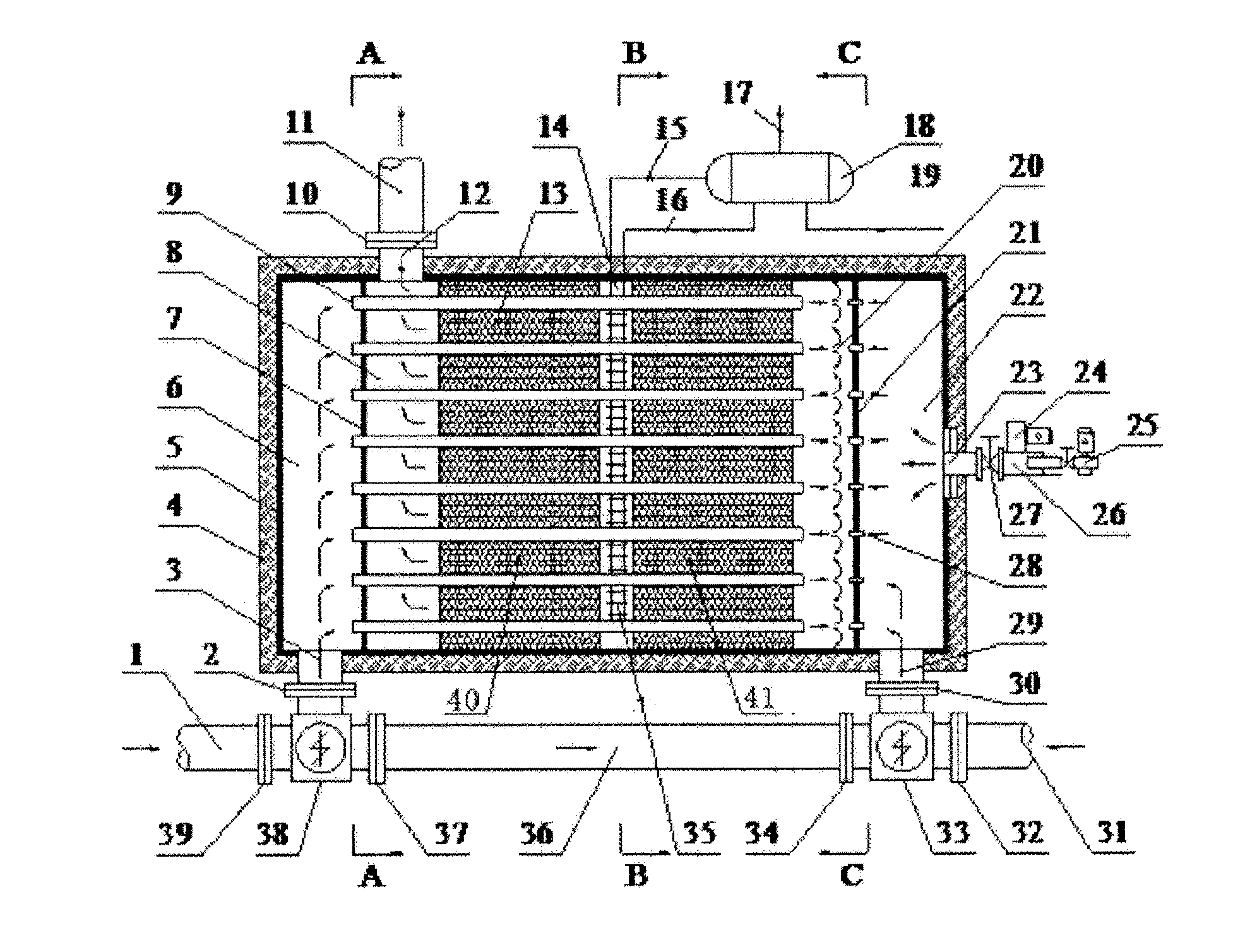

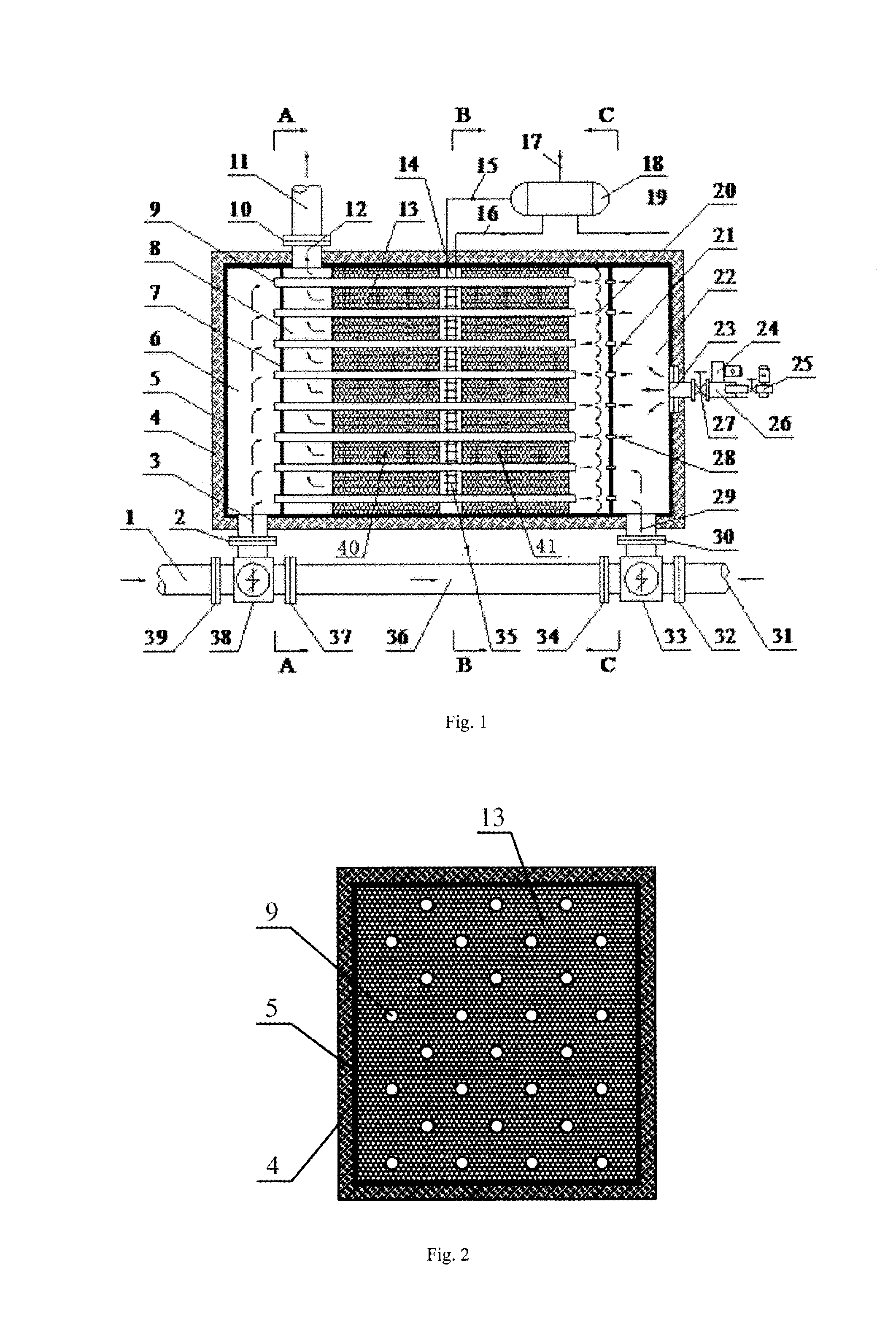

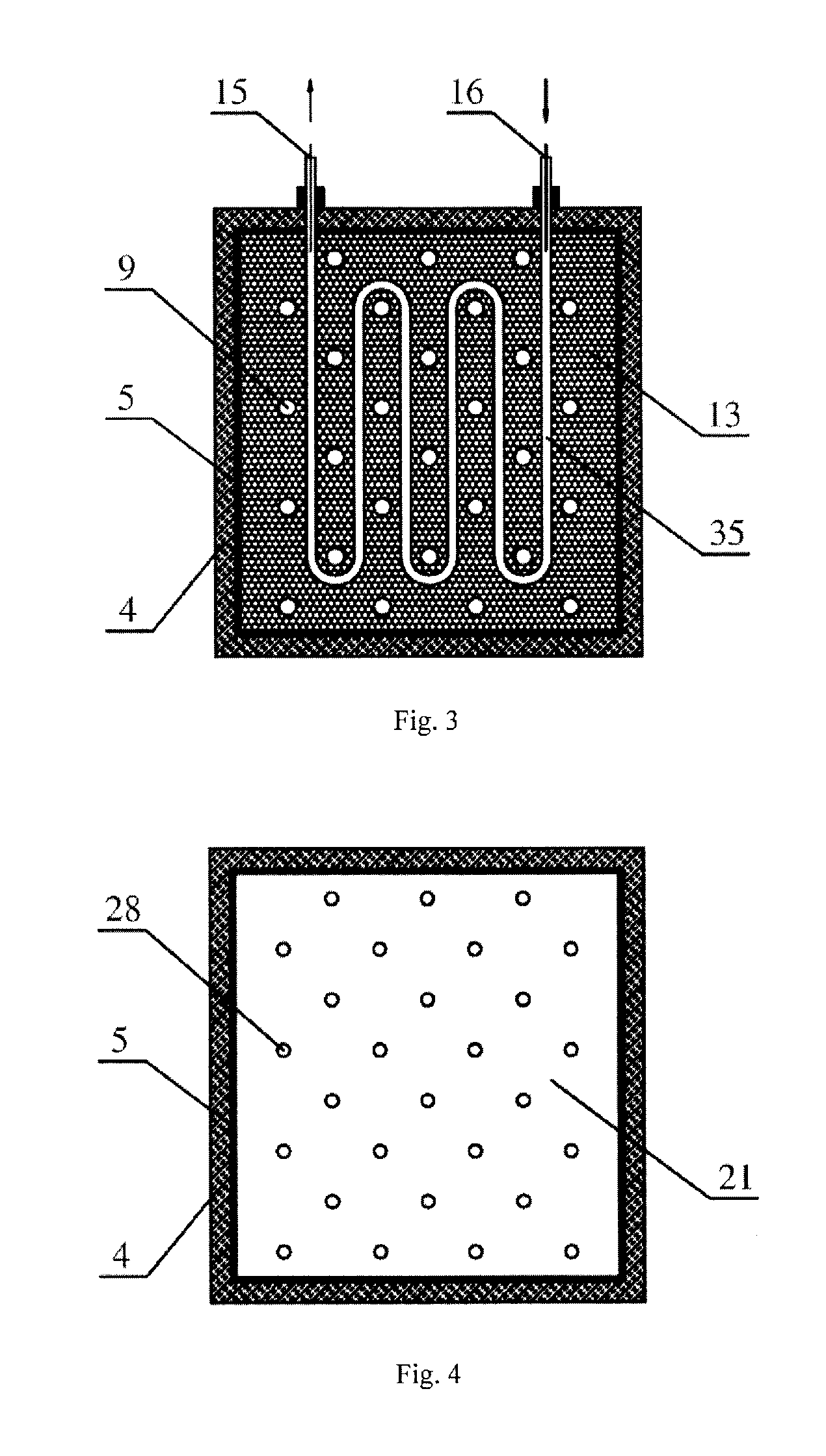

Disclosed is a self-regenerative integrated device for the synergetic oxidation of low-concentration gas and ventilation gas in a coal mine. The integrated device comprises a metal shell (5). A honeycomb ceramic oxidation bed (13) is arranged within the metal shell (5) and divided into a regenerative section (40) and an oxidation section (41) by a heat exchange chamber (14). A first cavity between the regenerative section (40) and the inner wall of the metal shell (5) is divided into a first inlet chamber (6) and an exhaust chamber (8) by an inlet partition plate (7), a second cavity between the oxidation section (41) and the inner wall of the metal shell (5) is divided into a second inlet chamber (22) and a mixing chamber (20) by a partition plate (21) for averaging gas, and a plurality of gas nozzles (28) are provided on the partition plate (21) for averaging gas. An internal heat exchanger (35) is arranged within the heat exchange chamber (14), and a heat exchanger inlet (16) and a heat exchanger outlet (15) of the internal heat exchanger (35) are respectively connected with a boiler drum (18). The first inlet chamber (6) is connected with an inlet (1) of the ventilation gas through a proportional control valve (38), the second inlet chamber (22) is connected with an inlet (31) for extracting the low-concentration gas through a proportional mixer (33), and the proportional control valve (38) is connected with the proportional mixer (33) through a connecting pipeline (36). The two ends of an inlet preheating pipe (9) on the honeycomb ceramic oxidation bed (13) are respectively communicated with the first inlet chamber (6) and the mixing chamber (20).

Owner:CHINA UNIV OF MINING & TECH

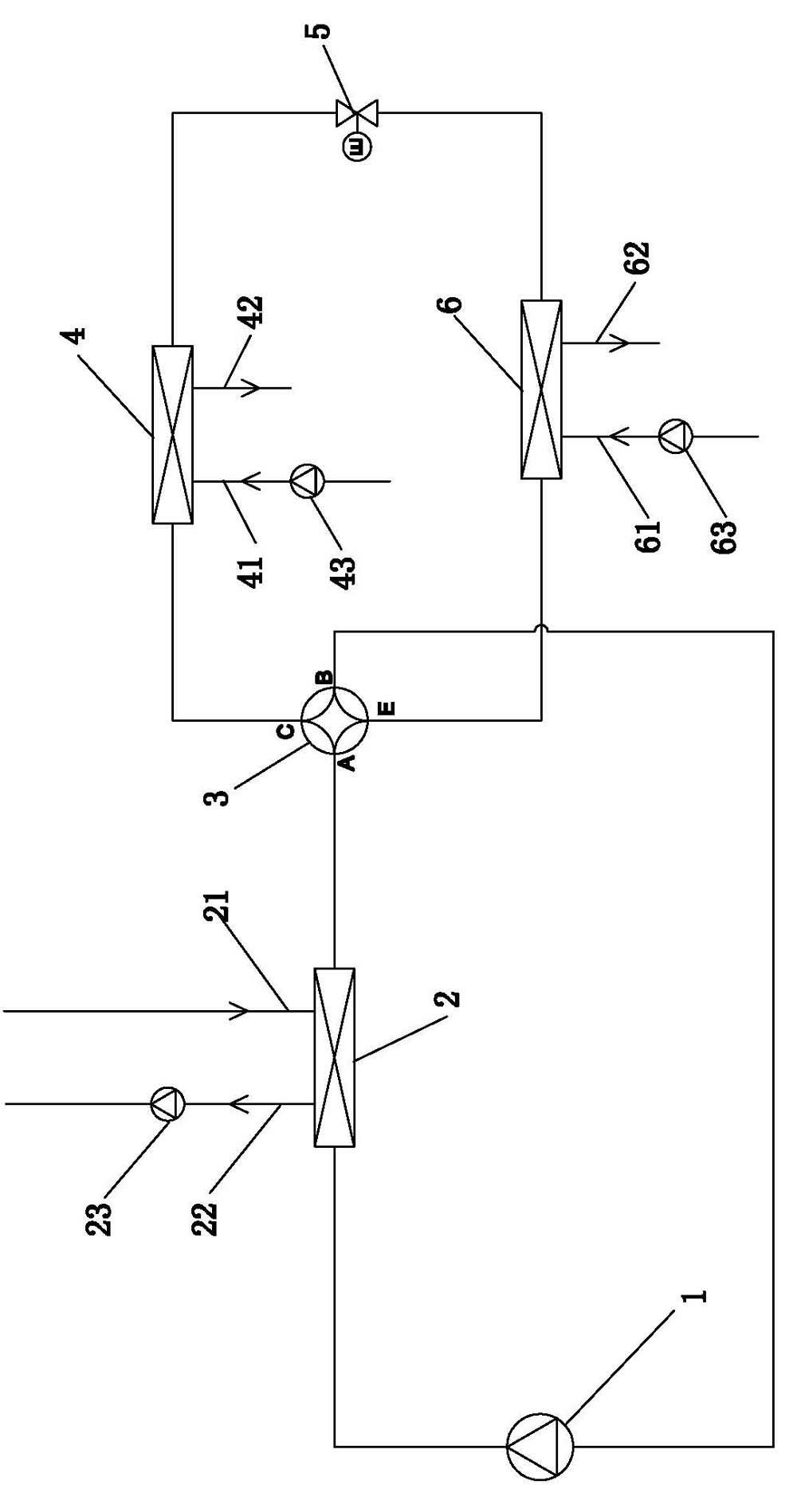

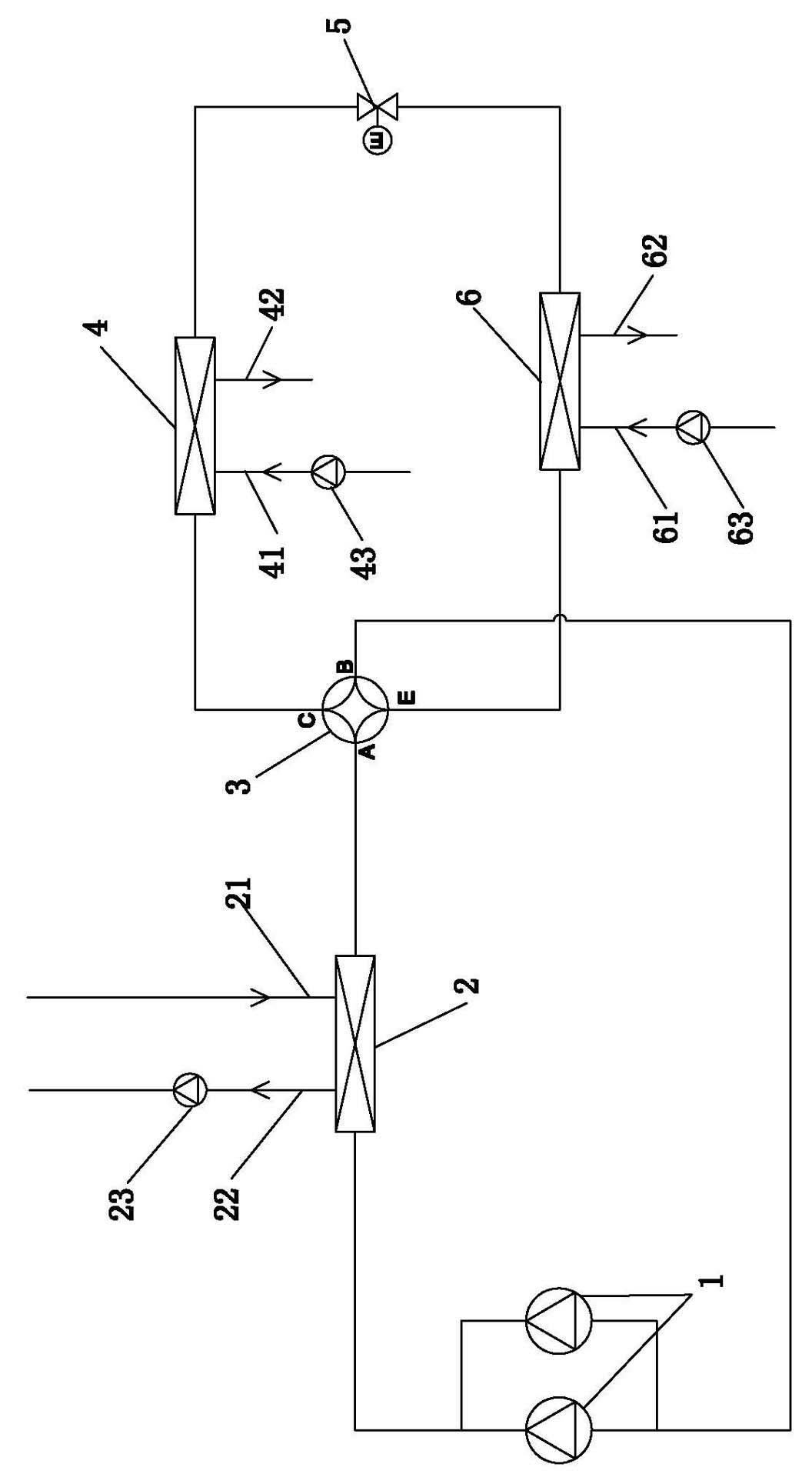

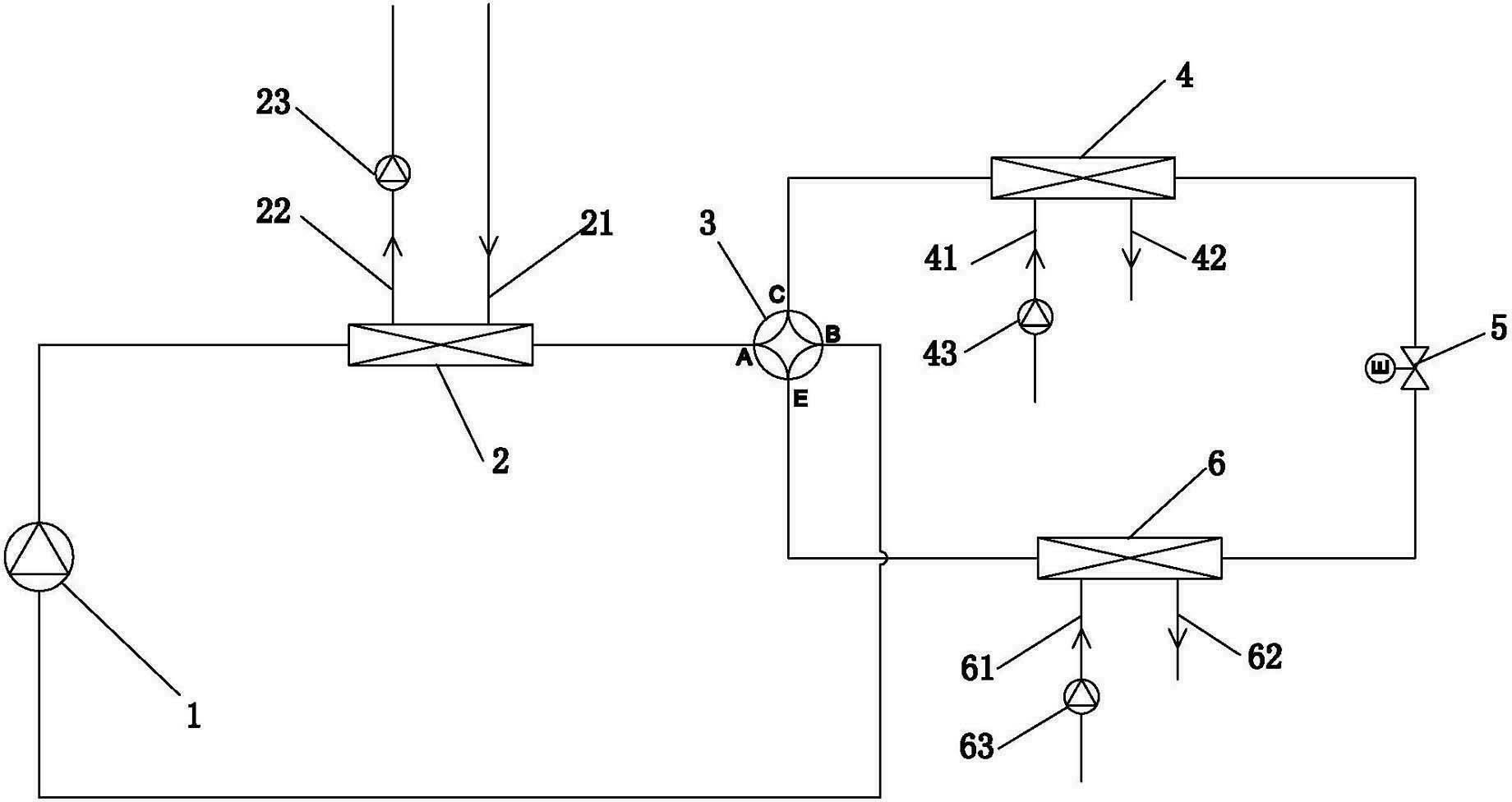

Air conditioning system capable of partial heat recovering and total heat recovering

ActiveCN102519173ARealize full heat recoveryRealize functionEnergy recovery in ventilation and heatingHeat recovery systemsAir conditioningThermal water

An air conditioning system capable of partial heat recovering and total heat recovering includes a heat recovery heat exchanger, an air conditioning side heat exchanger, a ground source side heat exchanger, a four-way valve, a throttling device and a compressor, wherein the heat recovery heat exchanger is provided with a first water inlet pipe and a first water outlet pipe; the first water inlet pipe is communicated with a water inlet of the heat recovery heat exchanger, the first water outlet pipe is communicated with a water outlet of the heat recovery heat exchanger, and the first water outlet pipe is provided with a hot water pump; the air conditioning side heat exchanger is provided with a second water inlet pipe and a second water outlet pipe; the second water inlet pipe is communicated with a water inlet of the air conditioning side heat exchanger, the second water outlet pipe is communicated with a water outlet of the air conditioning side heat exchanger, and the second water inlet pipe is provided with an air conditioning water pump; the ground source side heat exchanger is provided with a third water inlet pipe and a third water outlet pipe; and the third water inlet pipe is communicated with a water inlet of the ground source side heat exchanger, the third water outlet pipe is communicated with a water outlet of the ground source, and the third water inlet pipe is provided with a ground source water pump. Compared with the prior art, the air conditioning system provided by the invention has the characteristics that fewer system components are used, the cost is low, and the system is simple to control and highly reliable.

Owner:GUANGDONG EUROKLIMAT AIR CONDITIONING & REFRIGERATION

Batch dishwasher with waste water heat recovery

ActiveUS8176926B2Facilitates heat recoveryAutomatic washing/rinsing machine detectionElectrostatic cleaningWastewaterFresh water

A cleaning machine, in particular a batch dishwasher, comprising an individual cleaning chamber in which the items to be cleaned are accommodated, a pump which circulates washing liquid within the cleaning chamber, and a further pump which delivers fresh water, and also a boiler which stores and heats fresh water, wherein the boiler has an associated heat exchanger by means of which heat is indirectly or directly transferred from waste water which is stored in a reservoir to the fresh water which is stored in the boiler.

Owner:MEIKO MASCHENBAU

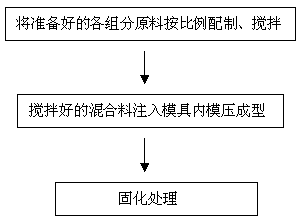

Technology for preparing brake lining through 3D printing

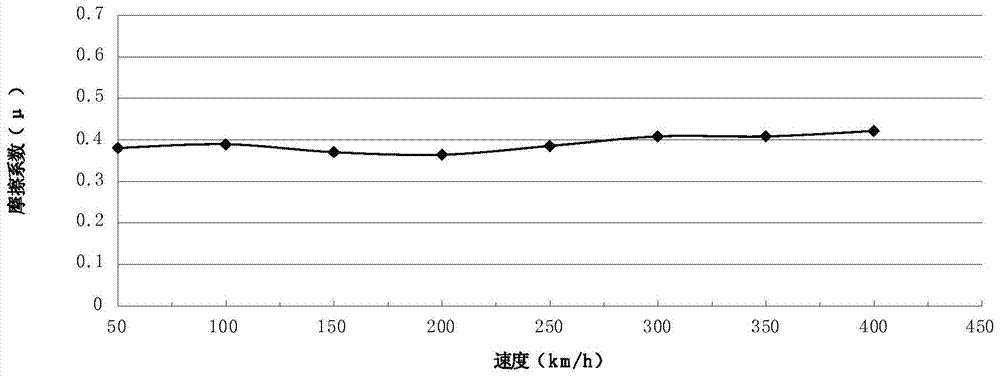

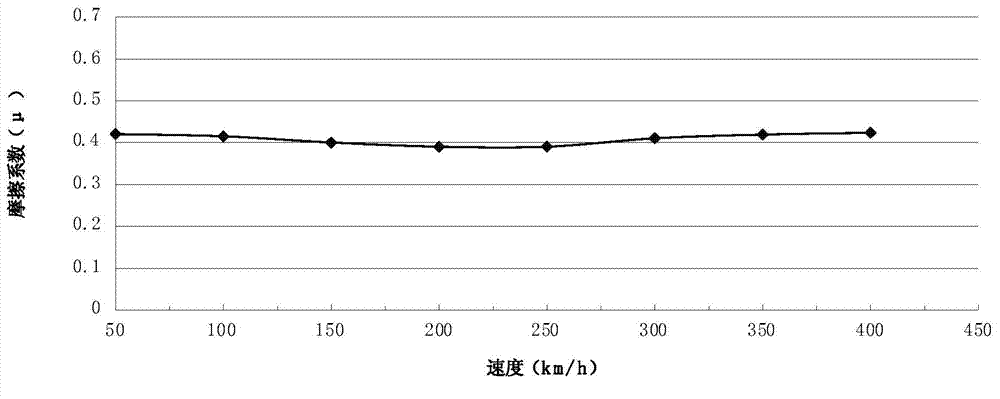

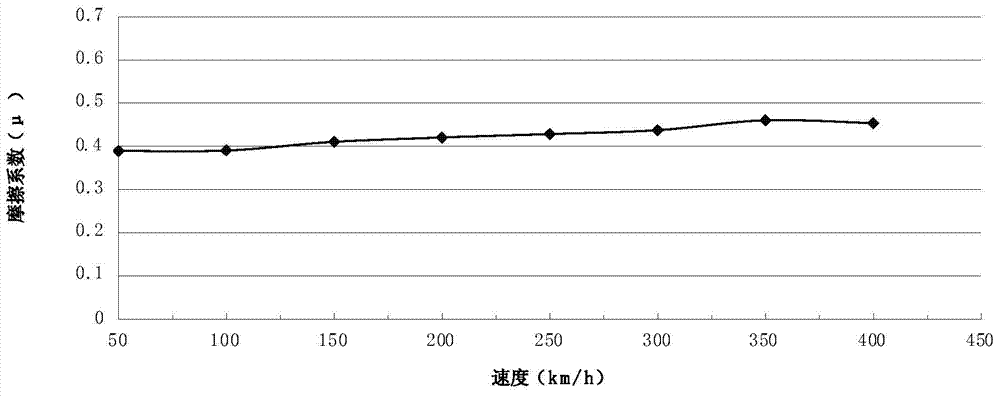

InactiveCN106286657ASmall thermal recessionFacilitates heat recoveryOther chemical processesFriction liningFrictional coefficientAdhesive

The invention discloses a technology for preparing a brake lining through 3D printing. The technology comprises the following steps: (1) materials mixing: performing evenly dry mixing to solid-state filler, preparing a liquid-state adhesive and other additives into a gel forming solution, and spraying to the solid-state filler; (2) paving powder; (3) spraying of gel: adjusting the density of a gel body to be 700kg / m<3> and the injection pressure to be 150kPa, and spraying gel; (4) quick drying with hot-air: drying for 100-130min at the temperature of 50 DEG C; then cutting materials and superposing; and (5) hydraulic molding: performing hydraulic molding at the molding temperature of 130-170 DEG C and under the forming pressure of 18-30MPa, wherein the holding time lasts 15-30min. The frictional coefficient of the brake lining prepared by adopting the technology is stabilized to range from 0.476-0.53 at 100-250 DEG C, the heat fade is small, and the brake lining has good heat restoration, wear resistance and shearing resistance properties.

Owner:WUXI MINGSHENG STRONG BLOWER

Process for producing unsaturated nitrile

InactiveUS6013825AExtension of timeShorten the timeOrganic compound preparationOrganic chemistry methodsOrganic acidSimple Organic Compounds

PCT No. PCT / JP96 / 00148 Sec. 371 Date Sep. 30, 1997 Sec. 102(e) Date Sep. 30, 1997 PCT Filed Jan. 26, 1996 PCT Pub. No. WO96 / 23766 PCT Pub. Date Aug. 8, 1996The present invention is a process for producing an unsaturated nitrile such as acrylonitrile or methacrylonitrile by ammoxidation of an organic compound such as propylene, isobutene or tertiary butanol. The process comprises carrying out the ammoxidation such that the organic acid / unreacted ammonia ratio in an ammoxidation product gas is controlled to remain within the range from 0.8 to 3.0 inclusive in a reactor, introducing the ammoxidation product gas into a quench tower, and reacting in the tower the unreacted ammonia with the organic acid produced in a reactor, to fix the unreacted ammonia as an ammonium salt of the organic acid.

Owner:ASAHI KASEI KK

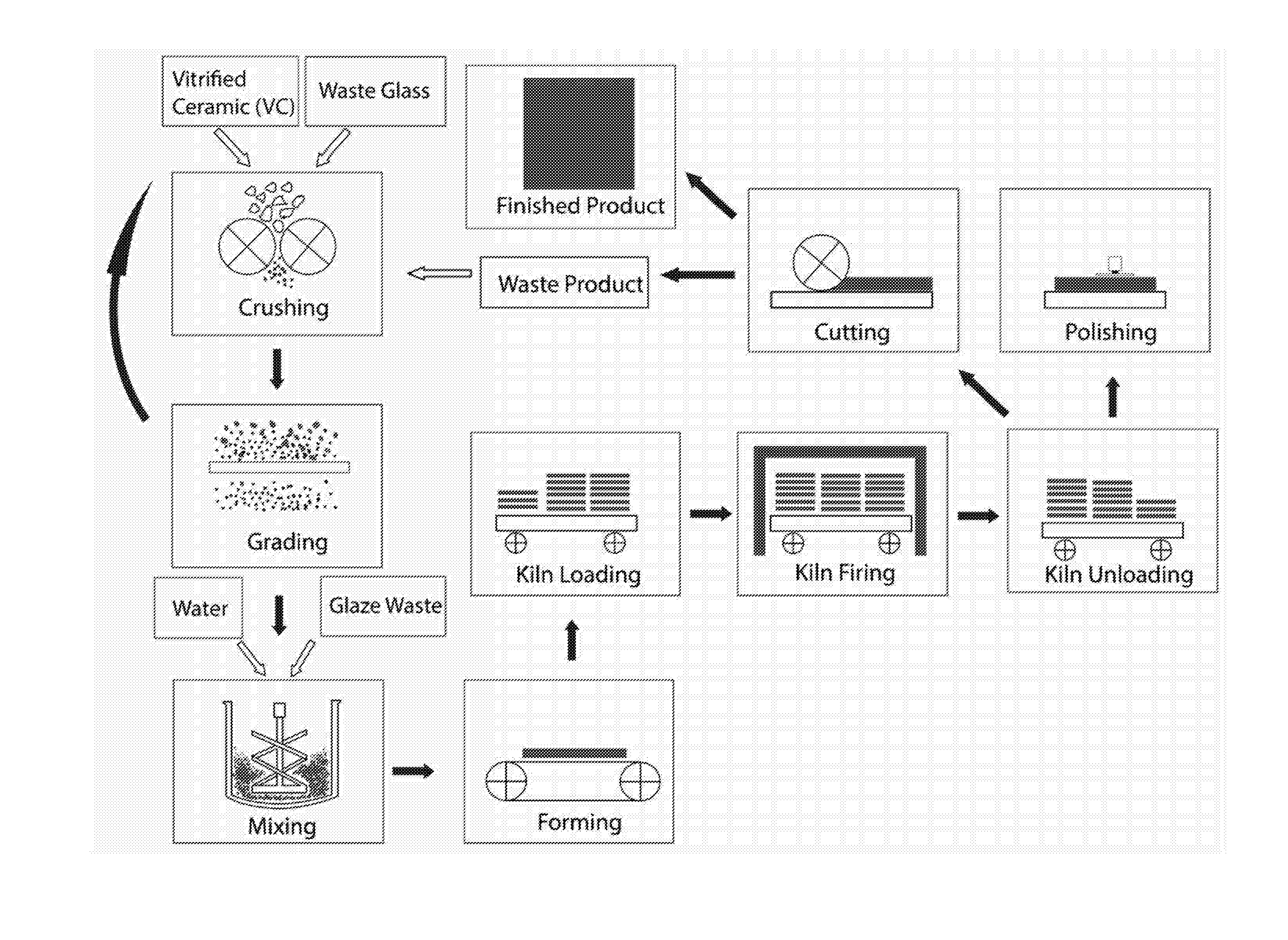

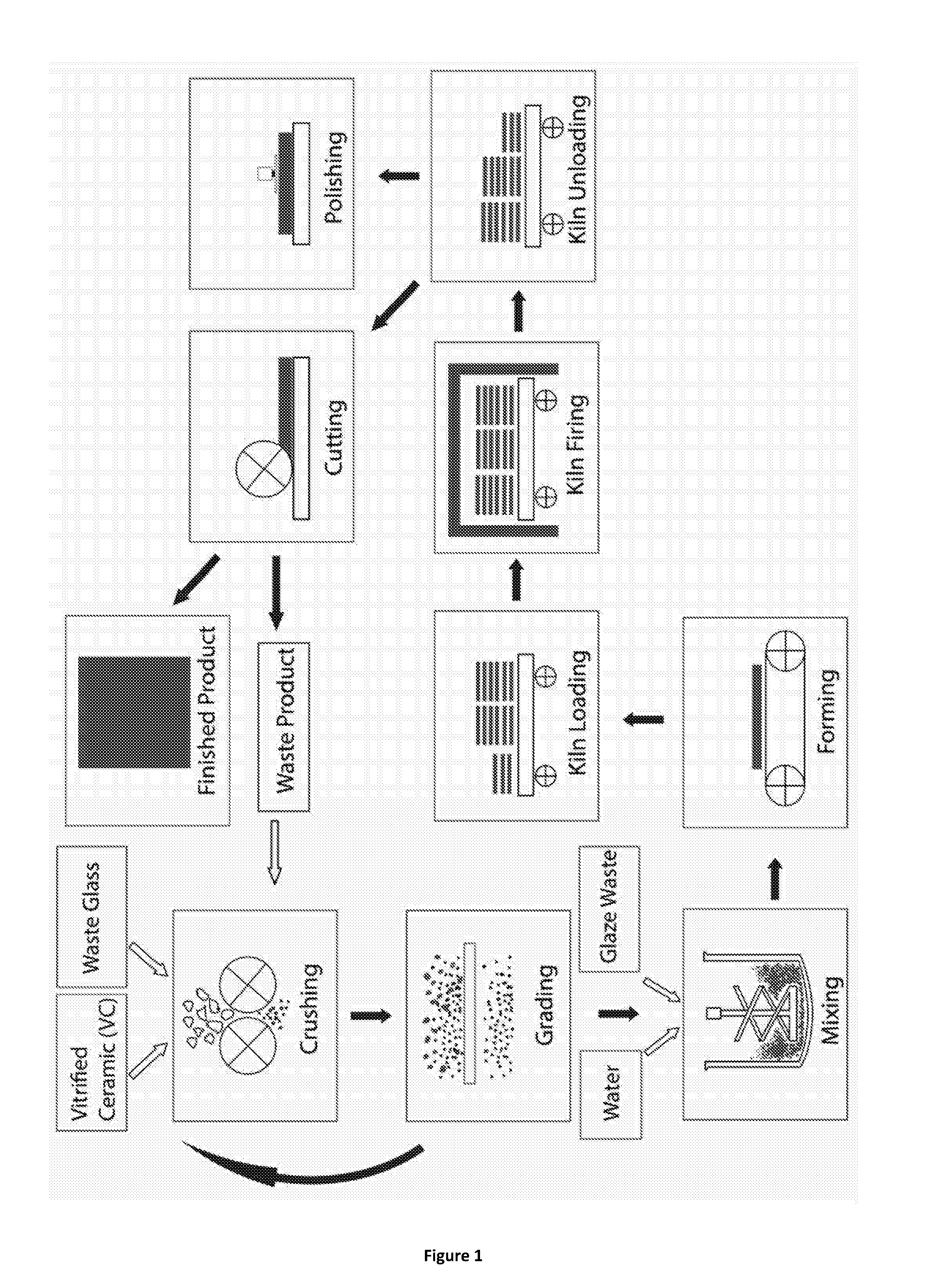

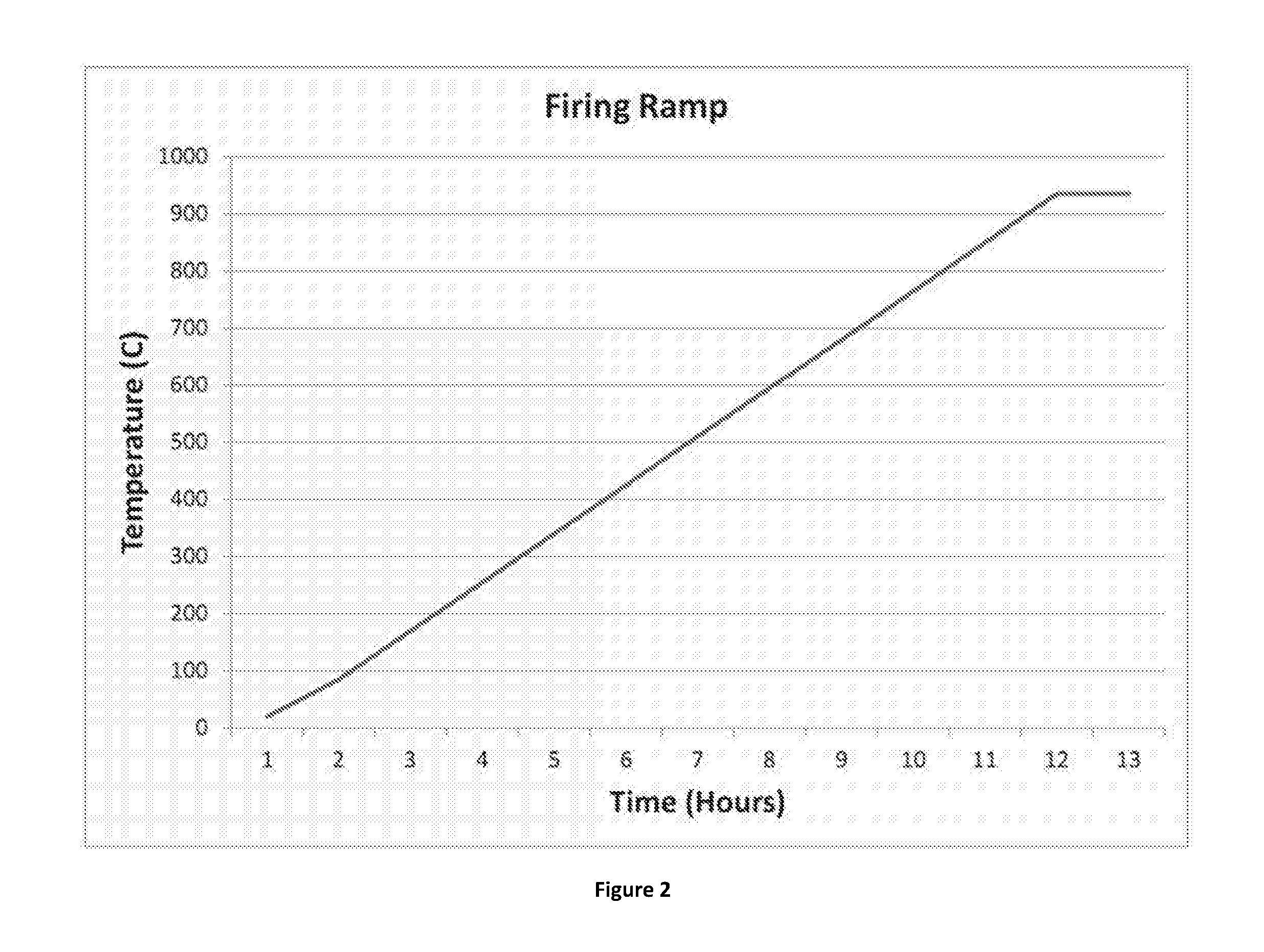

Composite material

ActiveUS20150299032A1Low costReduce energy burdenSolid waste managementTransportation and packagingWaste productMaterials science

The present invention relates to a composite material, particularly a composite material for ceramic tiles, stone cladding, surface tops (e.g. worktops), and the like. The composite materials are typically derived from waste products. The composite materials of the present invention are formed from a glass component and a non-glass mineral component (e.g. ceramics and / or glaze). Generally the composite materials do not require any binders (especially synthetic binders) to hold the materials together. Therefore, the composite materials and products made therefrom are typically recyclable.

Owner:ALUSID LTD

Wear-resistant flame-retardant heat-conducting insulating material and preparation method thereof

The invention discloses a wear-resistant flame-retardant heat-conducting insulating material and a preparation method thereof. The wear-resistant flame-retardant heat-conducting insulating material comprises the following raw materials in parts by weight: 80-120 parts of compound rubber, 10-20 parts of wear-resistant additives, 8-14 parts of modified reinforcing fibers, 10-14 parts of a flame-retardant additive, 3-5 parts of a coupling agent, 7-9 parts of a processing auxiliary agent, 6-8 parts of a toughening auxiliary agent and 7-9 parts of a modified nano additive. The wear-resistant flame-retardant heat-conducting insulating material provided by the invention has good performances of being insulating, stretch-resistant and wear-resistant, excellent in heat-conducting flame-retardant effect, cold and hot impact resistant and high in toughness, free from toxicity and free of peculiar smells, high in strength, good in elasticity, relatively long in service life and safe and environment-friendly; meanwhile, the preparation method is relatively low in cost, easily available in raw material and concise in process, and has relatively high practical value and good application prospect.

Owner:合肥市闵葵电力工程有限公司

Oxidative Dehydrogenation Process With Hydrocarbon Moderator Gas and Reduced Nitrogen Feed

ActiveUS20160002126A1Reduce device sizeLower cost of capitalHydrocarbon by hydrogenationCatalystsButeneButadiene Dioxide

Oxidative dehydrogenation includes: (a) providing a gaseous feed stream to a catalytic reactor, the feed stream comprising a dehydrogenation reactant, oxygen, superheated steam, hydrocarbon moderator gas and optionally nitrogen, wherein the molar ratio of moderator gas to oxygen in feed stream is typically from 4:1 to 1:1 and the molar ratio of oxygen to nitrogen in the feed stream is at least 2; (b) oxidatively dehydrogenating the reactant in the reactor to provide a dehydrogenated product enriched effluent product stream; and (c) recovering dehydrogenated product from the effluent product stream. One preferred embodiment is a process for making butadiene including dimerizing ethylene to n-butene in a homogeneous reaction medium to provide a hydrocarbonaceous n-butene rich feed stream and oxidatively dehydrogenating the n-butene so formed.

Owner:TPC GROUP

Coal gas scrubbing tower

InactiveCN101497822AFacilitates heat recoveryImprove heat transfer performanceCombustible gas purificationSoft waterEngineering

The invention relates to a coal gas wash tower which comprises a tower body, wherein the upper part of the tower body is provided with a spray pipe and a gas outlet pipe, the lower part of the tower body is provided with a gas inlet pipe and a water outlet pipe, the side wall at the middle part of a cavity of the tower body is provided with a baffle plate, the baffle plate divides the cavity of the tower body into an upper section and a lower section and is provided with a coal gas channel which is internally provided with a coal gas through hole, the upper end of the coal gas channel above the coal gas through hole is provided with a rising pipe, the side wall at the lower part of the upper section of the cavity of the tower body is provided with the water outlet pipe, the side wall at the upper part of the lower section of the cavity of the tower body is provided with the spray pipe, the lower section of the cavity of the tower body is internally provided with a heat pipe soft water heater, the heat pipe soft water heater comprises vacuum heat pipes and a heating pipe, the vacuum heat pipes are internally provided with liquid heat transfer medium, and the oblique inserted vacuum heat pipes are distributed around the outer side wall of the heating pipe from top to bottom; the outer end of each vacuum heat pipe is arranged in the cavity of the tower body, and the inner end of each vacuum heat pipe is inserted in the heating pipe; the upper part of the heating pipe is provided with a soft water inlet and the lower part is provided with a soft water outlet pipe, and the soft water inlet pipe and the soft water outlet pipe respectively penetrate out of the side wall of the tower body.

Owner:NANTONG JUNYUAN TECH COMPANY

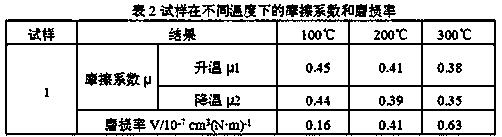

Composite friction material by using truck waste brake shoe friction material as filler and preparation method thereof

The invention discloses a composite friction material by using a truck waste brake shoe friction material as a filler, relating to the technical fields of friction materials and vehicle brake shoes. The composite friction material comprises a resin matrix, a reinforcing fiber, a filler and assistants, wherein the resin matrix is a phenol formaldehyde resin, the filler is a truck waste brake shoe friction material, and the assistants comprise iron powder, an accelerator, molybdenum disulfide, stearic acid and graphite. The preparation method comprises the following steps: material preparation, stirring, compression molding and curing treatment. By utilizing the truck waste brake shoe friction material as the filler, combining the optimal selection and proportioning of the phenol formaldehyde resin, reinforcing fiber and other assistants and optimizing various parameters of the molding technique, the prepared composite friction material has the characteristics of stable friction factor, low heat fading, favorable thermal restorability, low wear rate and high carrying capacity, can be used for manufacturing multiple friction components, has excellent frictional wear performance, favorable bending strength and favorable impact toughness, and achieves favorable use effect.

Owner:CRRC SHIJIAZHUANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com