Heating and heat recovery unit for an air conditioning system

a technology of heat recovery unit and air conditioning system, which is applied in the direction of indirect heat exchangers, lighting and heating apparatus, heating types, etc., can solve the problems of difficult to maintain water temperature, large water tank heat loss, and relatively long time requirements, so as to improve heating and heat recovery, improve heat recovery efficiency, and increase the temperature of water outflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

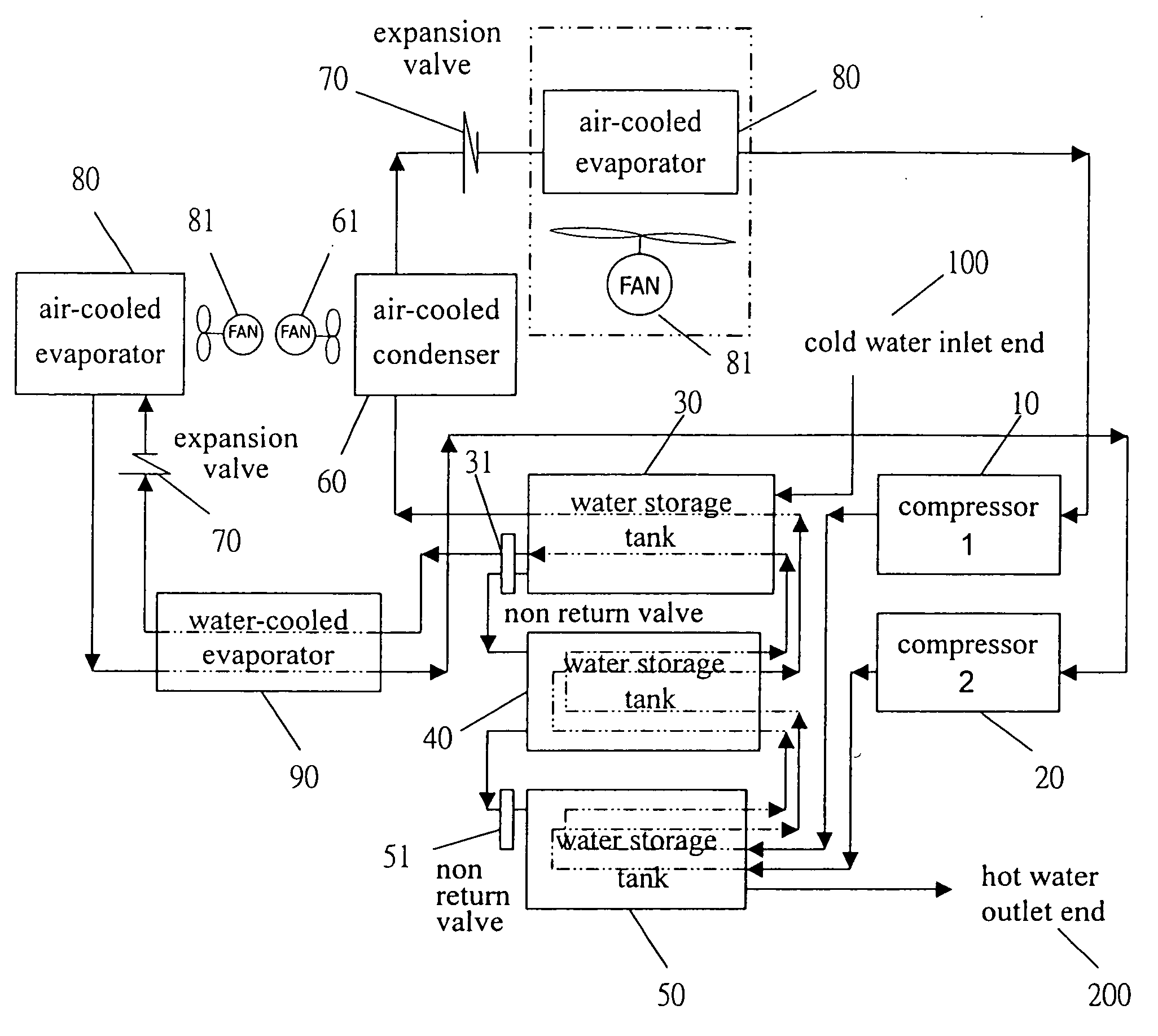

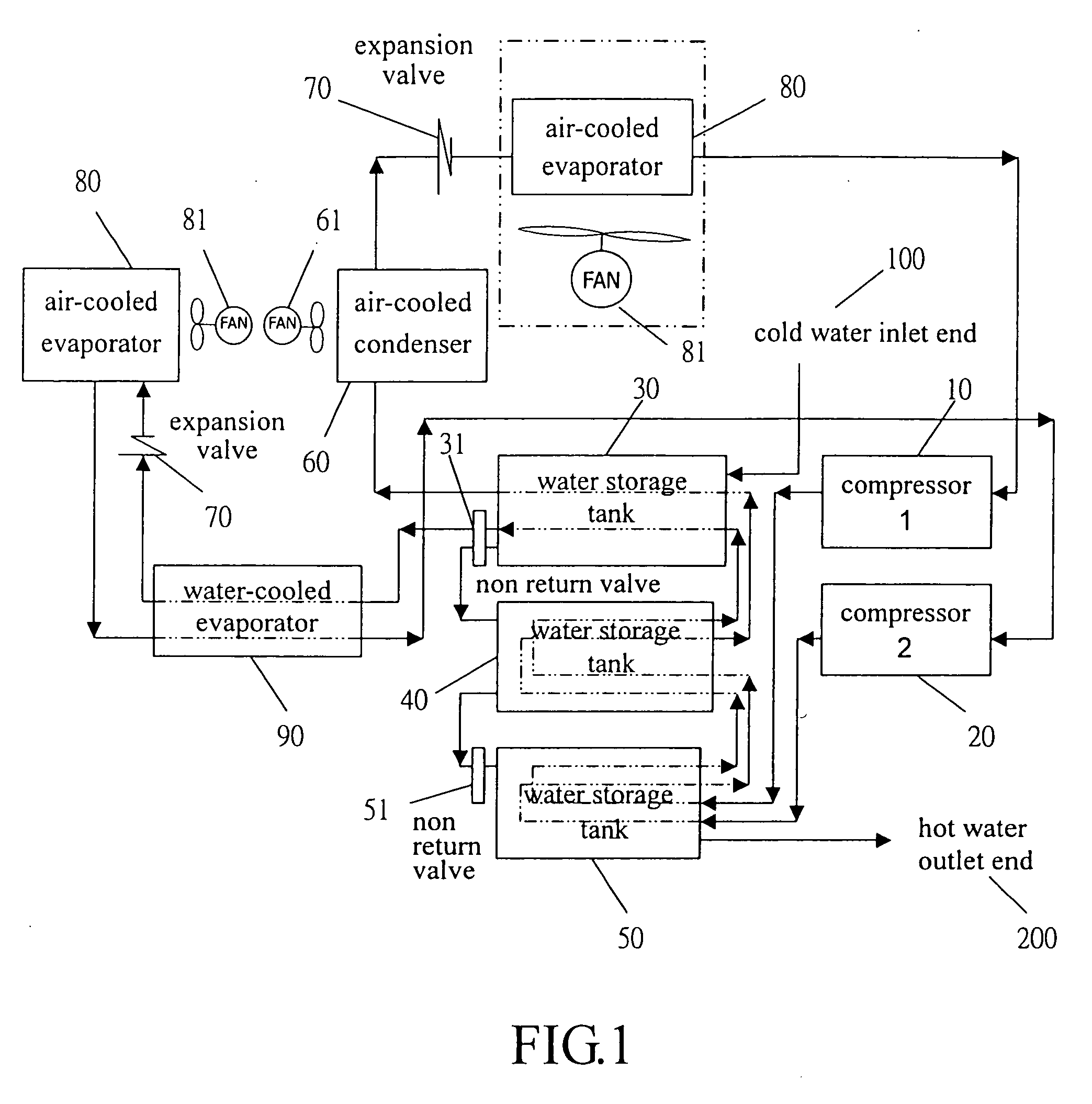

[0009]Referring to FIG. 1, the present invention is structured to comprise first and second compressors 10, 20, large, medium and small insulated water storage tanks 30, 40, 50, an air-cooled condenser 60, an expansion valve 70, air-cooled evaporators 80 and a water-cooled evaporator 90, wherein the first compressor 10 is suitable for various types of air conditioner heat recovery systems, and the second compressor 20 is suitable for refrigerant heat pump water heater systems. Working method of a refrigerant of the present system involves using a high-temperature and high-pressure end refrigerant of the first, second compressors 10, 20 to pass through bottom end heat exchangers (plate type, fin type, bare pipe) within the small, medium and large insulated water storage tanks 50, 40, 30 to effect heat exchange with water, and the heat is stored within the small, medium and large insulated water storage tanks 50, 40, 30. When the temperature reaches a set value, then surplus heat is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com