Coal gas scrubbing tower

A gas scrubber and gas technology, applied in combustible gas purification, combustible gas purification/transformation, petroleum industry, etc., can solve phase change heat cannot be recovered, empty tower spray gas distribution is uneven, gas-liquid contact is not good, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

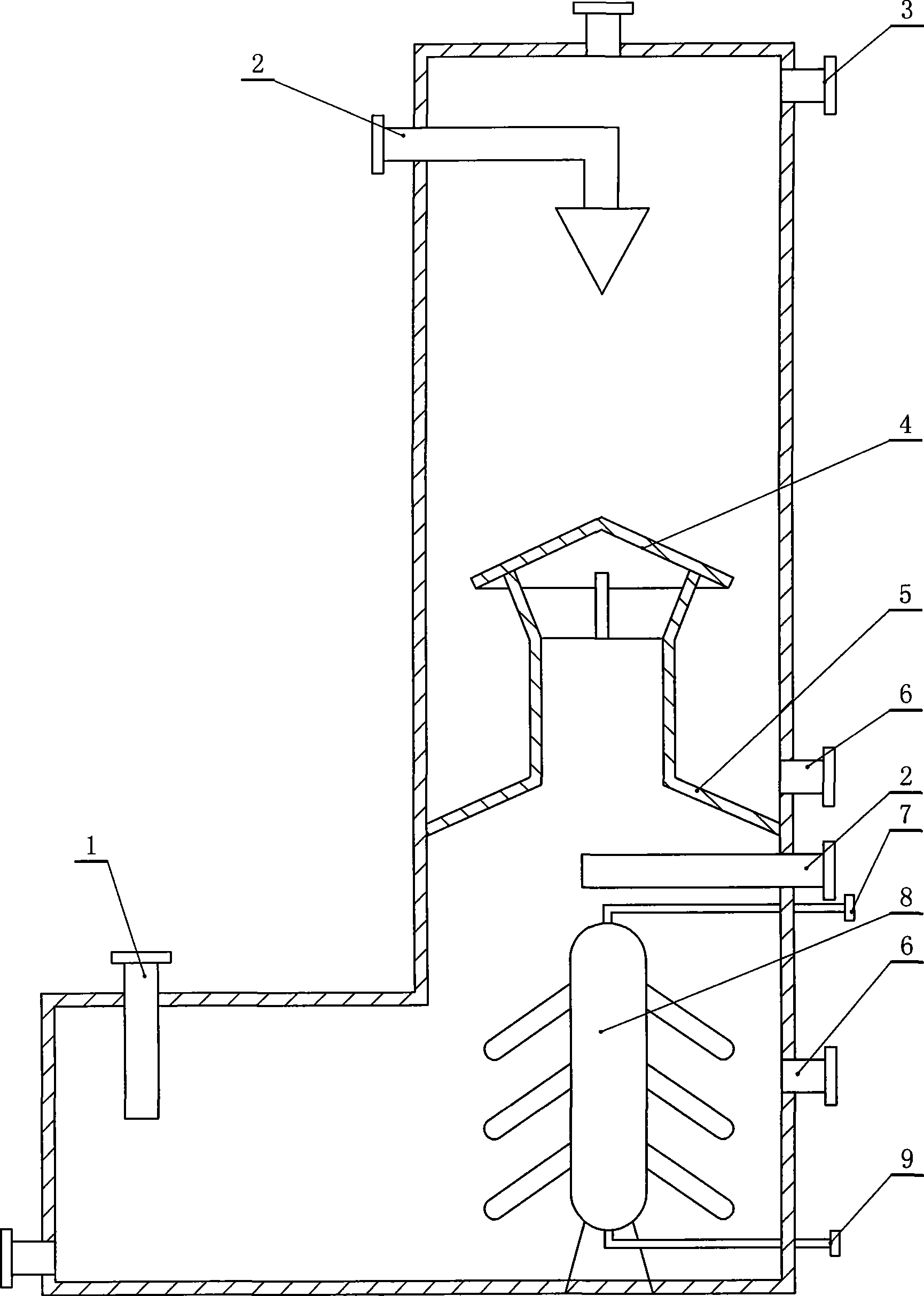

[0016] A gas scrubber, such as figure 1 Shown, wherein comprise tower body, tower body upper part has spray pipe 2, air outlet pipe 3, tower body bottom has air inlet pipe 1, water outlet pipe 6, and partition plate 5 is installed on the side wall of tower body cavity middle part, partition The plate 5 divides the cavity of the tower body into upper and lower sections. The upper section is the washing and cooling section, and the lower section is the water vapor condensation heat recovery section. The upper end of the gas channel above the hole is equipped with a gas-rising cap 4, which corresponds to the gas through-hole. The upper and lower sections of the tower body cavity are connected through the gas-through hole. The water outlet pipe 6, the water spray pipe 2 is installed on the upper side wall of the lower part of the tower body cavity, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com