Heat recovery system of gas cooker

A technology of heat recovery and gas stoves, which is applied in household heating, heating methods, water heaters/stoves, etc., can solve the problems of non-energy-saving hot water heating methods, high production costs of hot water, and waste of heat, and achieve heat recovery Ideal effect, low production cost, and improved comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

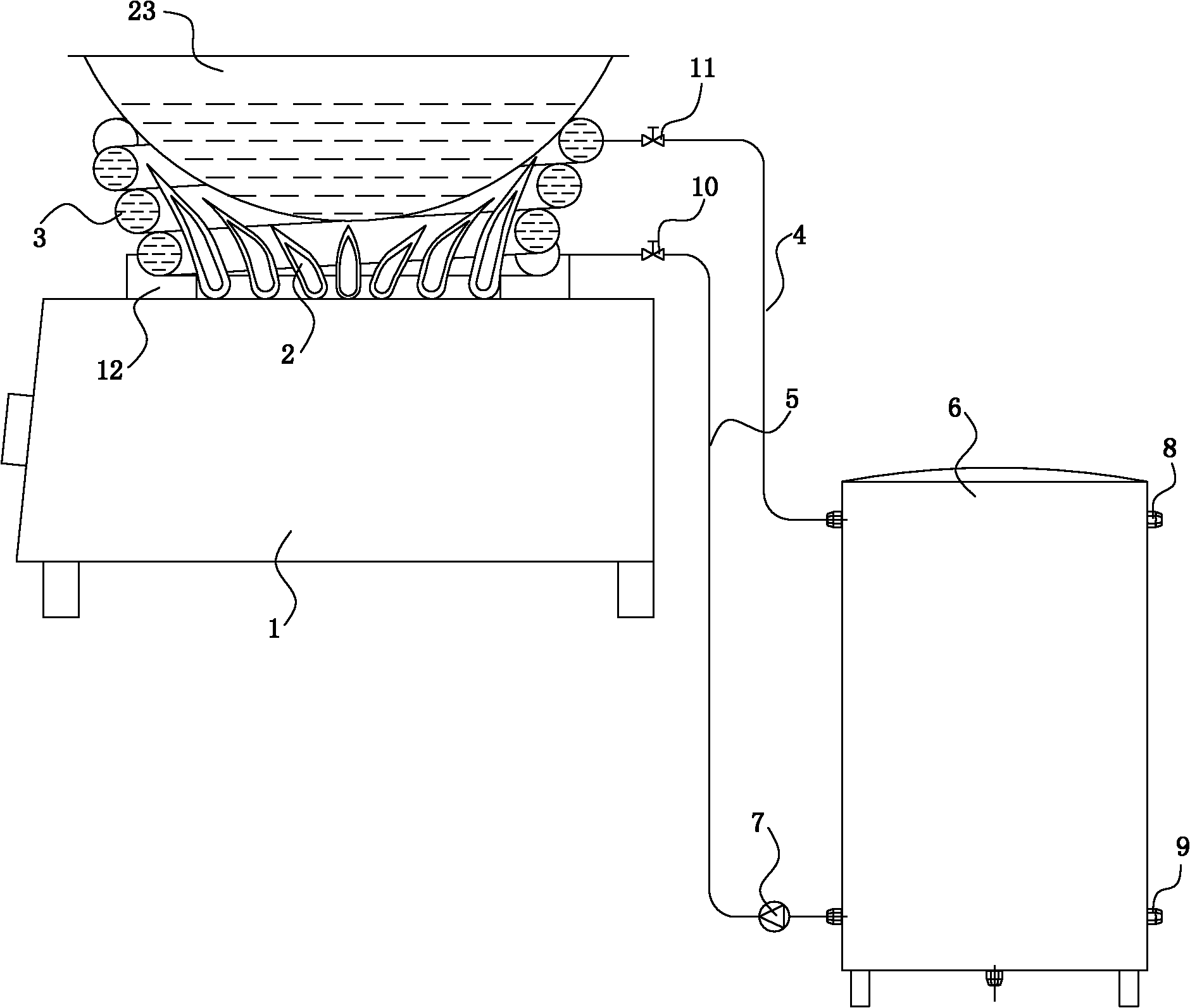

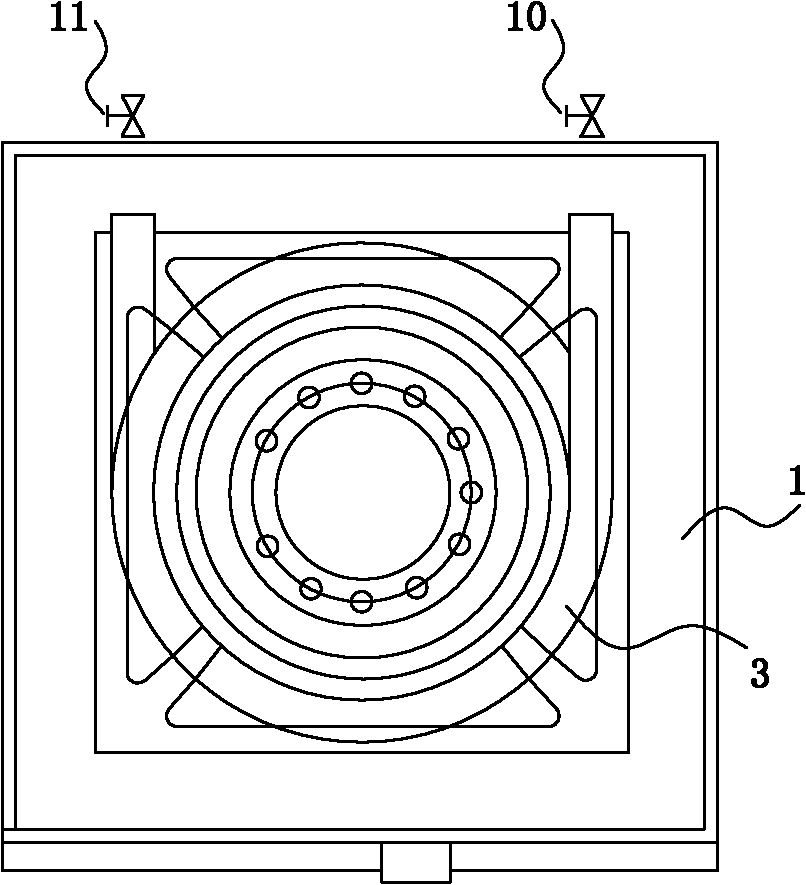

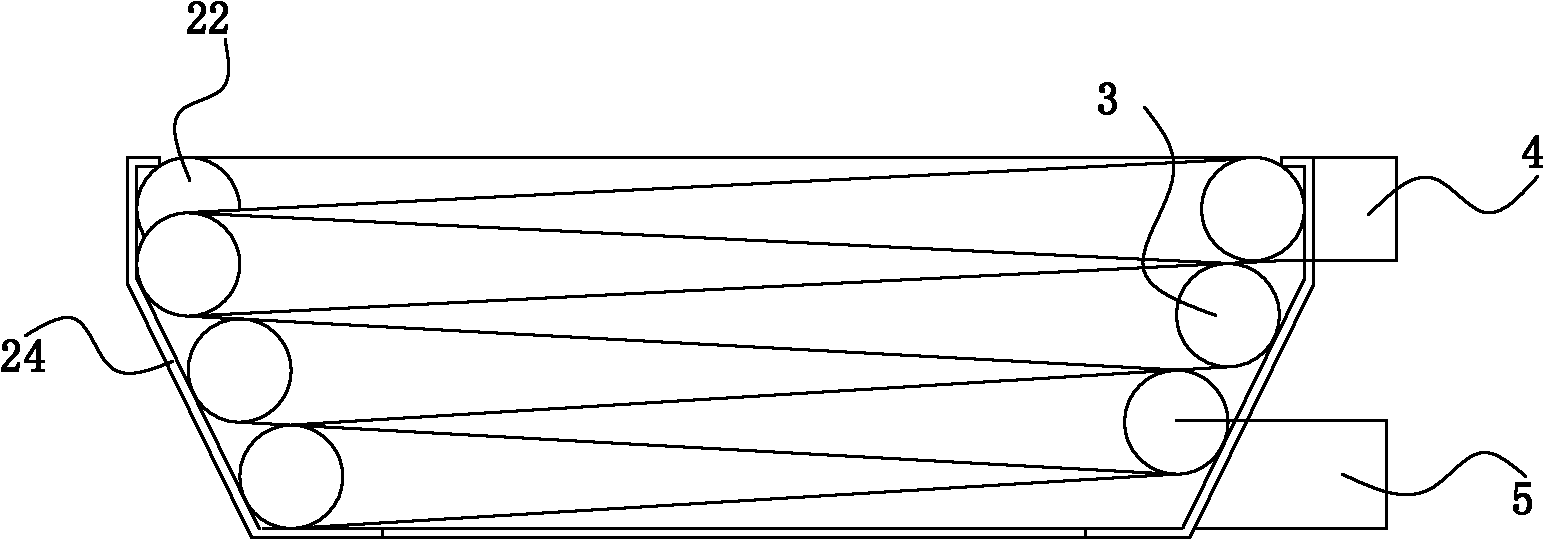

[0028] Example as figure 1 , figure 2 and image 3 As shown, a gas stove heat recovery system includes a gas stove 1, a fire outlet 2 is arranged above the gas stove 1, a cooker 23 is placed above the fire outlet 2, and a heat recovery heat exchanger 3, hot water The outlet pipe 4, the return pipe 5 and the hot water storage tank 6, the heat recovery heat exchanger 3 is arranged around the fire outlet 2, and the two ends of the heat recovery heat exchanger 3 pass through the hot water outlet pipe 4, the return water pipe 5 and the storage tank respectively. The hot water tanks 6 are connected to form a heat recovery pipeline, and a water pump 7 , a hot water outlet 8 and a water replenishment port 9 are arranged on the heat recovery pipeline. The water pump 7 is arranged on the return pipe 5, and the hot water outlet 8 and the replenishment port 9 are arranged on the hot water storage tank 6; There is a water outlet valve 11 on it. A pan support 12 is provided around the ...

Embodiment 2

[0033] Example two such as Figure 4 As shown, in this embodiment, an electric heater 13 is also provided in the hot water storage tank 6. If the heat recovered from the gas stove 1 is insufficient, the electric heater 13 can be used for auxiliary heating.

Embodiment 3

[0034] Embodiment three such as Figure 5 As shown, in this embodiment, a compressor 14, an evaporator 16, a condenser 15, a throttling element 17 and a four-way valve 18 are also included, the condenser 15 is a water side heat exchanger, the compressor 14, the evaporator 16 , the throttling element 17, the four-way valve 18 and the heat exchange working medium side of the condenser 15 are connected through the heat exchange working medium connecting pipe 19 to form a heat exchange working medium circulation loop, and the water side of the condenser 15 is connected to the heat exchange working medium through the connecting water pipe 20 The recovery pipeline is connected, and a solenoid valve 21 is provided on the connecting water pipe 20 . Compared with the second embodiment, in this embodiment, if the heat recovered from the gas stove 1 is not enough, the compressor 14 can be started for auxiliary heating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com