Pure membrane MBBR coupled carbon capture autotrophic nitrogen removal system and use method thereof

An autotrophic denitrification and carbon capture technology, applied in chemical instruments and methods, special treatment targets, water/sludge/sewage treatment, etc., can solve the problems of low purification degree, high energy consumption in the treatment process, poor energy saving and environmental protection effect and other issues, to achieve the effect of reducing output, reducing operating costs, and improving environmental protection and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

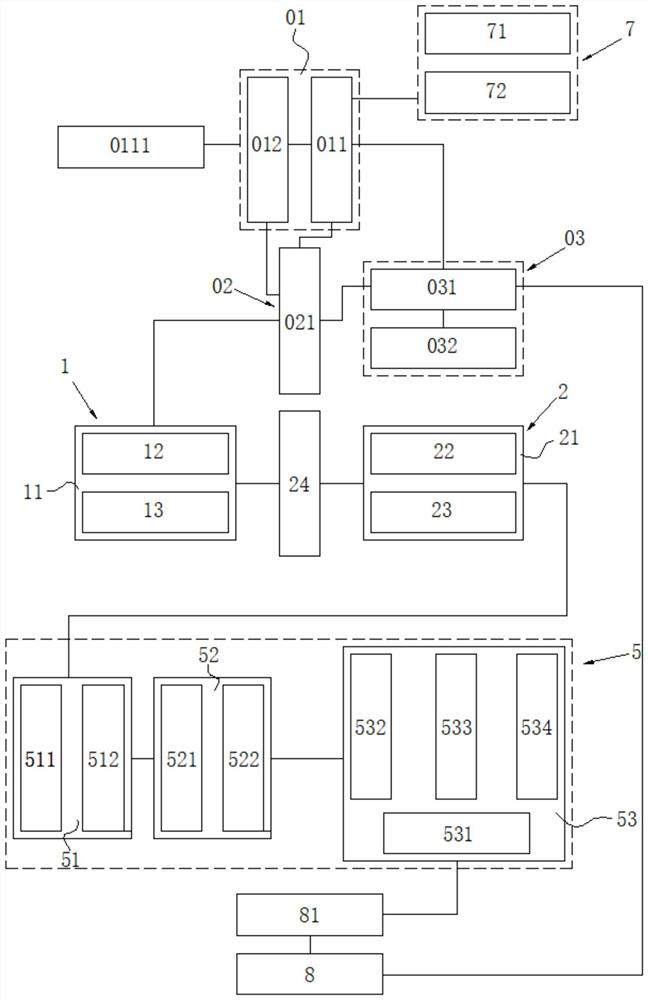

[0041] Embodiment 1: A kind of autotrophic denitrification system of pure membrane MBBR coupling carbon capture, refer to attached figure 1 , including a carbon source capture module 01, a carbon source recovery module 02 and a methane power generation module 03, the carbon source capture module 01 includes a contact pool 011 and a stabilization pool 012, the carbon source recovery module 02 includes a sedimentation tank 021, the methane The power generation module 03 includes an anaerobic fermentation tank 031 and a methane collector 032, and an aeration device 0111 is installed at the bottom of the contact pool 011 and the stabilization pool 012;

[0042] It also includes a first-stage anoxic MBBR module 1, a first-stage aerobic MBBR module 2, and a high-efficiency separation module 5 arranged in series, and the first-stage anoxic MBBR module includes a first standard size tank 11, an underwater agitator 12 and anoxic Biological filler 13, the first-stage aerobic MBBR module...

Embodiment 2

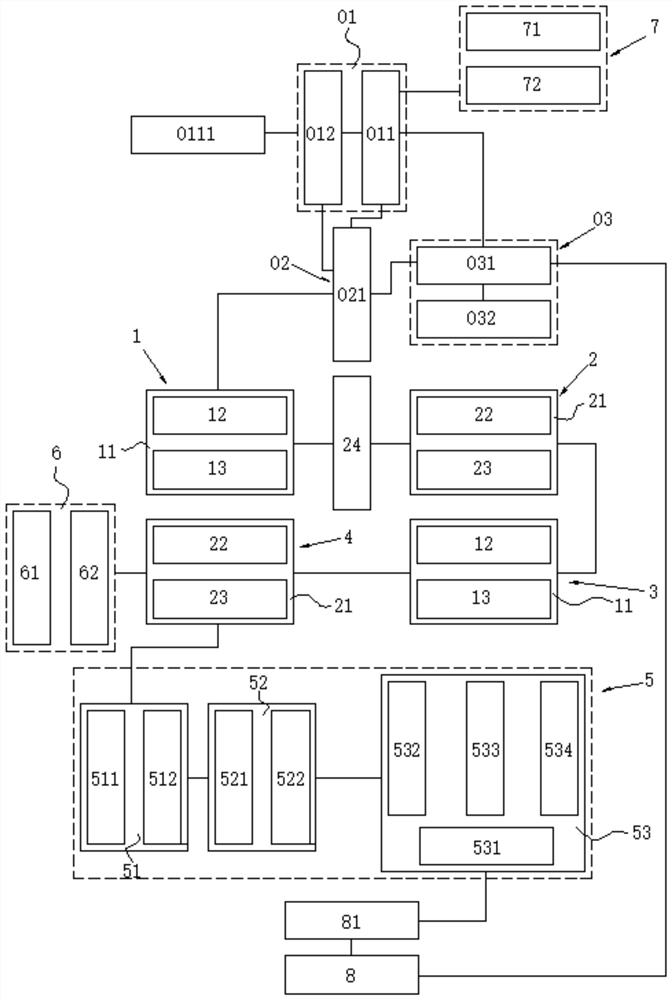

[0047] Embodiment 2: A kind of autotrophic denitrification system of pure membrane MBBR coupling carbon capture, refer to the attached figure 2 , including a carbon source capture module 01, a carbon source recovery module 02 and a methane power generation module 03, the carbon source capture module 01 includes a contact pool 011 and a stabilization pool 012, the carbon source recovery module 02 includes a sedimentation tank 021, the methane The power generation module 03 includes an anaerobic fermentation tank 031 and a methane collector 032, and an aeration device 0111 is installed at the bottom of the contact pool 011 and the stabilization pool 012;

[0048] It also includes a first-level anoxic MBBR module 1, a first-level aerobic MBBR module 2, a second-level anoxic MBBR module 3, a second-level aerobic MBBR module 4, and a high-efficiency separation module 5 arranged in series. The first-level anoxic MBBR module 1 and the secondary anoxic MBBR module 3 both include a fi...

Embodiment 3

[0053] Embodiment 3: a kind of use method of the autotrophic denitrification system of pure membrane MBBR coupling carbon capture, comprises the following steps:

[0054] S1: Introduce the sewage into the pretreatment module, the sewage first passes through the combined grid, and then enters the grit chamber, and settles for 30-60s:

[0055] S2: The sewage after passing through the grit chamber enters the contact tank 011, wherein the dissolved oxygen content of the sewage in the contact tank 011 is not more than 1mg / L, and the sludge inoculated separately in the mixed solution captures the granular COD and colloidal COD in the sewage ; The main function of the aeration device in the contact tank is to increase the EPS (extracellular polymer) content, improve the bioflocculation ability, and increase the carbon source recovery rate;

[0056] S3: The sewage passing through the contact tank 011 flows into the sedimentation tank 021, the supernatant liquid flows into the first-st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com