New energy heat supply floor heat preservation equipment based on energy-saving residence

A new energy and residential technology, applied in the field of new energy heating floor insulation equipment, to achieve the effect of improving heating effect, improving environmental protection and energy saving, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

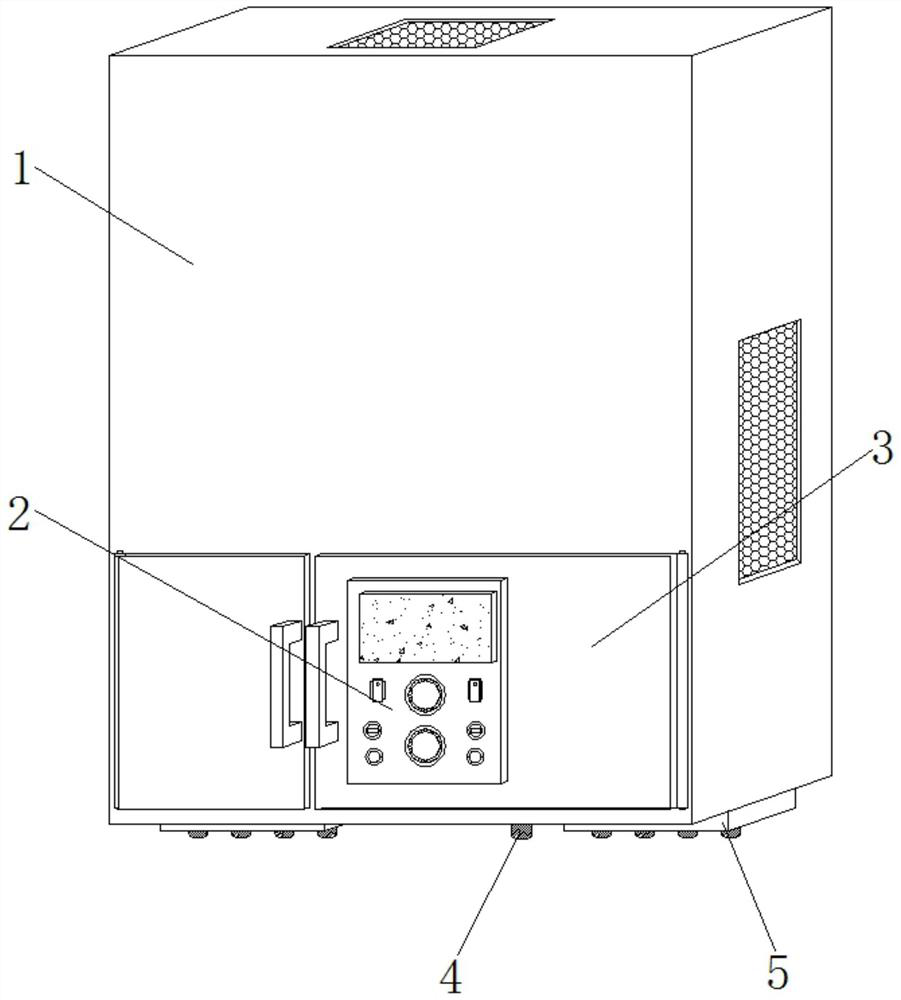

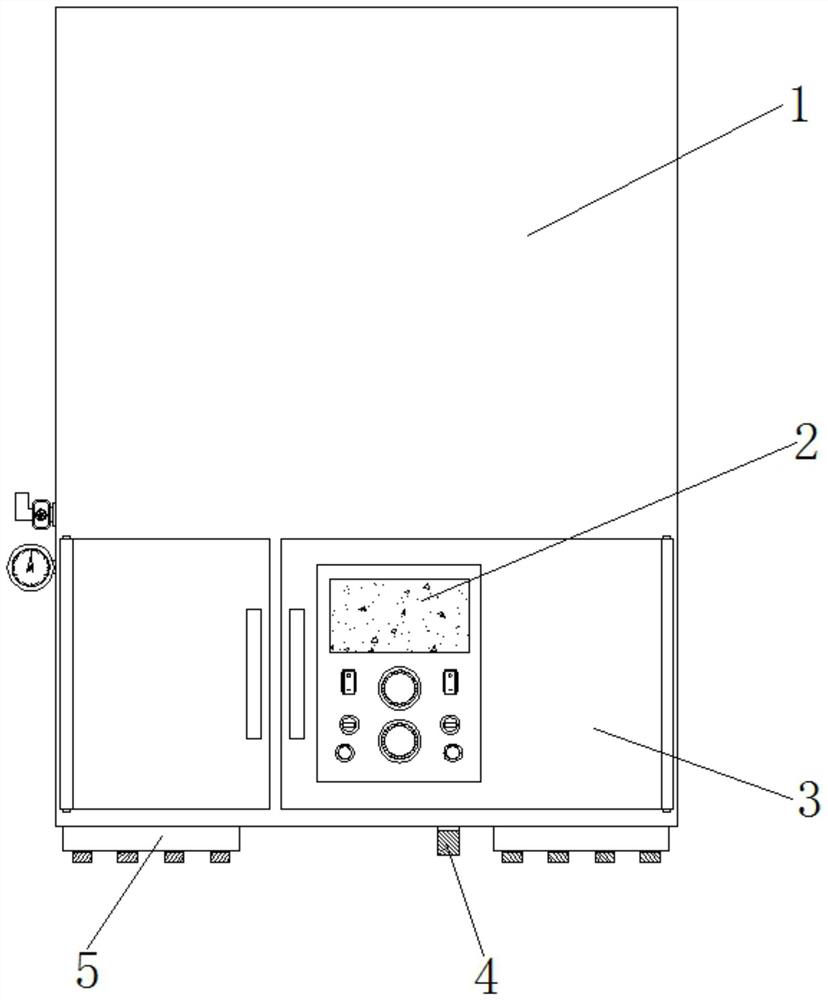

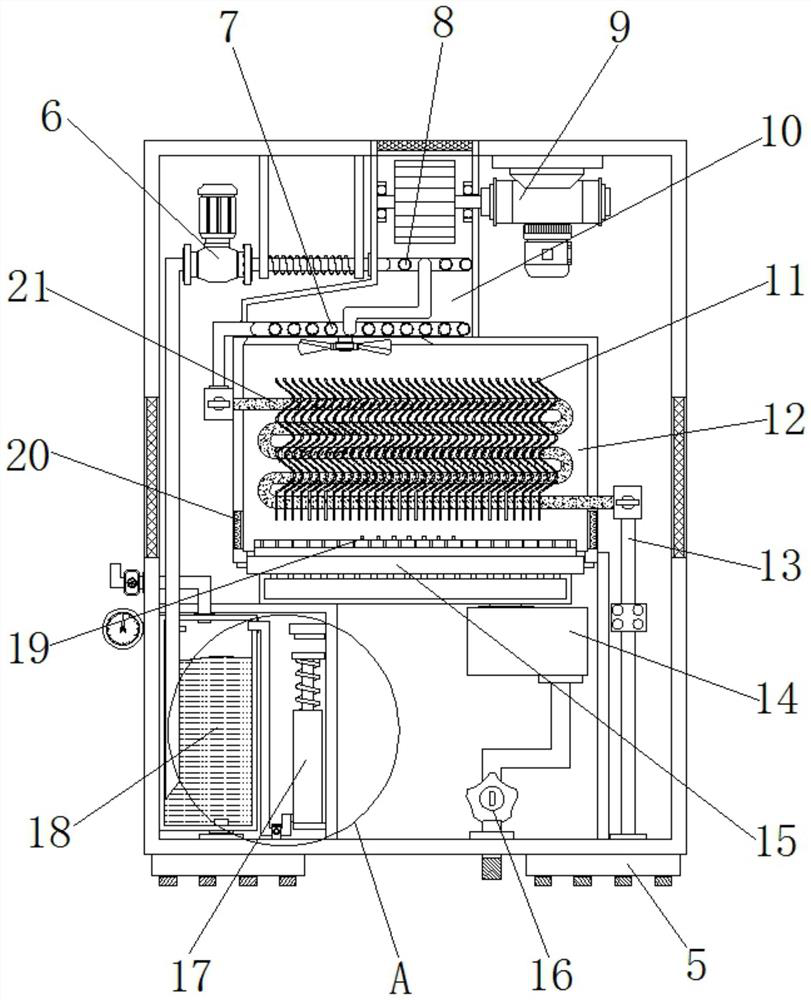

Embodiment 1

[0038] Example 1, such as Figure 1-7 As shown, when it is necessary to heat the floor and the ground, the ignition electrode 19 is first controlled by the control panel 2 to ignite the gas ejected from the burner 15, and the ignited flame heats the heat conducting sheet 11 and the third heat exchange tube 21, While the flame is heating, the hot air generated by the flame will also flow upwards in the gaps between multiple groups of heat conducting fins 11, and then flow into the inside of the air guiding chamber 10. When the hot air enters the air guiding chamber 10, The liquid inside the first heat exchange tube 7 is heated, and then the liquid inside the second heat exchange tube 8 is heated, and then the fan 9 is used to accelerate the air to be discharged from the top of the air guide chamber 10 in the external environment. Heating the liquid inside the second heat exchange tube 8 plays a preliminary preheating effect, and heating the liquid inside the first heat exchange...

Embodiment 2

[0039] Example 2, such as Figure 1-7 As shown, if the pressure inside the collecting box 18 and inside the heating pipe increases due to liquid heating, the user can see the pressure inside the collecting box 18 through the pressure gauge, and when the pressure reaches the fixed value of the pressure relief valve, The pressure relief valve is opened to reduce the pressure inside the collection box 18, and when the pressure relief valve cannot be opened in time to release the pressure due to a fault, due to the increase in the internal pressure of the collection box 18, the piston 175 will be pushed up inside the collection box 186, and the spring 173 will be pressed. The force stretches and stores the elastic potential energy, and after the top plate 172 is pressed to the touch sensor 171, the touch sensor 171 transmits a signal to the control panel 2, and the control panel 2 controls the solenoid valve 16 to close, thereby stopping the burner 15 from continuously burning the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com