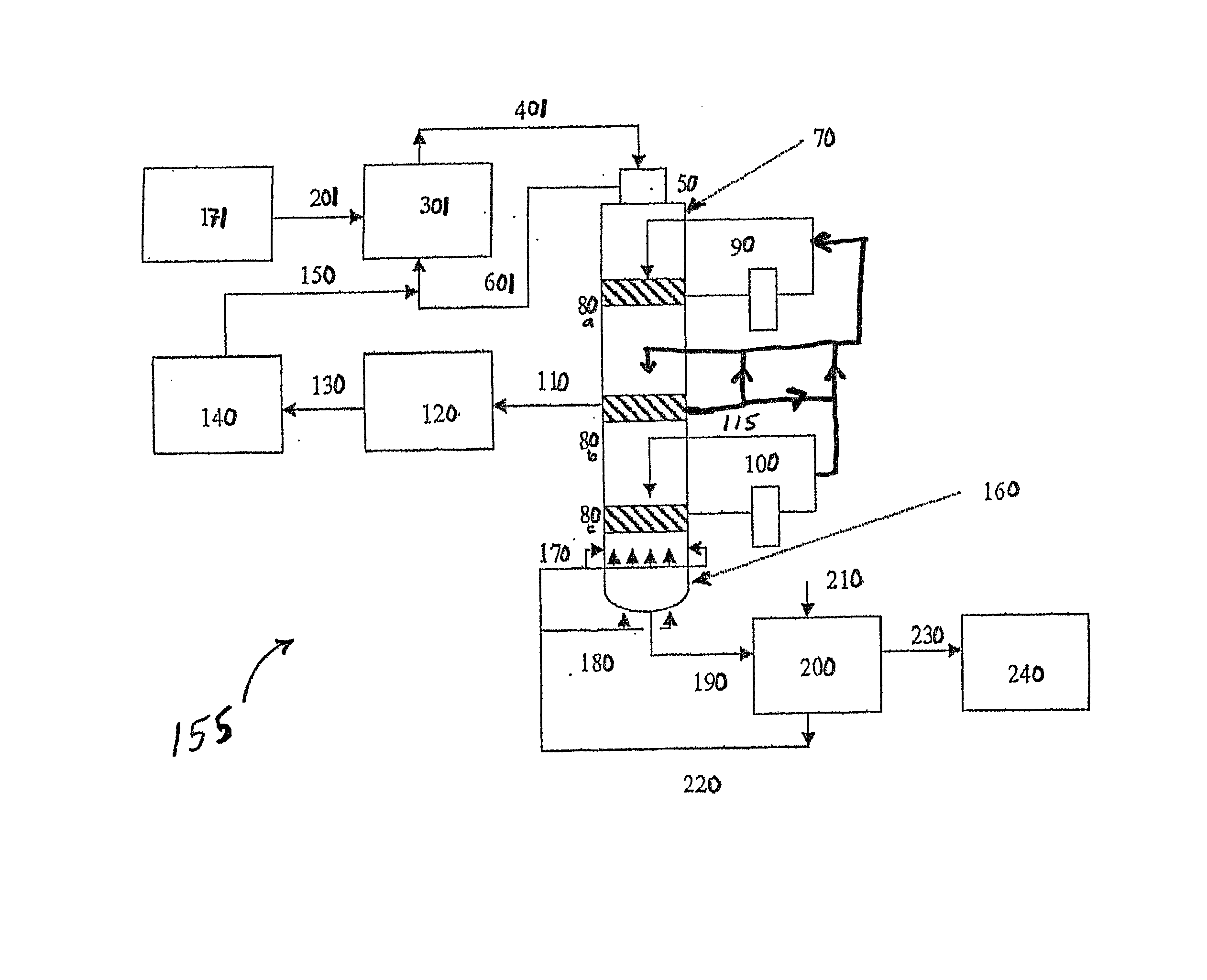

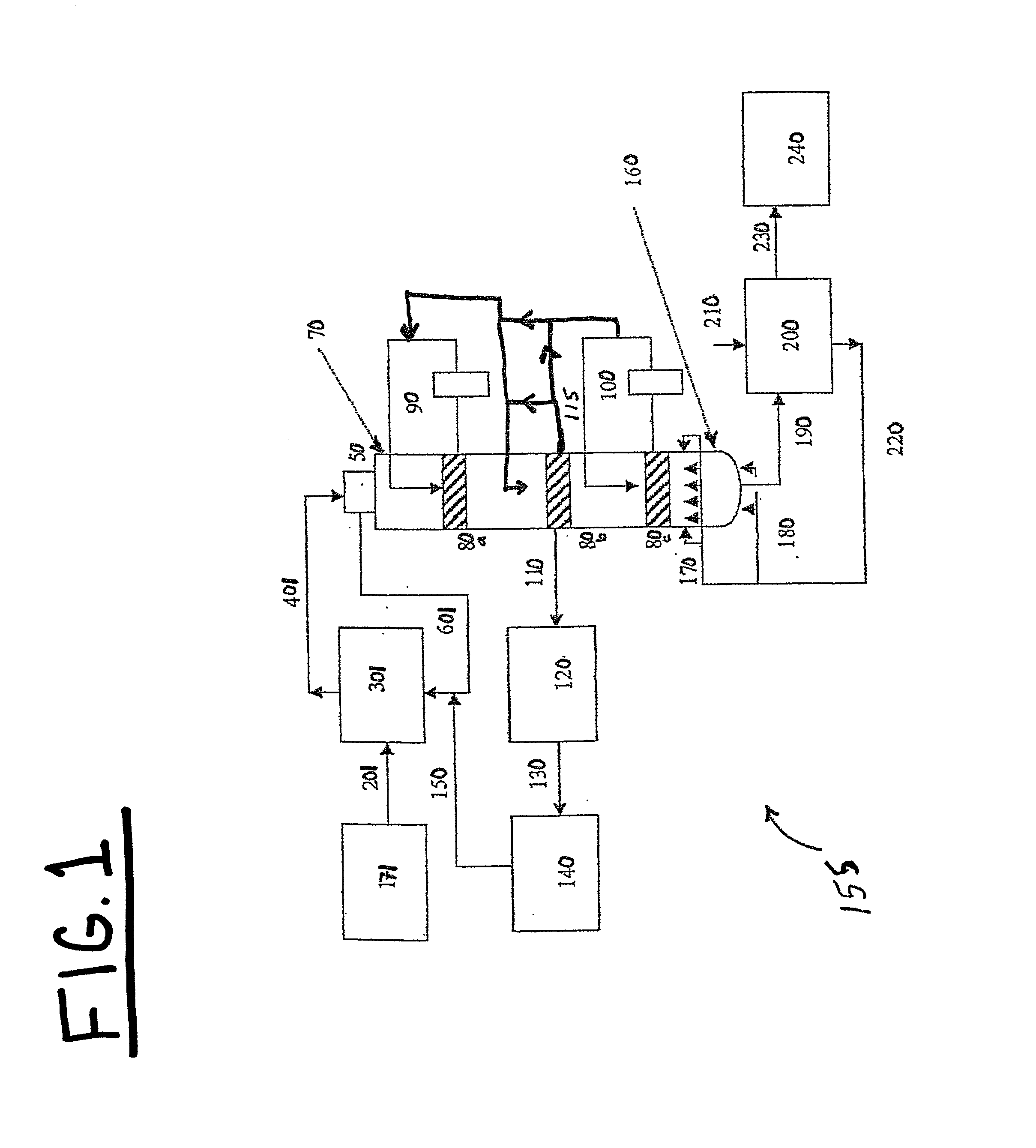

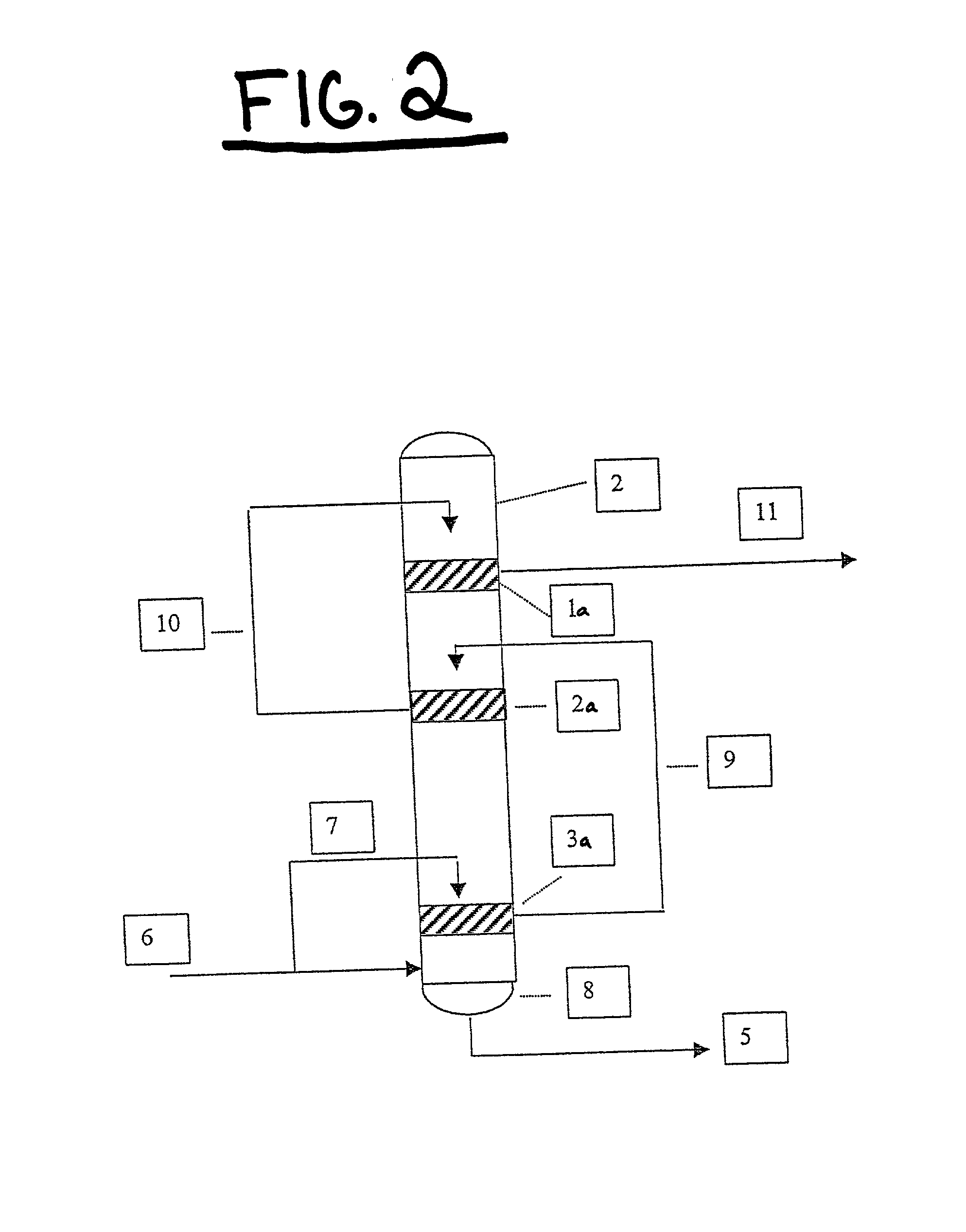

Process and configuration for providing external upflow/internal downflow in a continuous digester

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0083] The following examples and experimental results are included to provide those of ordinary skill in the art with a complete disclosure and description of particular manners in which the present invention can be practiced and evaluated, and are intended to be purely exemplary of the invention and are not intended to limit the scope of what the inventors regard as their invention. Efforts have been made to ensure accuracy with respect to numbers (e.g., amounts, temperature, etc.); however, some errors and deviations may have occurred. Unless indicated otherwise, temperature is in .degree. C. or is at ambient temperature, and pressure is at or near atmospheric.

[0084] An extended digester trial was performed, wherein the digester process configuration was changed from upflow to downflow modified cooking. The primary objective of the trial was to quantify the effect of downflow cooking on overall mill operations and then use this information to perform a cost-benefit-risk analysis ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific volume | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com