Method and device for recovering energy

a technology of energy recovery and energy recovery, which is applied in the field of recovering energy, can solve the problems of poor efficiency, inability to control the entire range of various outside temperatures of any system, and inability to switch from cooling mode to heating mode, etc., and achieves the effect of increasing heat recovery system, large heat recovery, and increasing transfer power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

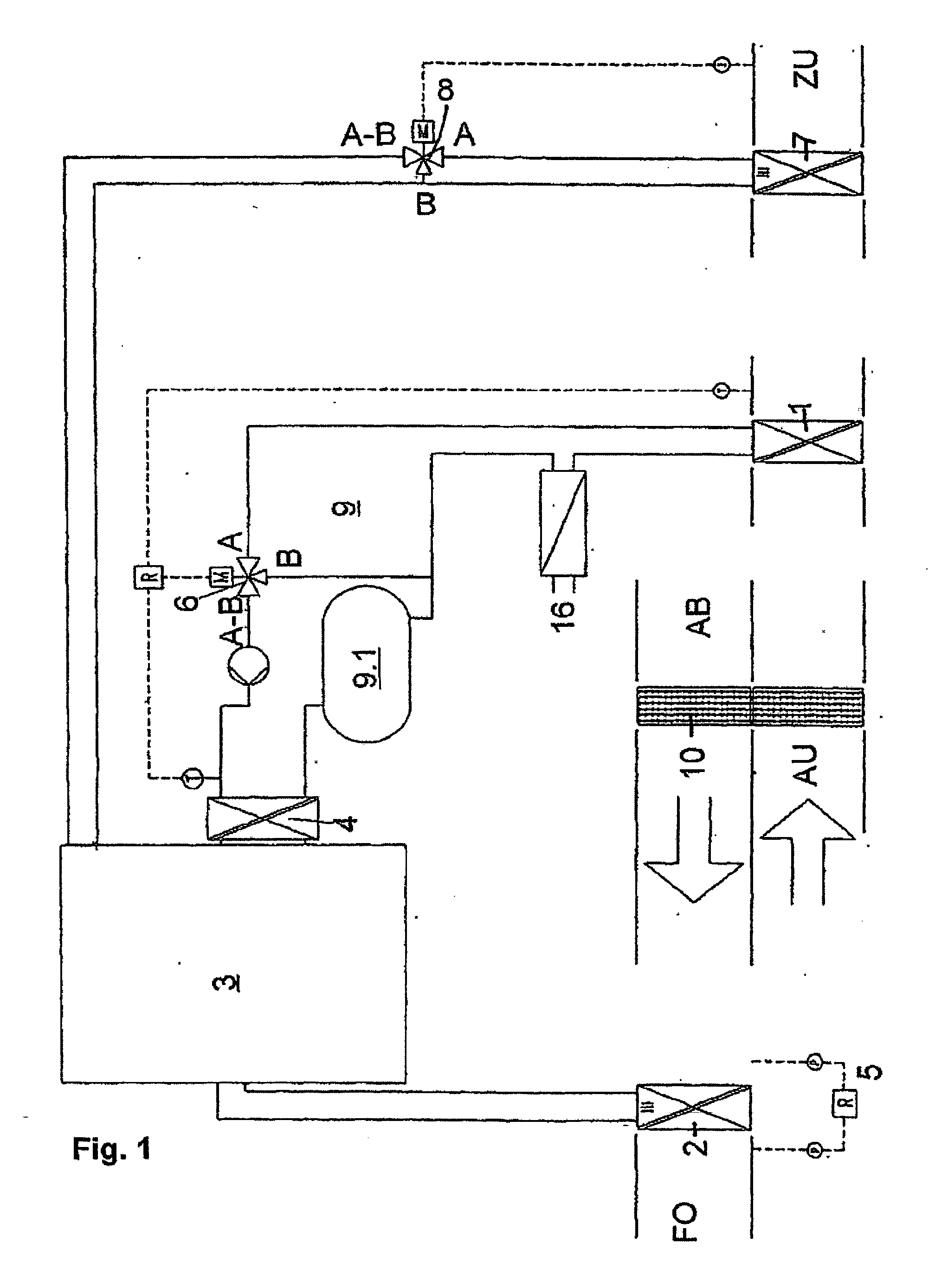

first embodiment

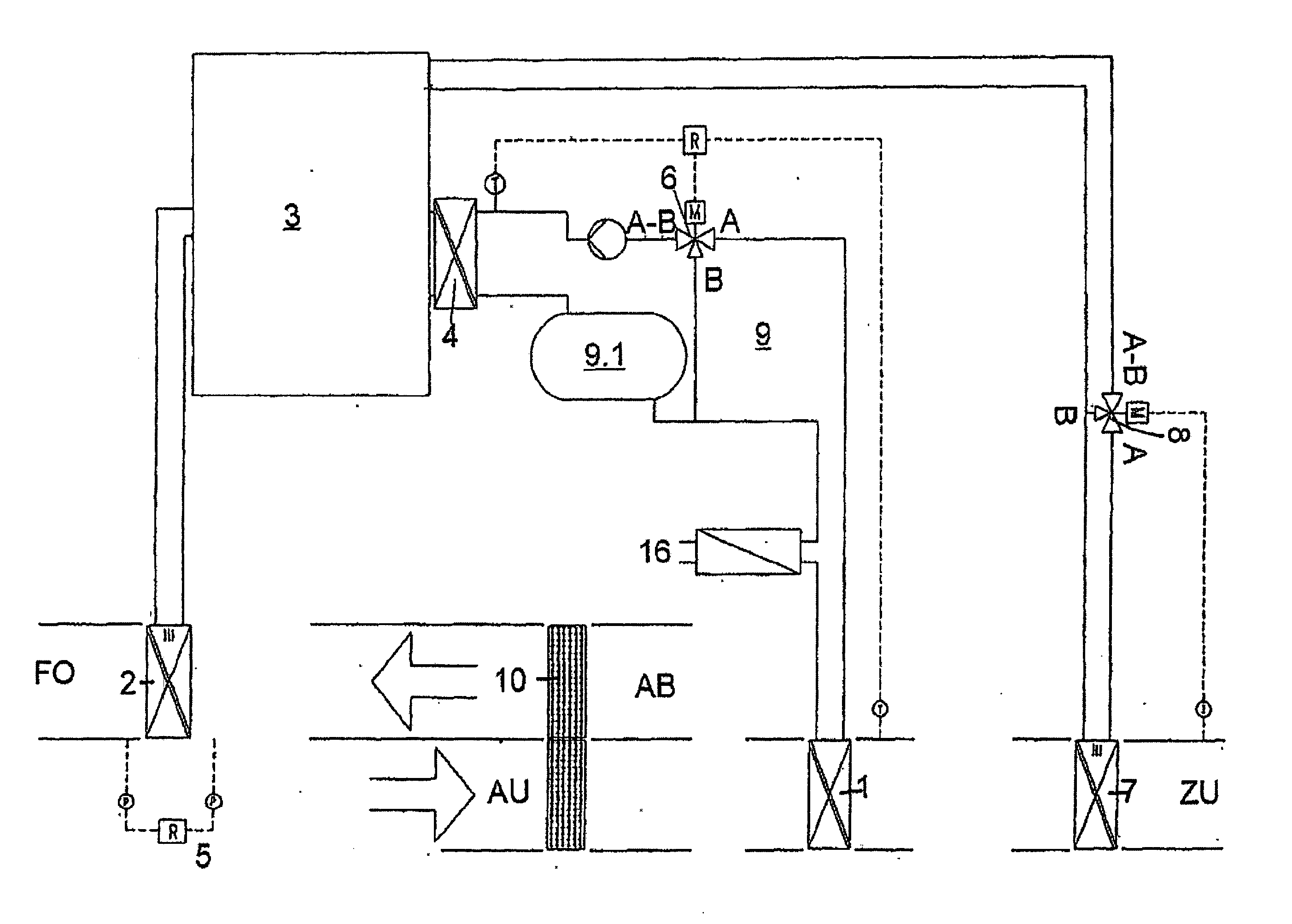

[0054] According to the invention from FIG. 1, a heat exchanger 2 is placed after a heat recovery system 10 in a used air volume flow AB, which becomes outgoing air FO through ventilation-specific handling. The heat recovery system 10 is coupled on the other side to a supply air volume flow ZU, which is obtained from the external air AU through ventilation-specific handling. The heat recovery system 10 can be formed according to one of the known configurations, e.g., as a KVS (interconnected circulating) system, rotary or plate heat exchanger, smooth tube heat exchanger, accumulator mass heat exchanger, or heat exchanger tube. The heat exchanger 2 is coupled to a heat pump 3 and in the heating case acts as an evaporator and in the optional cooling case as a condenser of the heat pump 3. In the refrigeration cycle of the heat pump 3, there is another heat exchanger 4, which is used in the heating case as a condenser, and in the cooling case as an evaporator. Furthermore, in the suppl...

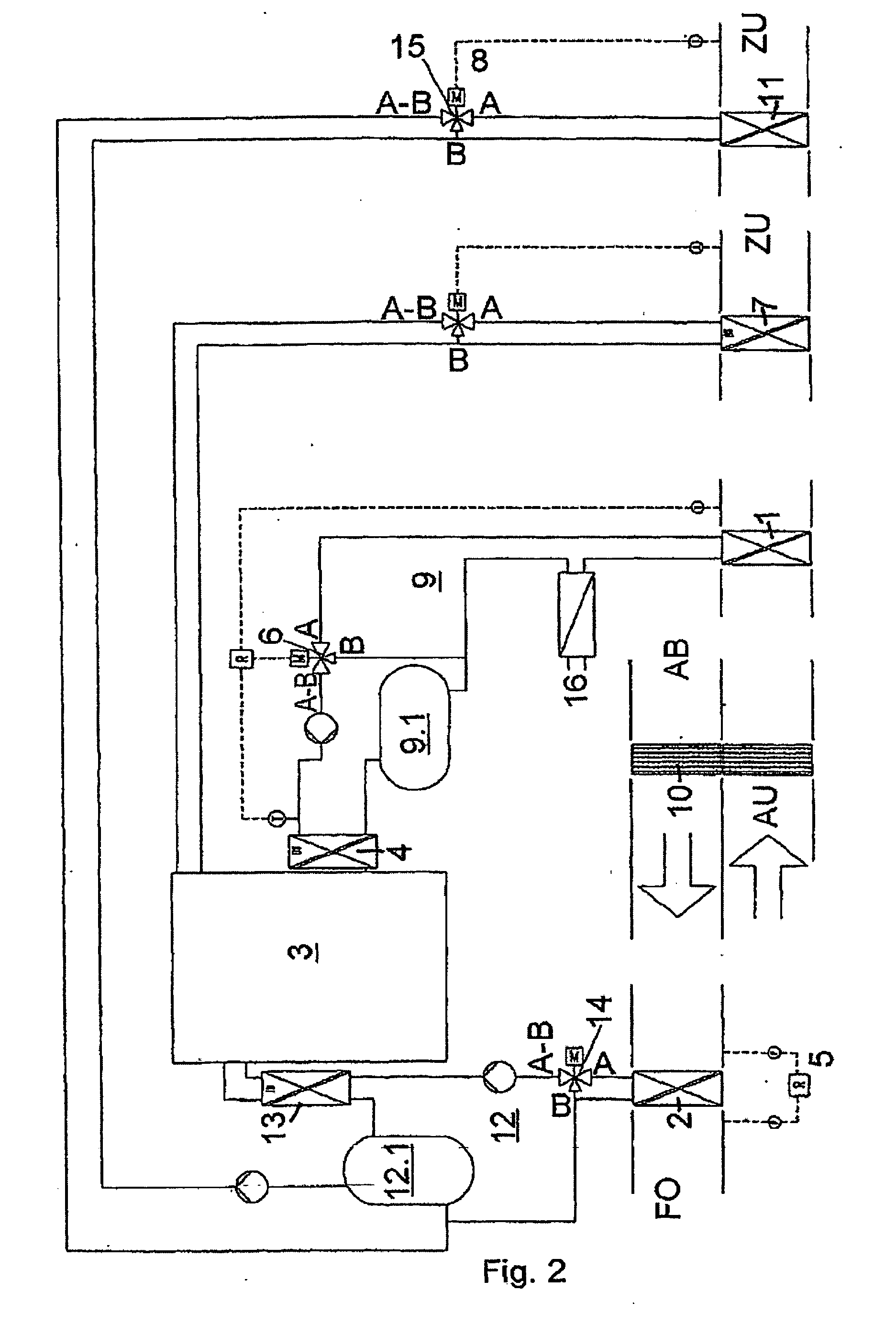

second embodiment

[0065] In the heating case, on the other hand, an optional humidity regulation of the supply air volume flow ZU is coupled to the energy accumulator 9, and is described in more detail below in the

[0066] To improve the heat dissipation in the cooling case, in the used air volume flow AB there is a device for adiabatic cooling between the heat recovery system 10 and the heat exchanger 2 of the heat pump 3. Thus, the heat transfer at this point is greatly improved in a simple manner.

[0067] To influence the air handling, air valves can be provided in the channels between the supply air volume flow ZU and the used air volume flow AB in a known way for the supply of mixed air from the used air volume flow AB to the supply air volume flow ZU or for performing an air-circulation operation, as mentioned above. For the use of mixed air, by increasing the air volume flow by means of the air valve, more thermal energy can be taken by the condenser at a lower air temperature. Thus, cold water c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com