Patents

Literature

238results about "Combustible gas thermal treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

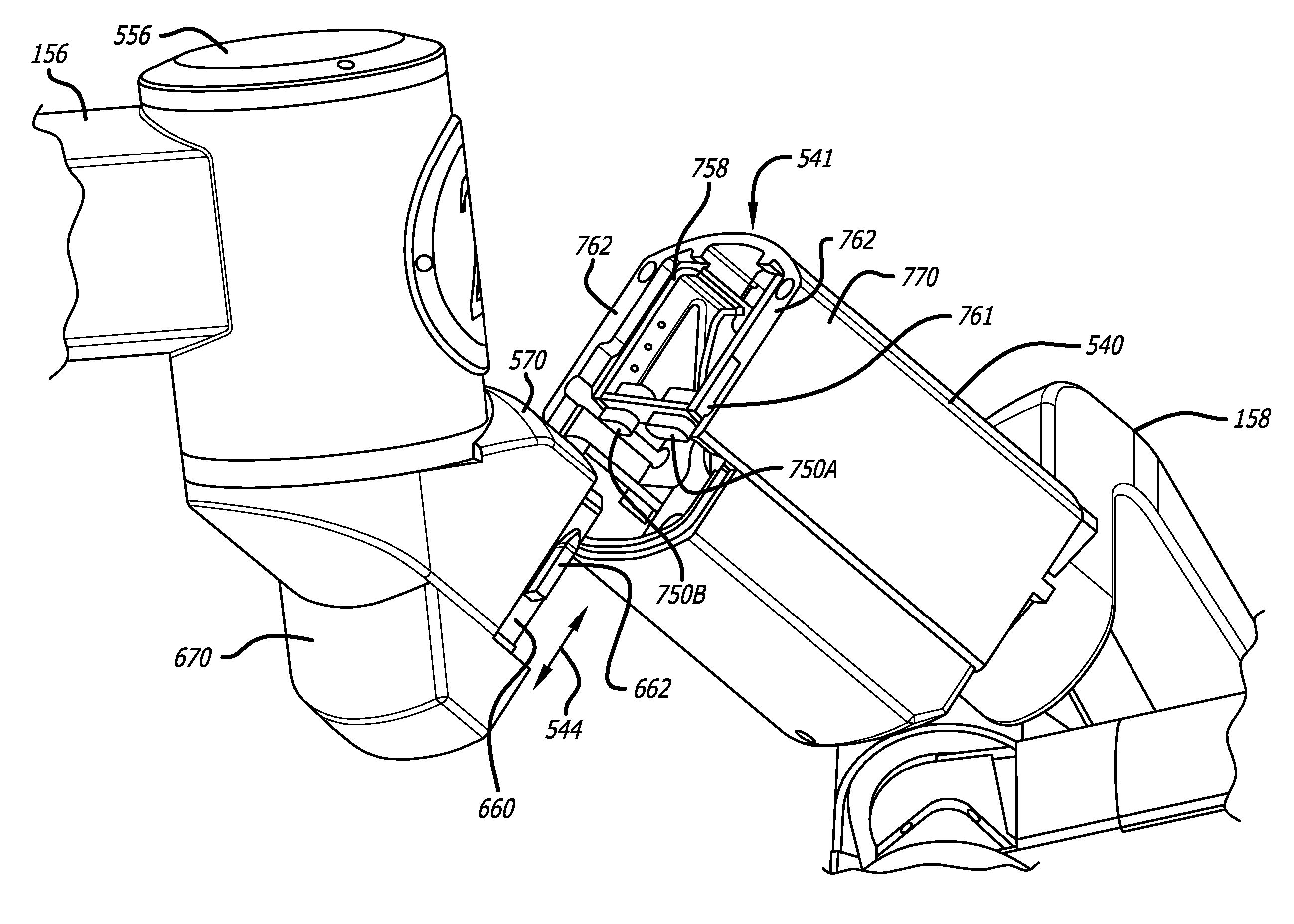

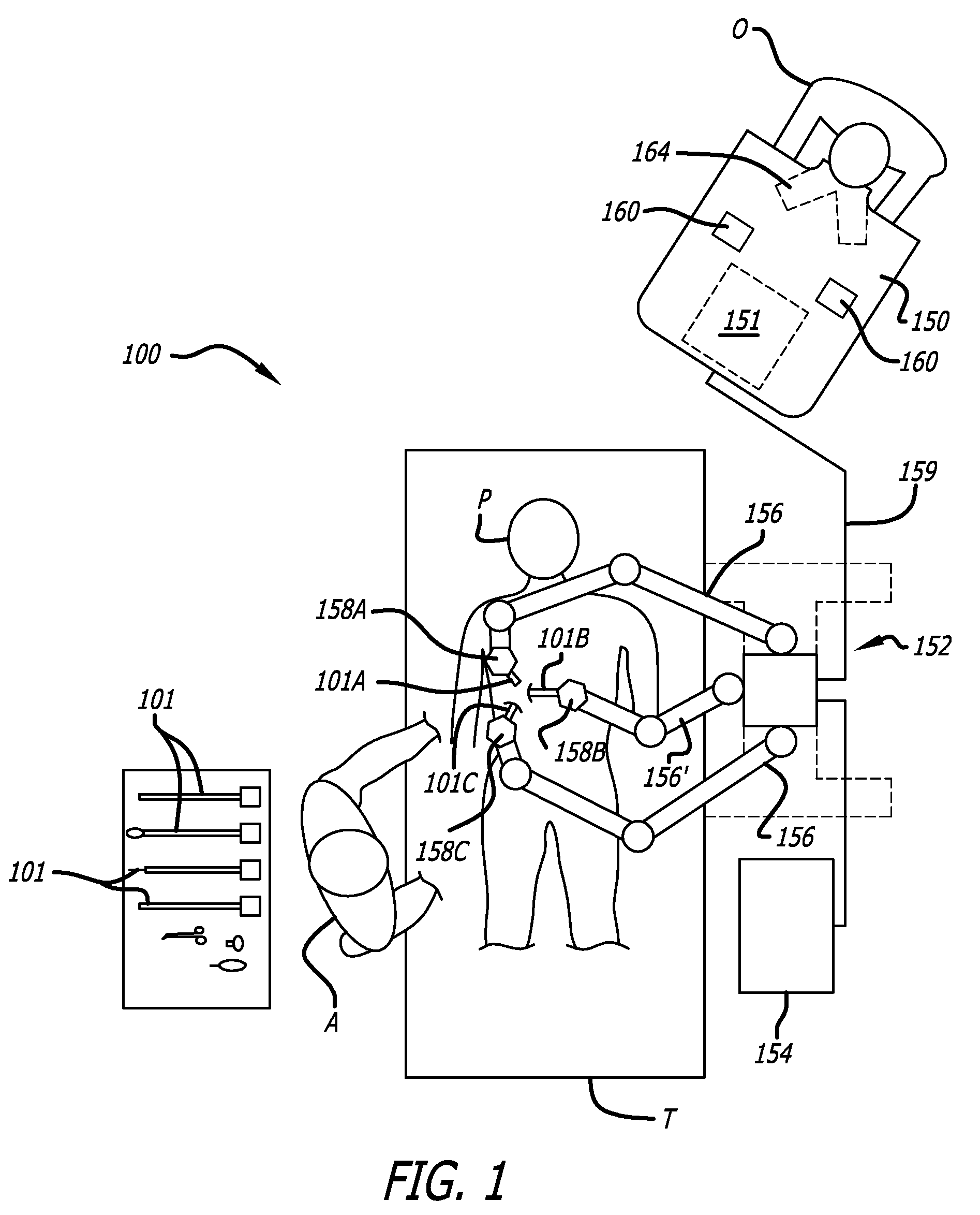

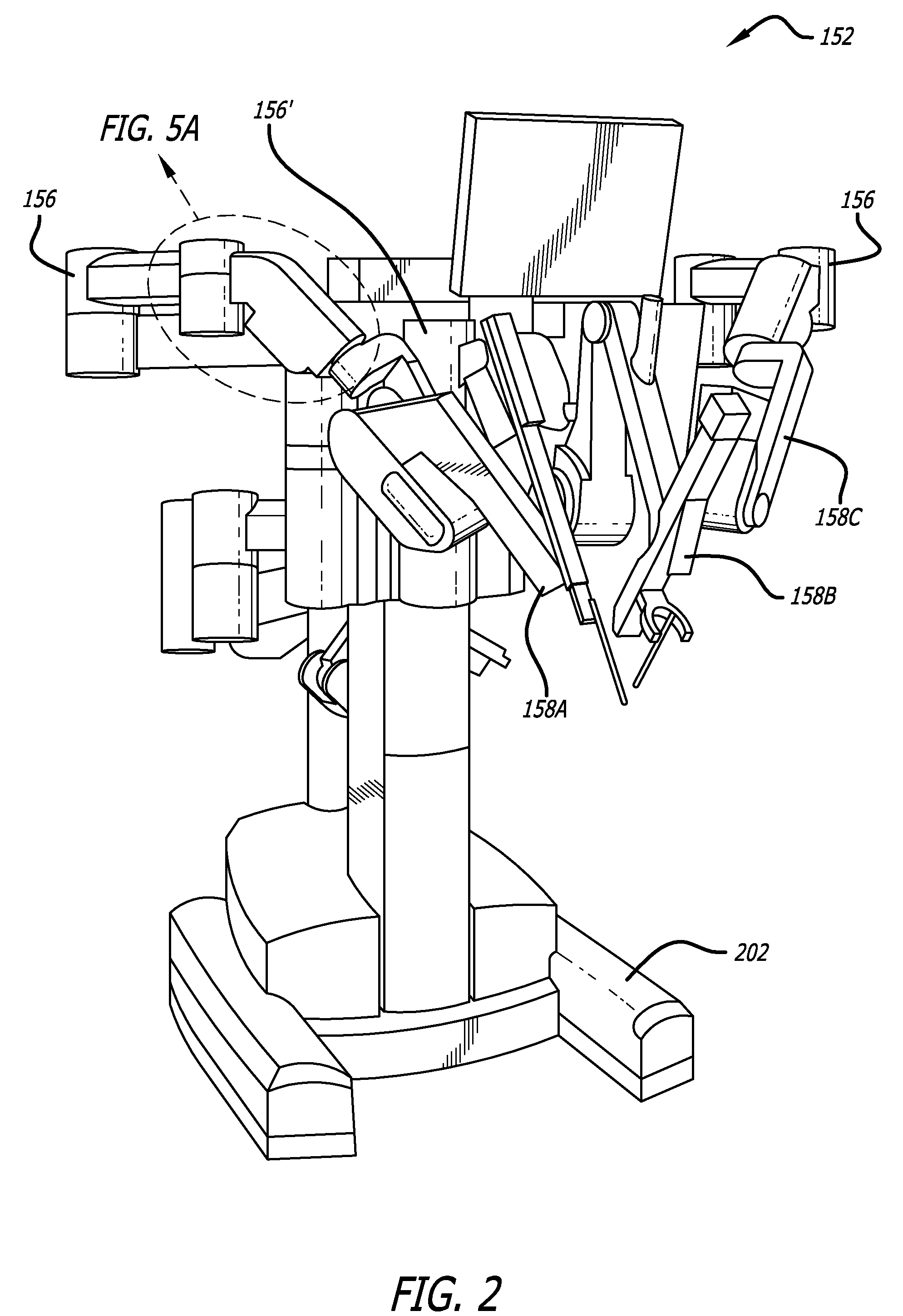

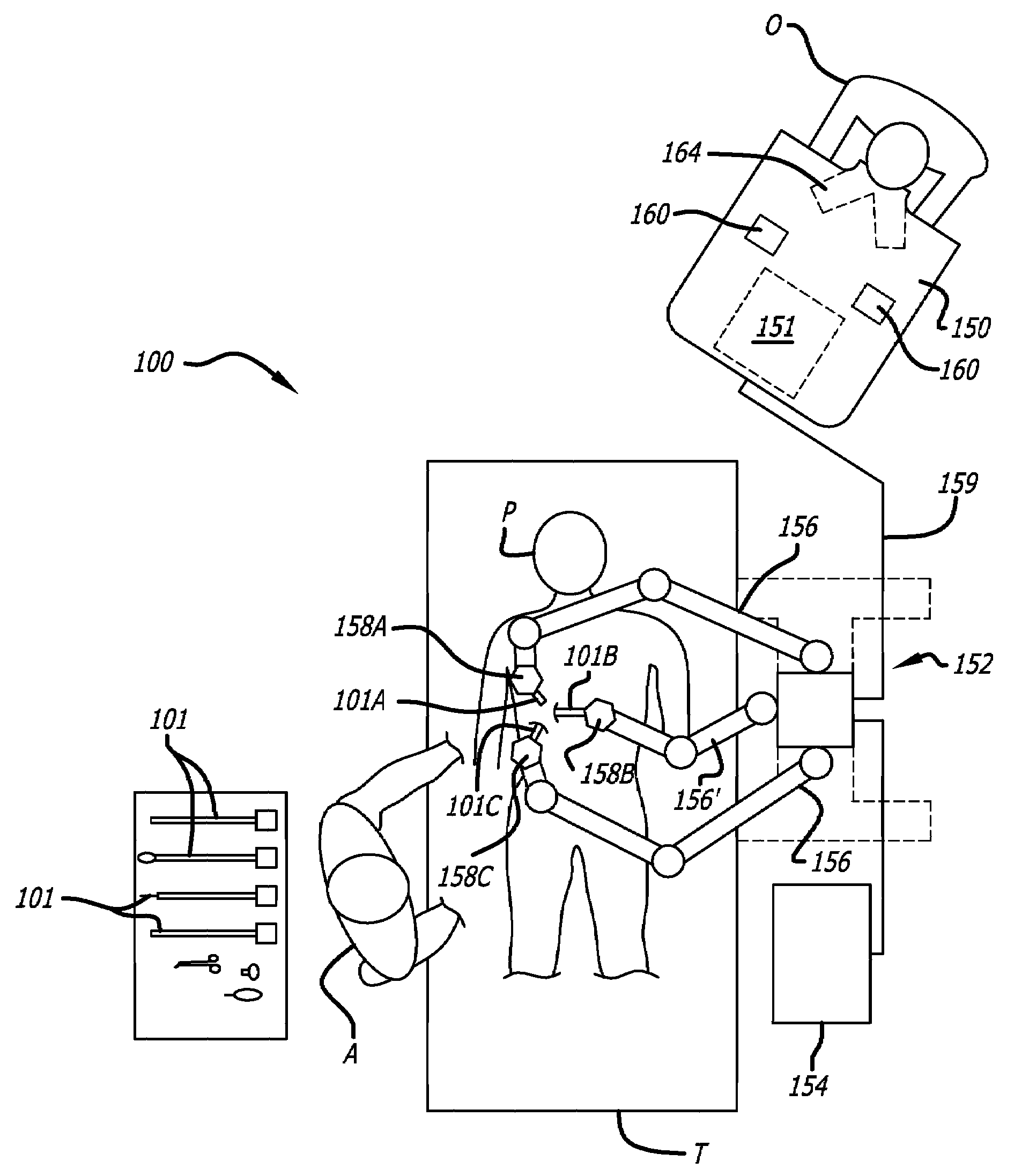

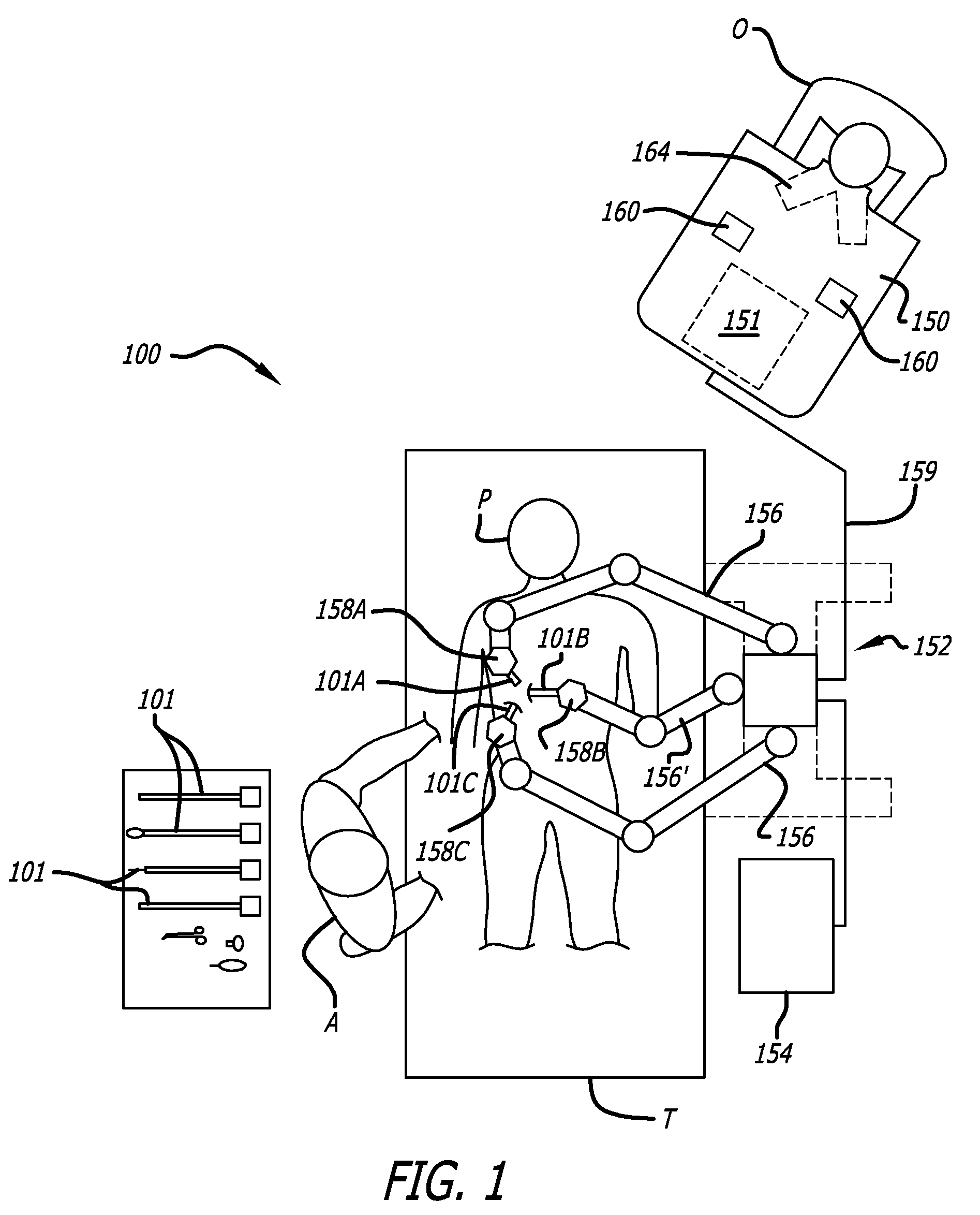

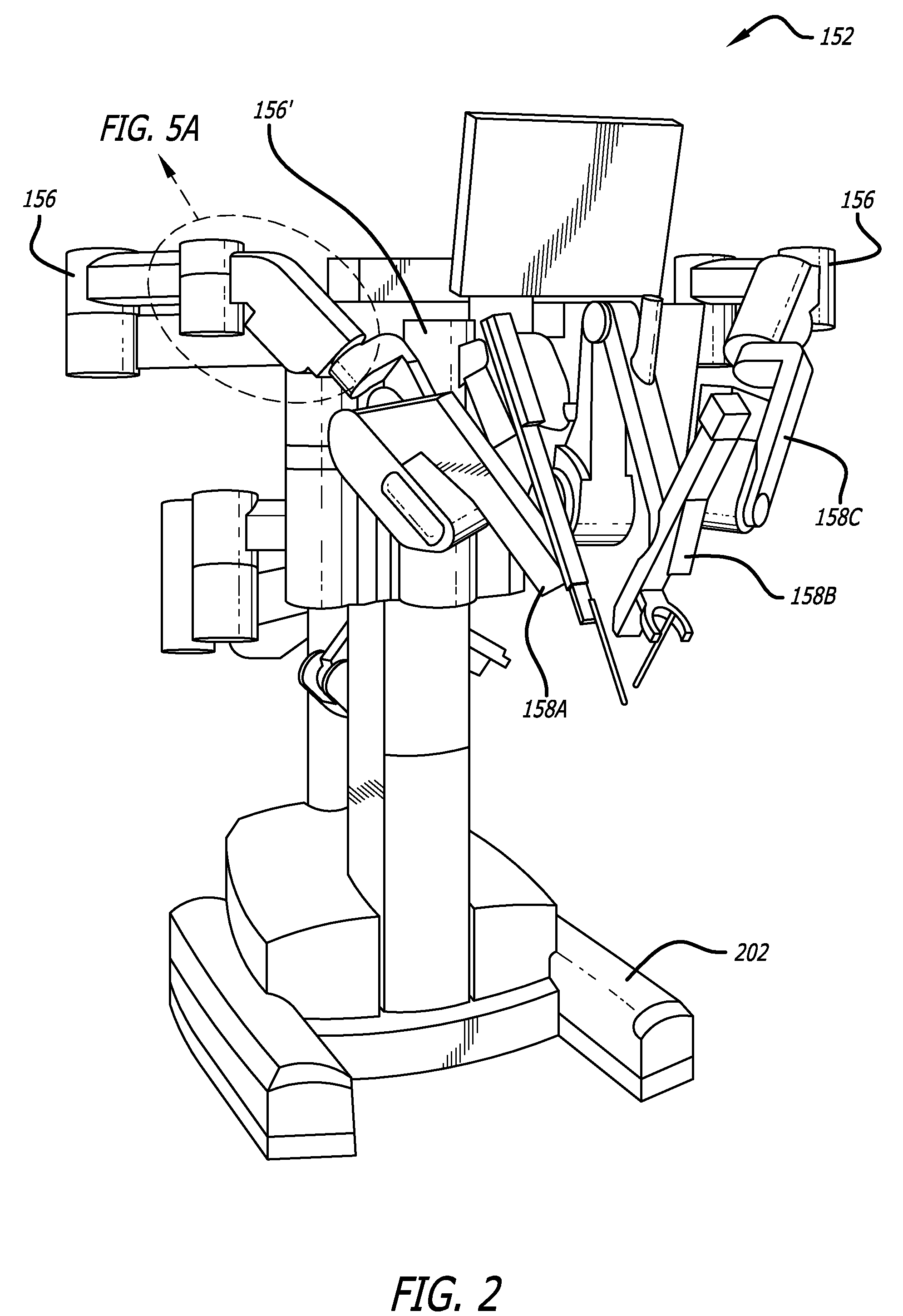

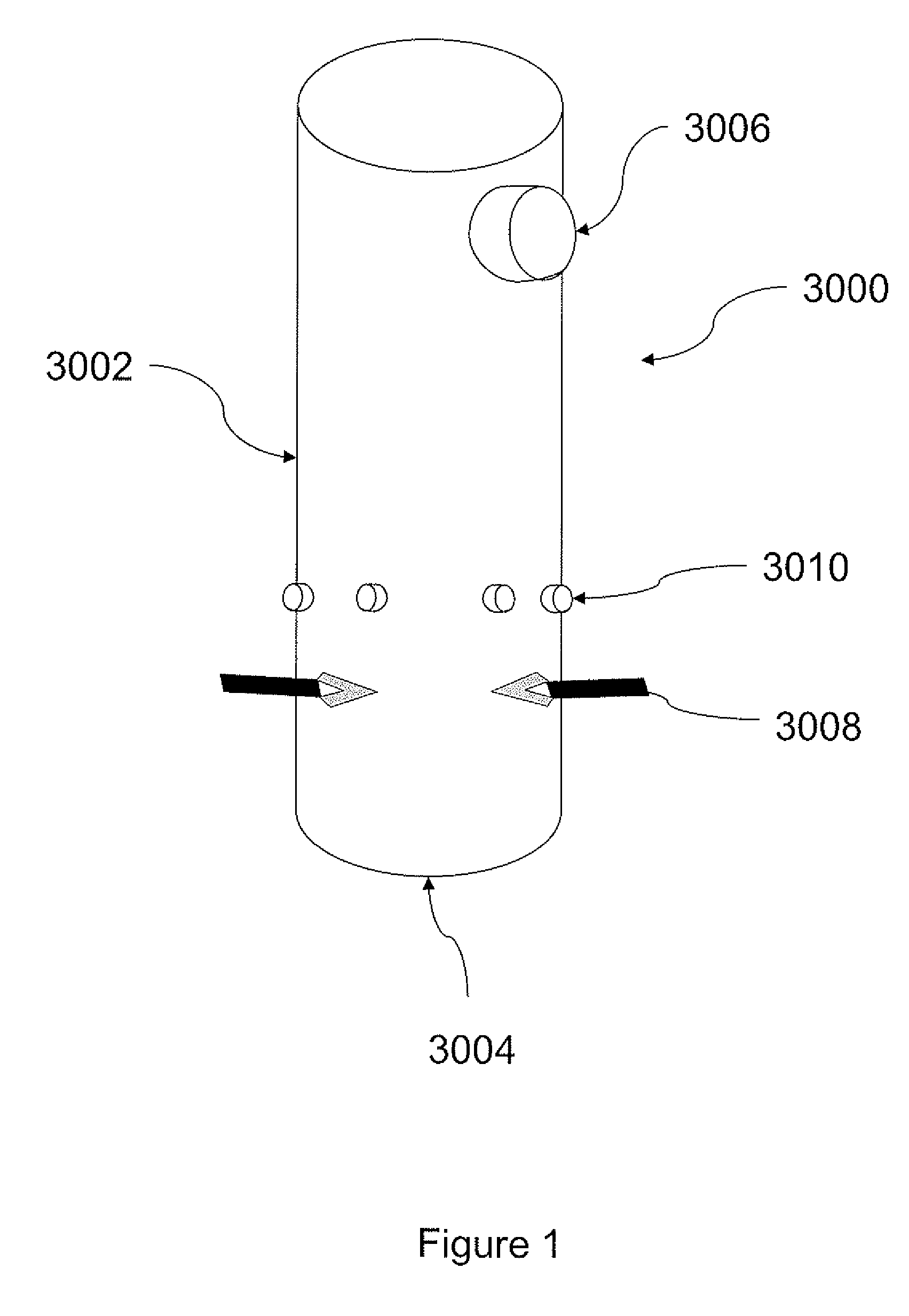

Electro-mechanical interfaces to mount robotic surgical arms

In one embodiment of the invention, a method of mounting a surgical robotic arm to a set-up arm of a robotic surgical system is provided that includes sliding a pair of guide slots of the surgical robotic arm over a pair of guide tabs in the set-up arm; aligning electrical connectors in the set-up arm to electrical connectors of the surgical robotic arm; and coincidentally mating male electrical connectors to female electrical connectors while finally mating the guide tabs in the set-up arm to flanges of a housing of the surgical robotic arm.

Owner:INTUITIVE SURGICAL OPERATIONS INC

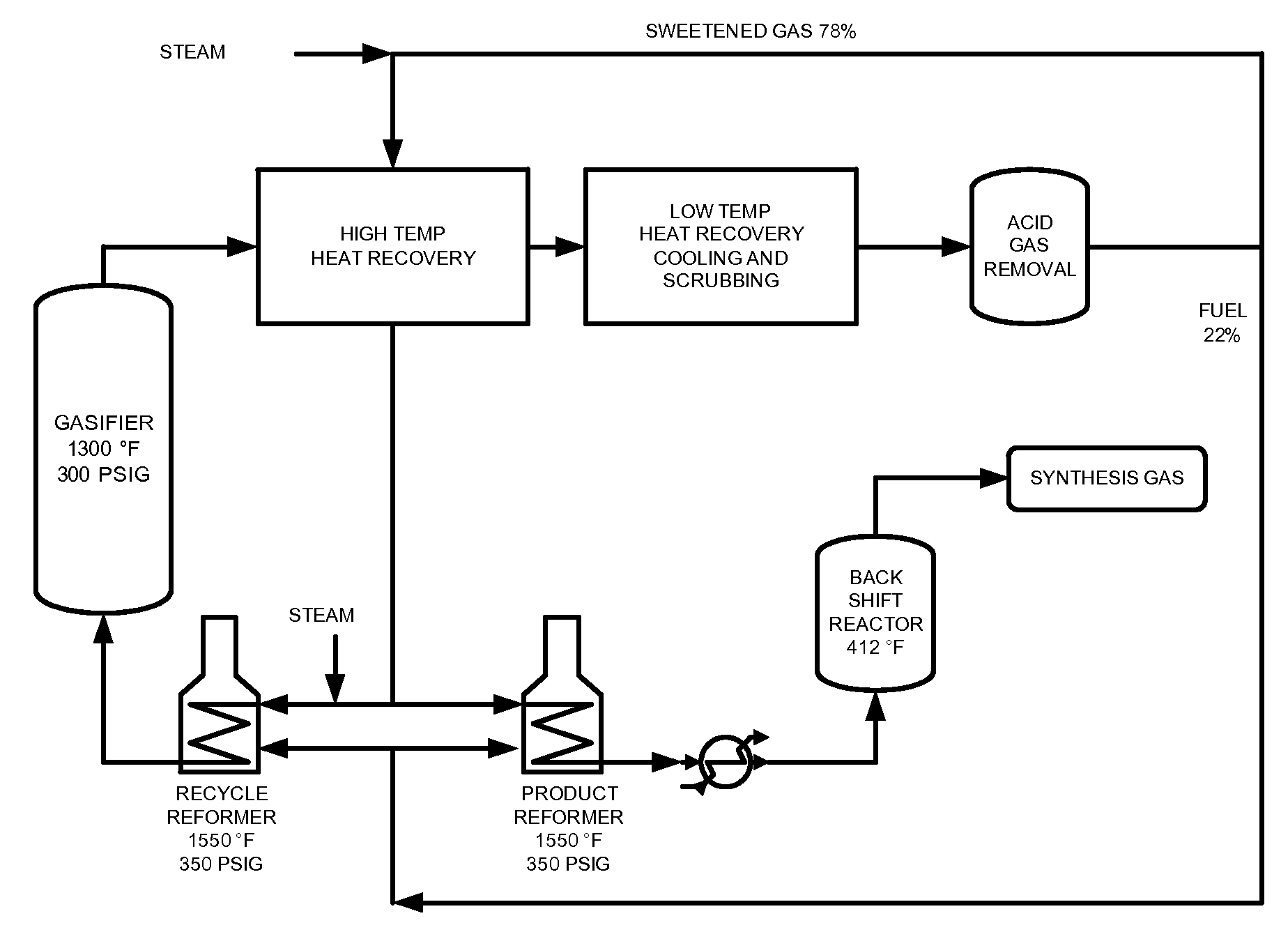

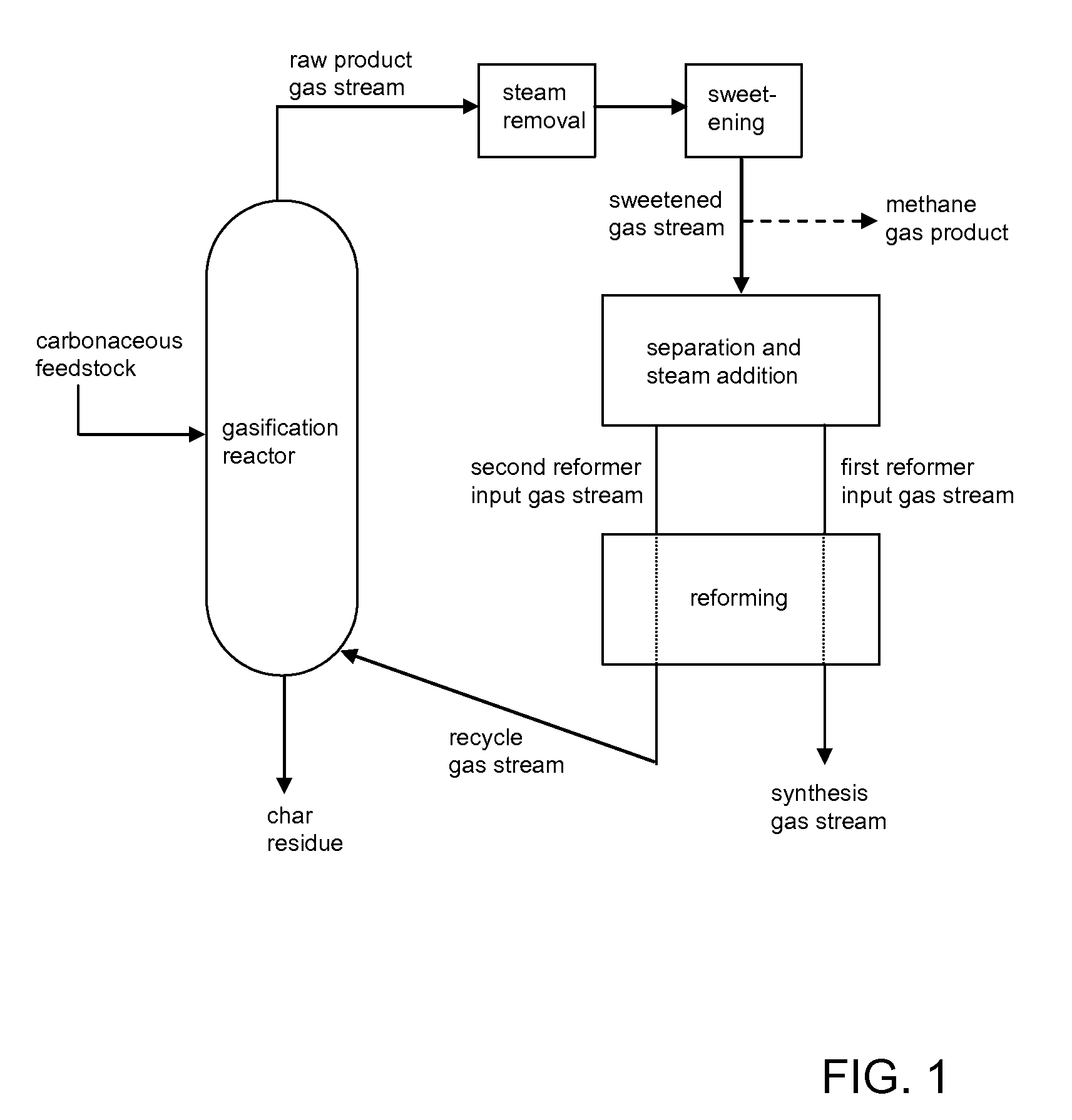

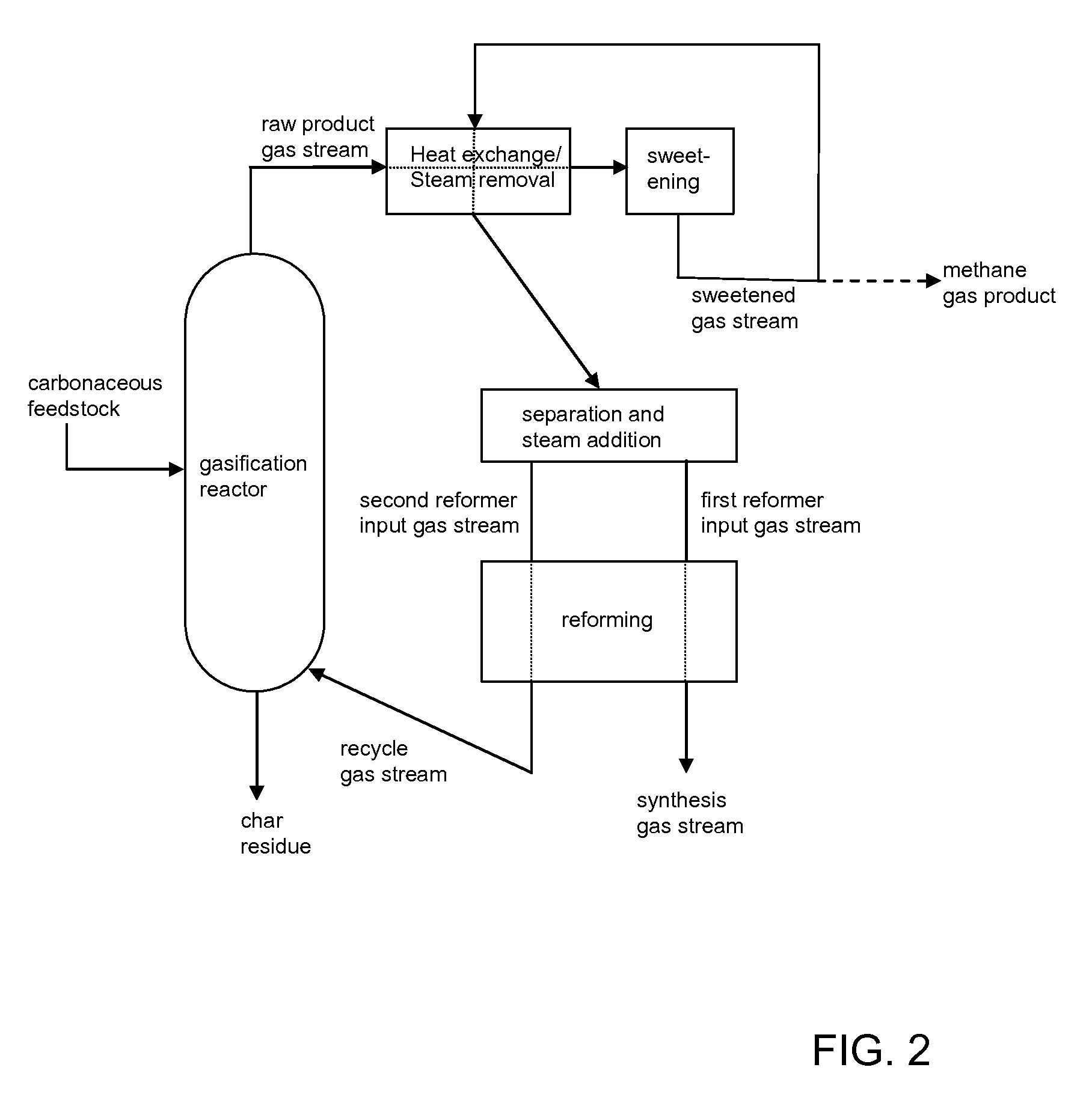

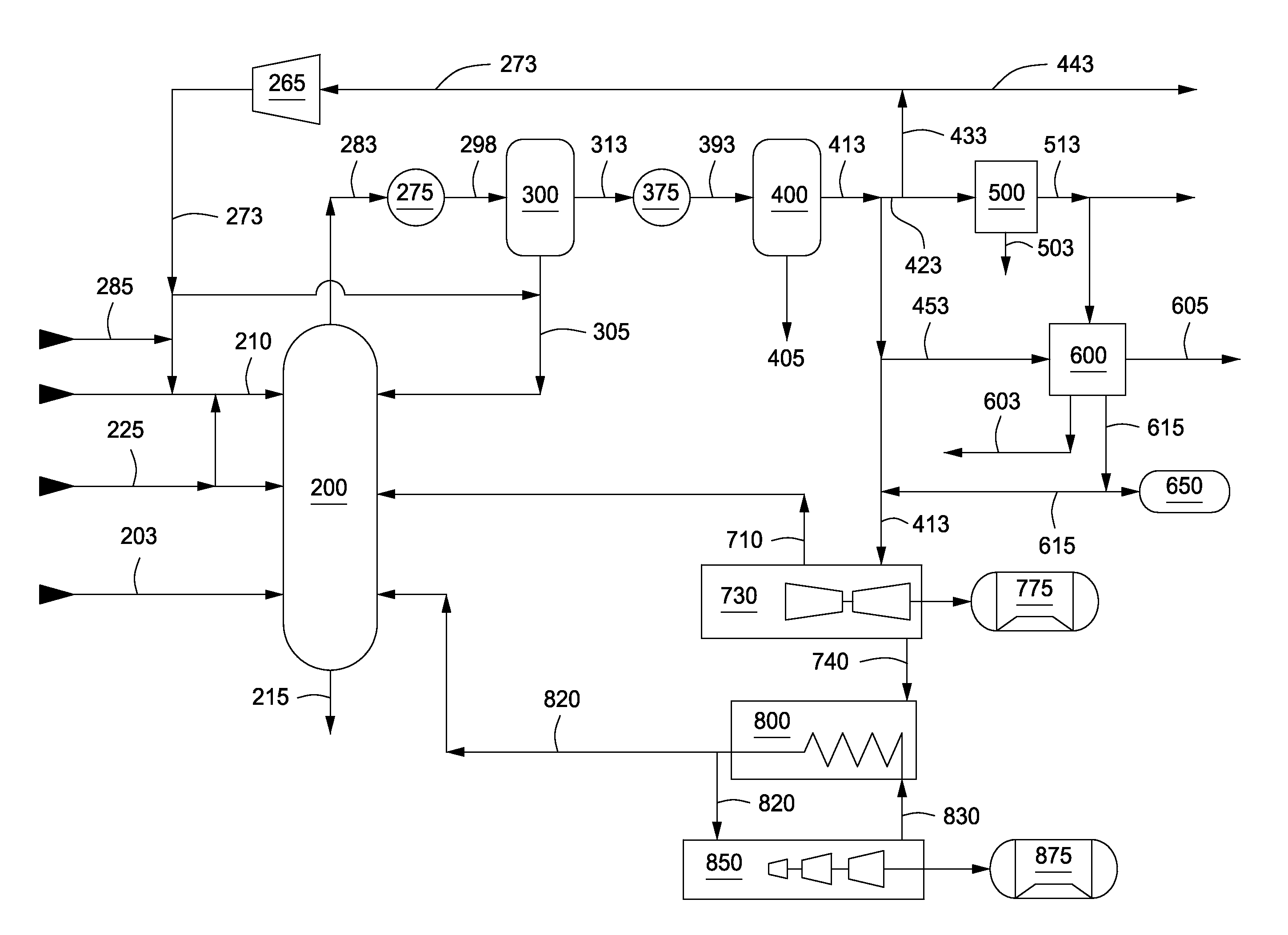

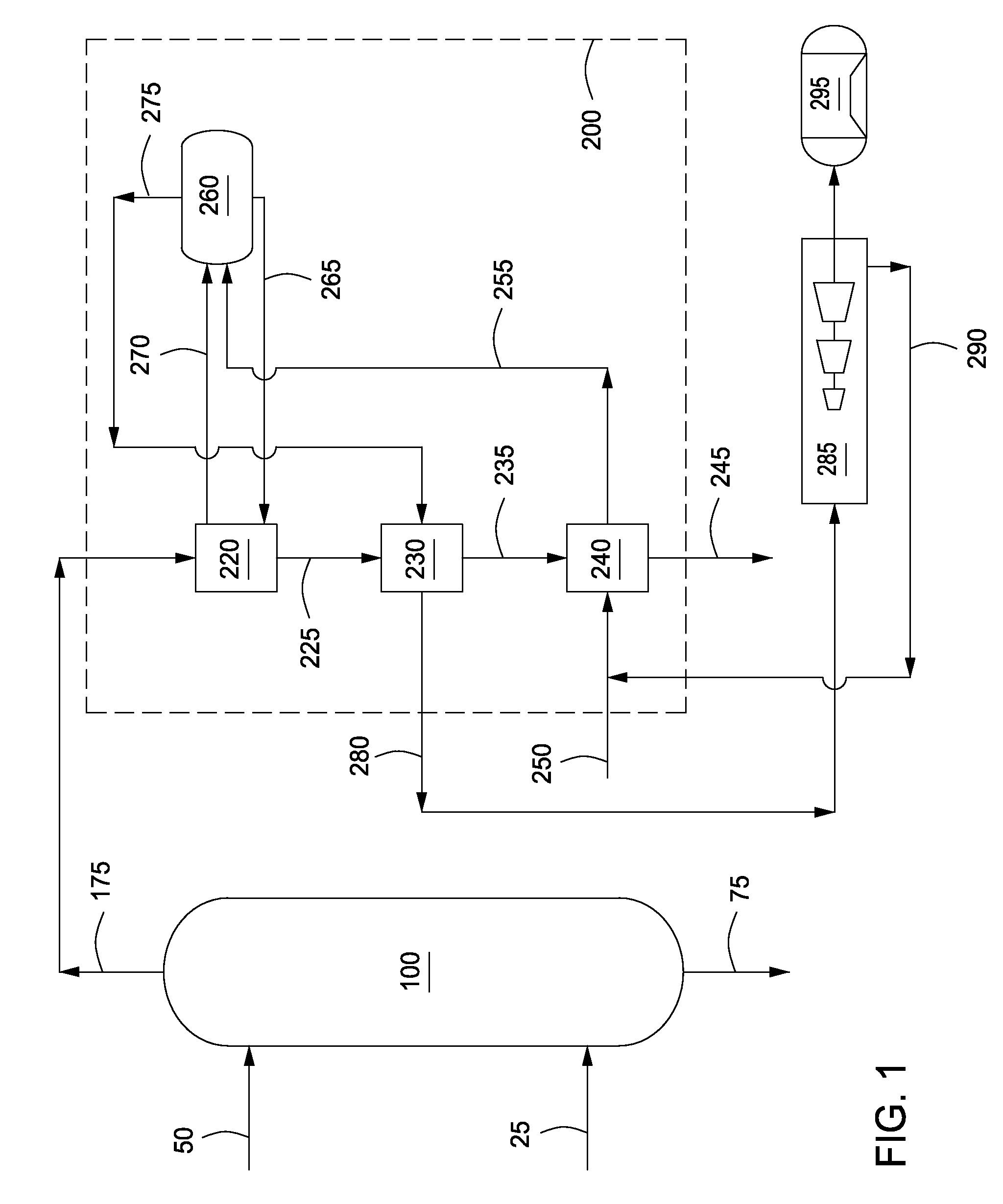

Processes for Making Synthesis Gas and Syngas-Derived Products

The present invention provides processes for making synthesis gas and processes for making syngas-derived products. For example, one aspect of the present invention provides a process for making a synthesis gas stream comprising hydrogen and carbon monoxide, the process comprising (a) providing a carbonaceous feedstock; (b) reacting the carbonaceous feedstock in a gasification reactor in the presence of steam and a gasification catalyst under suitable temperature and pressure to form a raw product gas stream comprising a plurality of gases comprising methane, hydrogen and carbon monoxide; (c) removing steam from and sweetening the raw product gas stream to form a sweetened gas stream; (d) separating and adding steam to the sweetened gas stream to form a first reformer input gas stream having a first steam / methane ratio; and a second reformer input stream having a second steam / methane ratio, in which the first steam / methane ratio is smaller than the second steam / methane ratio; (e) reforming the second reformer input stream to form a recycle gas stream comprising steam, carbon monoxide and hydrogen; (f) introducing the recycle gas stream to the gasification reactor; and (g) reforming the first reformer input stream to form the synthesis gas stream.

Owner:SURE CHAMPION INVESTMENT LTD

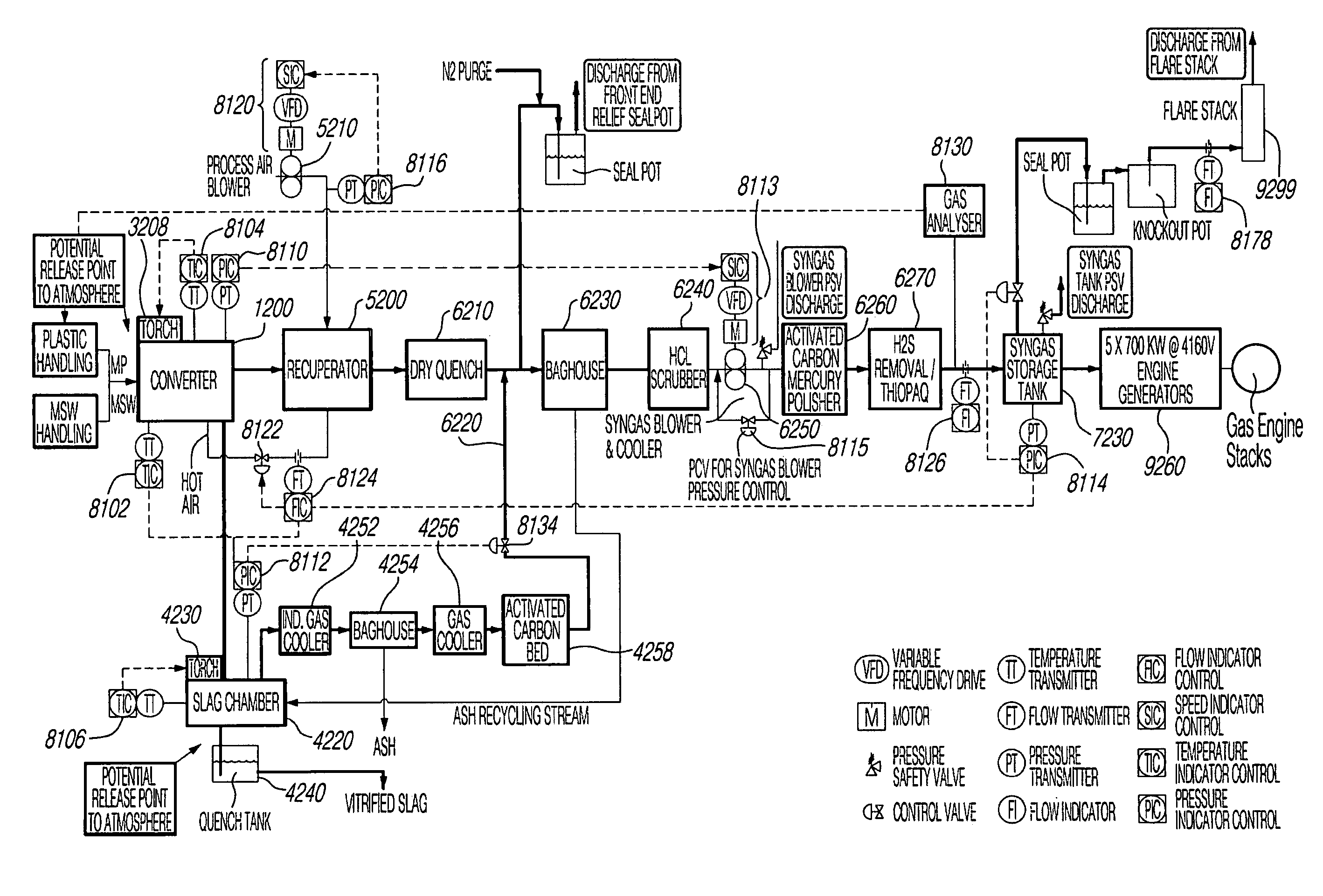

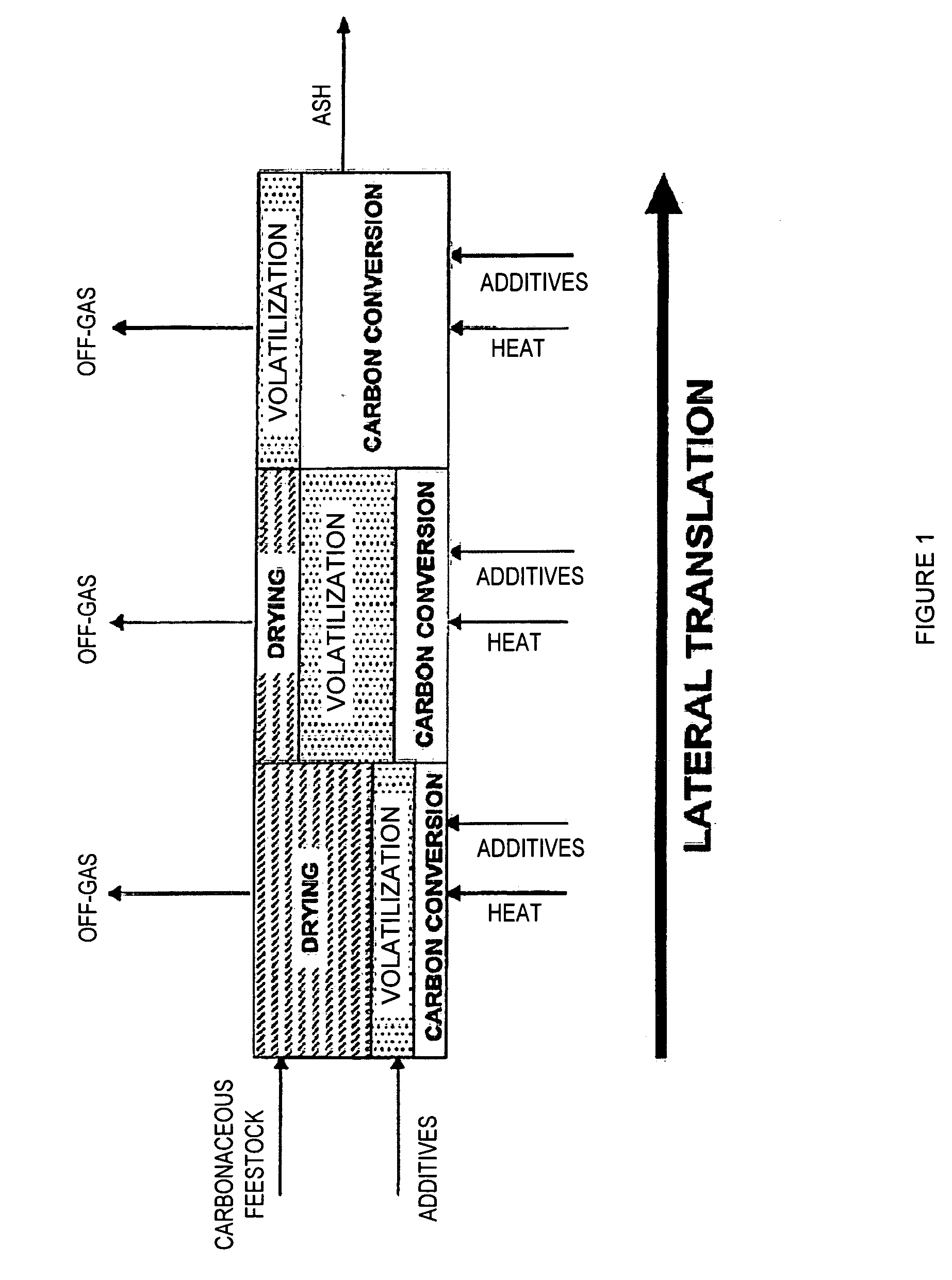

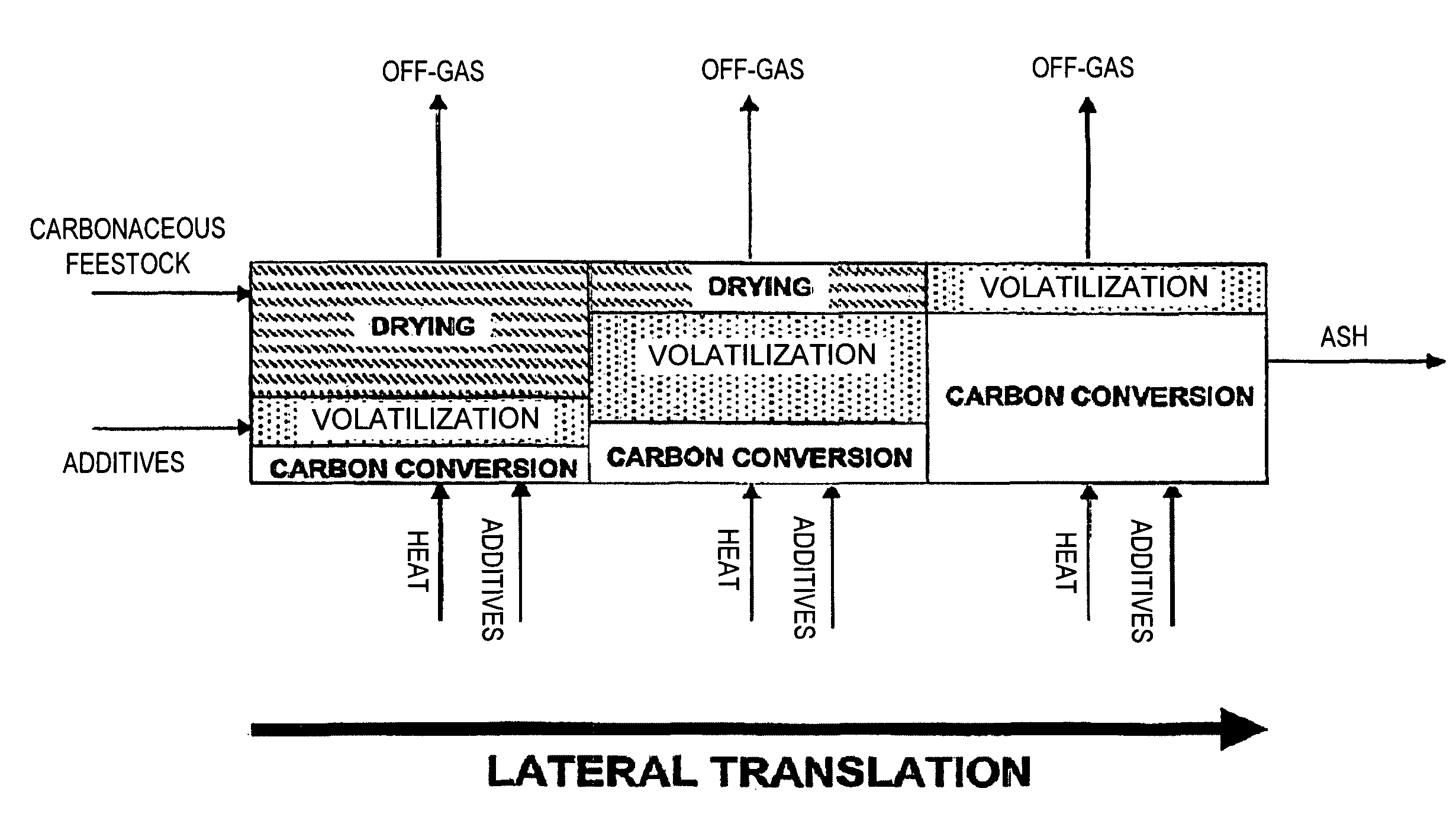

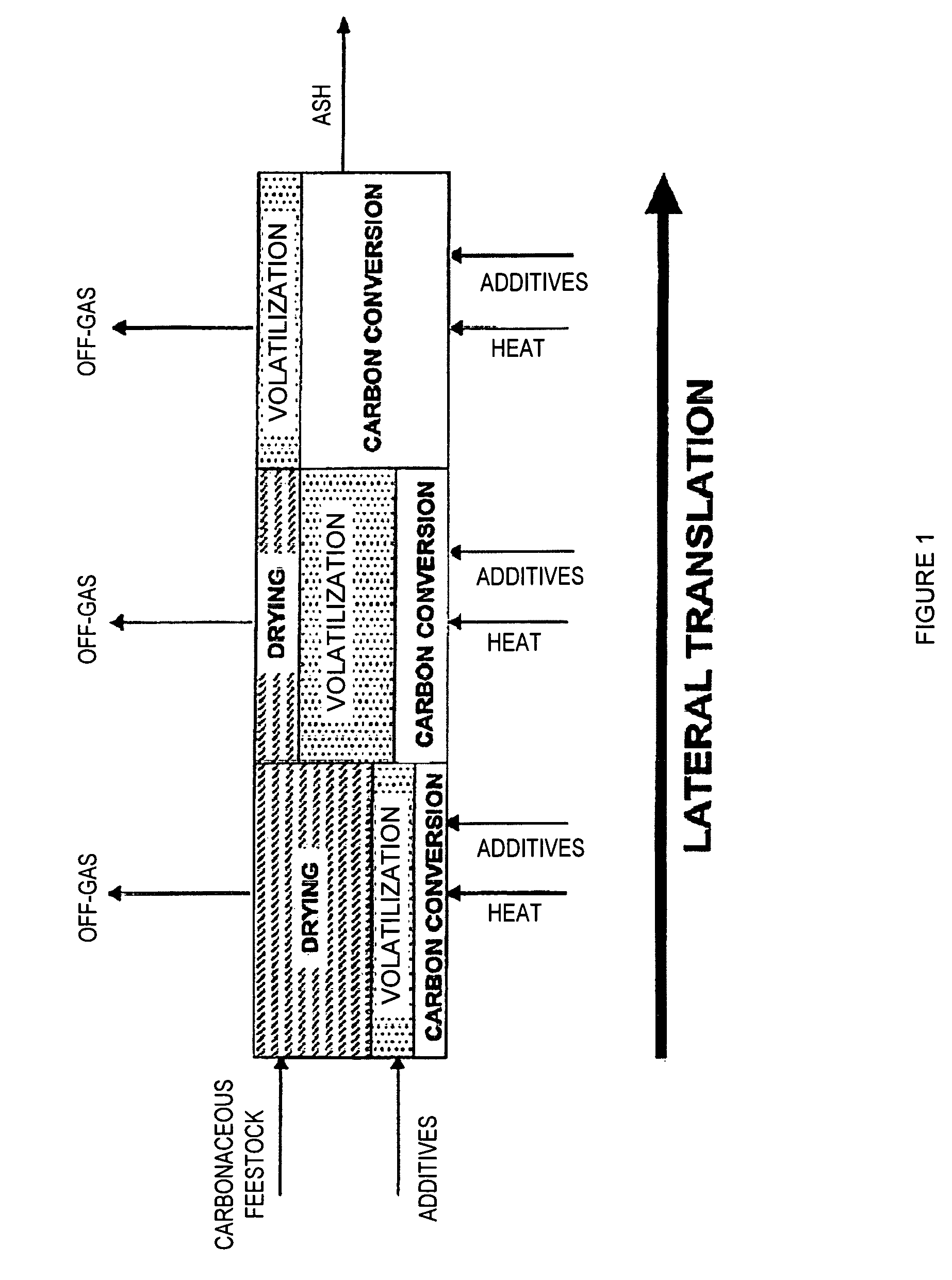

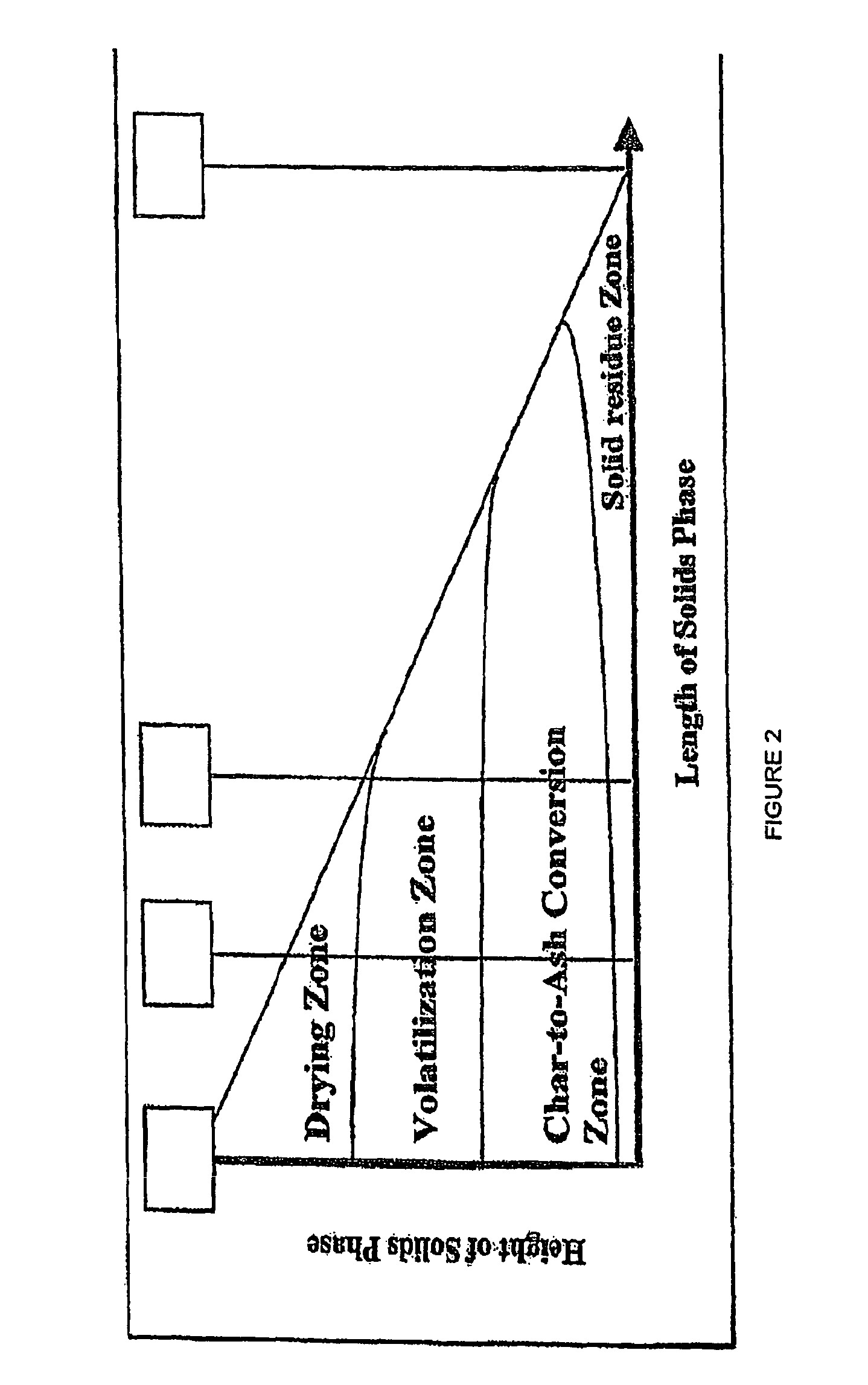

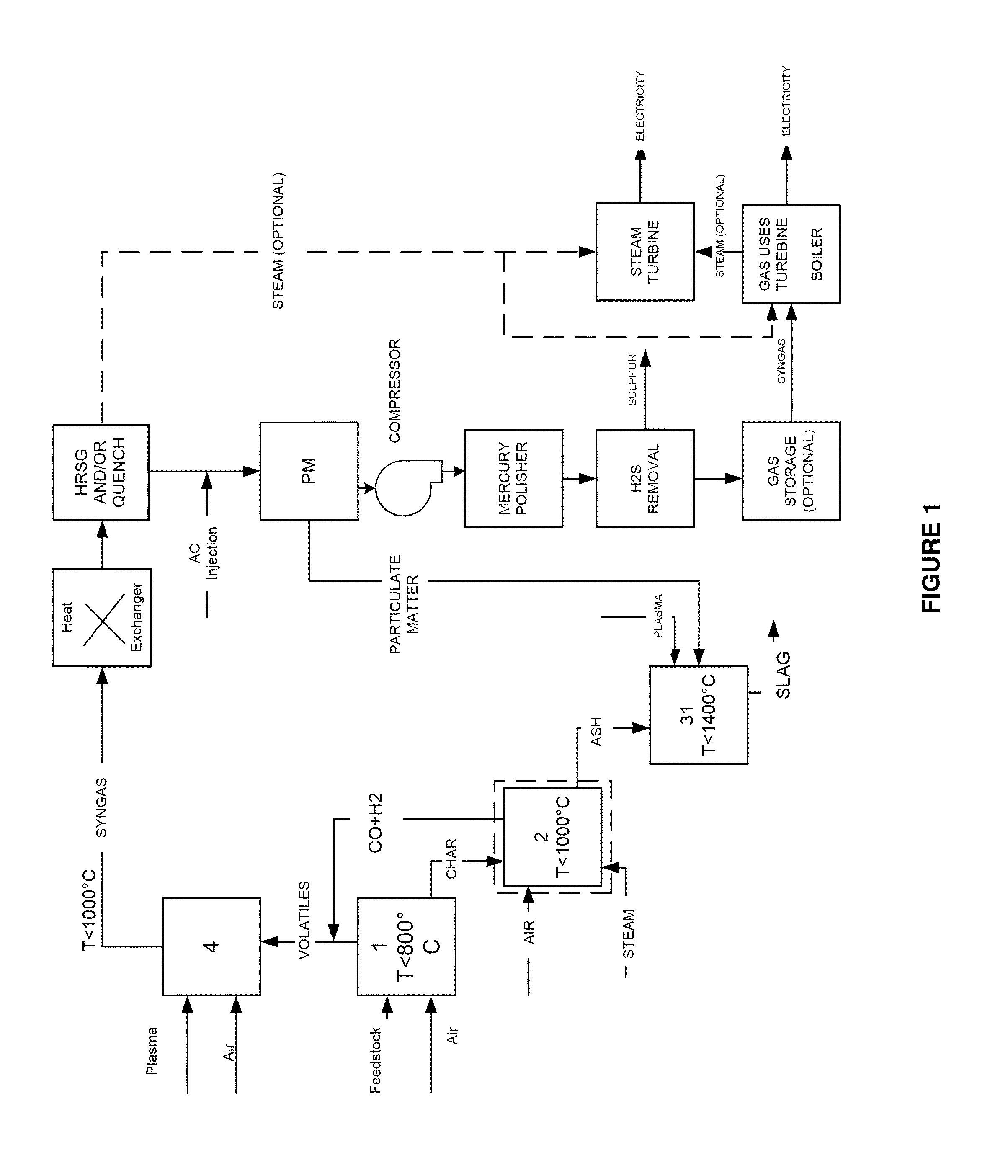

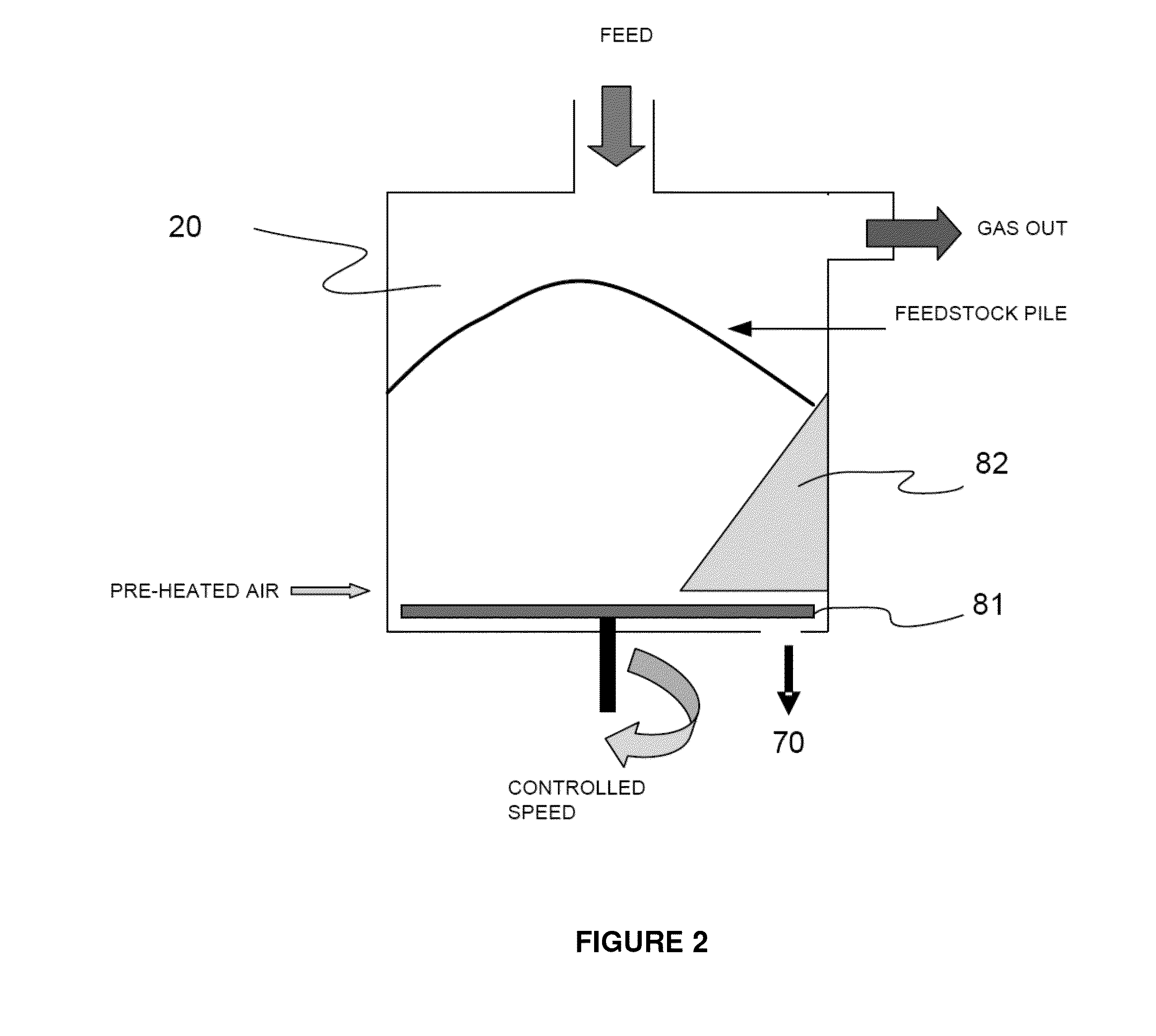

Low Temperature Gasification Facility with a Horizontally Oriented Gasifier

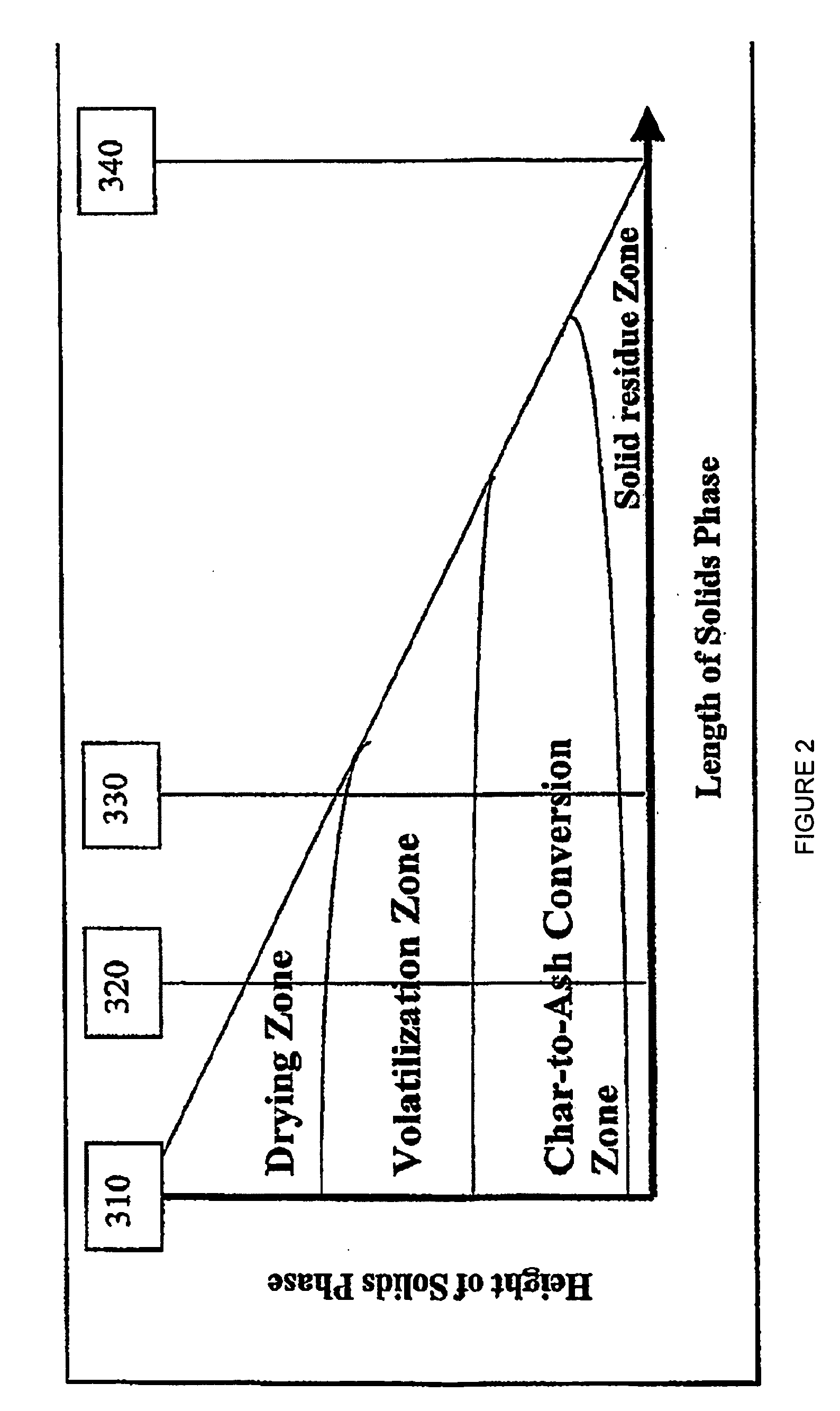

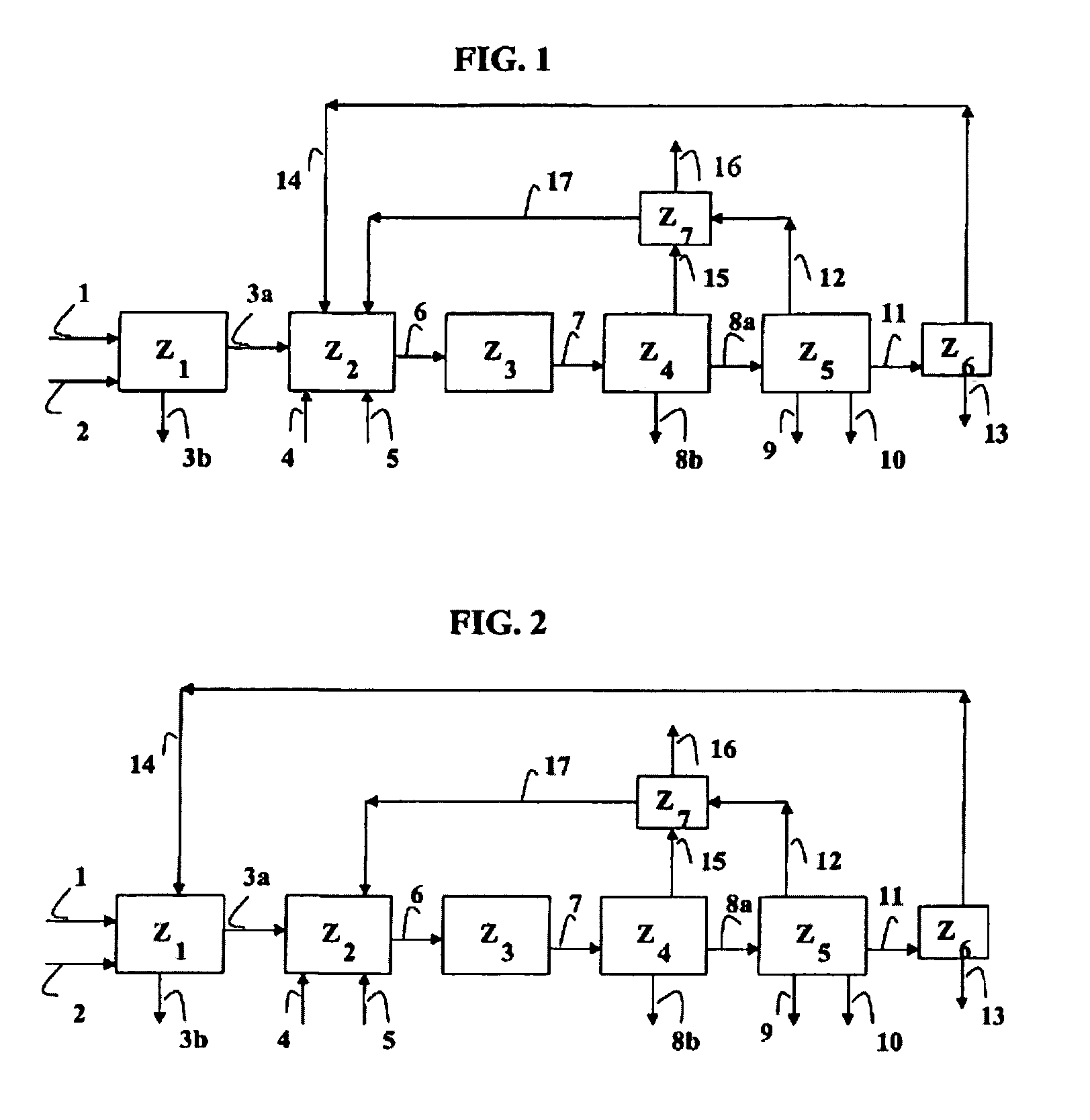

A low-temperature gasification system comprising a horizontally oriented gasifier is provided that optimizes the extraction of gaseous molecules from carbonaceous feedstock while minimizing waste heat. The system comprises a plurality of integrated subsystems that work together to convert municipal solid waste (MSW) into electricity. The subsystems comprised by the low-temperature gasification system are: a Municipal Solid Waste Handling System; a Plastics Handling System; a Horizontally Oriented Gasifier with Lateral Transfer Units System; a Gas Reformulating System; a Heat Recycling System; a Gas Conditioning System; a Residue Conditioning System; a Gas Homogenization System and a Control System.

Owner:PLASCO CONVERSION TECH INC

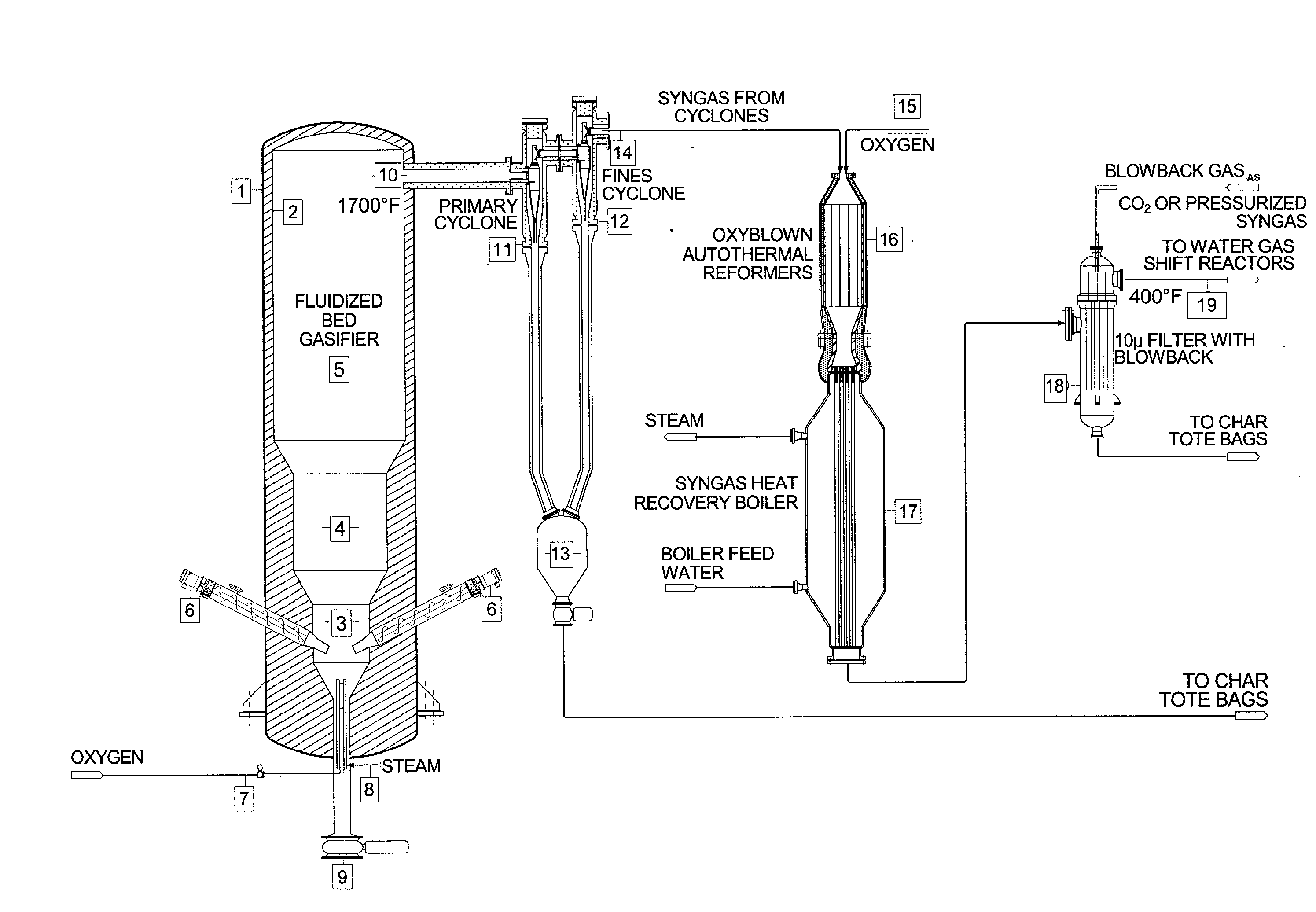

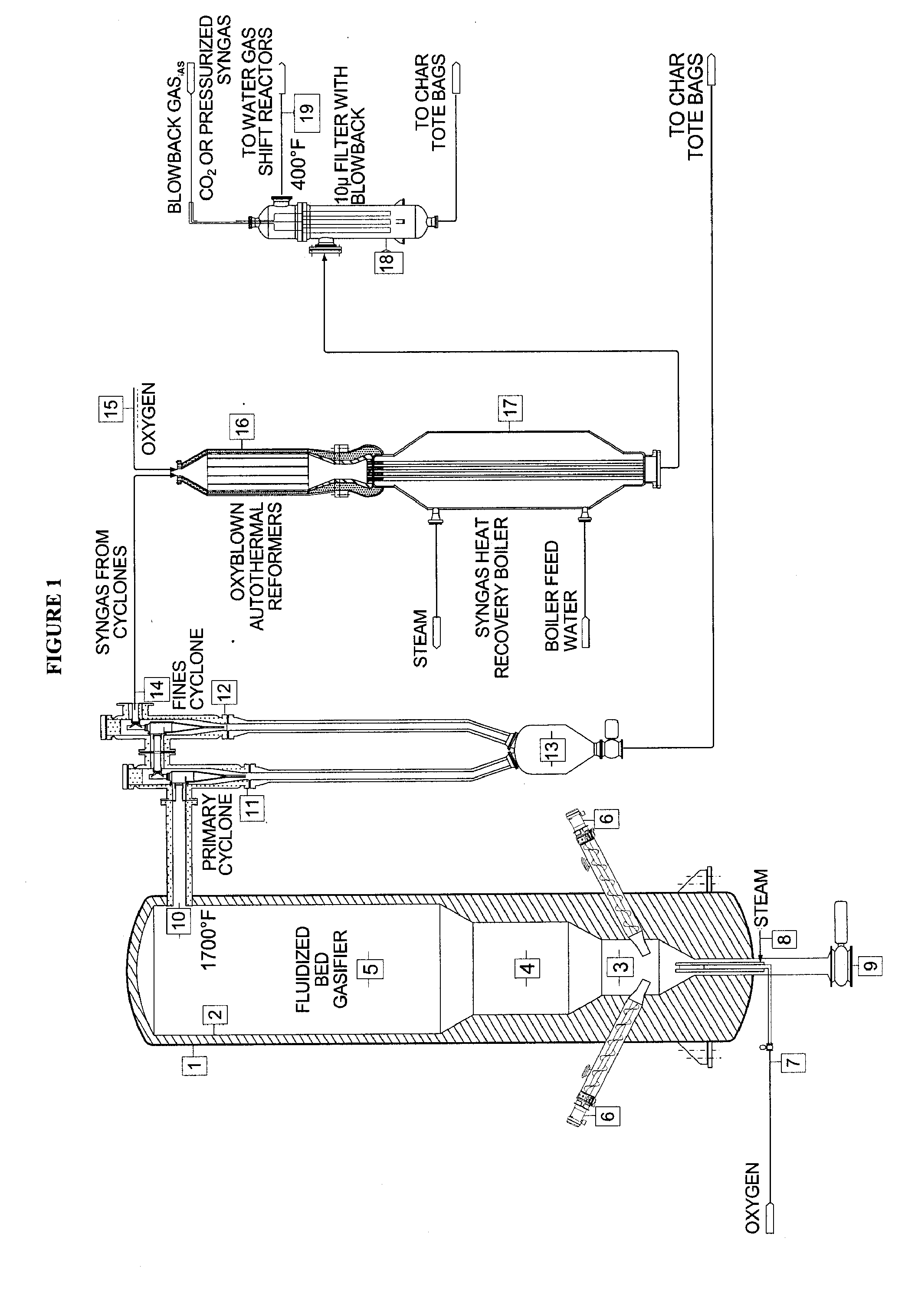

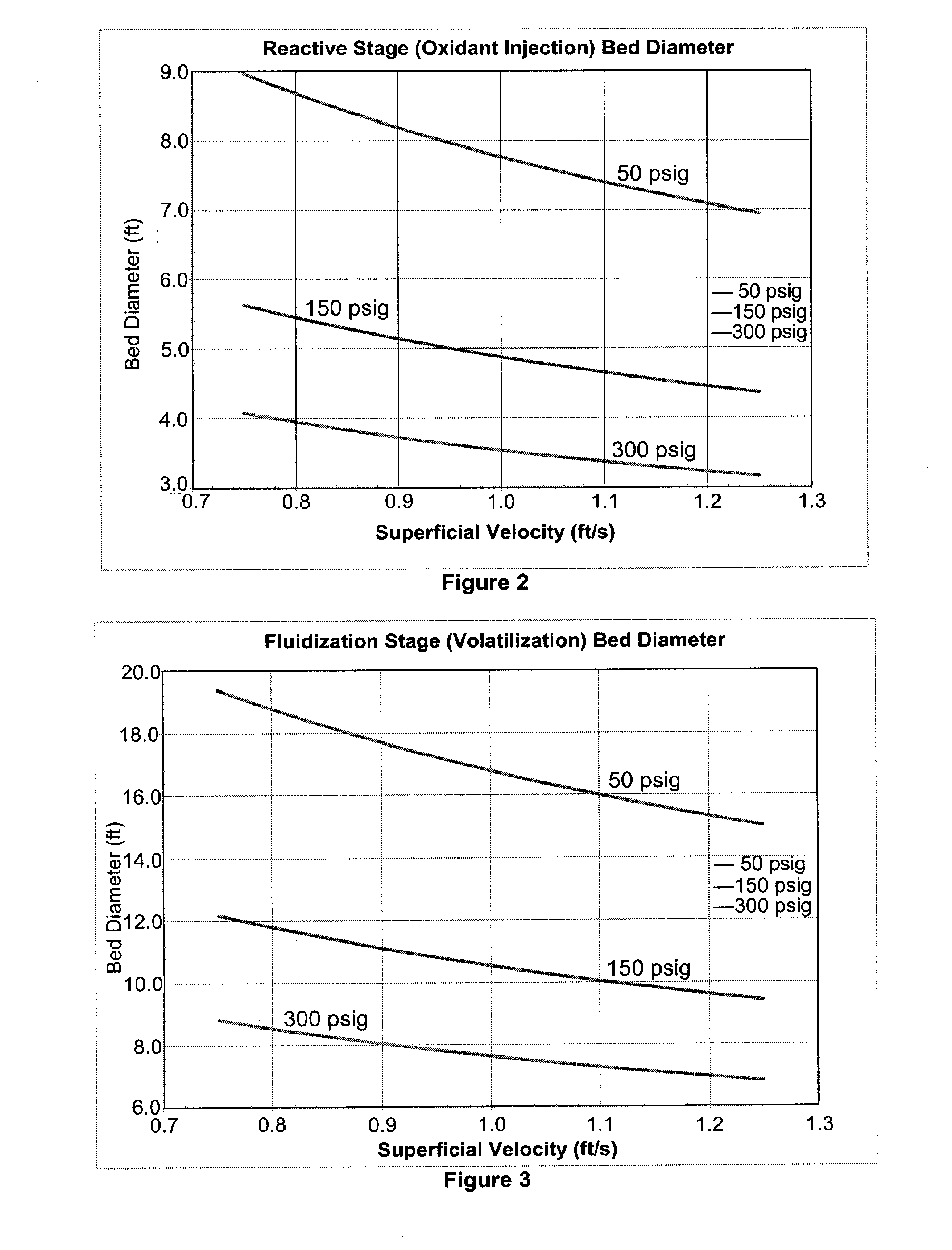

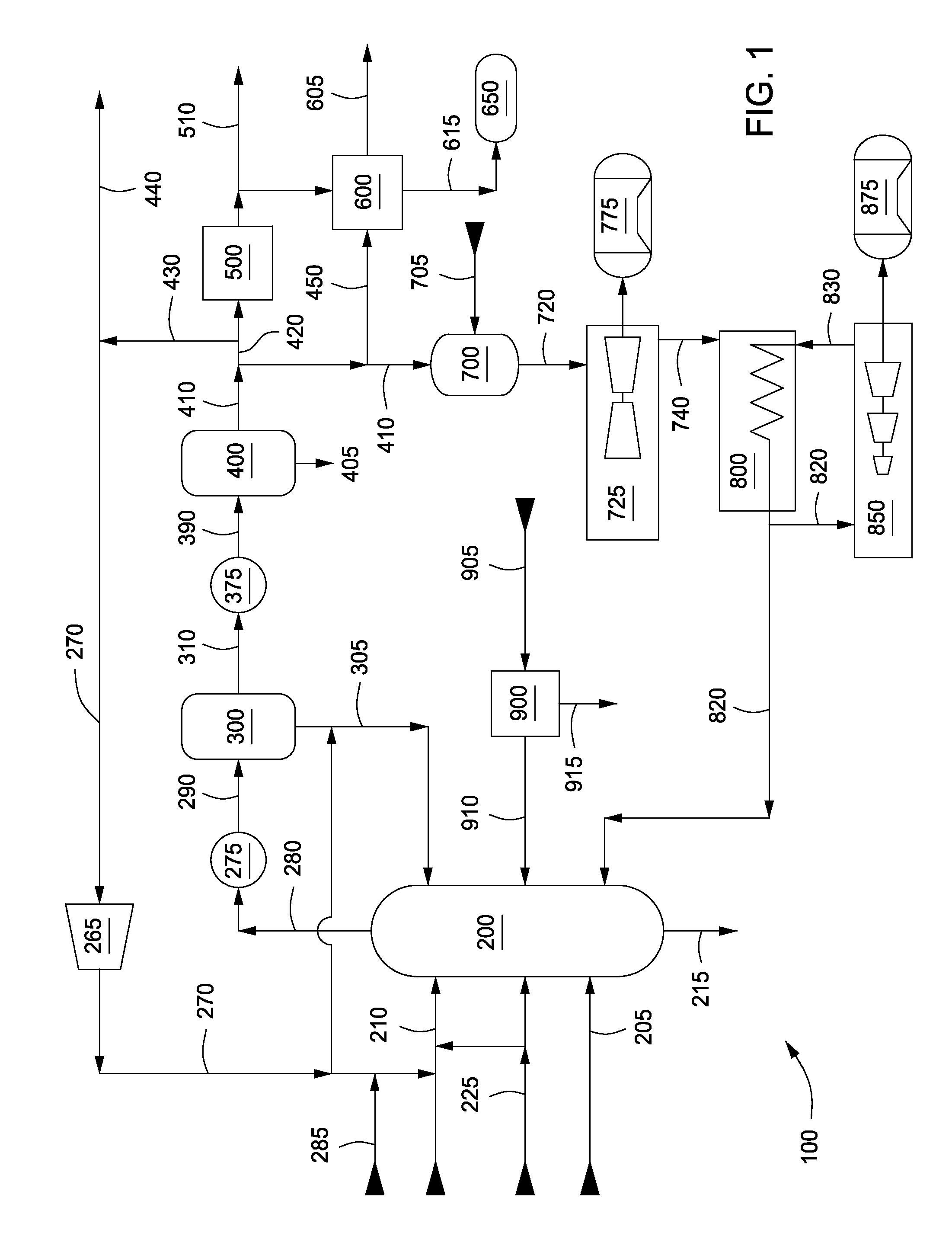

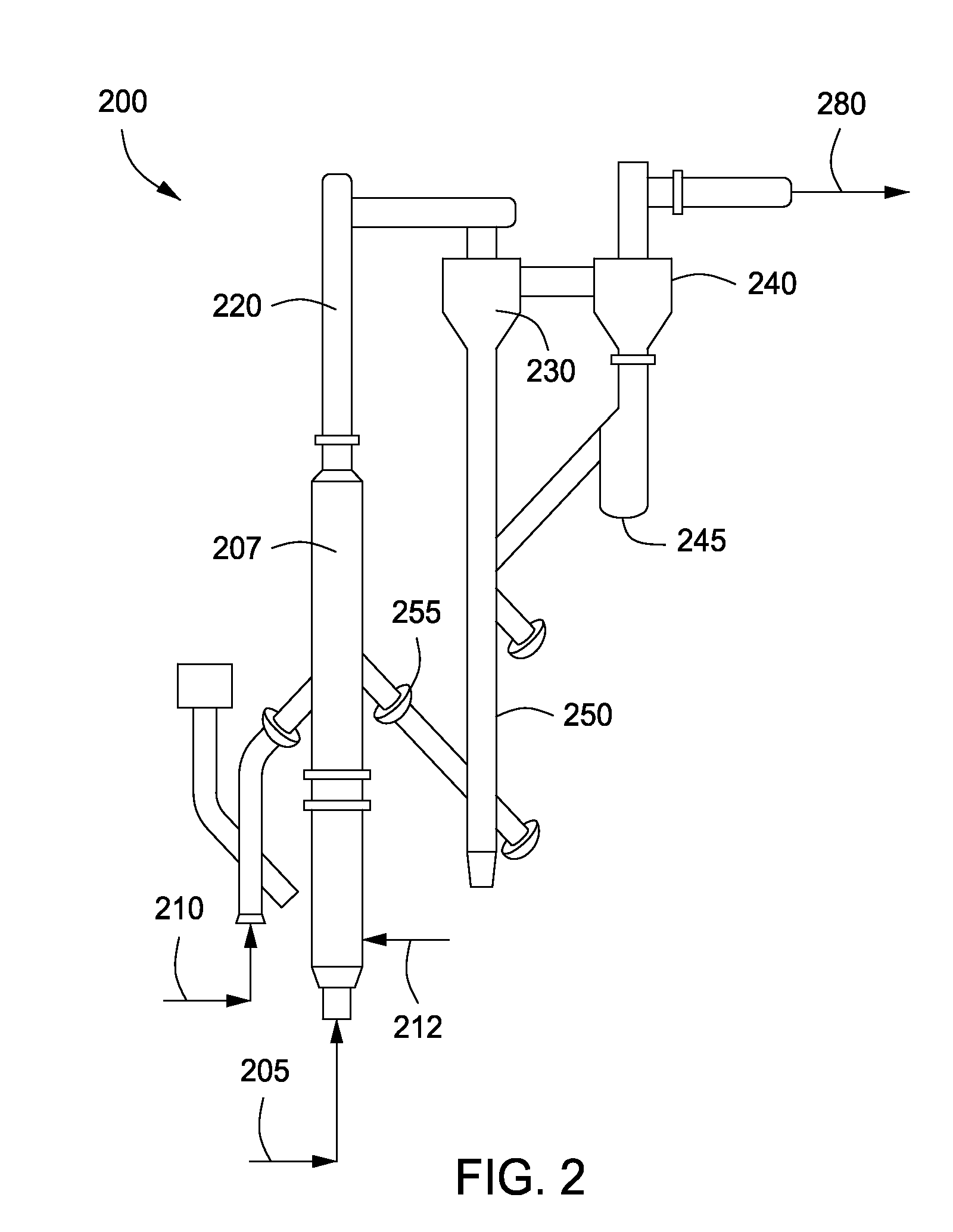

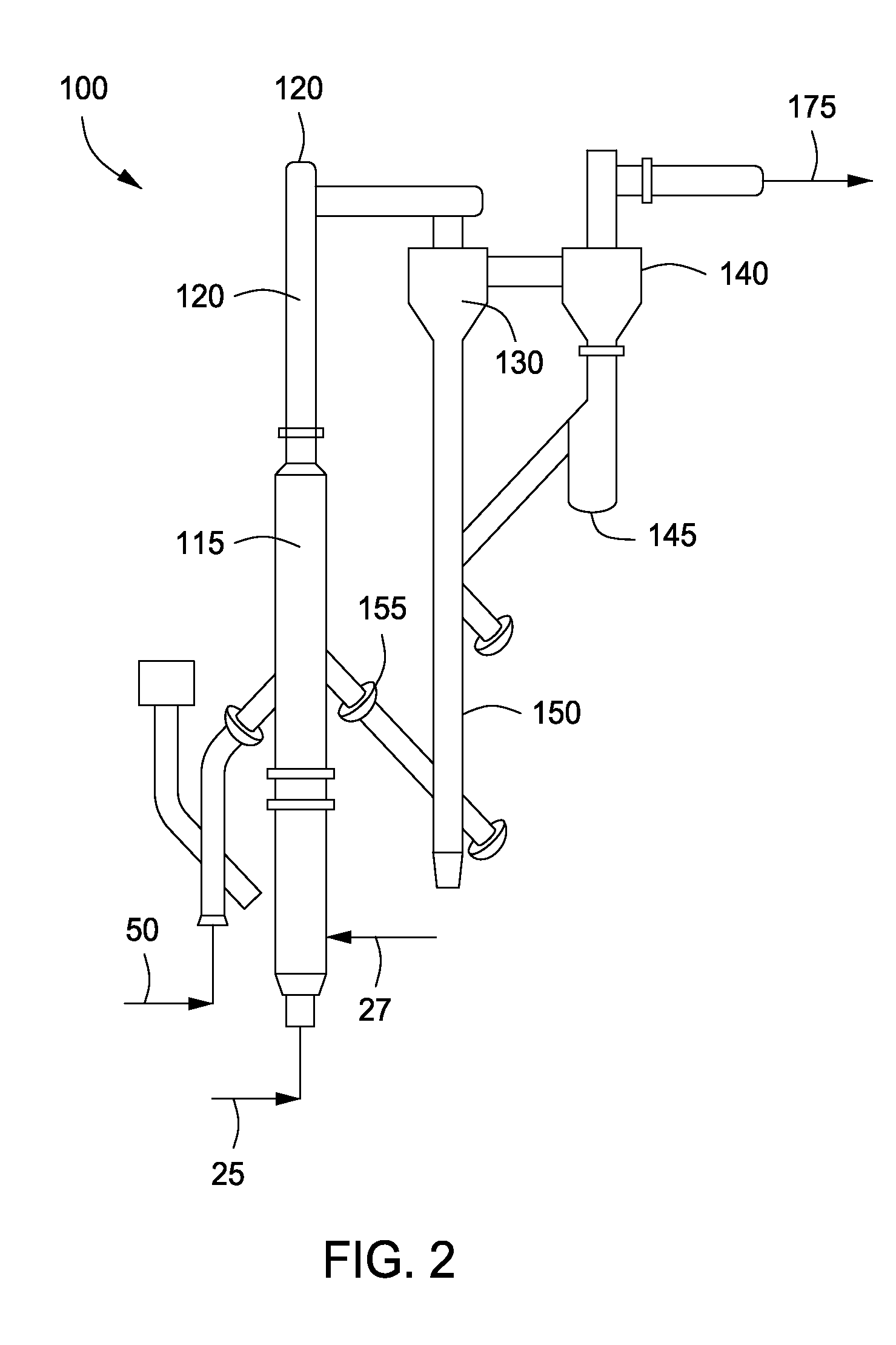

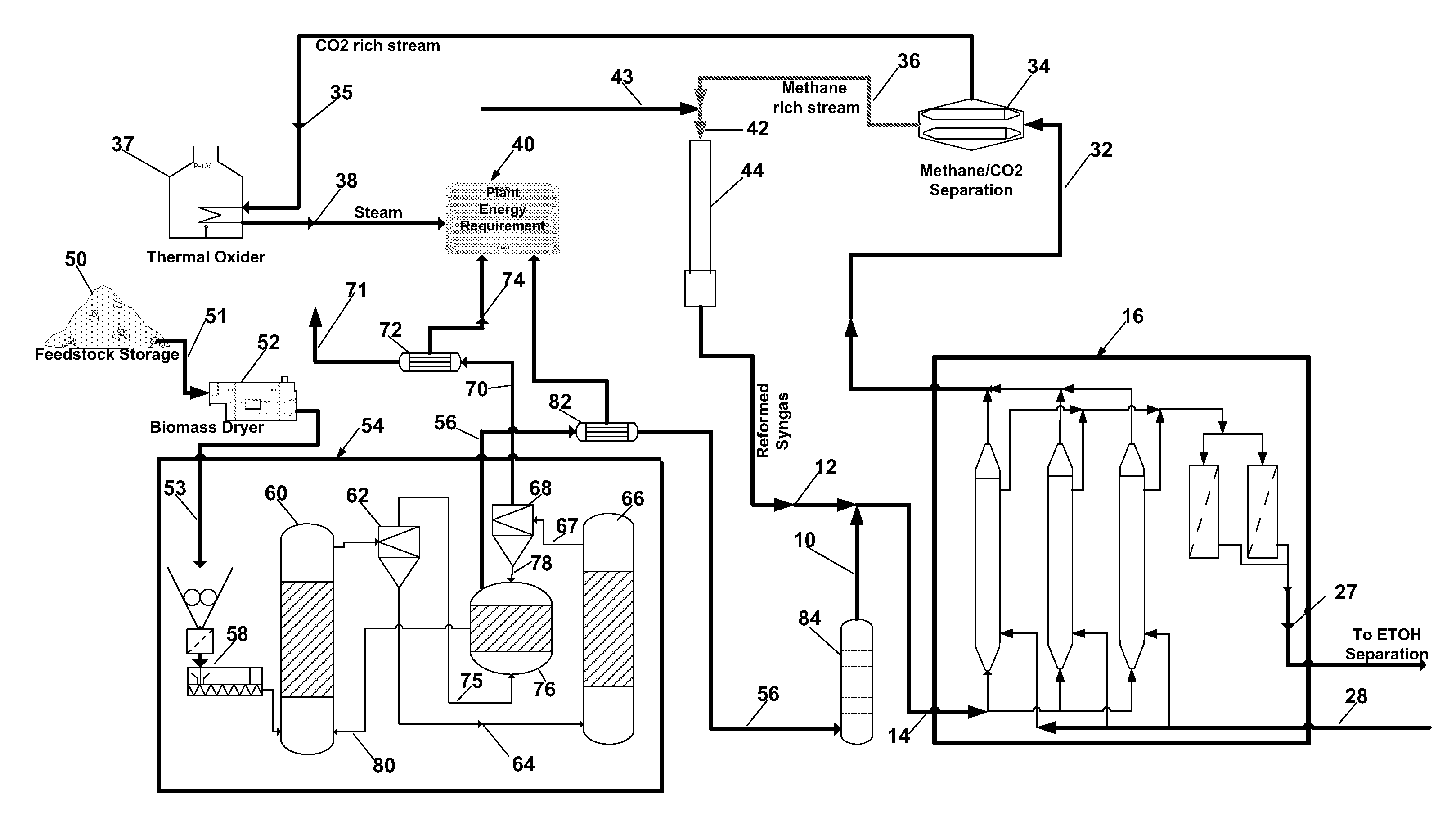

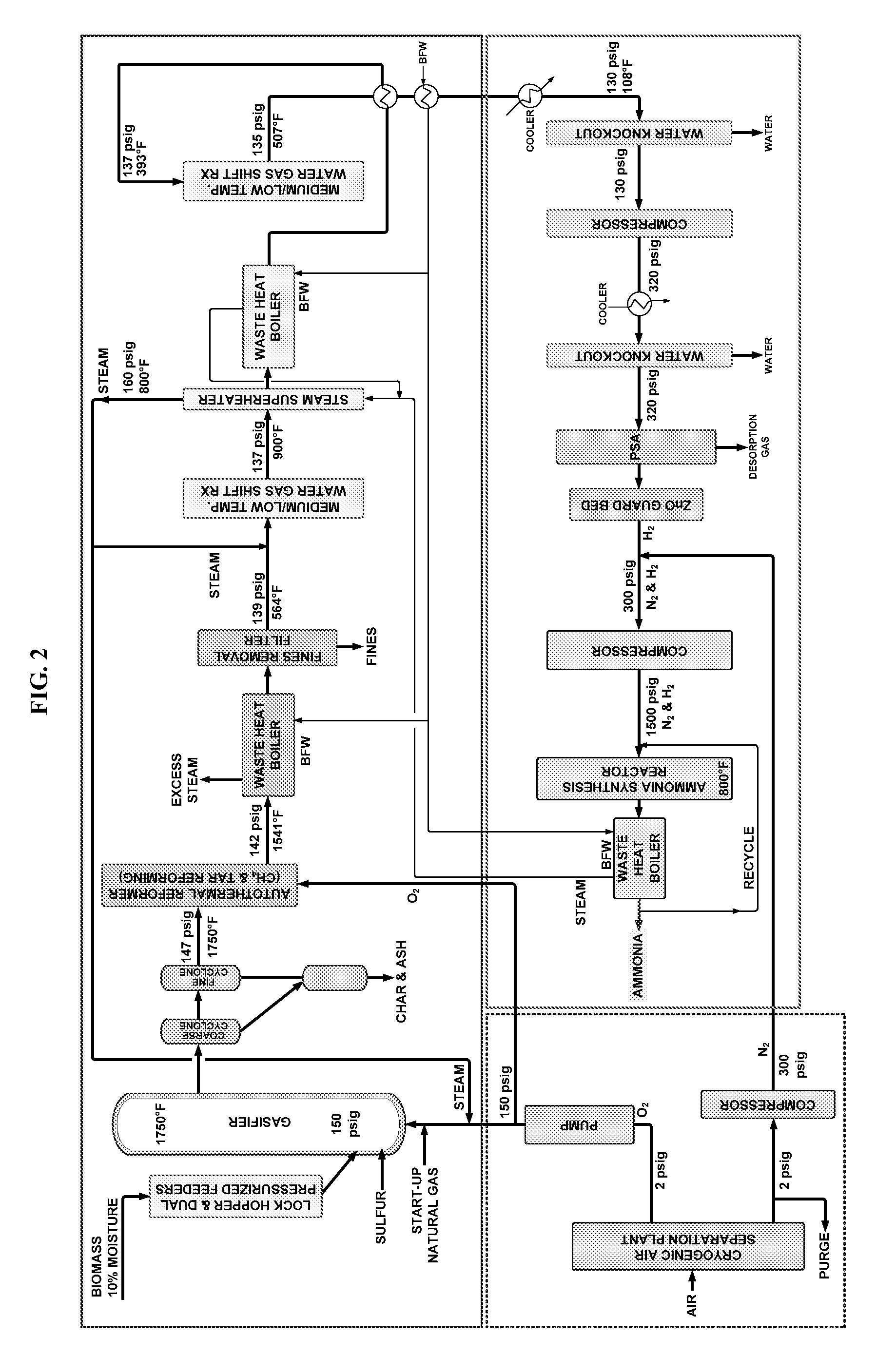

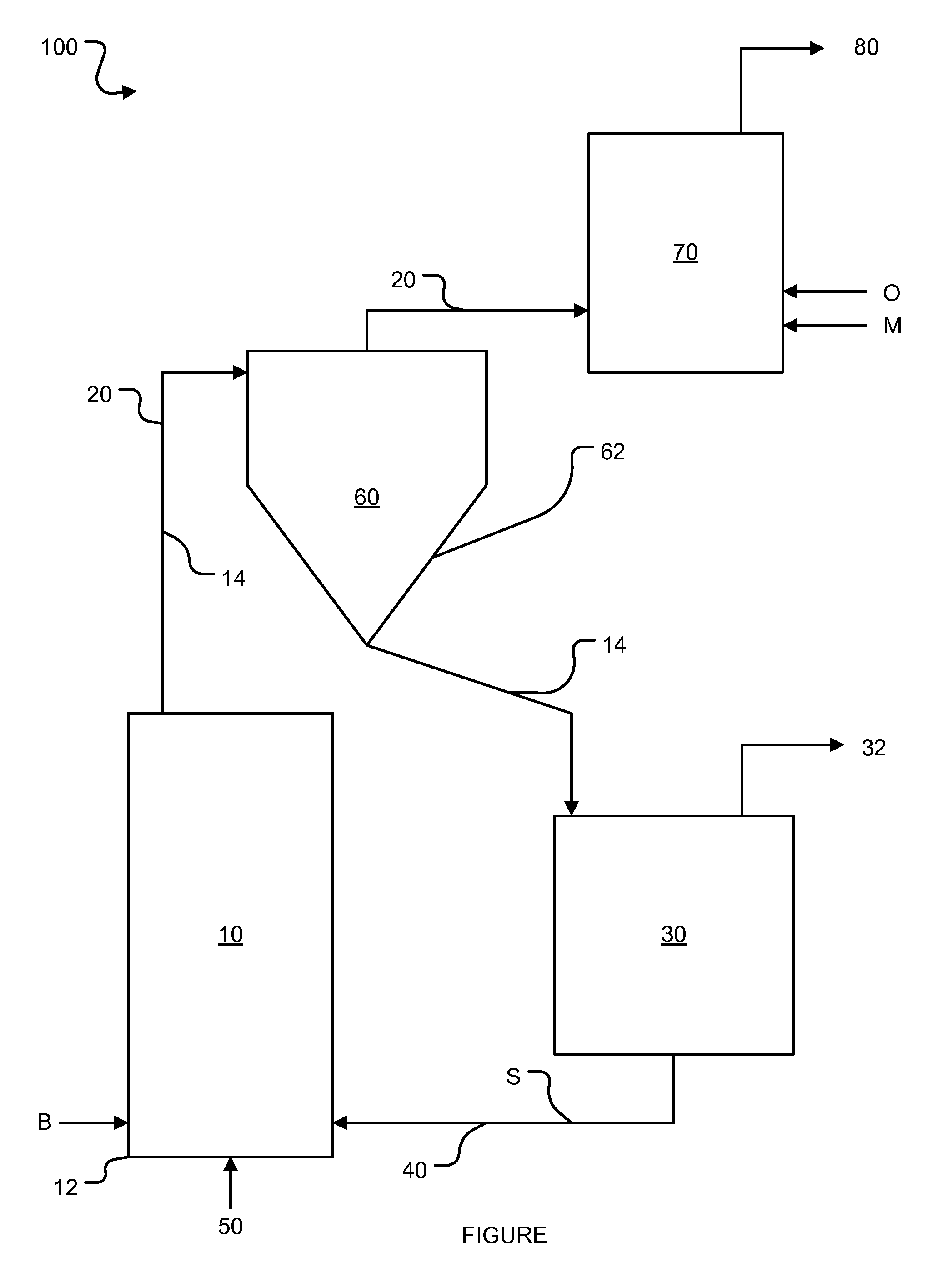

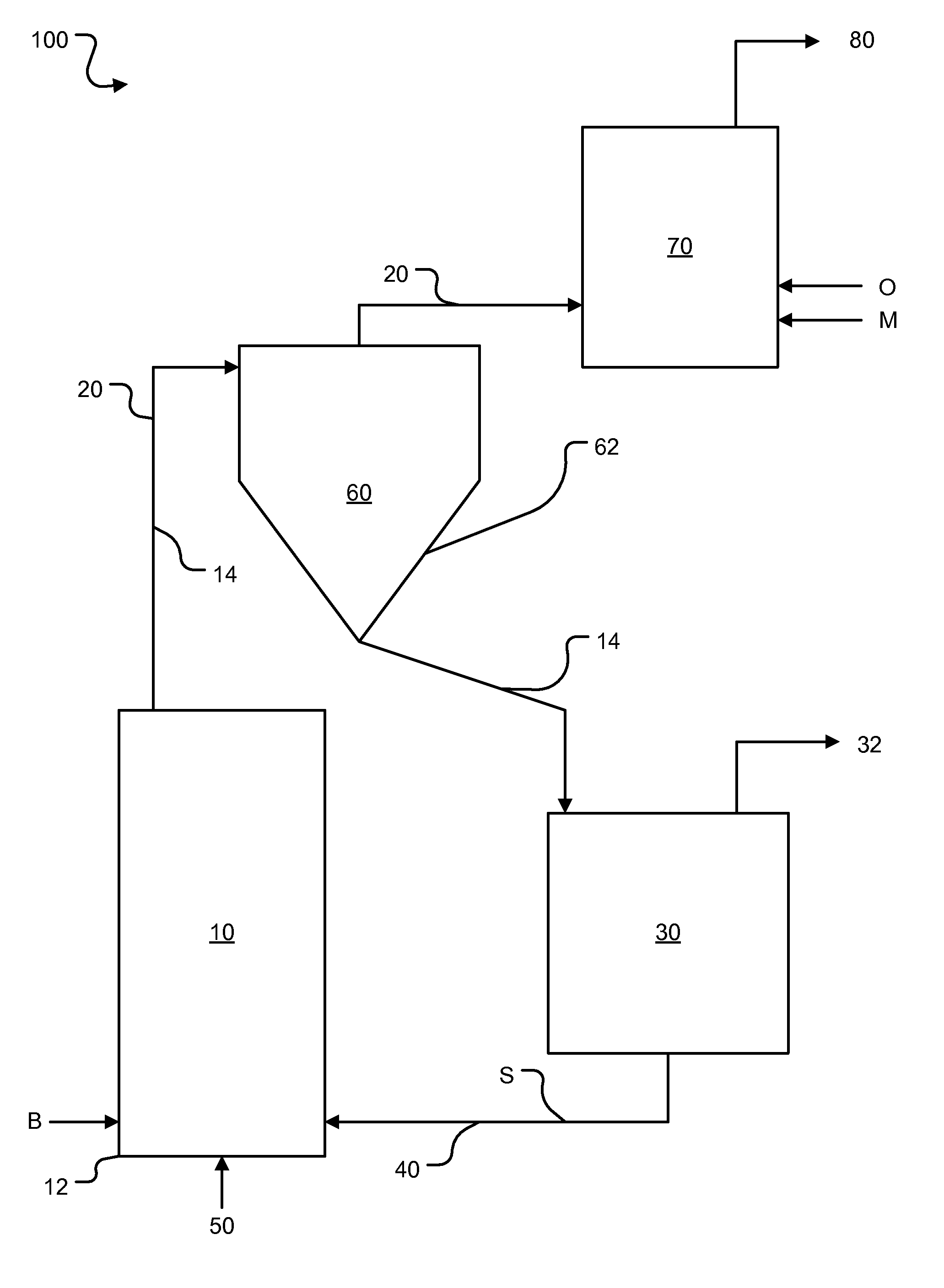

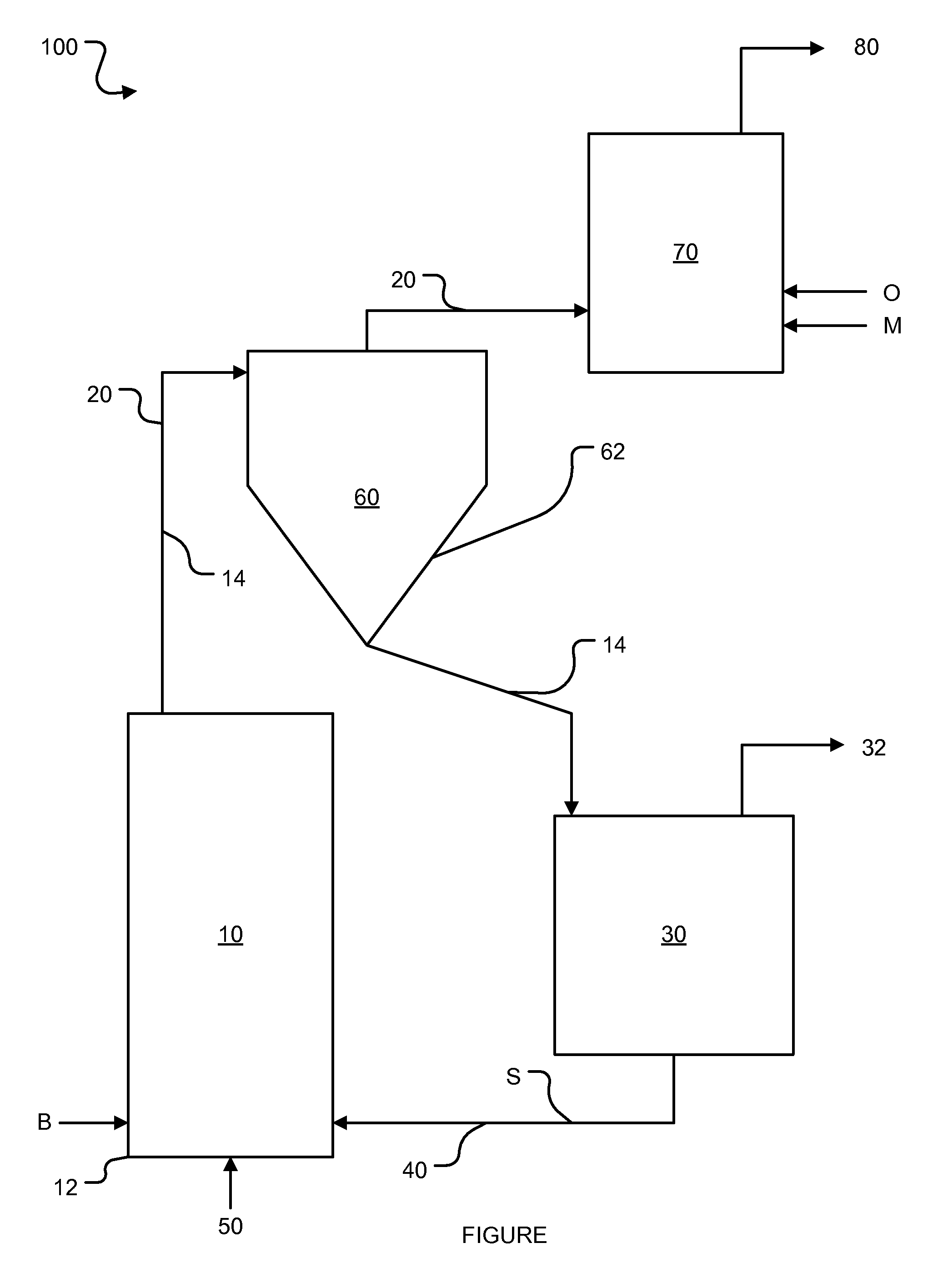

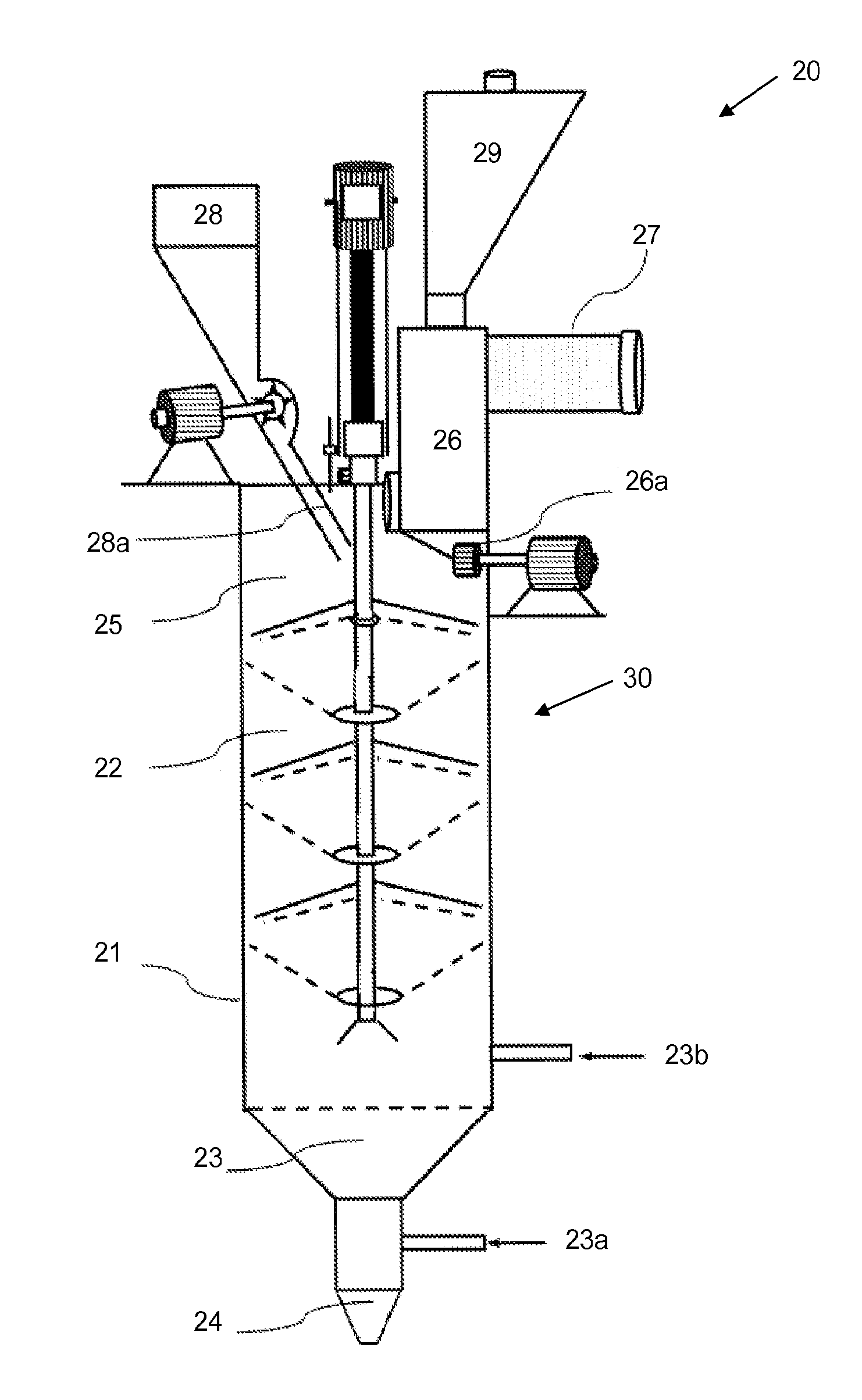

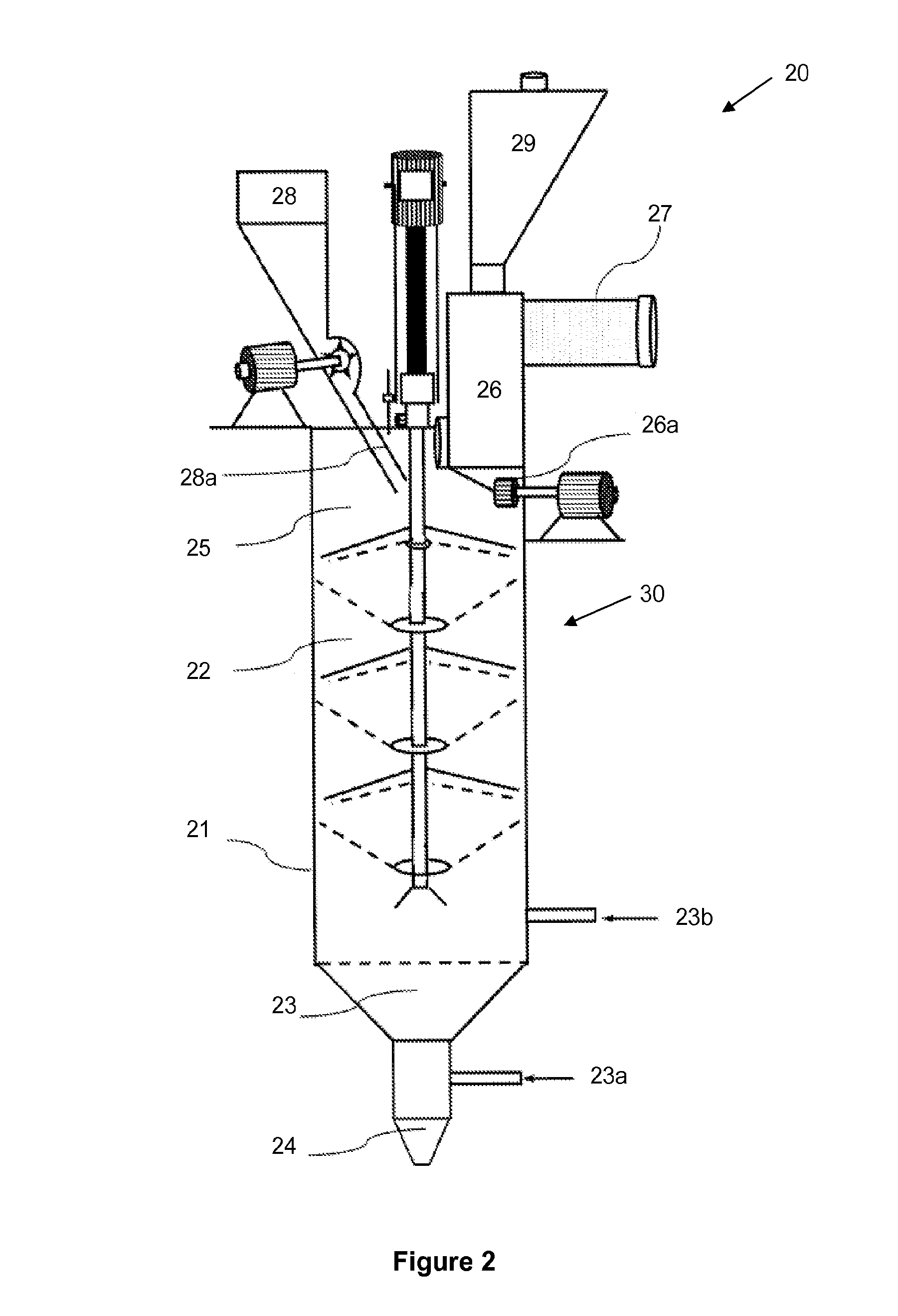

Method for converting biomass into synthesis gas using a pressurized multi-stage progressively expanding fluidized bed gasifier followed by an oxyblown autothermal reformer to reduce methane and tars

InactiveUS20100040510A1Lower Level RequirementsGasifier mechanical detailsCombustible gas catalytic treatmentSyngasFluidized bed gasifier

The invention provides systems and methods for converting biomass into syngas using a pressurized multi-stage progressively expanding fluidized bed gasifier to eliminate or reduce the formation of methane, volatiles such as BTX, and tars. The gasifier may include a reactive stage that may receive a biomass feed through a feed line and oxygen through an oxygen feed line. The gasifier may also include a fluidized bed section that may be configured to receive the reaction products from the first stage, mix them and perform fluidized bed activity. A gasifier may also have a disengagement section that may be configured to separate fluidized media and particulate matter from syngas product. A gasification system may also include oxyblown catalytic autothermal reactor and a cryogenic air separation unit.

Owner:SYNT

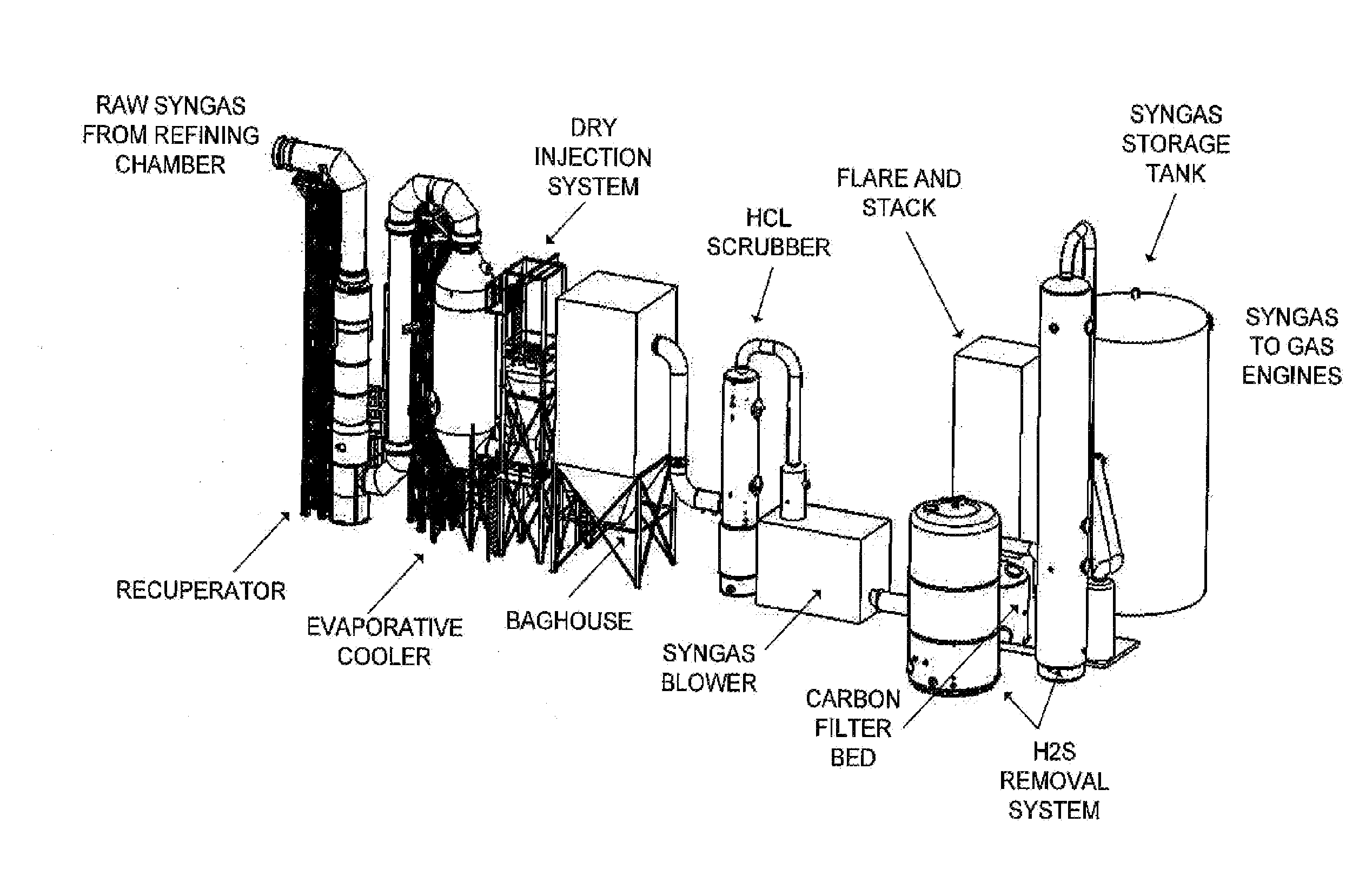

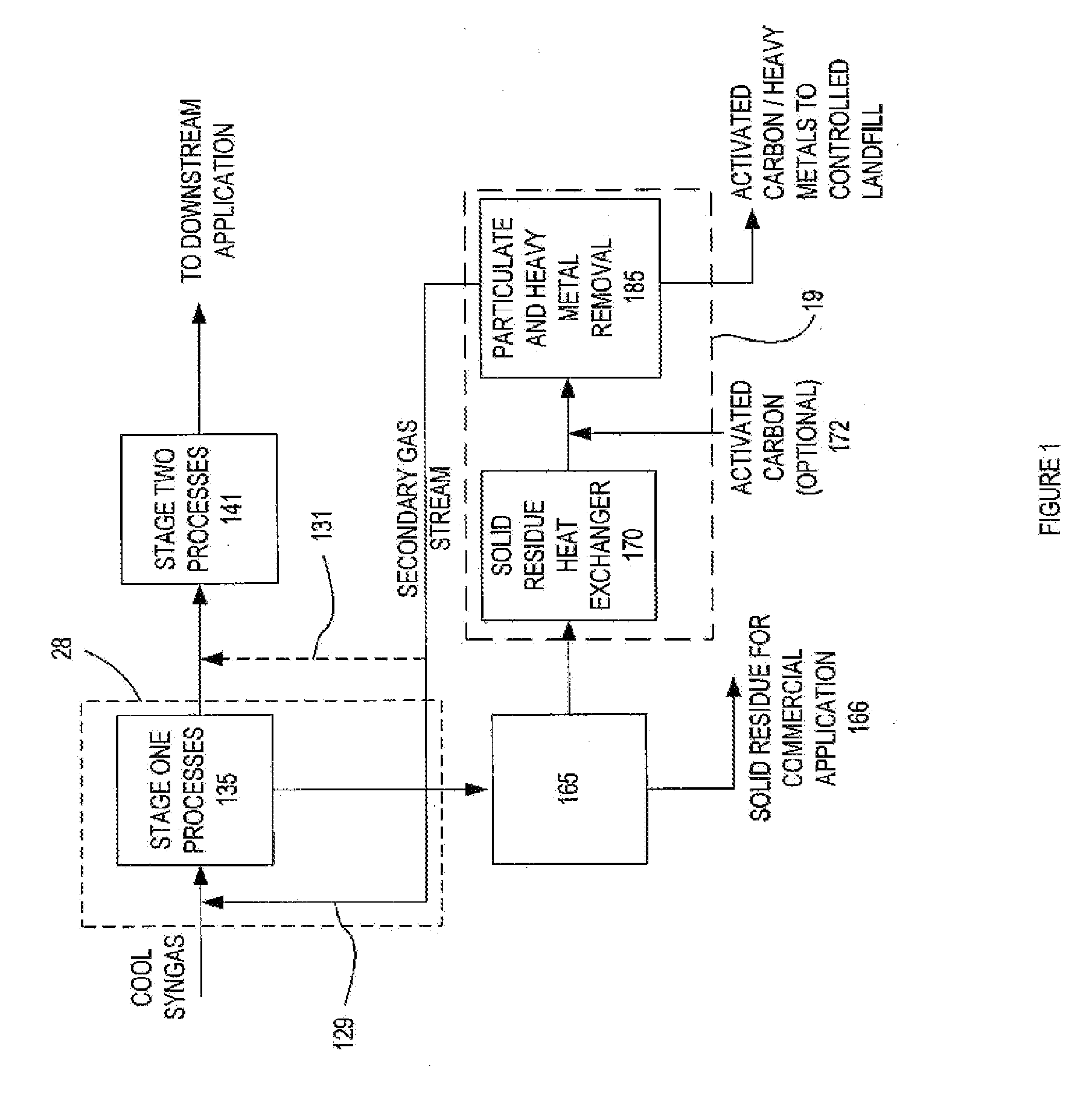

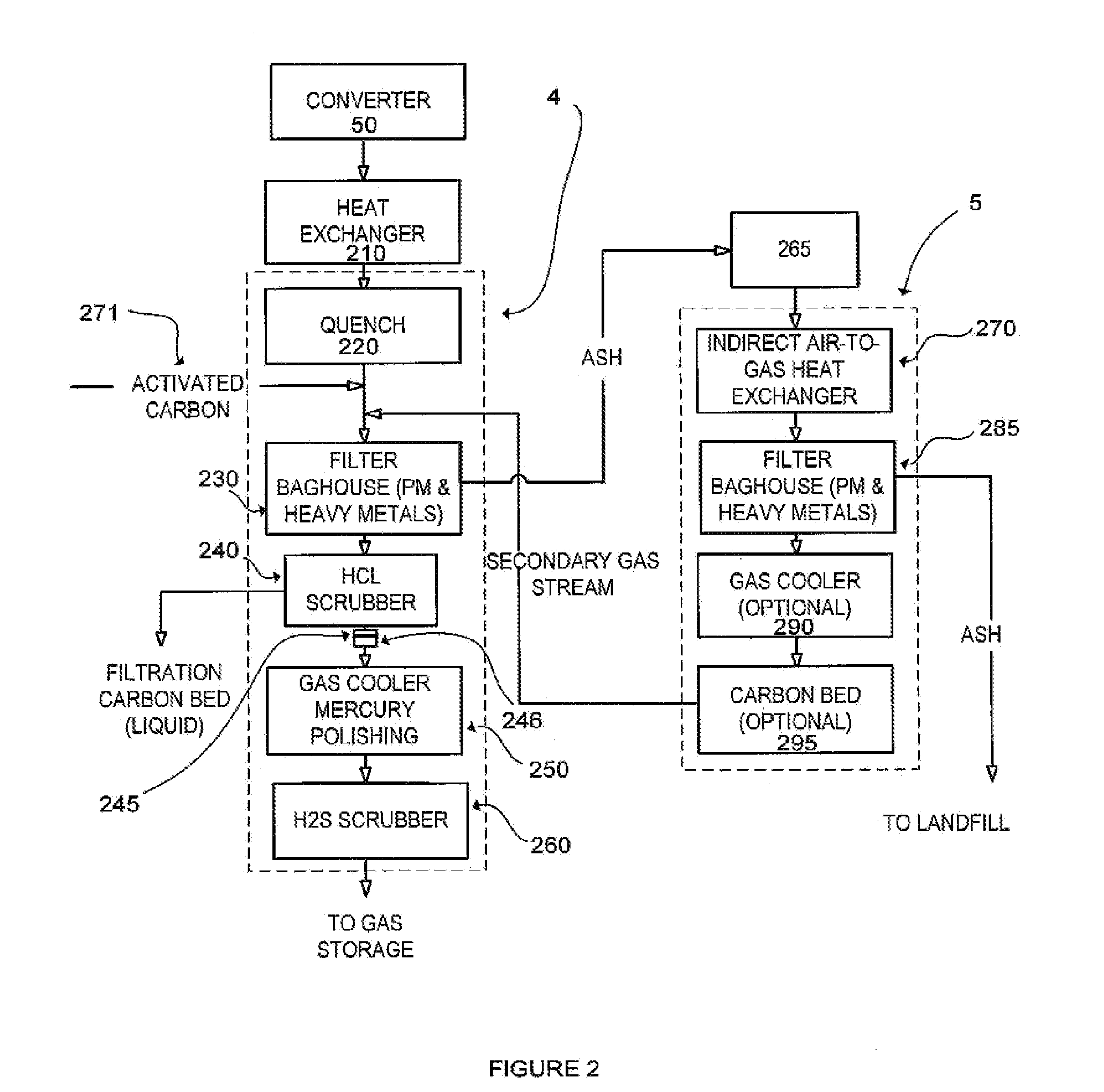

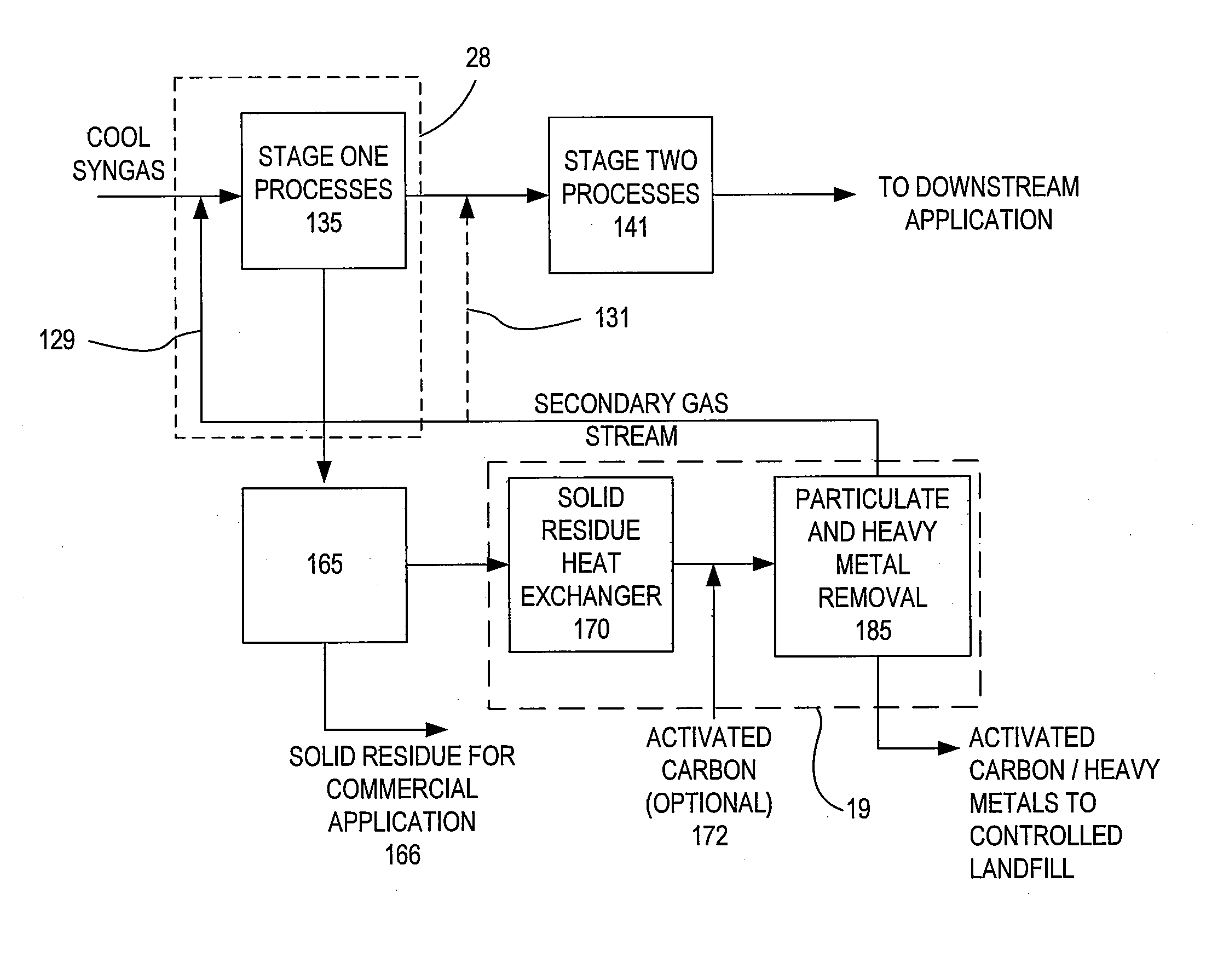

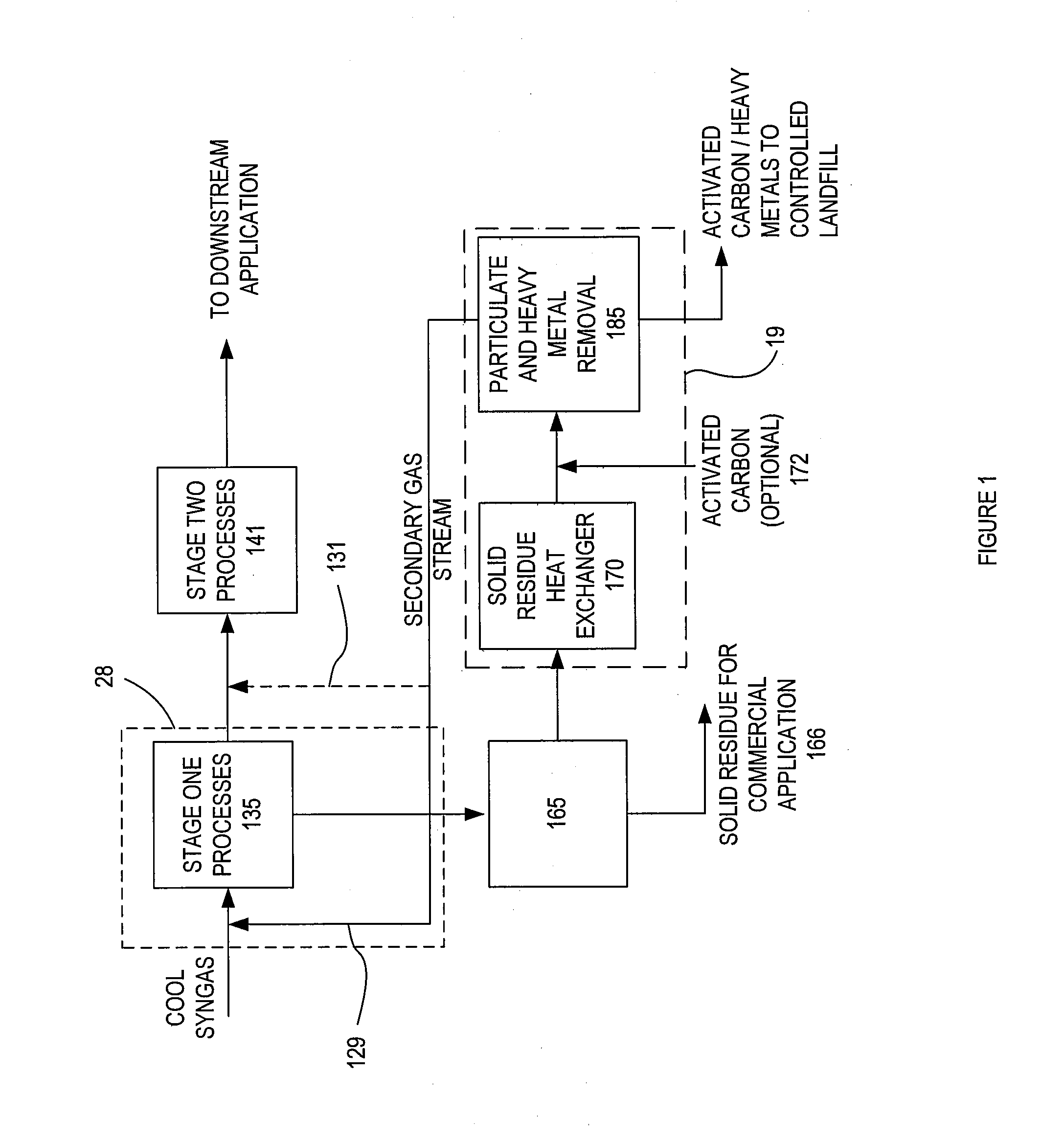

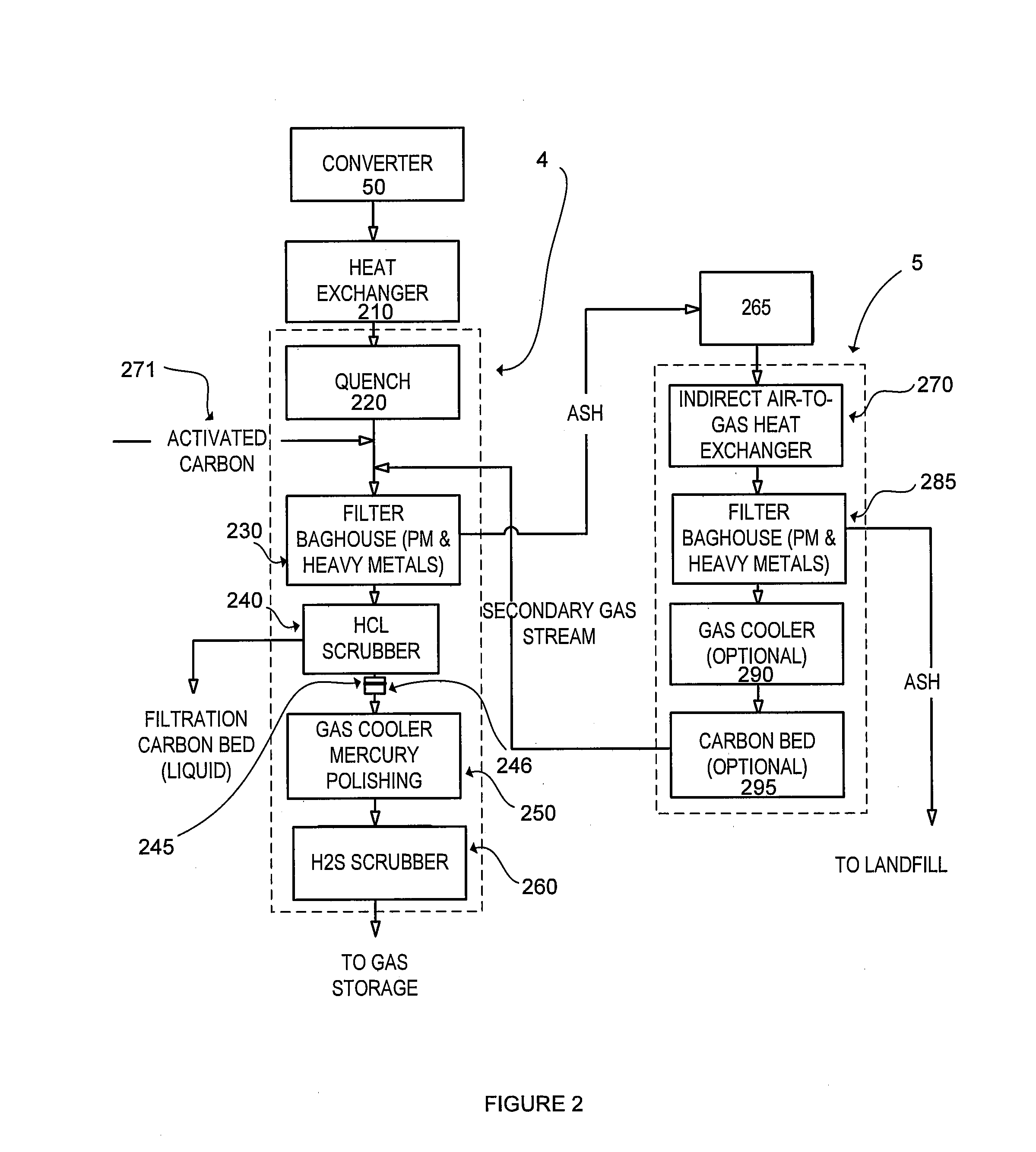

Gas conditioning system

The present invention provides a gas conditioning system for processing an input gas from a low temperature gasification system to an output gas of desired characteristics. The system comprises a two-stage process, the first stage separating heavy metals and particulate matter in a dry phase, and the second stage including further processing steps of removing acid gases, and / or other contaminants. Optional processes include adjusting the humidity and temperature of the input gas as it passes through the gas conditioning system. The presence and sequence of processing steps is determined by the composition of the input gas, the desired composition of output gas for downstream applications, and by efficiency and waste minimization.

Owner:PLASCO ENERGY GROUP INC

Gas Conditioning System

The present invention provides a gas conditioning system for processing an input gas from a low temperature gasification system to an output gas of desired characteristics. The system comprises a two-stage process, the first stage separating heavy metals and particulate matter in a dry phase, and the second stage including further processing steps of removing acid gases, and / or other contaminants. Optional processes include adjusting the humidity and temperature of the input gas as it passes through the gas conditioning system. The presence and sequence of processing steps is determined by the composition of the input gas, the desired composition of output gas for downstream applications, and by efficiency and waste minimization.

Owner:PLASCO ENERGY GROUP INC

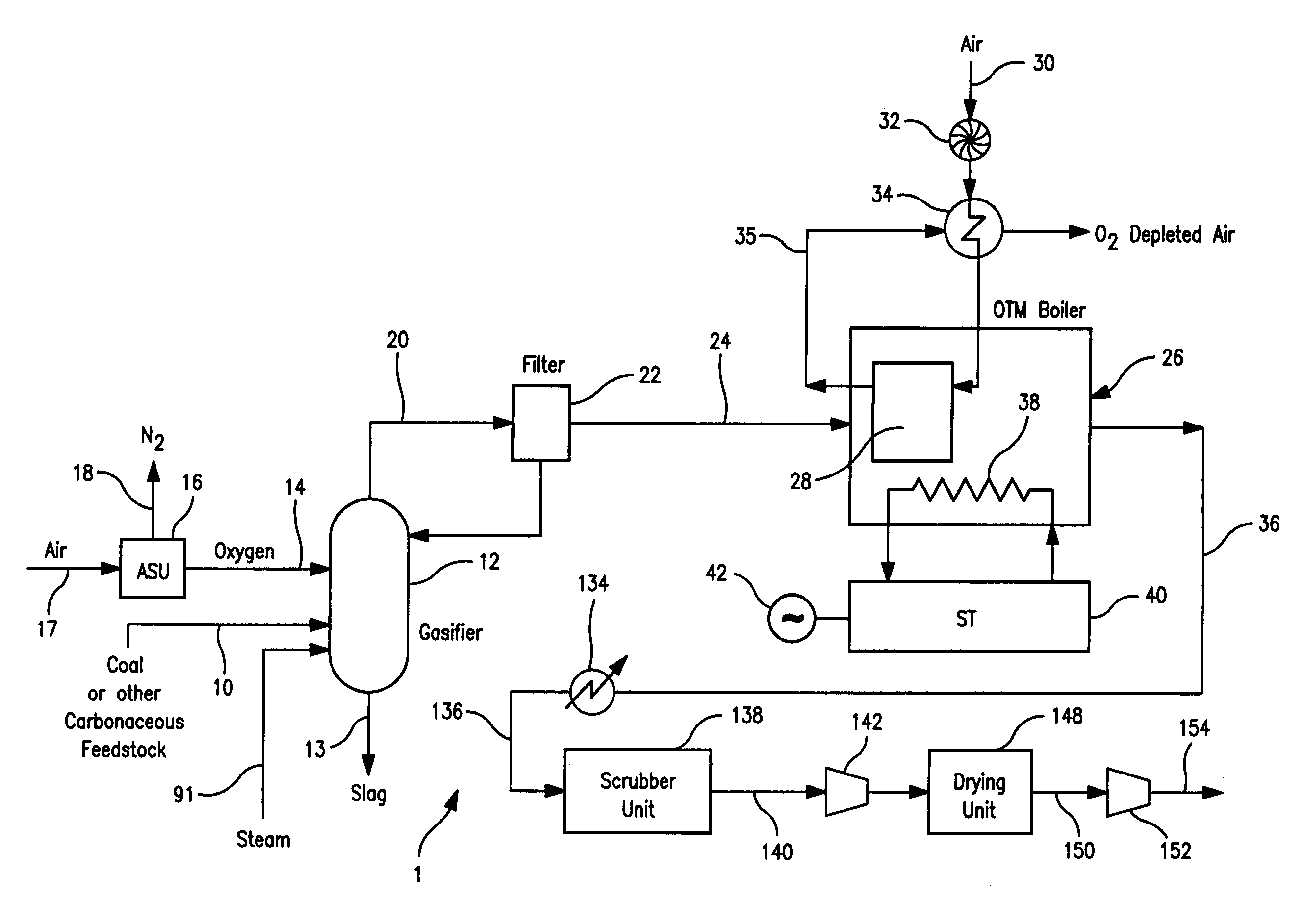

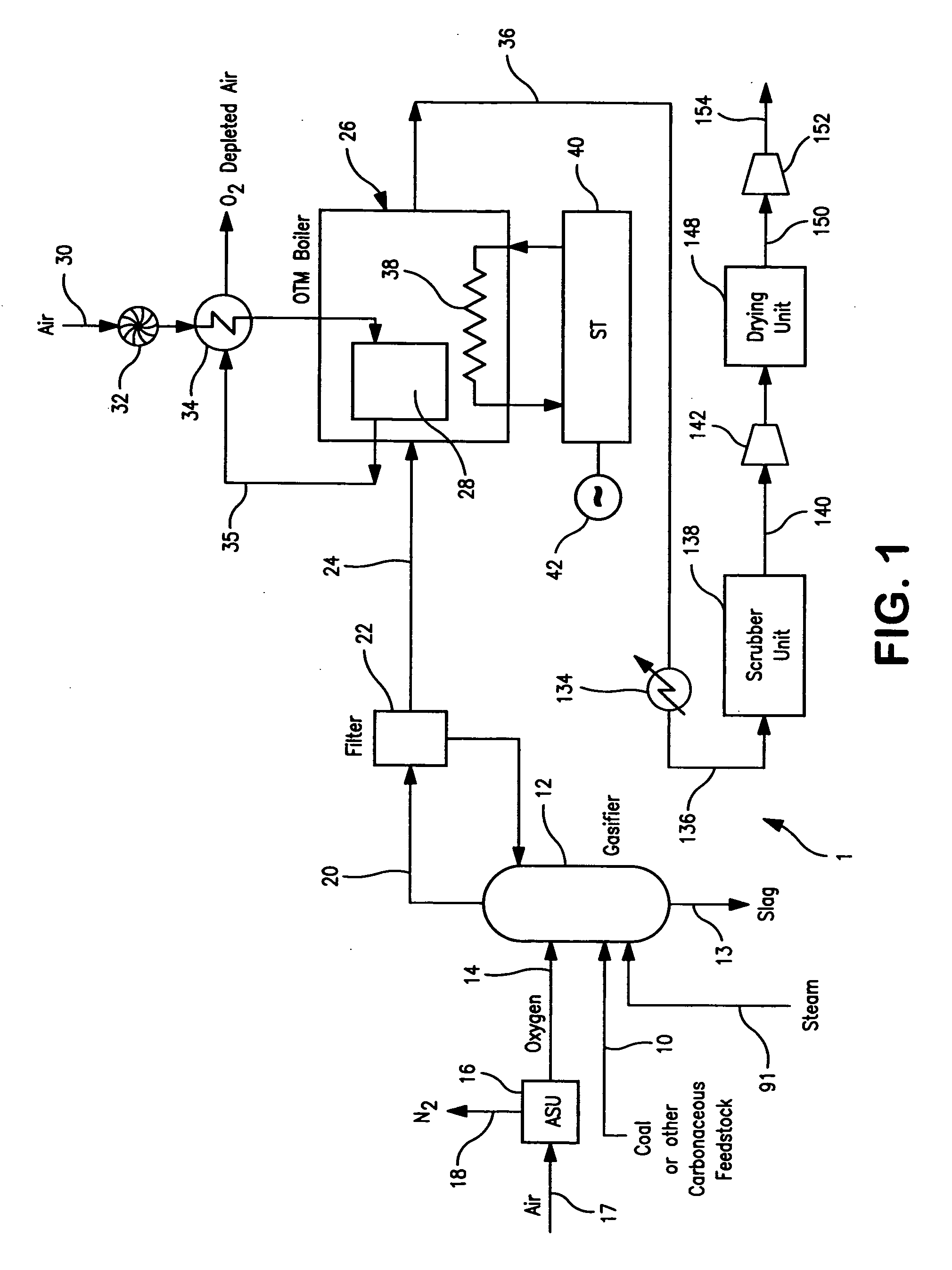

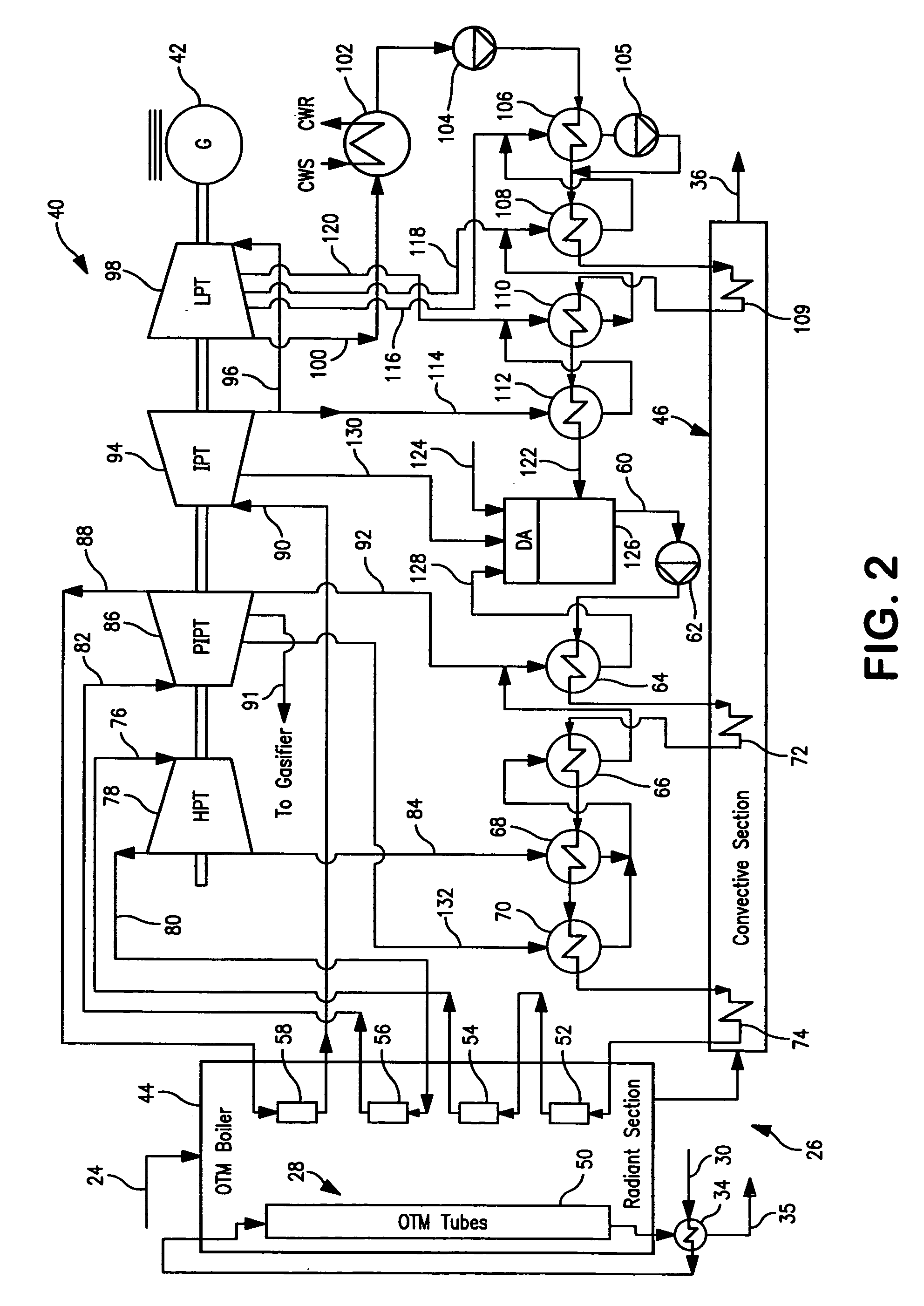

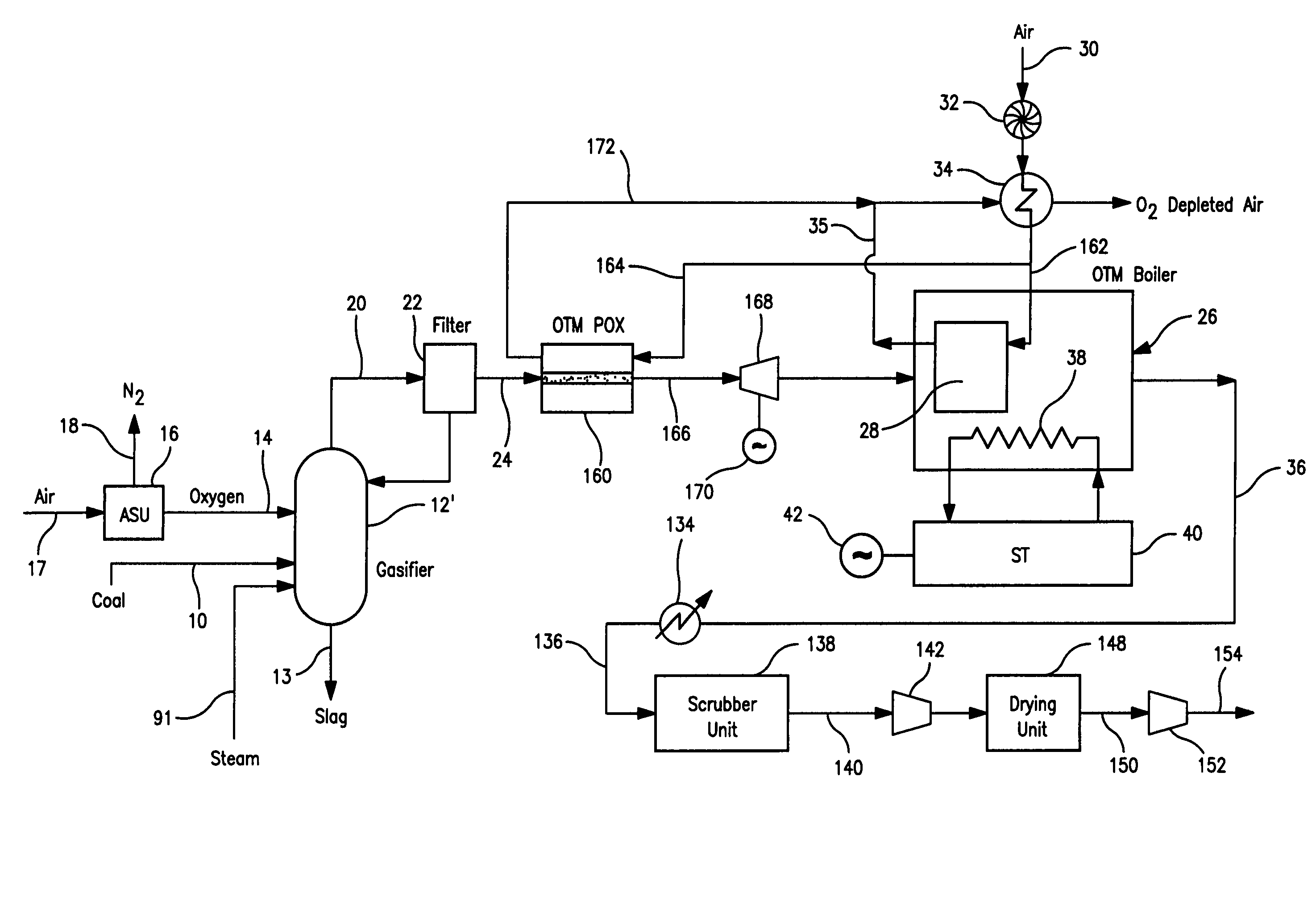

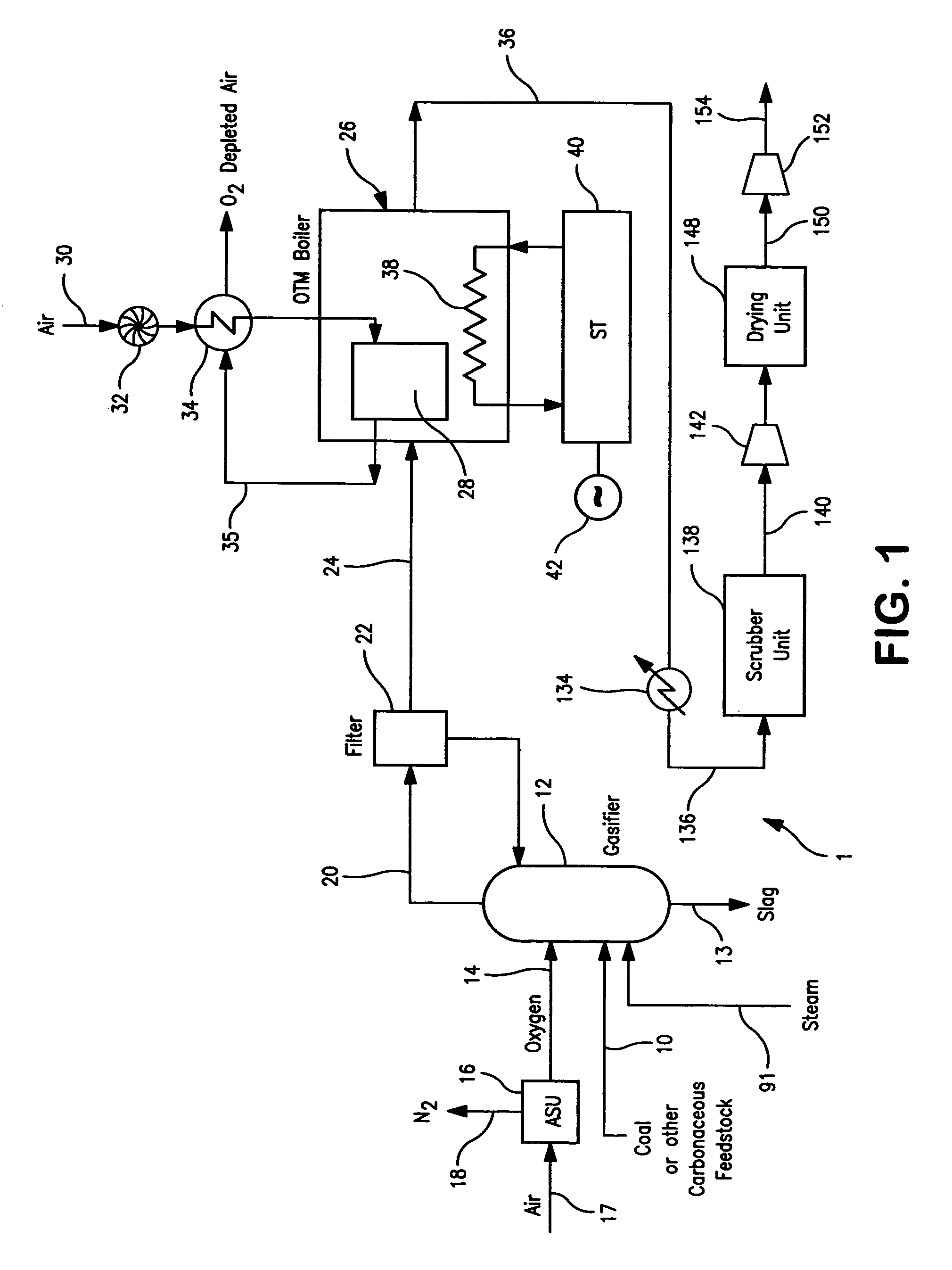

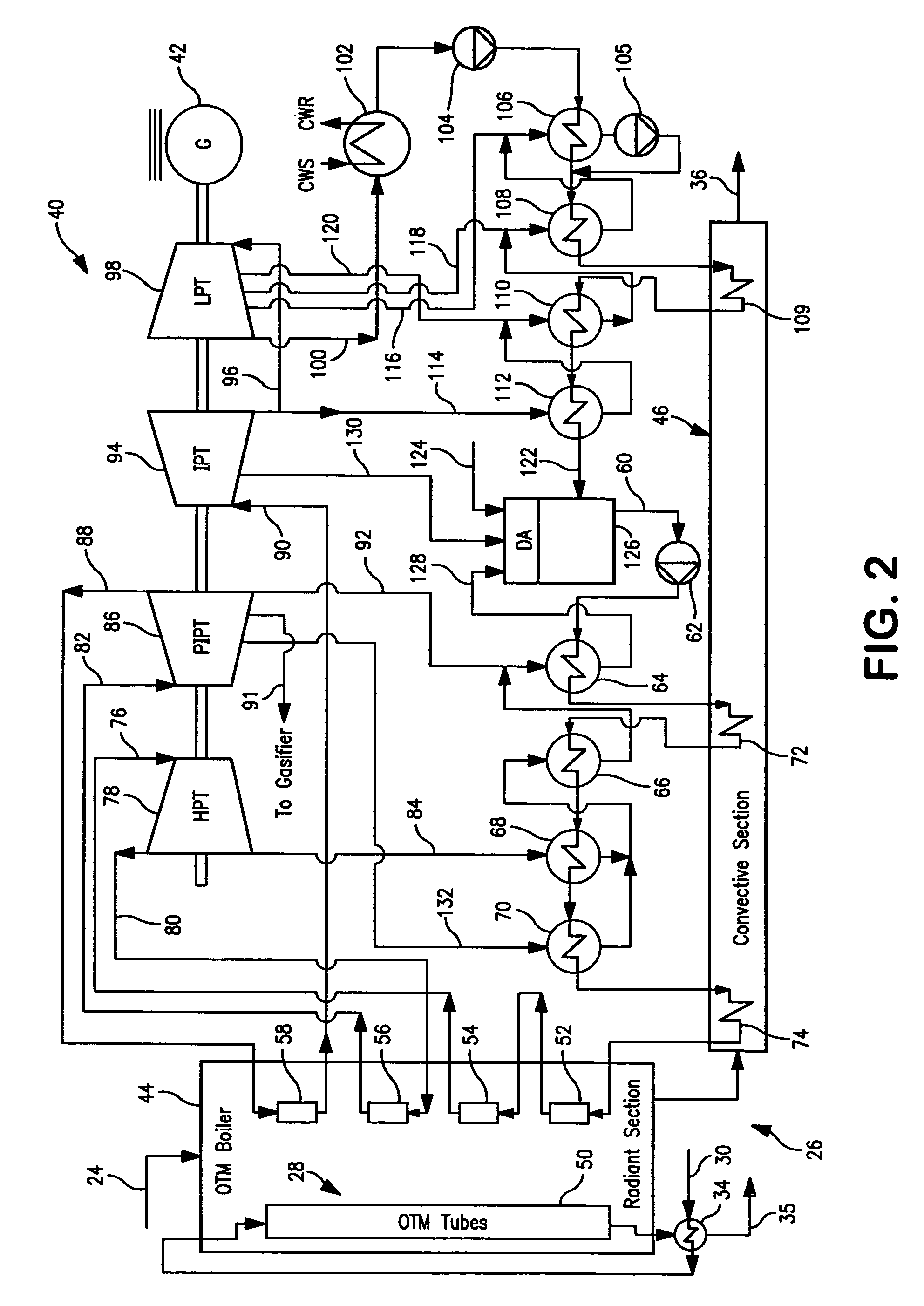

Electrical power generation method

A method of generating electrical power in which a synthesis gas stream generated in a gasifier is combusted in an oxygen transport membrane system of a boiler. The combustion generates heat to raise steam to in turn generate electricity by a generator coupled to a steam turbine. The resultant flue gas can be purified to produce a carbon dioxide product.

Owner:PRAXAIR TECH INC

Electro-Mechanical Interfaces to Mount Robotic Surgical Arms

In one embodiment of the invention, a method of mounting a surgical robotic arm to a set-up arm of a robotic surgical system is provided that includes sliding a pair of guide slots of the surgical robotic arm over a pair of guide tabs in the set-up arm; aligning electrical connectors in the set-up arm to electrical connectors of the surgical robotic arm; and coincidentally mating male electrical connectors to female electrical connectors while finally mating the guide tabs in the set-up arm to flanges of a housing of the surgical robotic arm.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Production of liquid fuels by a concatenation of processes for treatment of a hydrocarbon feedstock

ActiveUS7214720B2Maximize conversion of carbonReduce and to upgrade naphthaThermal non-catalytic crackingCatalytic crackingNaphthaKerosene

The invention relates to an installation and a process for the production of liquid fuels starting from a solid feedstock that contains the organic material in which:a) the solid feedstock is subjected to a gasification stage so as to convert said feedstock into synthesis gas,b) the synthesis gas is subjected to a purification treatment,c) the purified synthesis gas is subjected to a conversion stage that comprises the implementation of a Fischer-Tropsch-type synthesis so as to convert said synthesis gas into a liquid effluent and a gaseous effluent,d) the liquid effluent is fractionated so as to obtain a gaseous fraction, a naphtha fraction, a kerosene fraction and a gas oil fraction, ande) at least a portion of the naphtha fraction is recycled in gasification stage a).

Owner:INST FR DU PETROLE +1

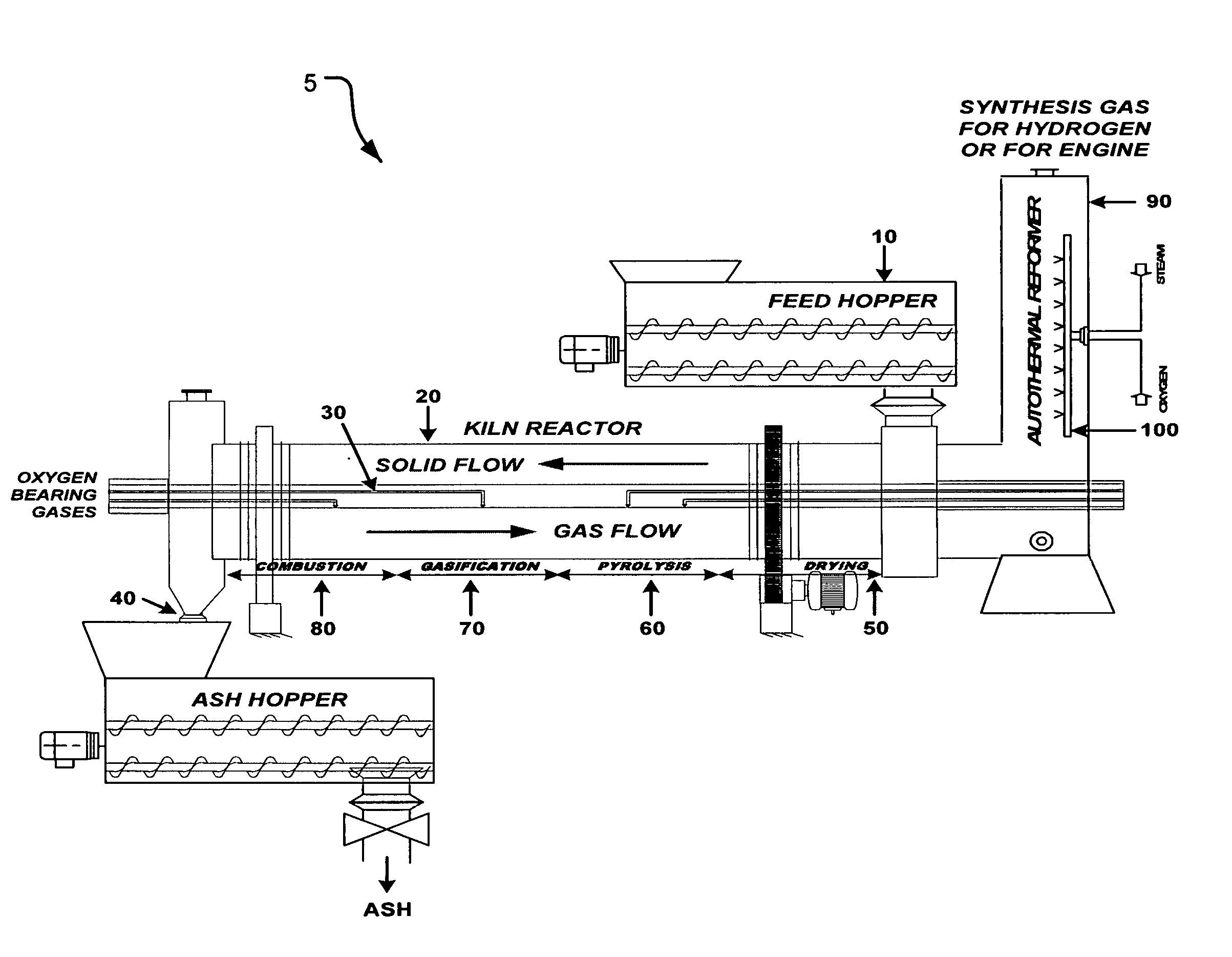

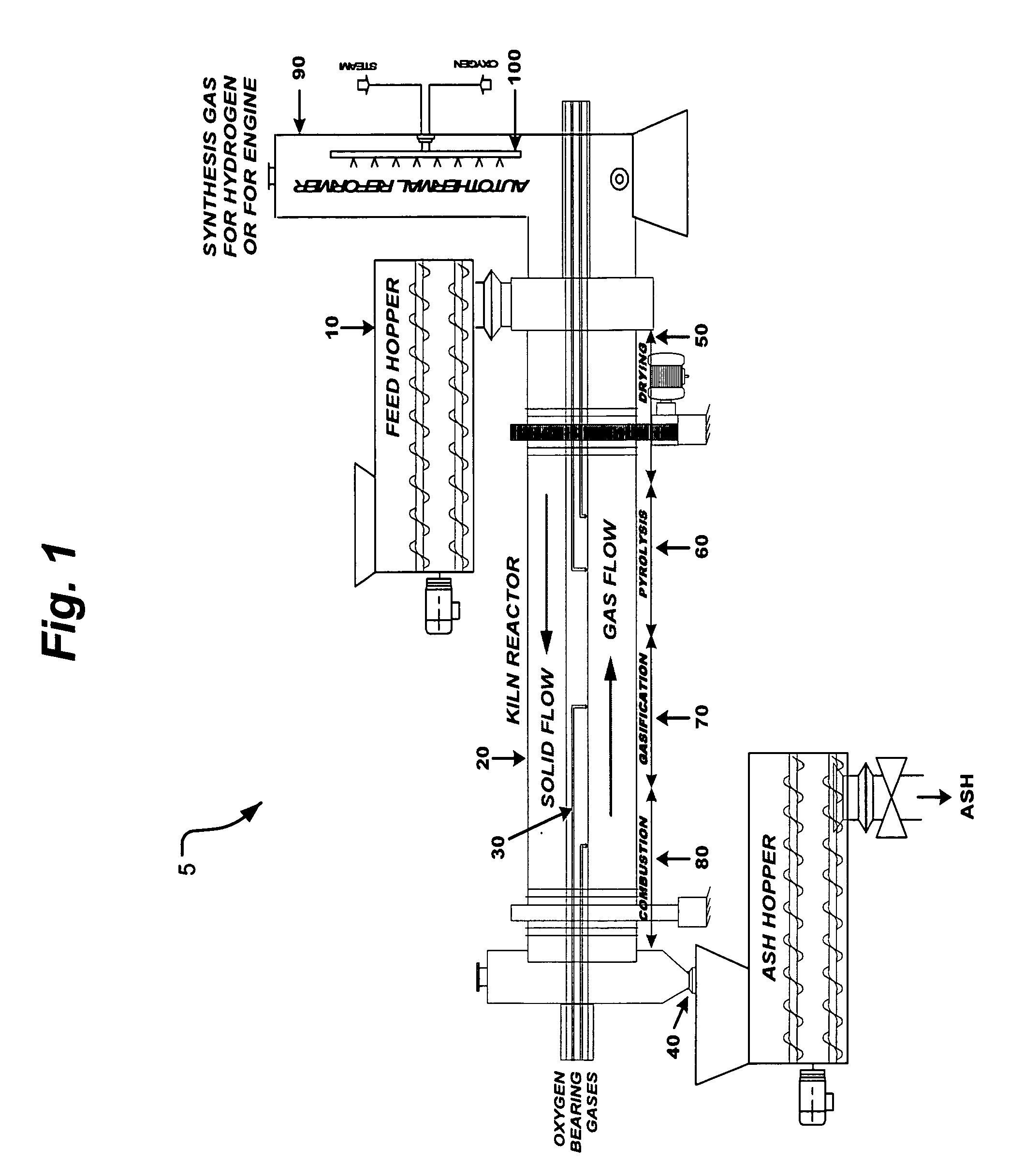

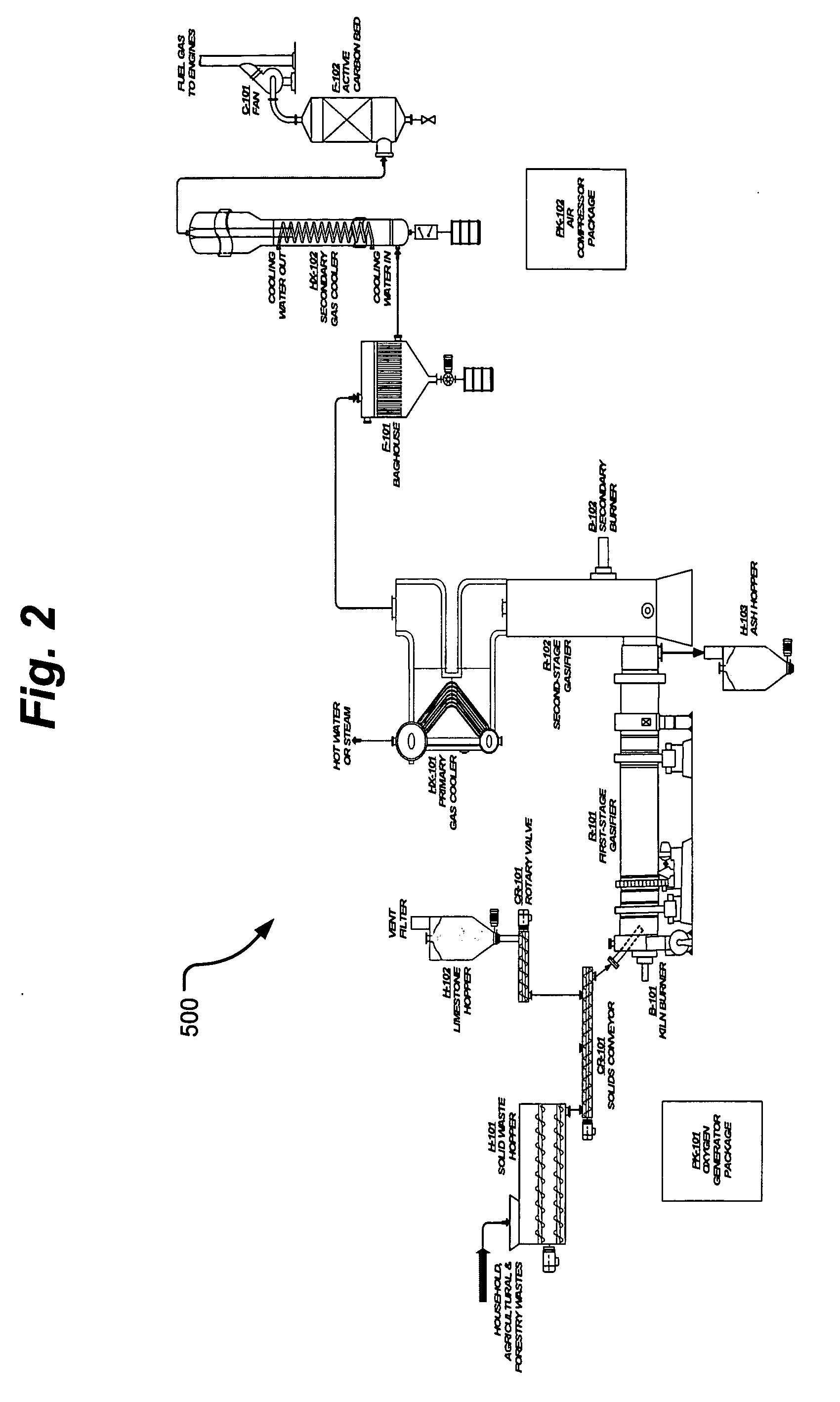

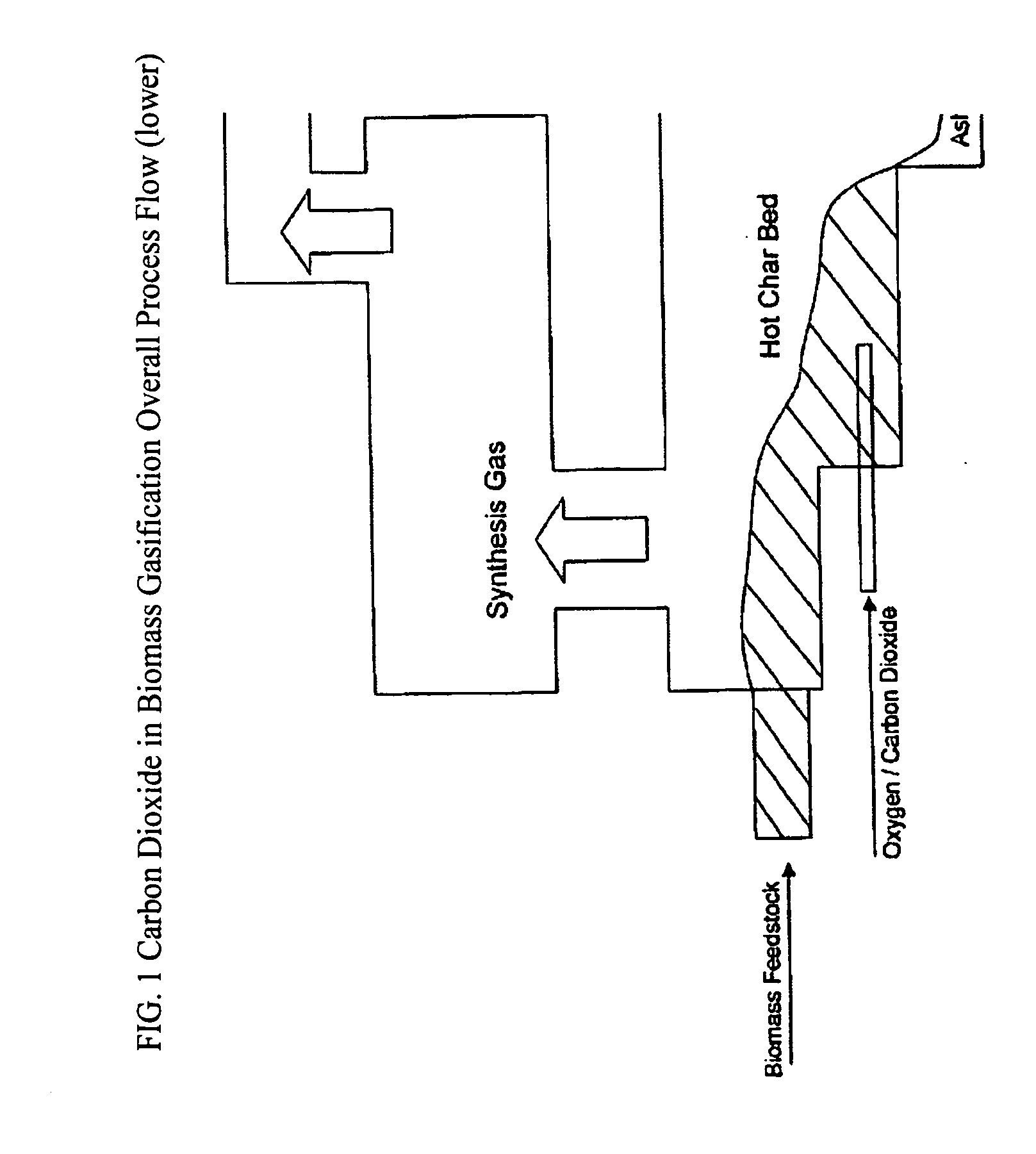

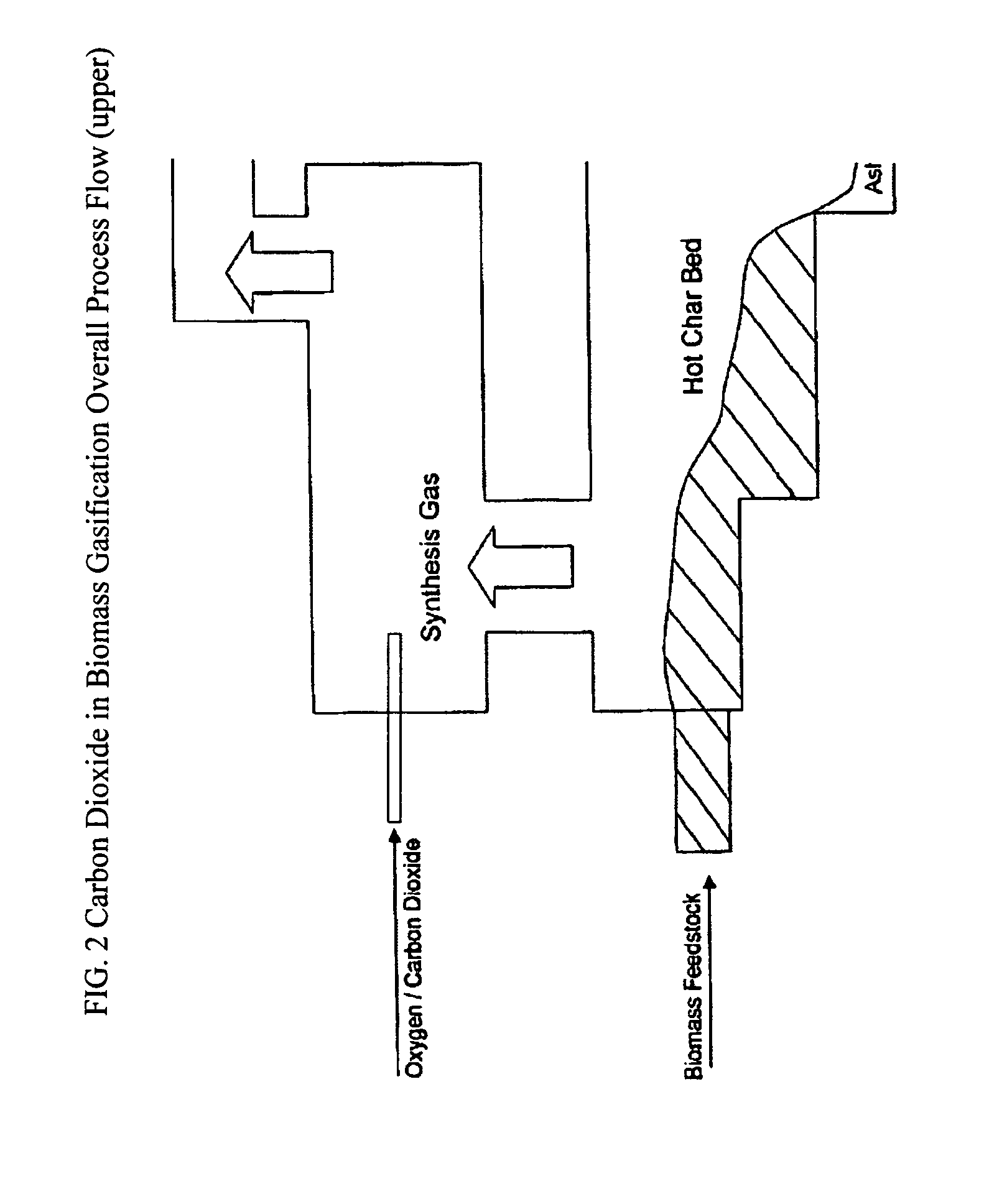

Process and apparatus for biomass gasification

InactiveUS20050095183A1Oxygen-containing compound preparationGasifier mechanical detailsForming gasTar

A waste-to-synthesis gas system including: a first gasifier for receiving biomass; a gas distributor for delivering reactant gas and oxygen into the first gasifier in a countercurrent direction to the biomass flow and to define a plurality of reaction regions including a drying region, a pyrolysis region, a gasification region and a combustion region; and, a second gasifier for receiving gases from the plurality of regions of the first gasifier and a gas distributor for delivering reactant gas and oxygen into the second gasifier in a concurrent direction to the flow of gases from the first gasifier. As a result, no carbon chars, oils or tars are expected to be present in the synthesis gas produced.

Owner:BIOMASS ENERGY SOLUTIONS

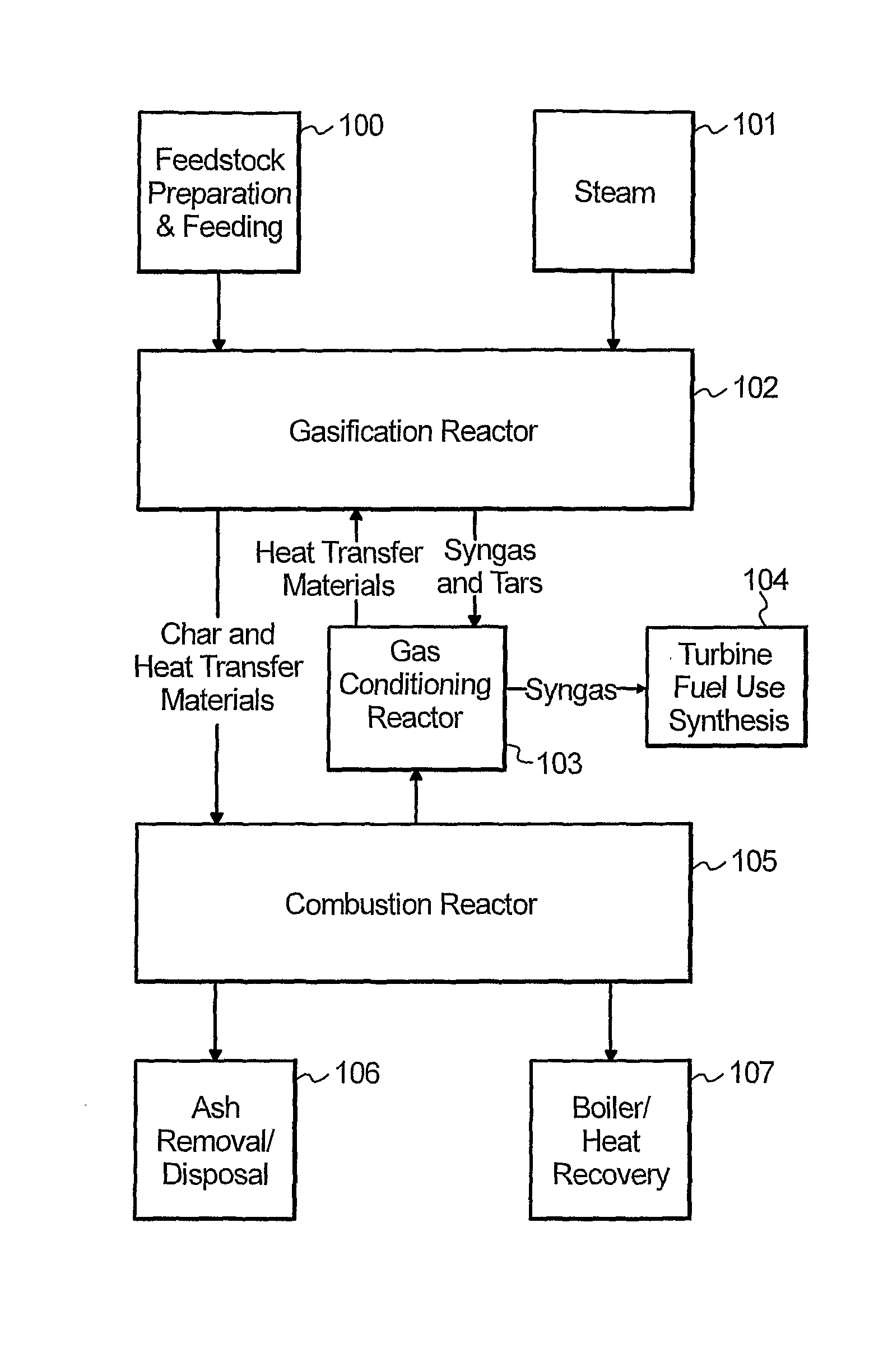

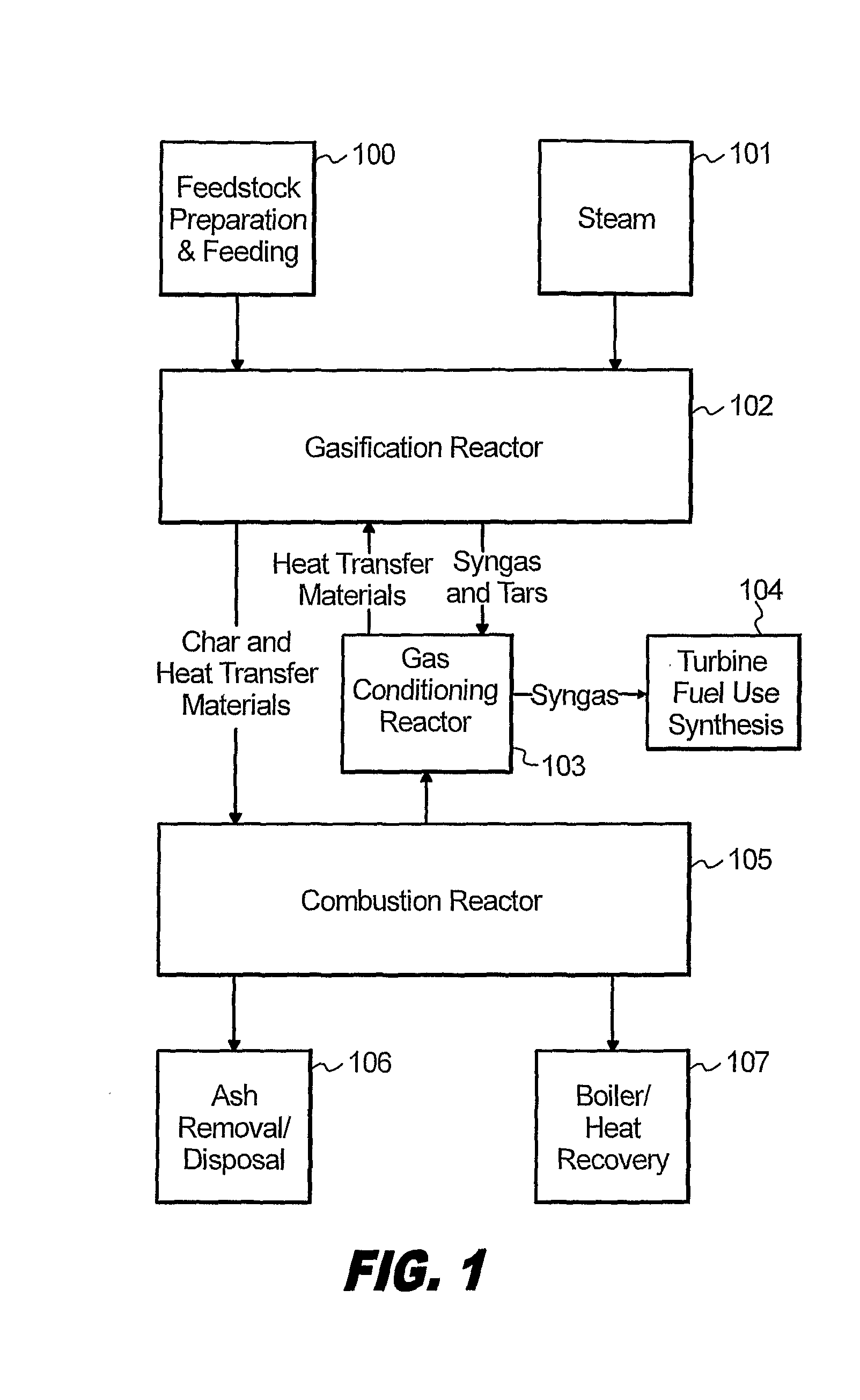

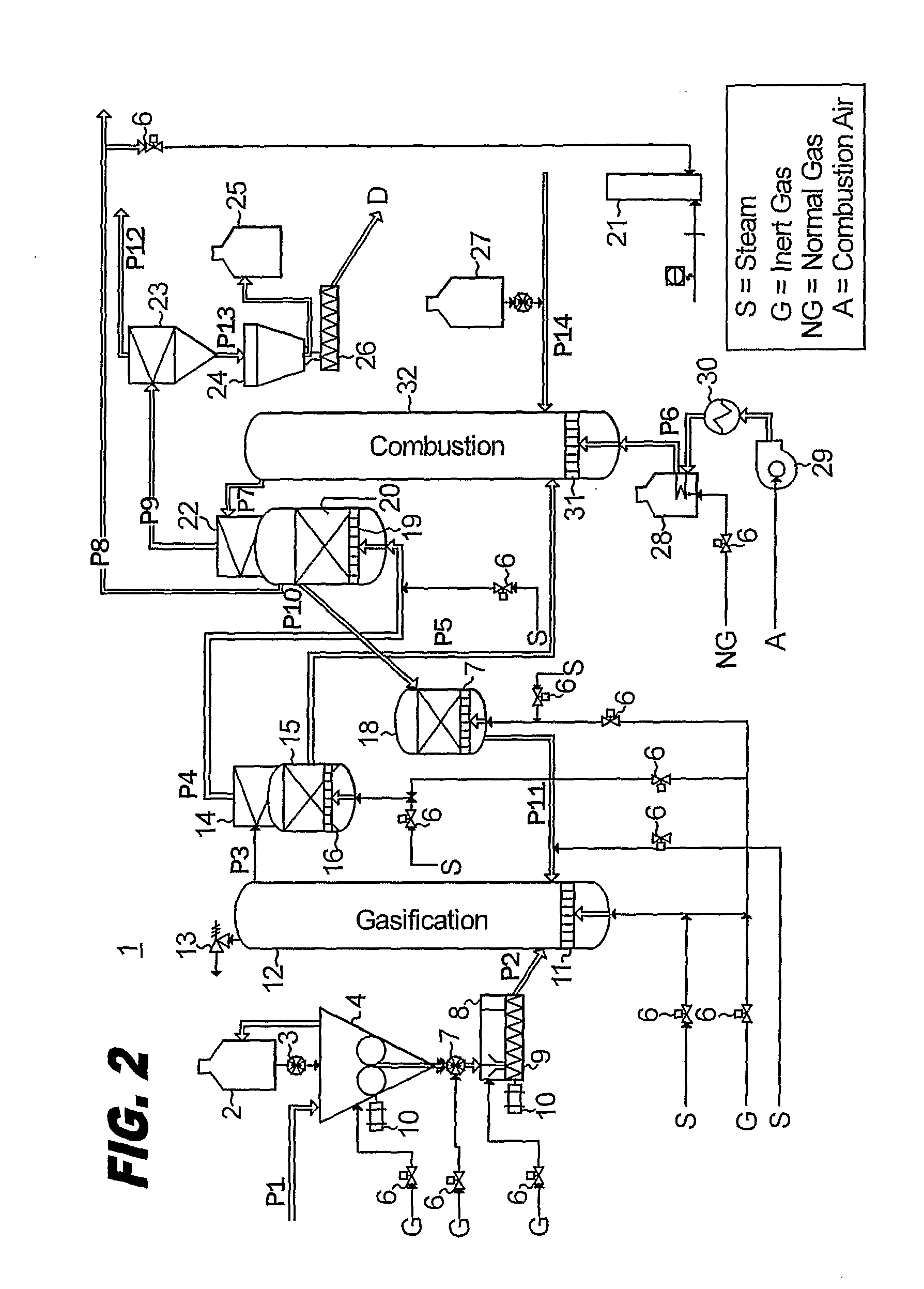

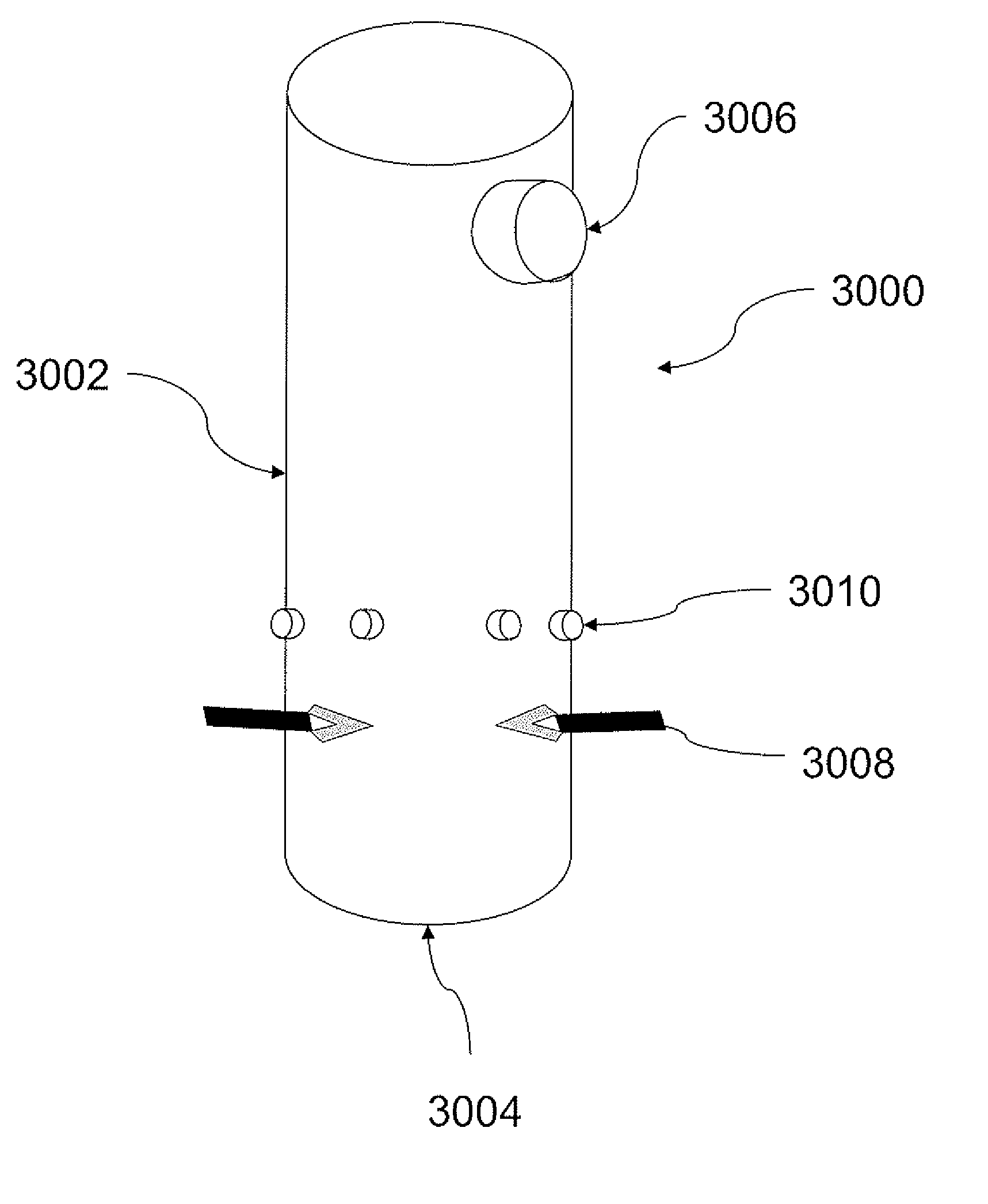

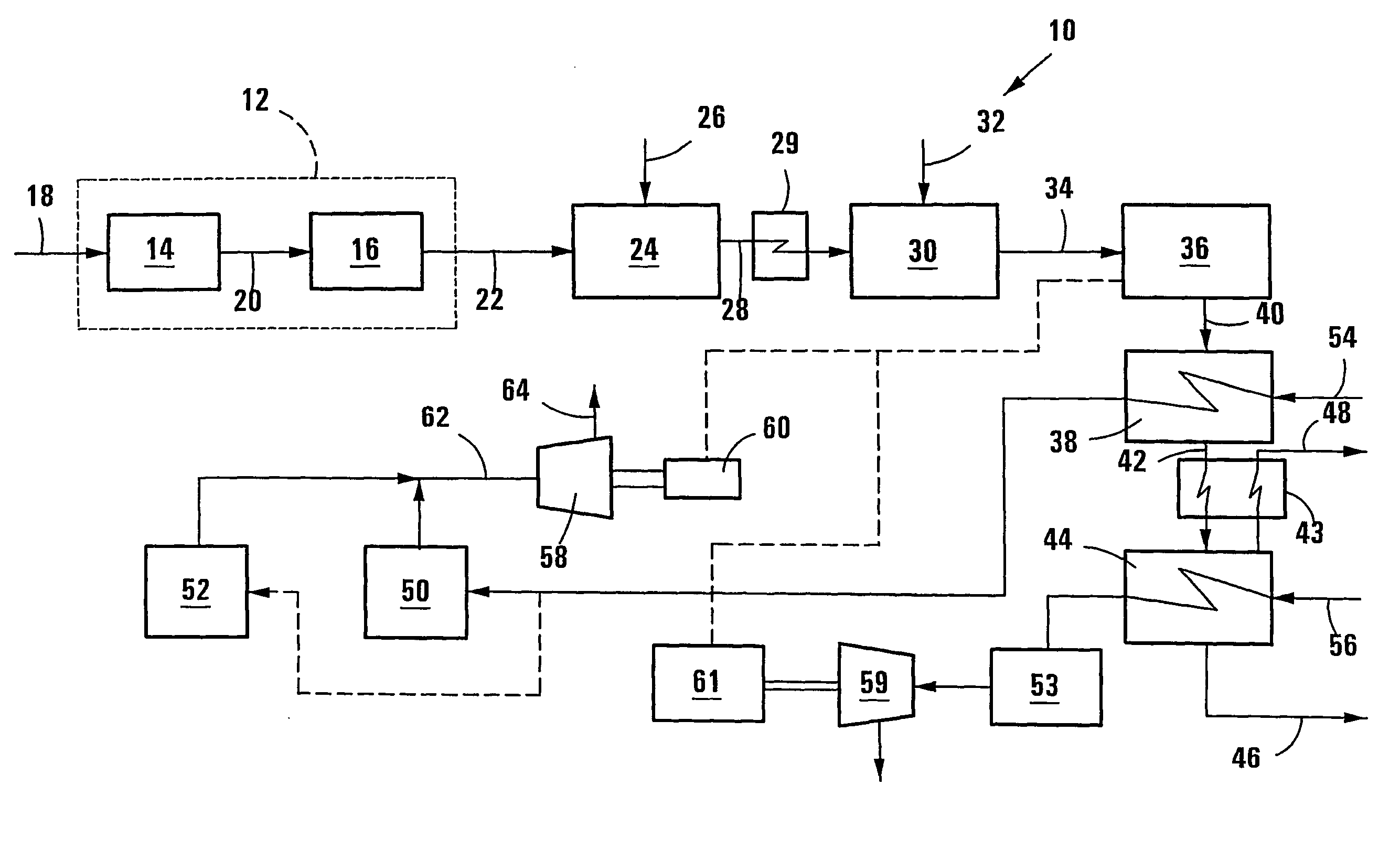

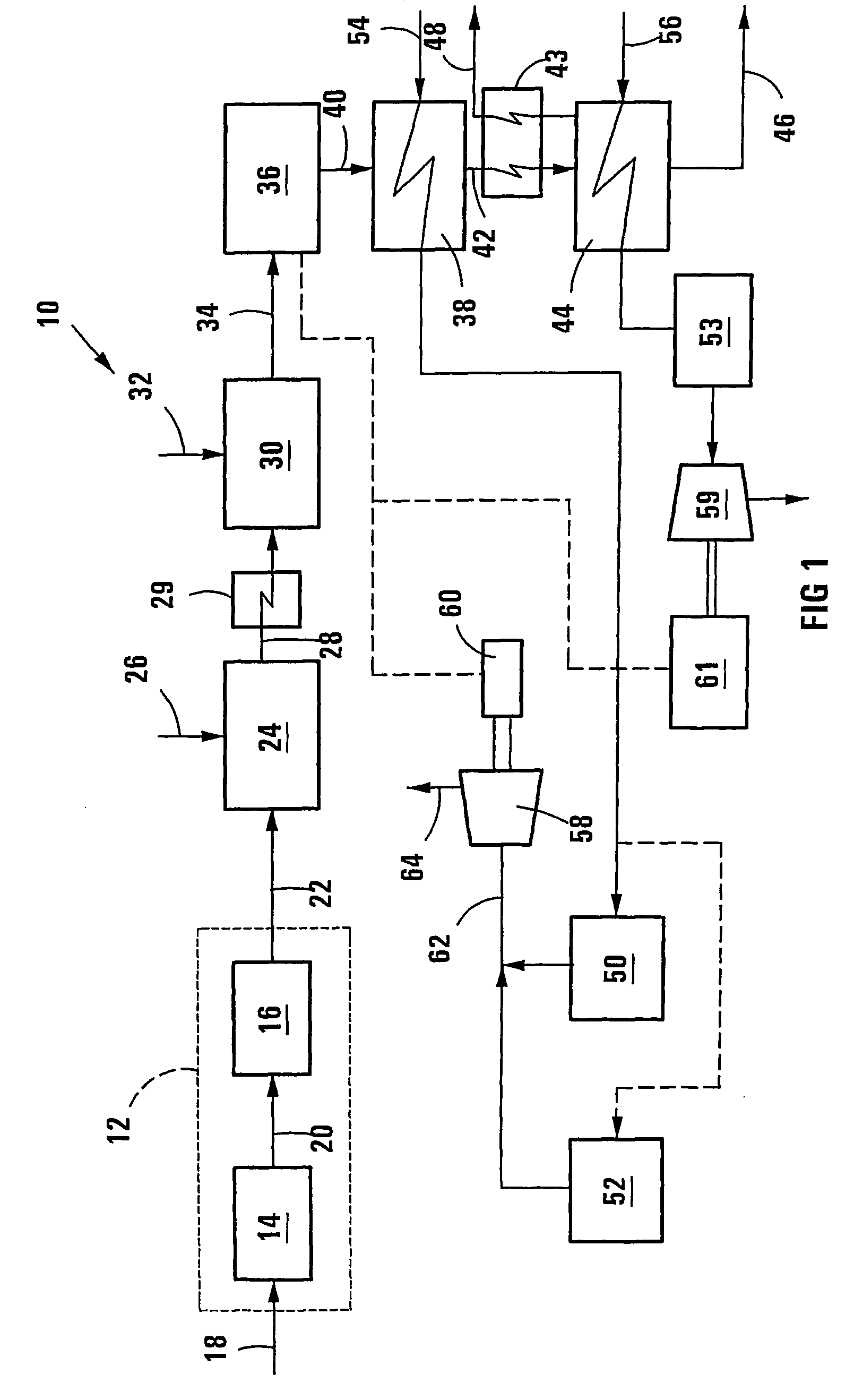

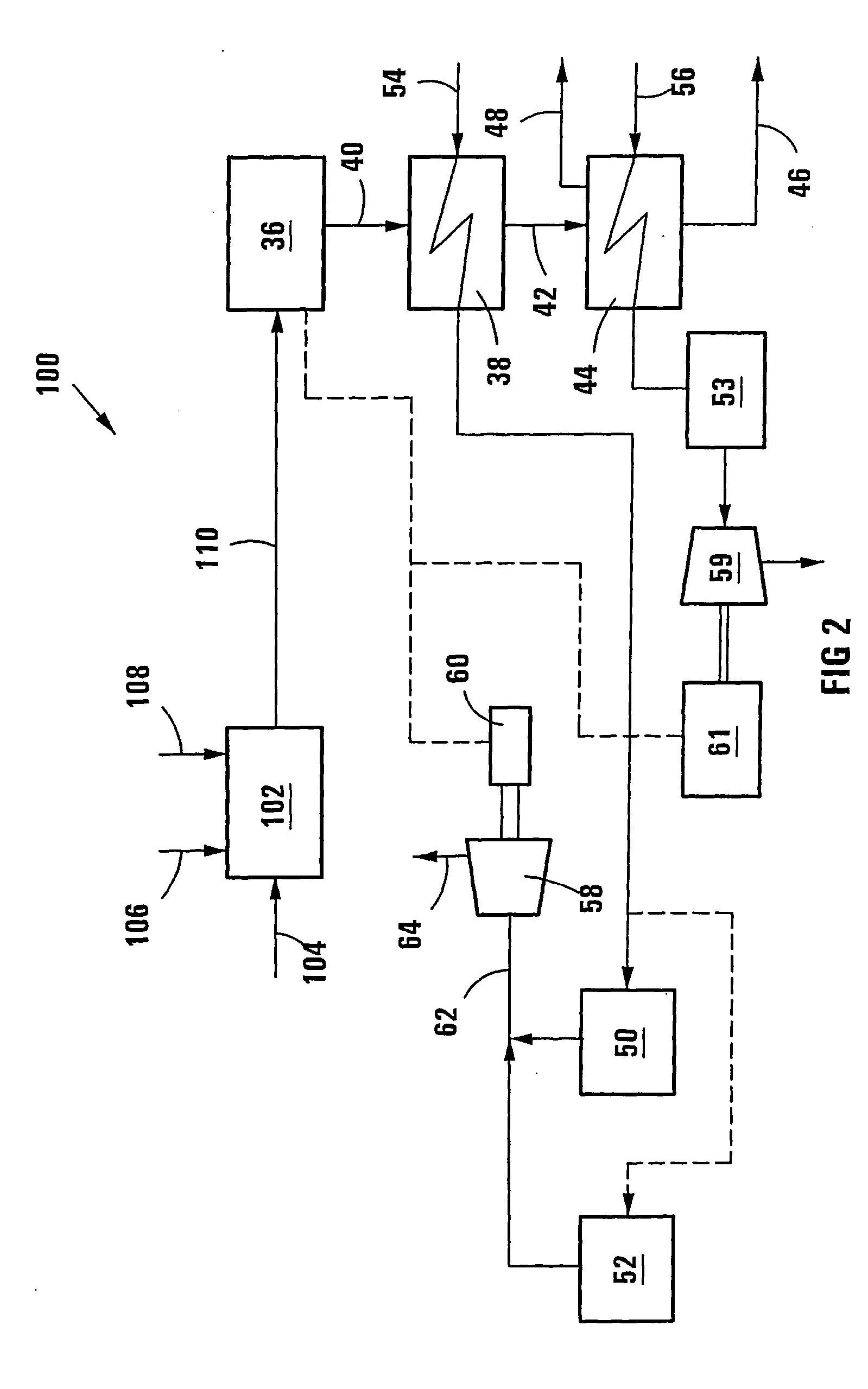

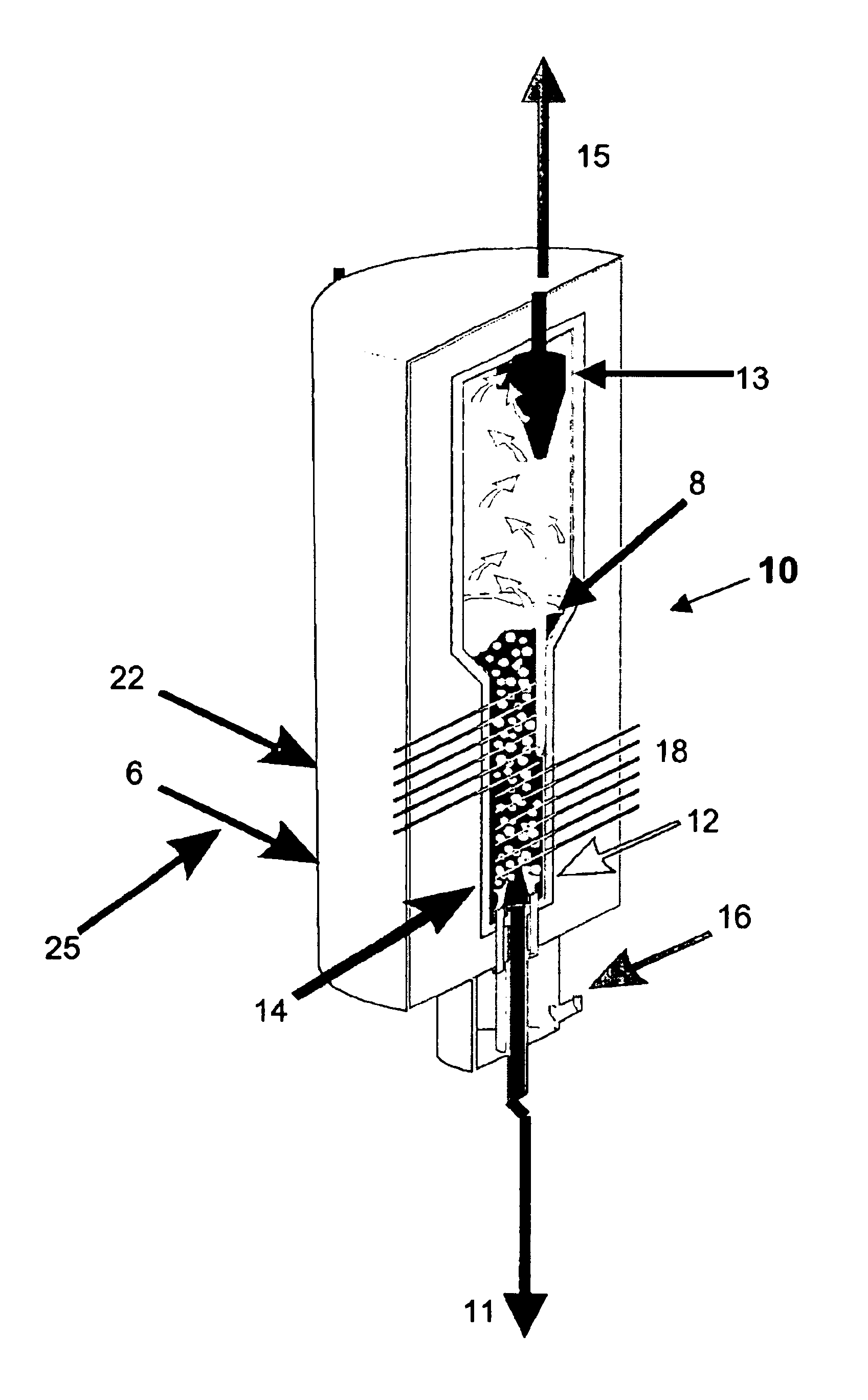

Process and System for Gasification with In-Situ Tar Removal

ActiveUS20080244976A1Simplifying downstream heat recoveryIncreased hydrogenCombustible gas catalytic treatmentCombustible gas thermal treatmentHeat carrierTar

The present invention relates to a process and system for gasifying biomass or other carbonaceous feedstocks in an indirectly heated gasifier and provides a method for the elimination of condensable organic materials (tars) from the resulting product gas with an integrated tar removal step. More specifically, this tar removal step utilizes the circulating heat carrier to crack the organics and produce additional product gas. As a benefit of the above process, and because the heat carrier circulates through alternating steam and oxidizing zones in the process, deactivation of the cracking reactions is eliminated.

Owner:TAYLOR BIOMASS ENERGY

Gas Reformulating System Using Plasma Torch Heat

ActiveUS20070266633A1Gasifier mechanical detailsGas modification by gas mixingControl systemProcess engineering

A method and apparatus is described for reformulating of an input gas from a gasification reaction into a reformulated gas. More specifically, a gas reformulating system having a gas reformulating chamber, one or more plasma torches, one or more oxygen source(s) inputs and control system is provided thereby allowing for the conversion of an input gas from a gasification reaction into a gas of desired composition.

Owner:PLASCO CONVERSION TECH INC

Low oxygen carrier fluid with heating value for feed to transport gasification

ActiveUS20090188165A1Reduce and eliminate partial and complete oxidationReduce and eliminate exothermic conversionMultiple metal hydridesCombustible gas catalytic treatmentCarrier fluidOxidizing agent

Systems and processes for producing synthesis gas. A carbonaceous feedstock can be combined with one or more low-oxygen carrier fluids having a high heating value. The feedstock and carrier fluid, in the presence of one or more oxidants, can be gasified to provide a synthesis gas. In one or more embodiments, at least a portion of the synthesis gas can be recycled for use as the carrier fluid.

Owner:KELLOGG BROWN & ROOT LLC

Production of synthesis gas and synthesis gas derived products

A process for upgrading raw synthesis gas comprising at least CH4, CO2, CO and H2, includes heating the raw synthesis gas by addition of energy derived from electricity to provide an upgraded synthesis gas comprising less CH4 and CO2 and more CO and H2 than the raw synthesis gas. The invention extends to a process for producing synthesis gas, which process includes reforming a hydrocarbonaceous gas feedstock which includes CH4 to raw synthesis gas comprising at least CH4, CO2, CO and H2, and upgrading the raw synthesis gas in a process which includes heating the raw synthesis gas by addition of energy derived from electricity to provide an upgraded synthesis gas comprising less CH4 and CO2 and more CO and H2 than the raw synthesis gas.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

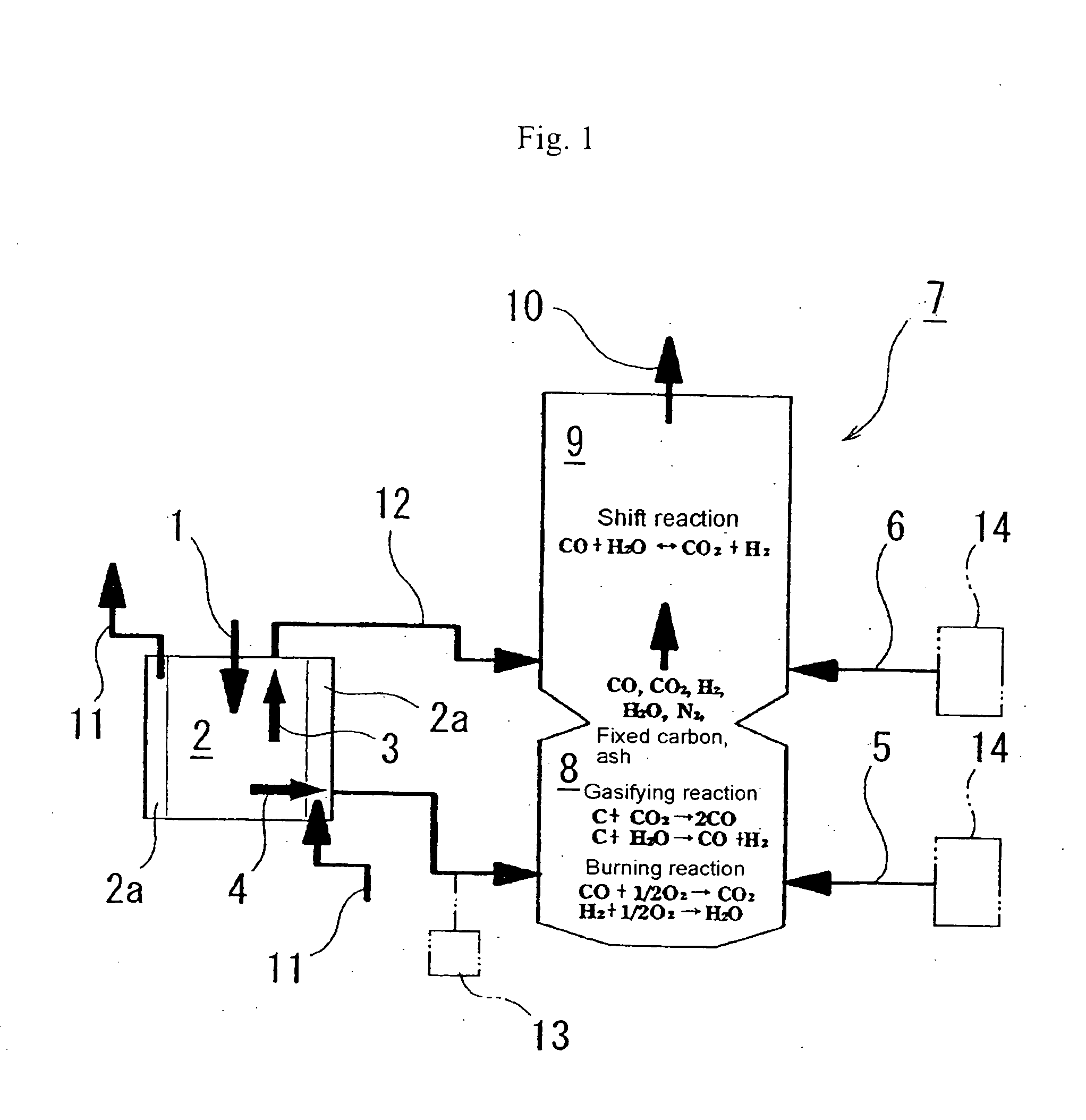

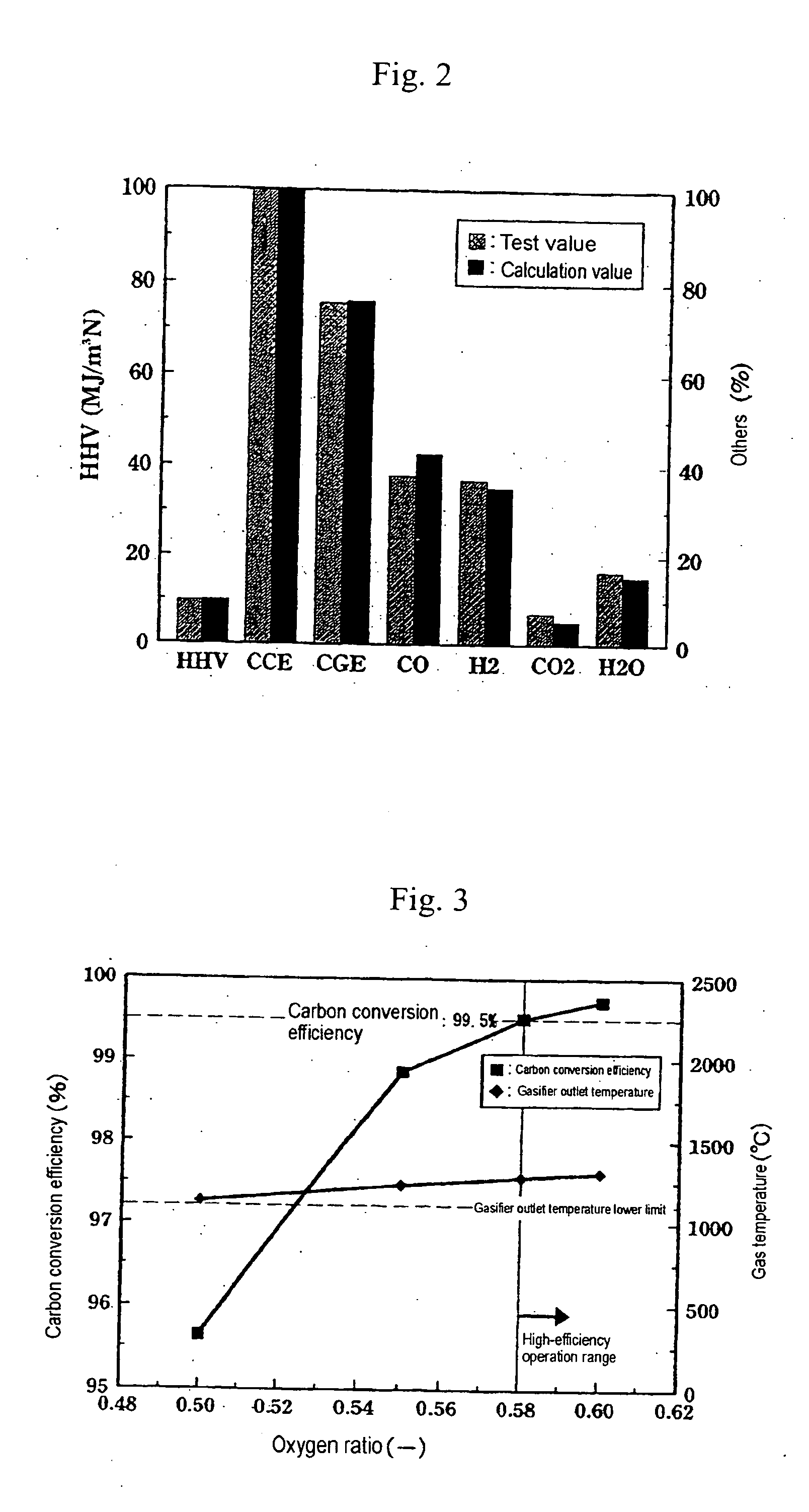

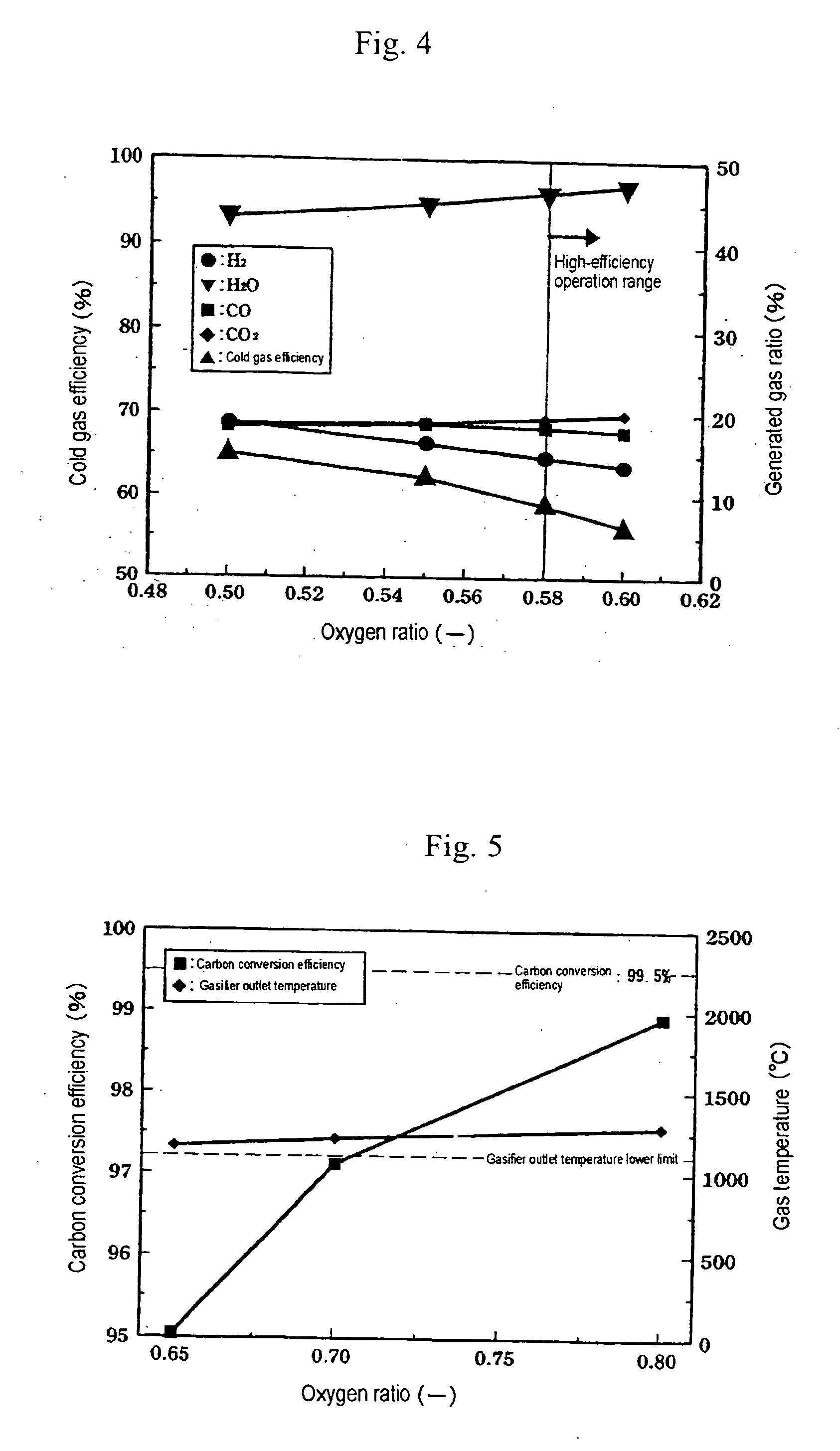

Carbonization and gasification of biomass and power generation system

InactiveUS20050247553A1Increase temperatureHigh thermal efficiencyBeehive ovensCombustible gas catalytic treatmentCarbonizationTar

Biomass, including waste biomass, is gasified by a process in which the biomass is first carbonized, and the char and pyrolysis gas from the carbonizer are respectively fed to a high temperature gasifying part and a gas reformer part of a two-stage gasifier. A gasifying agent is continuously fed to the gasifying part, and intermittently fed to the gas reformer, to maintain the temperature required to avoid tar formation in the gas reformer stage. Multiple carbonization chambers are operated in rotation. When the carbonization / gasification apparatus is used to provide fuel to an electric power generator set, exhaust heat from the generator power plant is fed back to the carbonizer, and can be supplemented by exchange of heat from the gas delivered to generator power plant from the outlet of the gasifier.

Owner:CENTRAL RESEARCH INSTITUTE OF ELECTRIC POWER INDUSTRY +1

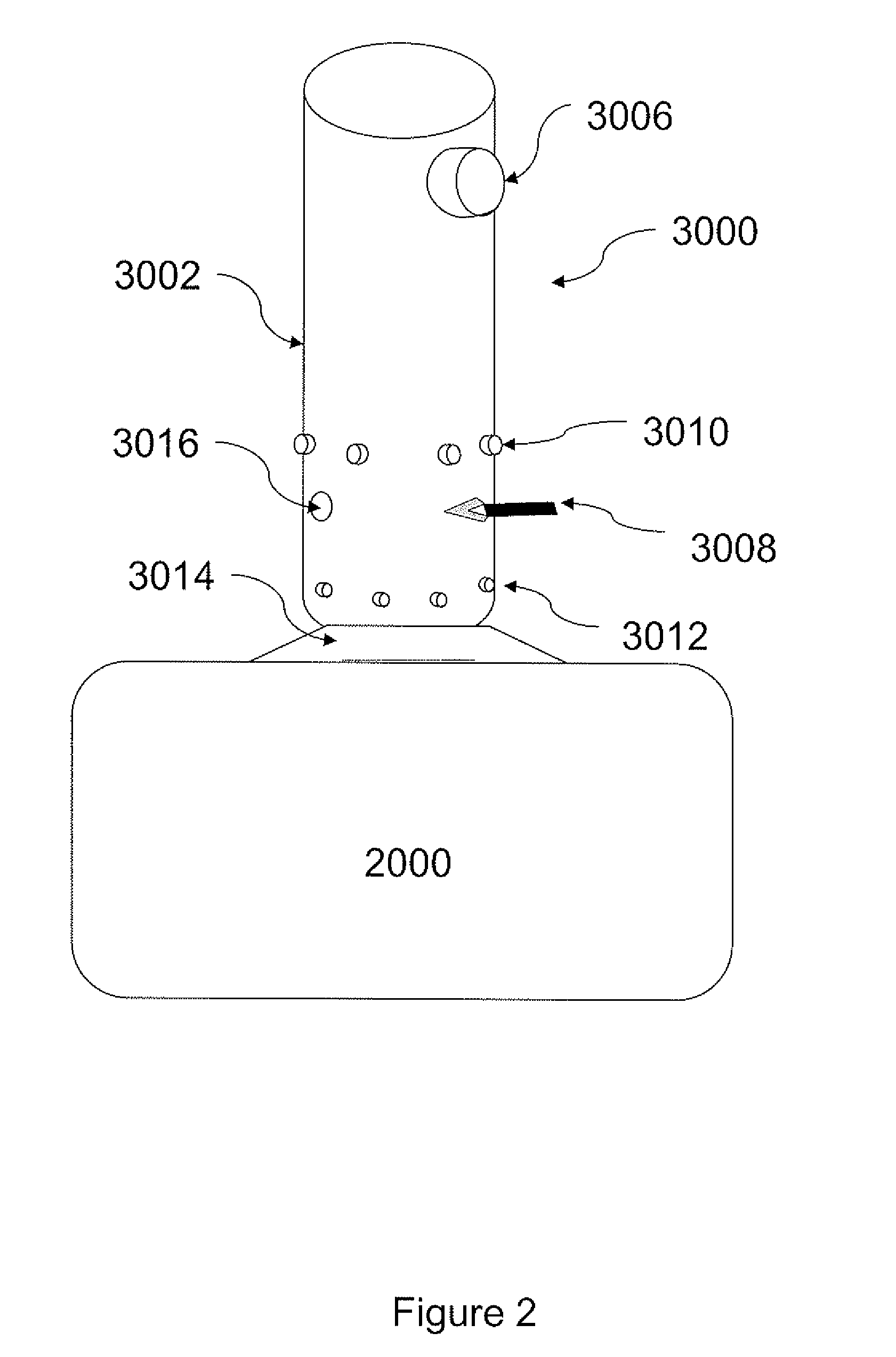

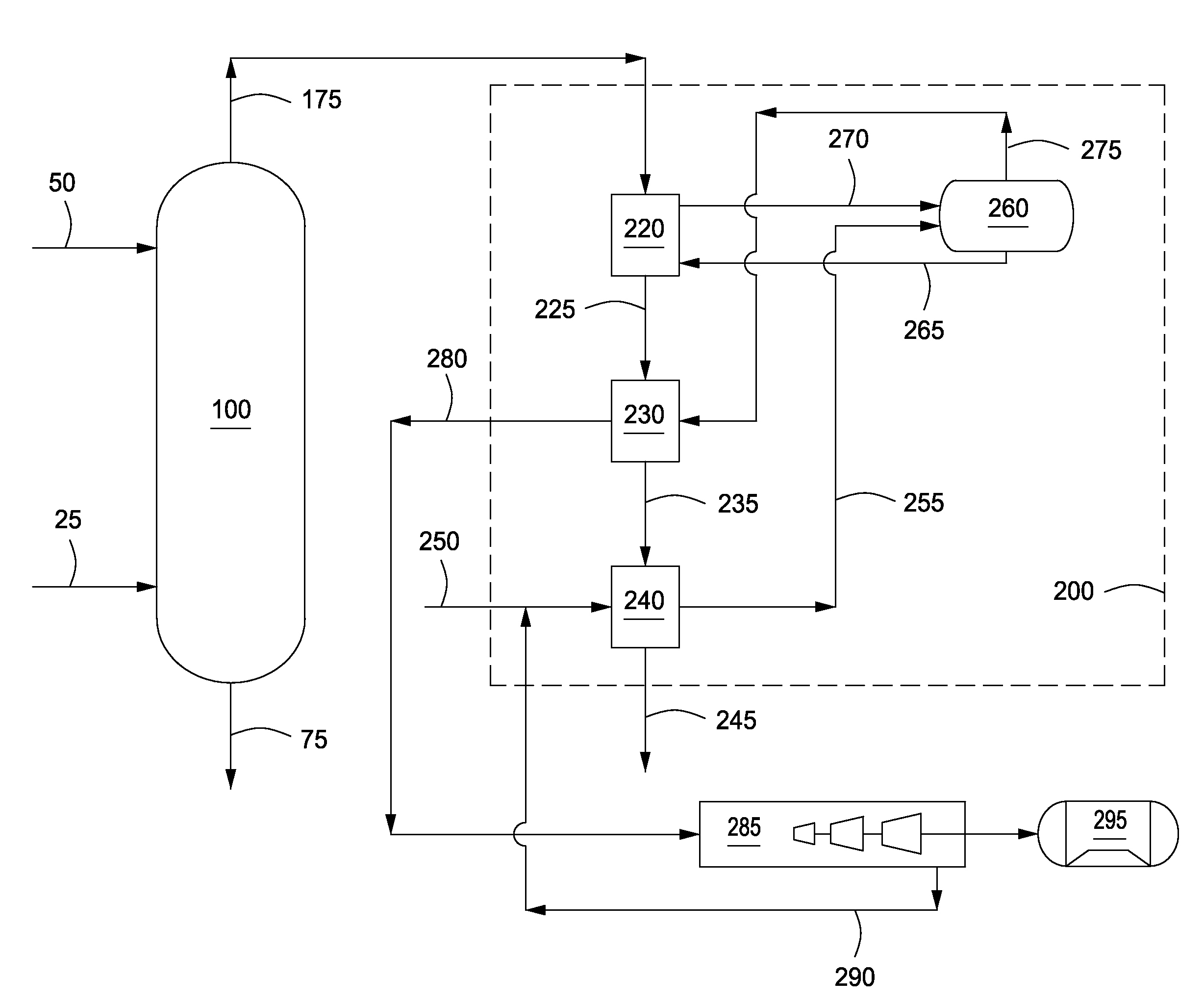

Efficiency of gasification processes

InactiveUS20090151250A1Combustible gas catalytic treatmentGas modification by gas mixingSyngasProcess systems

Systems and processes for producing syngas and power therefrom are provided. One or more feedstocks and one or more oxidants can be combined in a fluidized reaction zone operated at a temperature from 550° C. to 1,050° C. to provide a syngas. Heat can be indirectly exchanged in a first zone from the syngas to a condensate to provide steam. Heat can also be indirectly exchanged in a second zone from the syngas to the steam to provide superheated steam. Heat can then be indirectly exchanged in a third zone from the syngas to provide a cooled syngas and the condensate for the first zone. At least a portion of the superheated steam can be directly supplied to one or more steam turbines to produce power.

Owner:KELLOGG BROWN & ROOT LLC

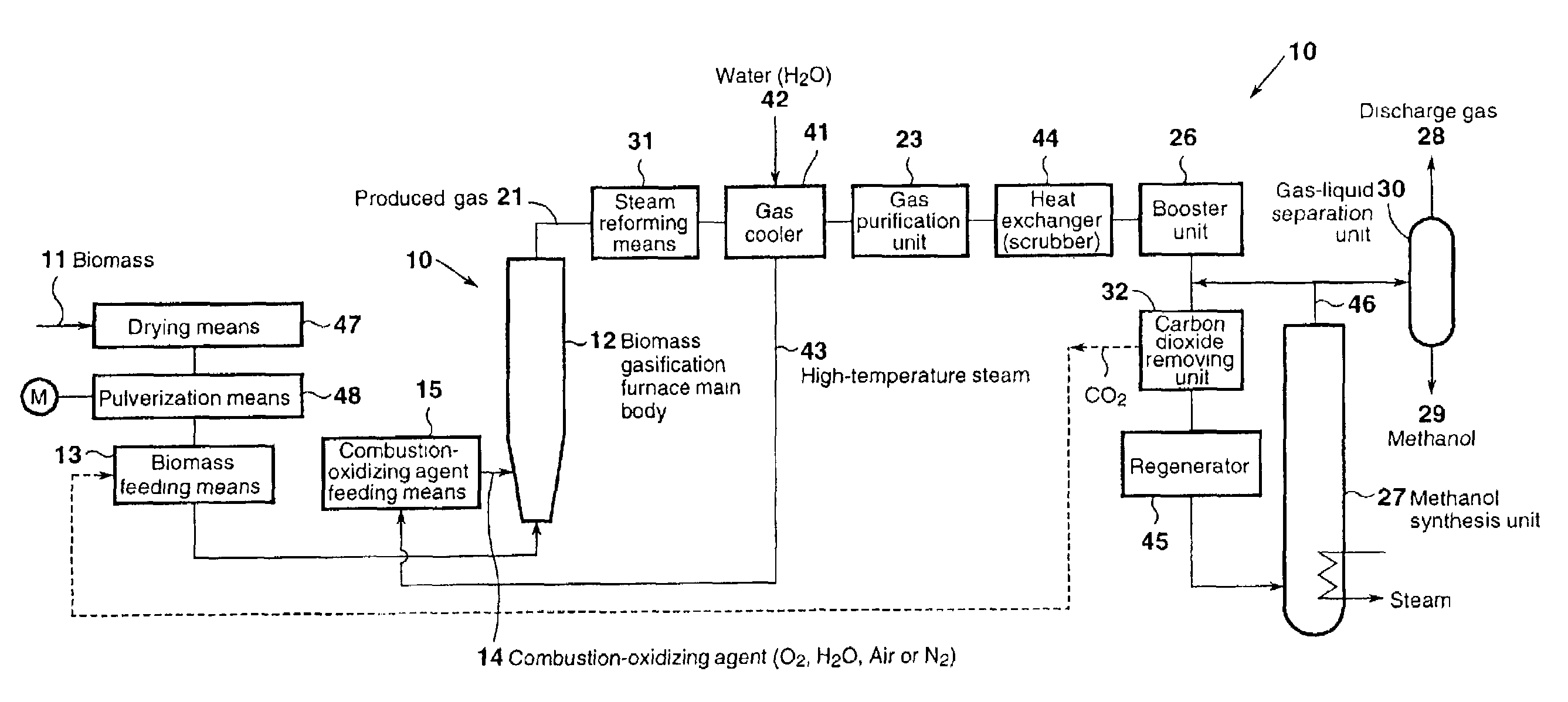

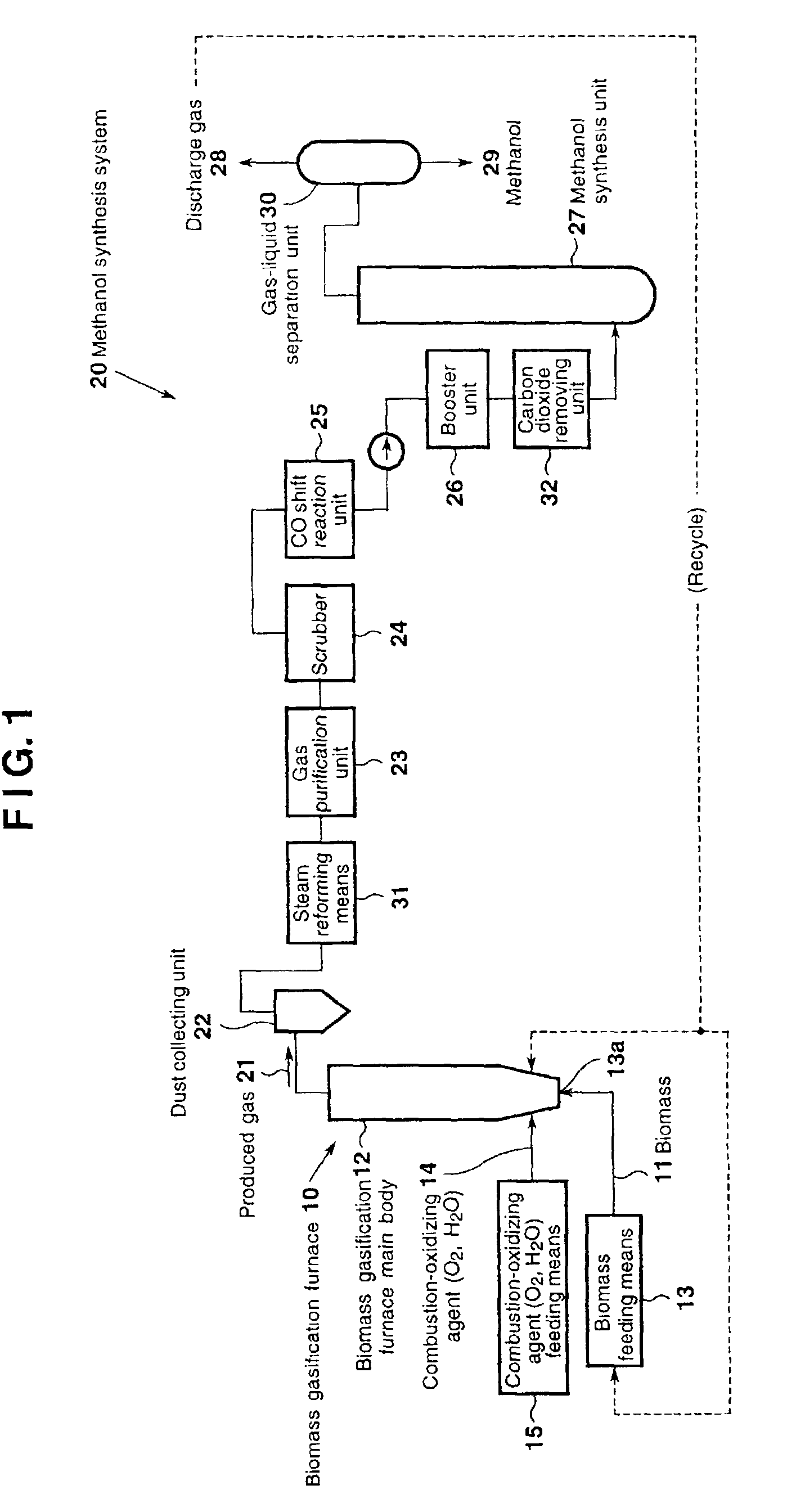

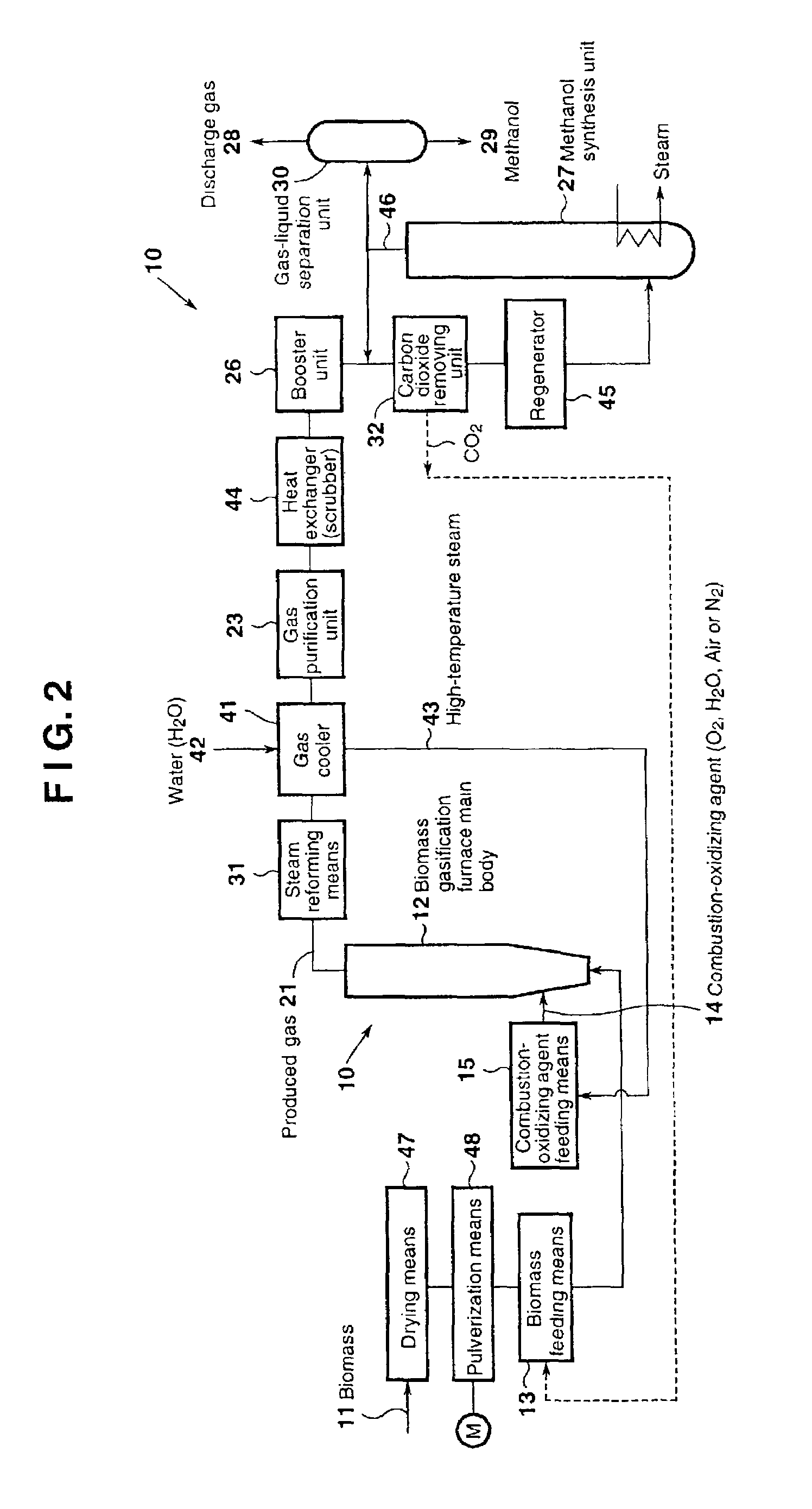

Biomass gasifycation furnace and system for methanol synthesis using gas produced by gasifying biomass

InactiveUS6991769B2Eliminate compression and entanglementCombustible gas catalytic treatmentBiofuelsCombustionProcess engineering

Methanol is synthesized from a gas produced through gasification of biomass serving as a raw material, making use of a biomass feeding means for feeding biomass into a furnace main body and, located above the biomass feeding means, combustion-oxidizing-agent-feeding means for feeding into the furnace main body a combustion-oxidizing agent containing oxygen or a mixture of oxygen and steam.

Owner:MITSUBISHI HEAVY IND LTD

Electrical power generation method

A method of generating electrical power in which a synthesis gas stream generated in a gasifier is combusted in an oxygen transport membrane system of a boiler. The combustion generates heat to raise steam to in turn generate electricity by a generator coupled to a steam turbine. The resultant flue gas can be purified to produce a carbon dioxide product.

Owner:PRAXAIR TECH INC

Method of Operation of Process to Produce Syngas from Carbonaceous Material

InactiveUS20120256131A1High CO/CO molar ratioEffective coolingGasifier feeding meansInternal combustion piston enginesSyngasProcess engineering

A process is provided for producing syngas that is effective for use in downstream processes. The process for producing syngas includes operating a gasification apparatus in a start-up mode until the gasification apparatus and equipment downstream of the gasification apparatus are adequately warmed up to a first target temperature. Upon reaching a first target temperature, the process is then operated in a production mode to produce a second syngas with a higher CO / CO2 molar ratio. Operation in a start-up mode until reaching a first target temperature, provides a process that is effective for reducing fouling in downstream equipment and for providing a second syngas can be more effectively cooled and cleaned.

Owner:INEOS BIO SA

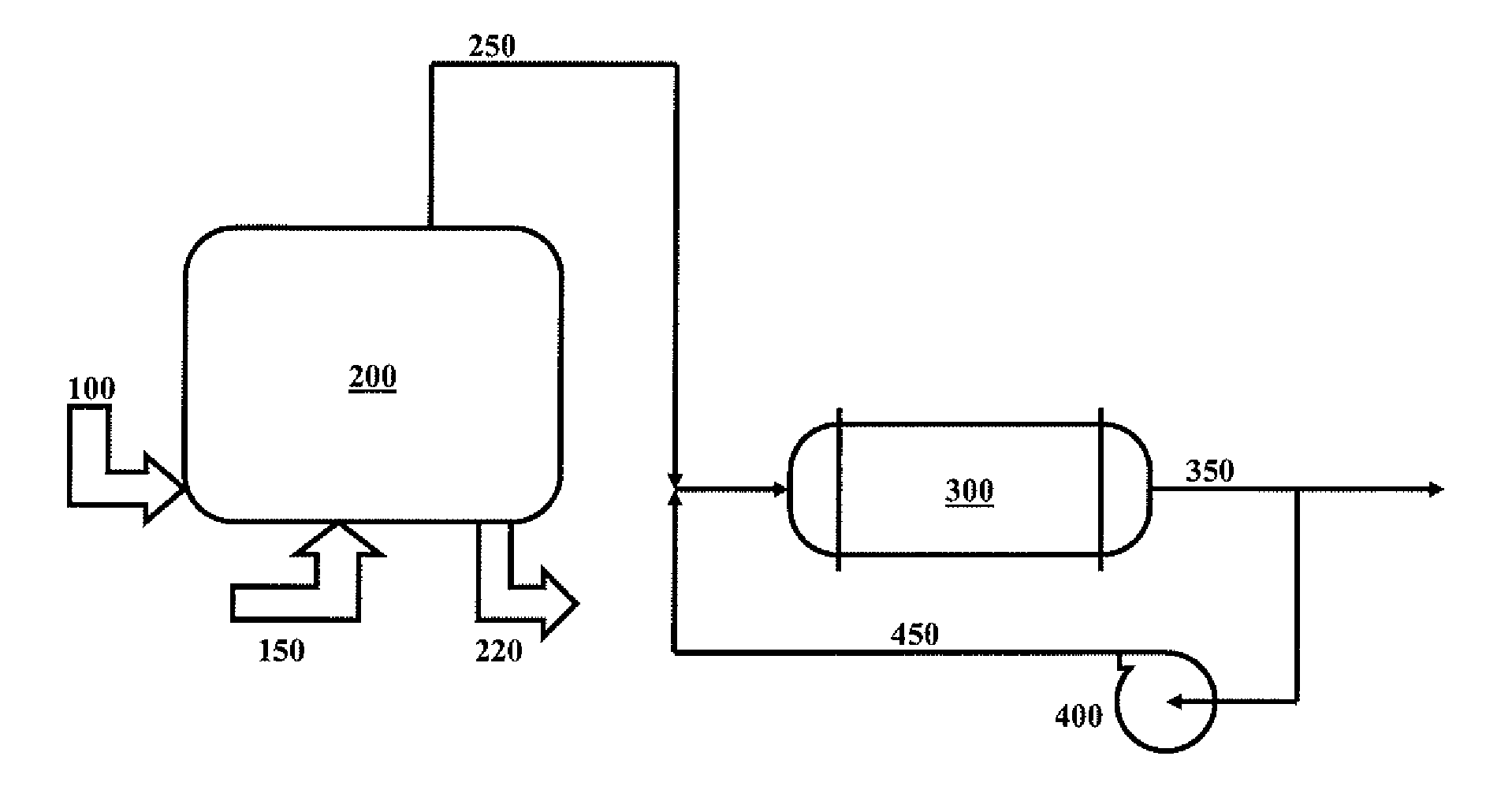

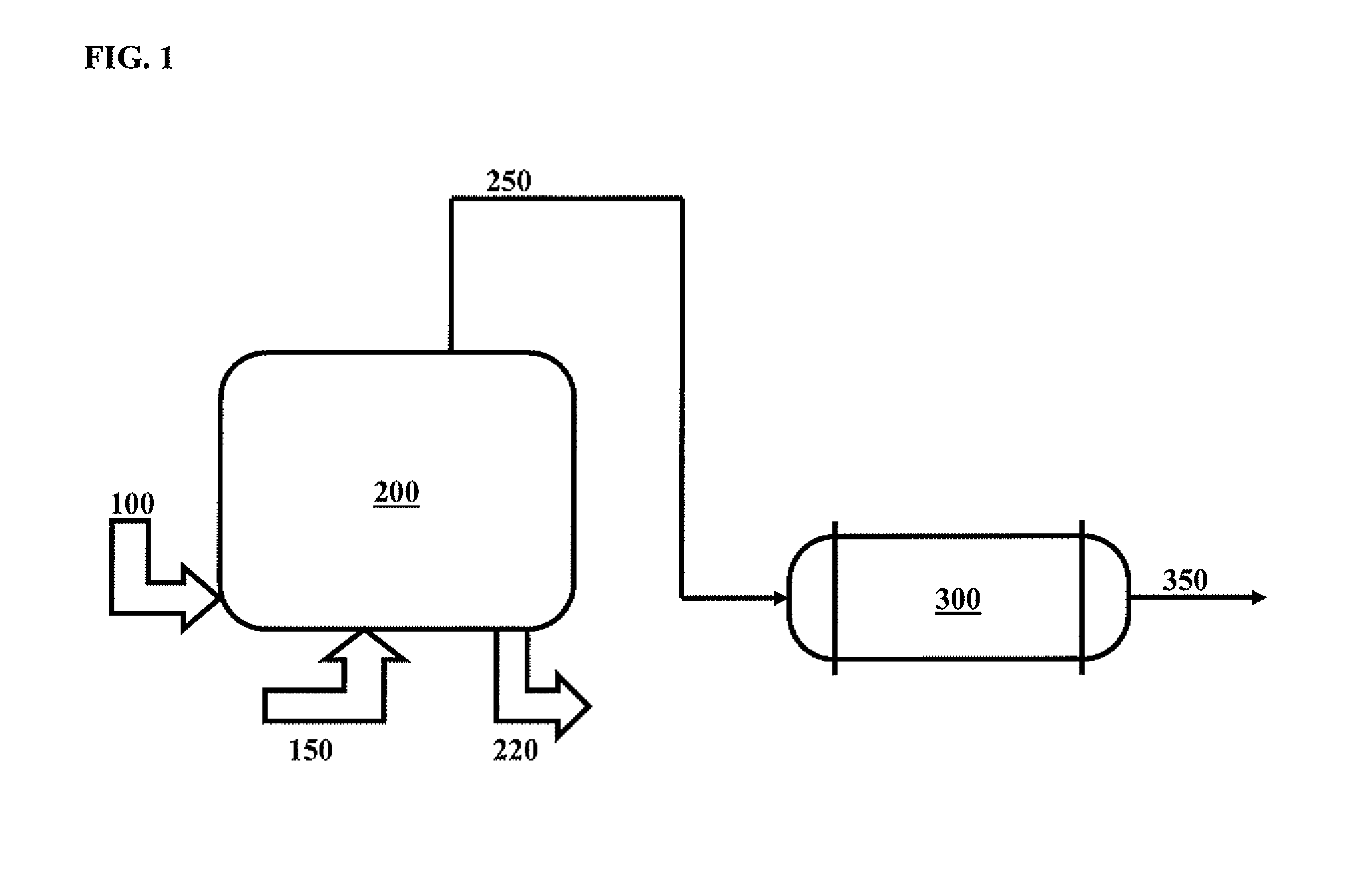

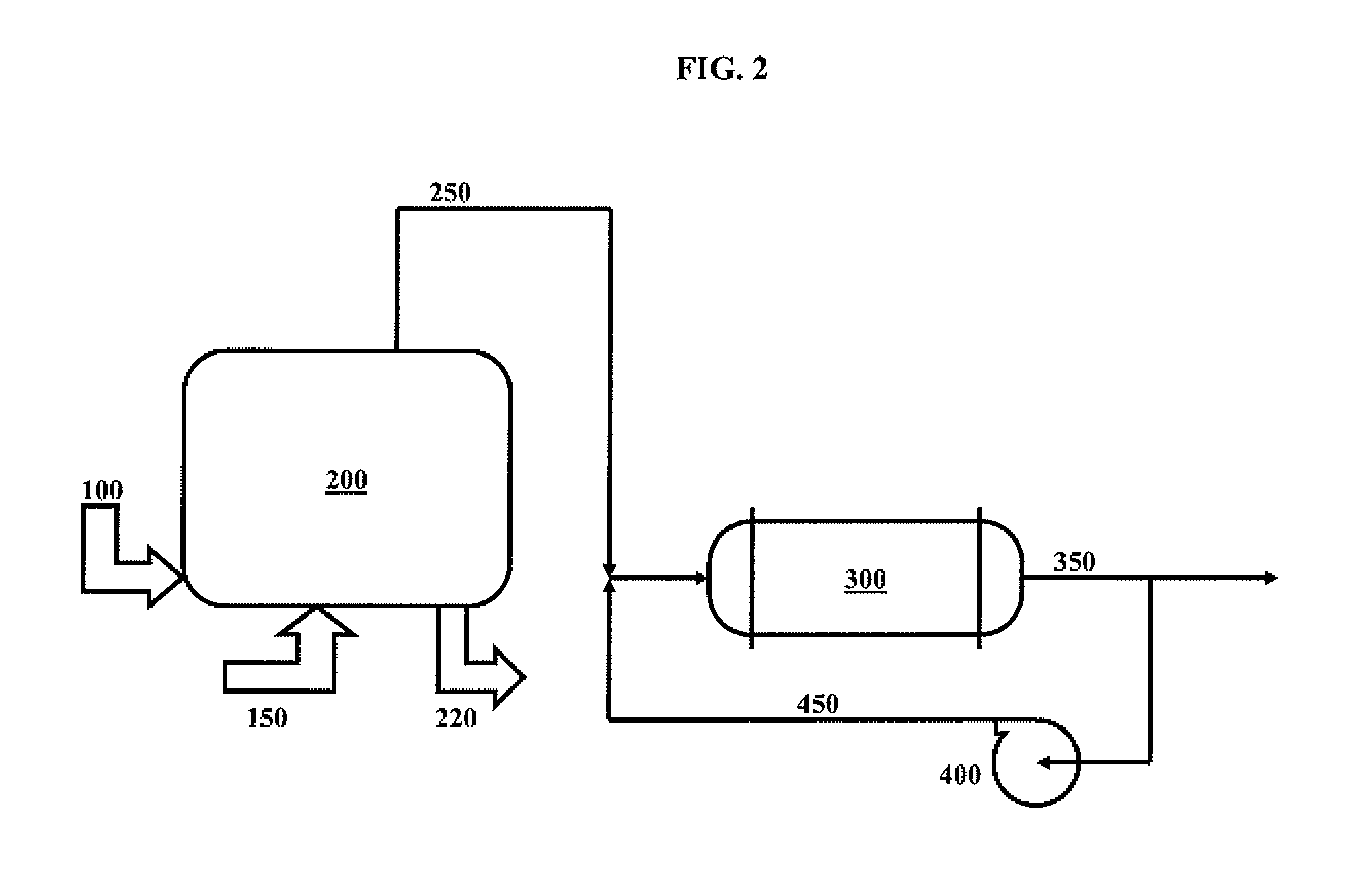

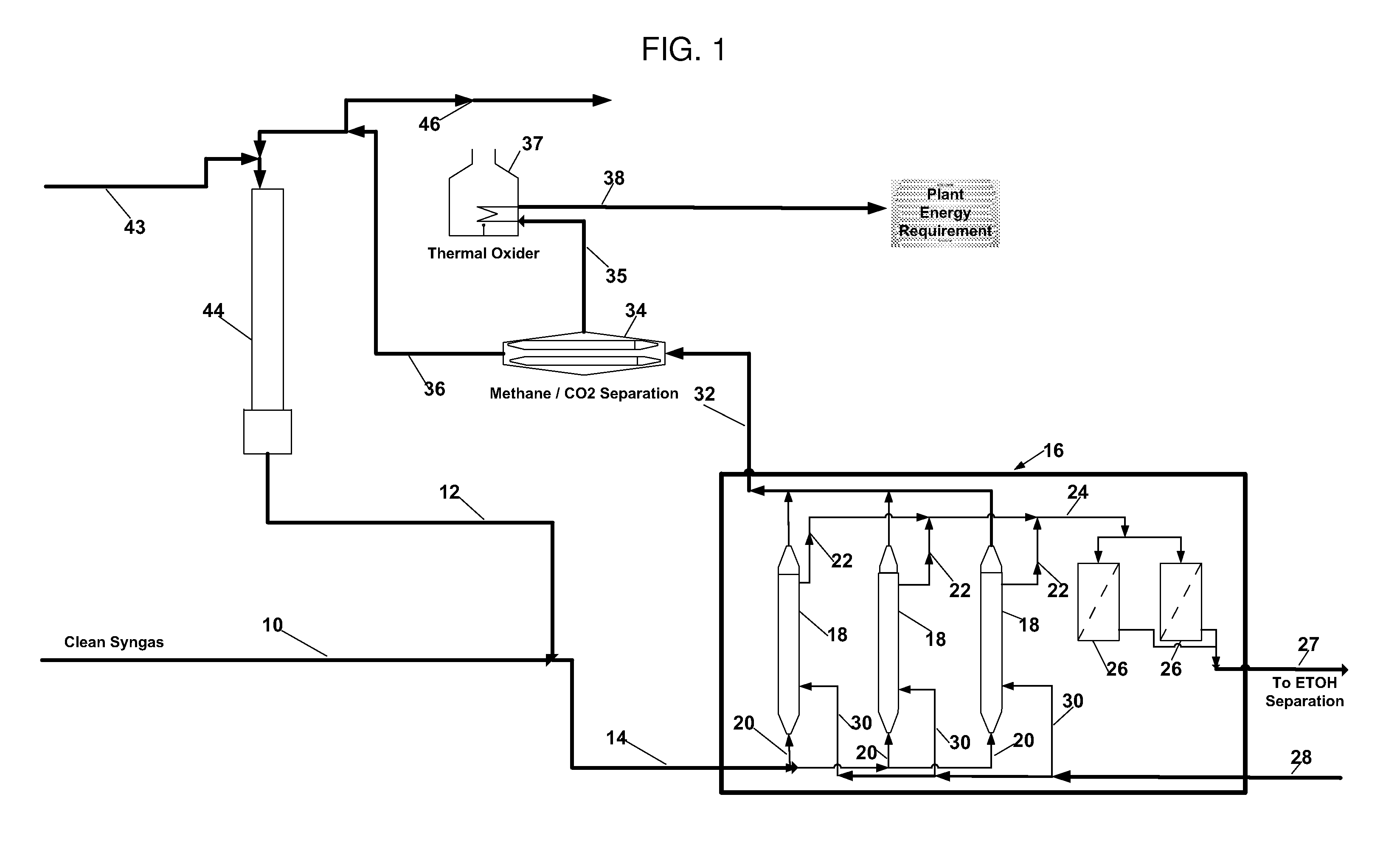

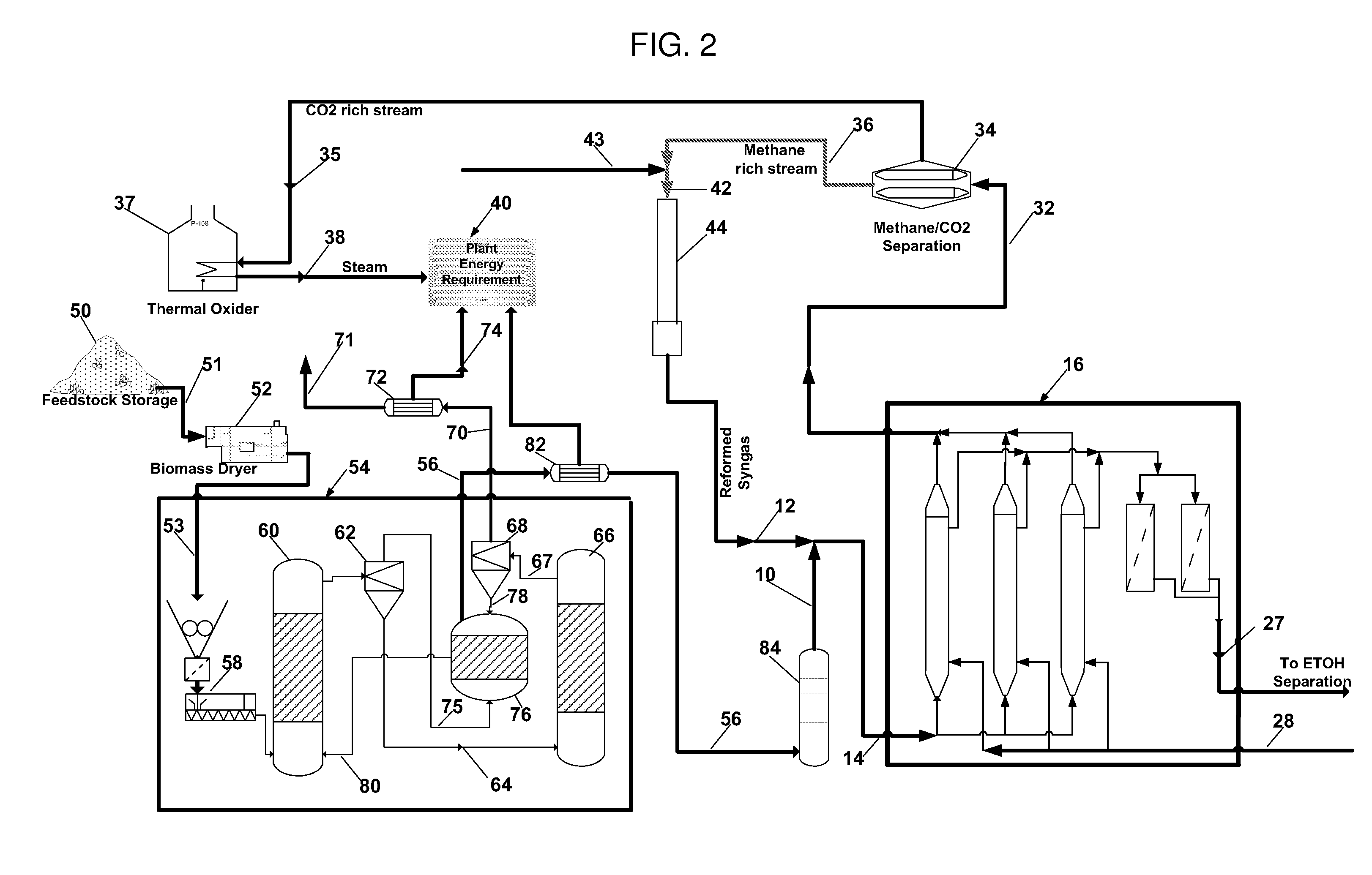

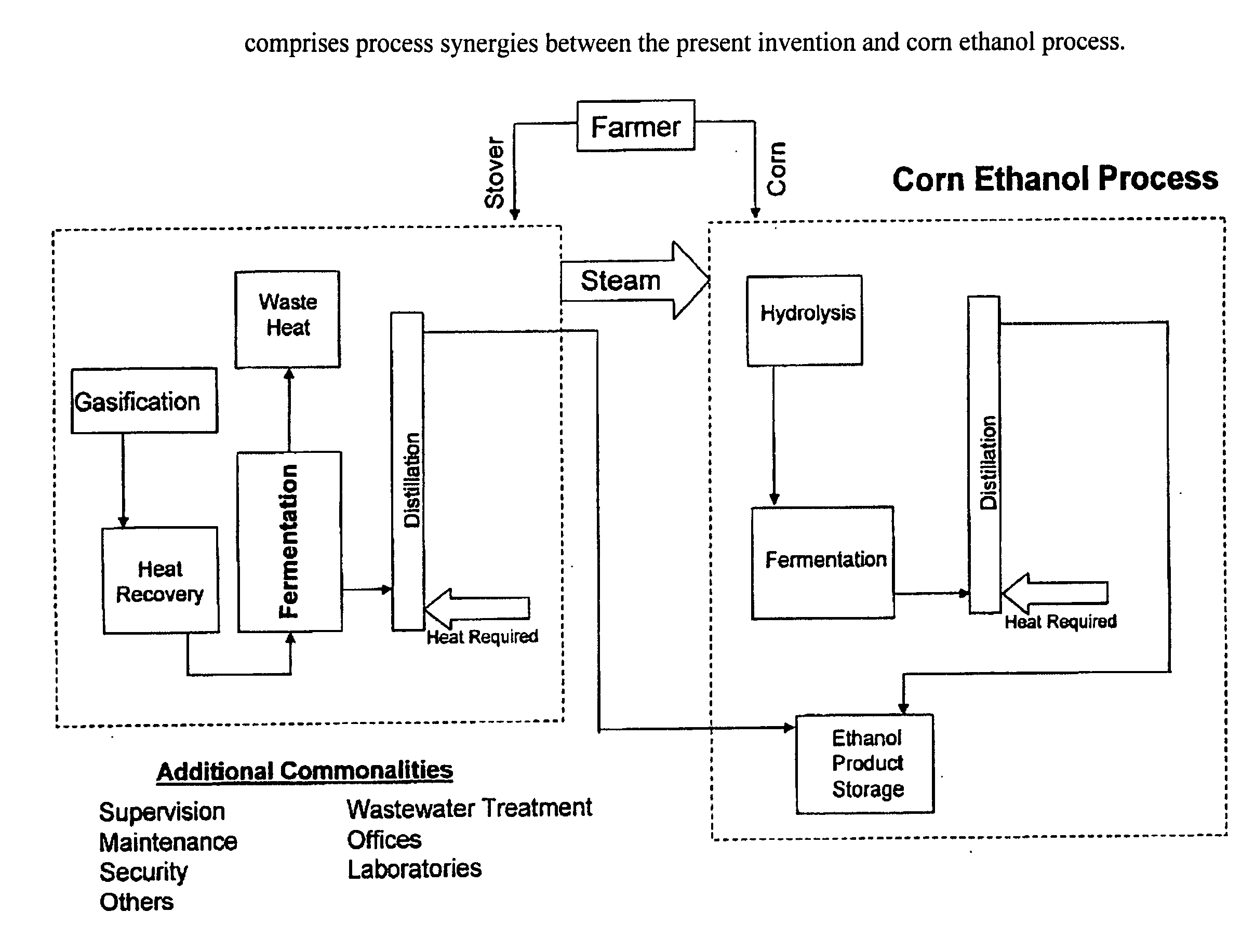

Process for fermentation of syngas from indirect gasification

ActiveUS20100298450A1Easy to separateEffective recoveryDirect heating destructive distillationBiofuelsSyngasLiquid product

Ethanol and other liquid products are produced from biomass using indirect gasification of the biomass to produce a syngas containing CO2, CO, H2 and methane that passes the syngas without substantial removal of the methane to a fermentation zone for the conversion of the CO and CO2 and H2 to ethanol and the production of a methane rich stream followed by the methane reforming of the methane rich stream to produce additional CO and CO2 and H2 that passes to the fermentation zone.

Owner:SYNATA BIO INC

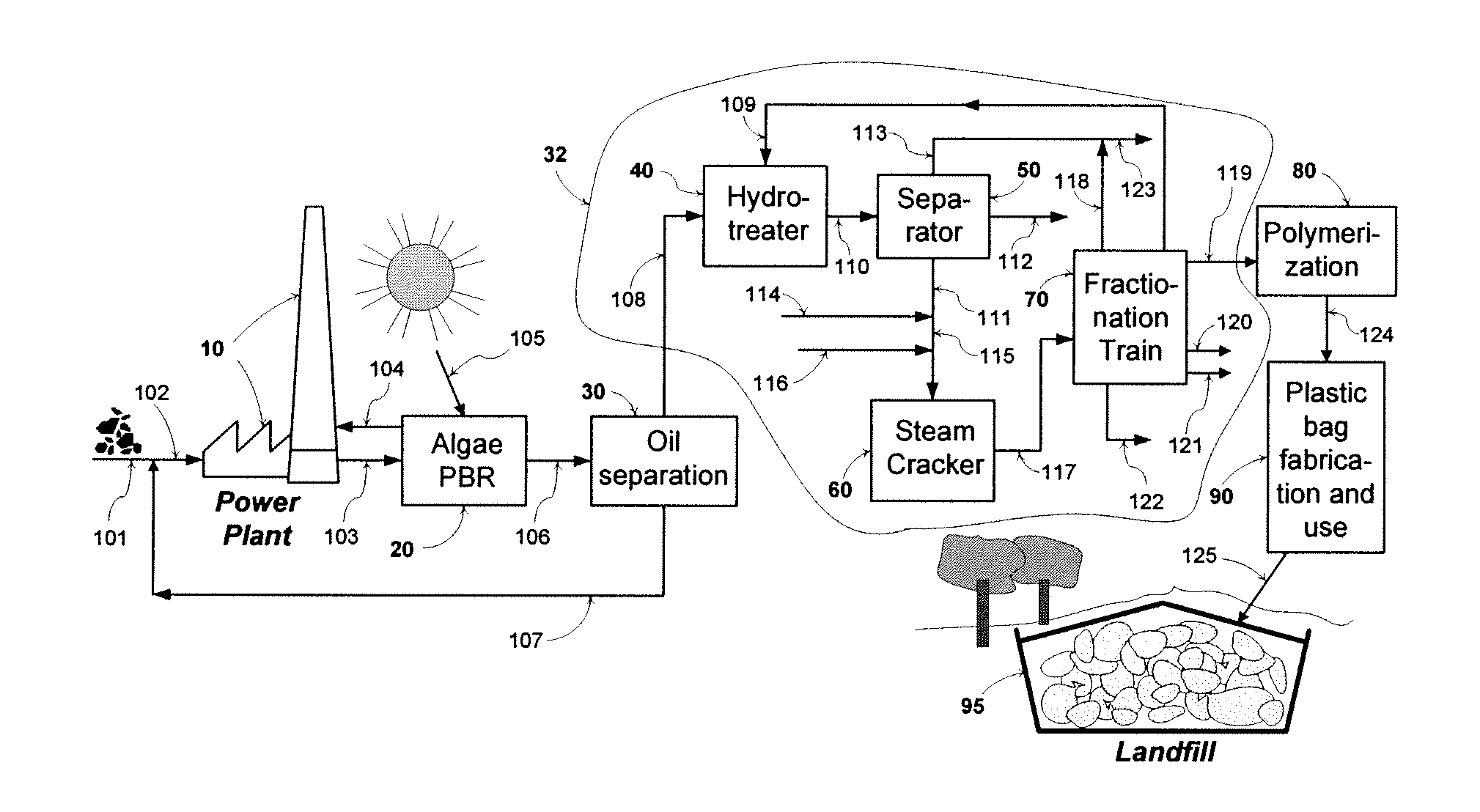

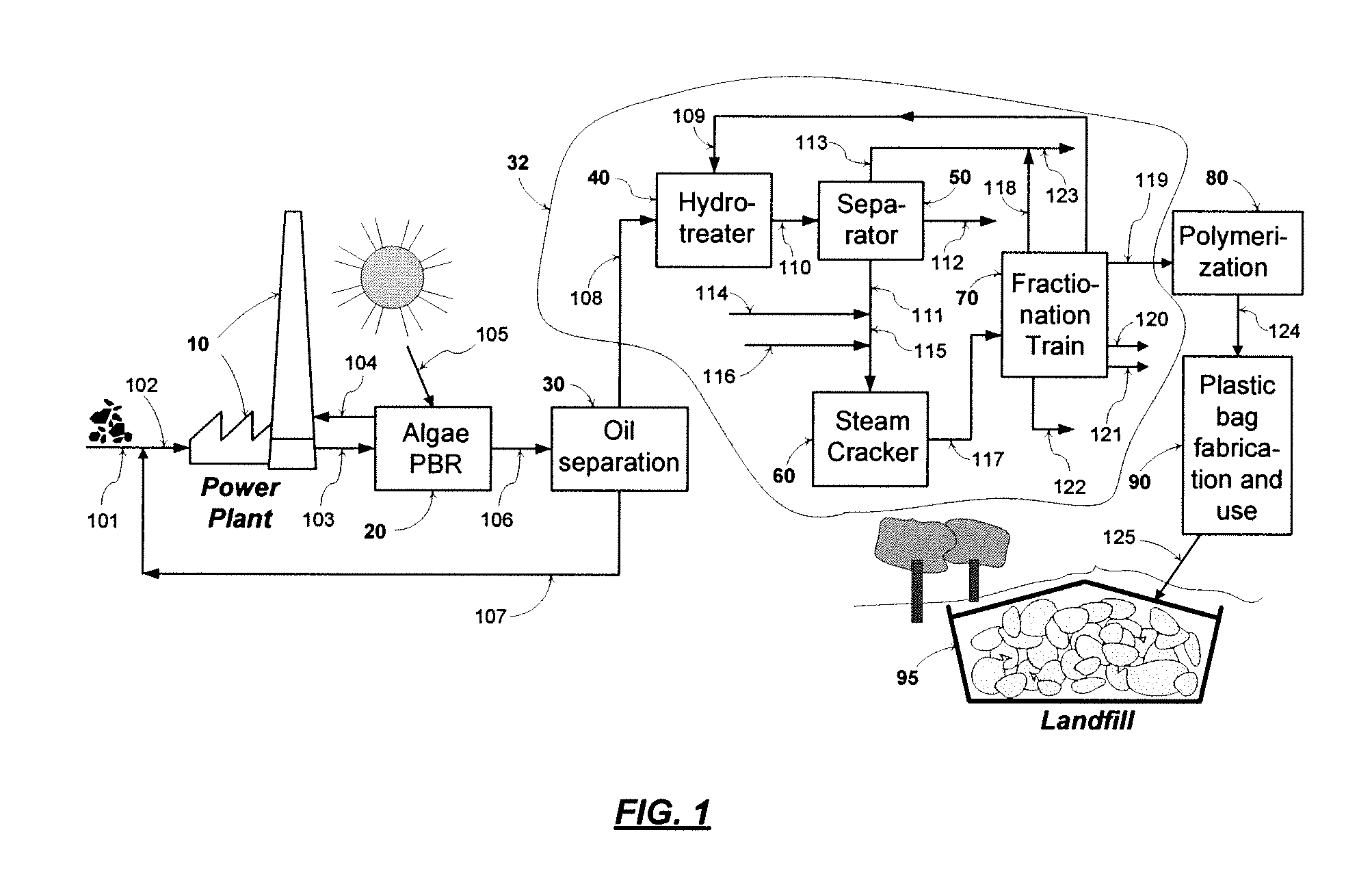

Profitable method for carbon capture and storage

The present invention generally relates to a method for sequestering carbon dioxide. Biomass is converted into paraffinic hydrocarbons. The paraffinic hydrocarbons are steam cracked into olefins. The olefins are polymerized into non-biodegradable polyolefins.

Owner:REG SYNTHETIC FUELS LLC

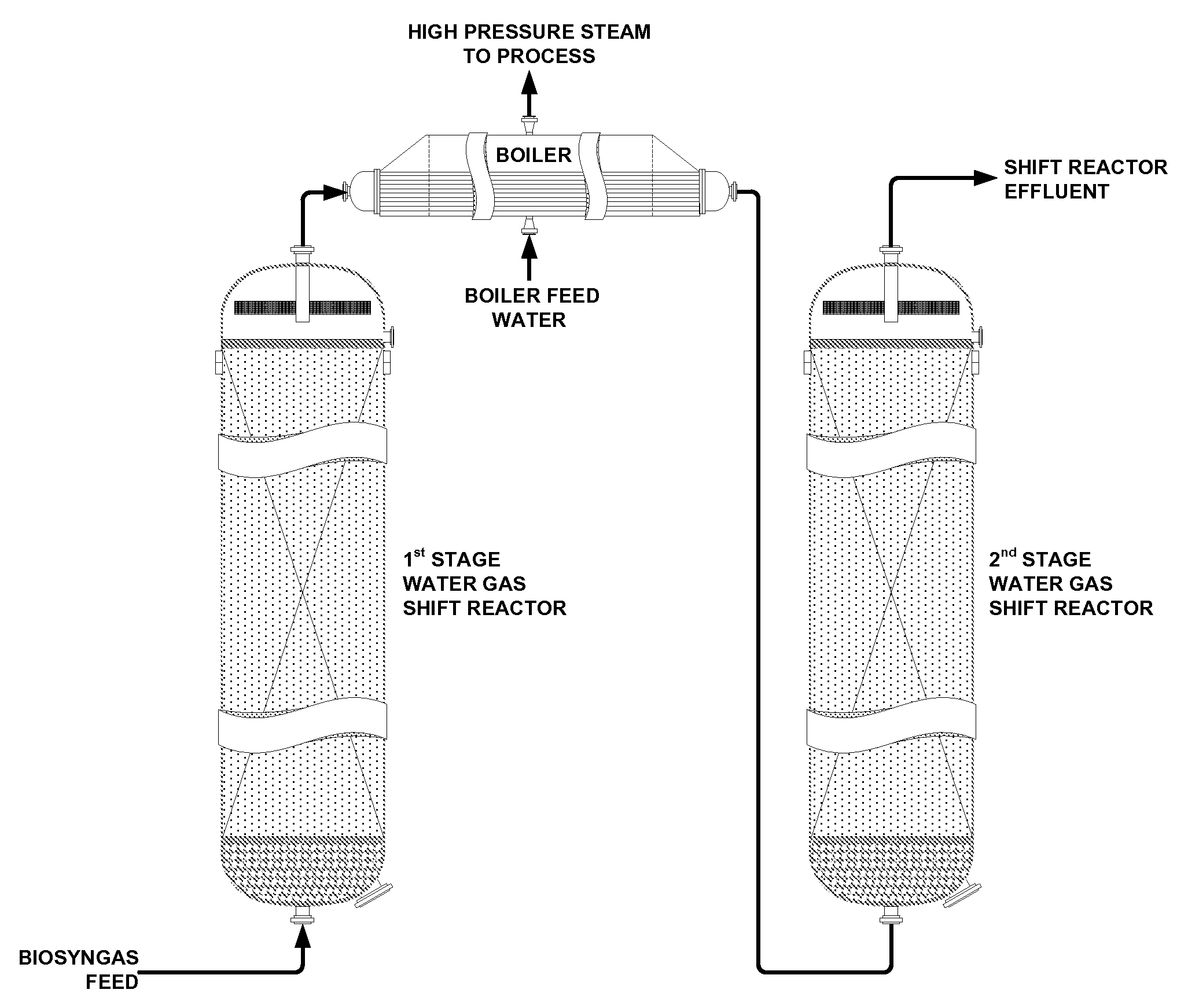

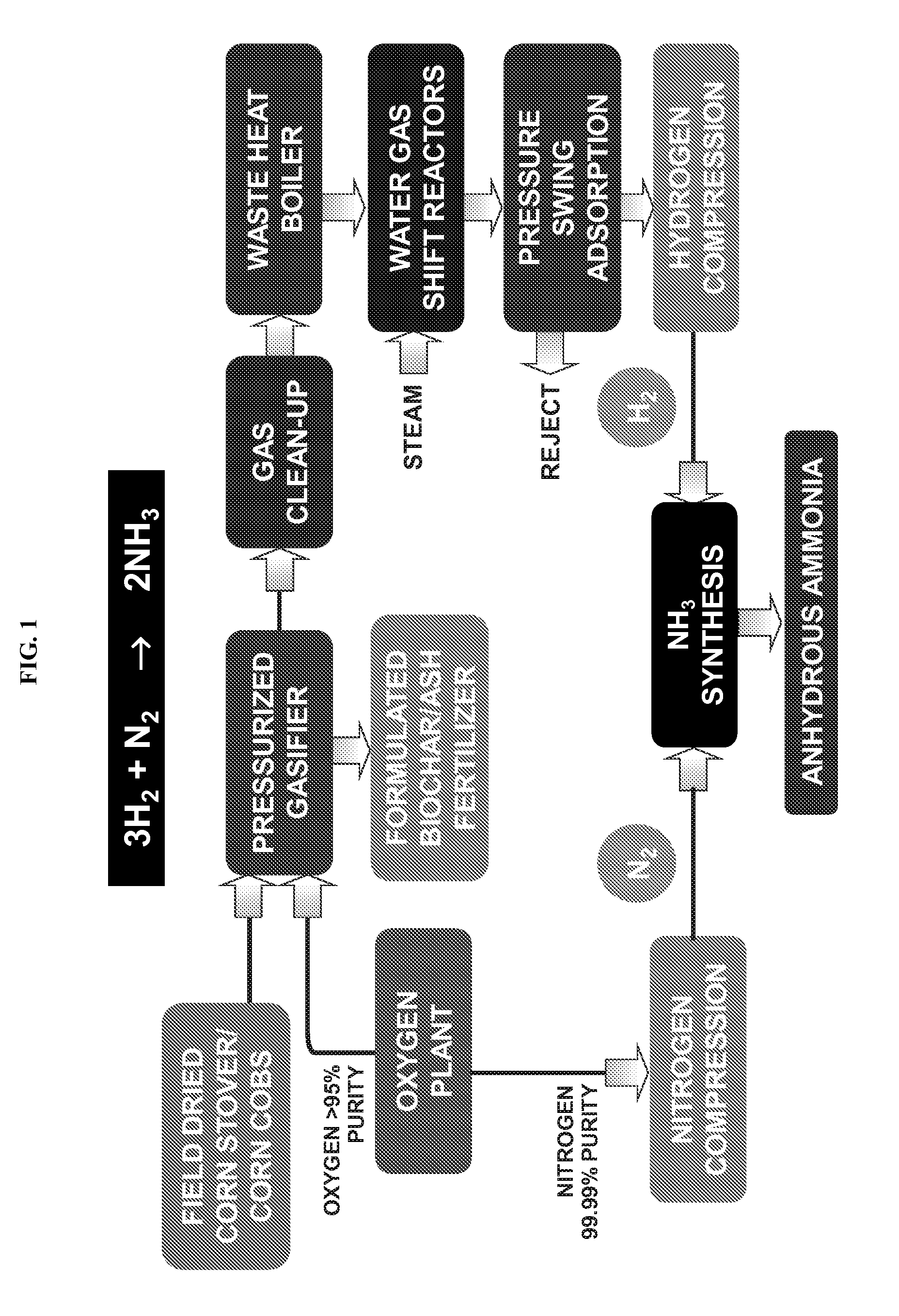

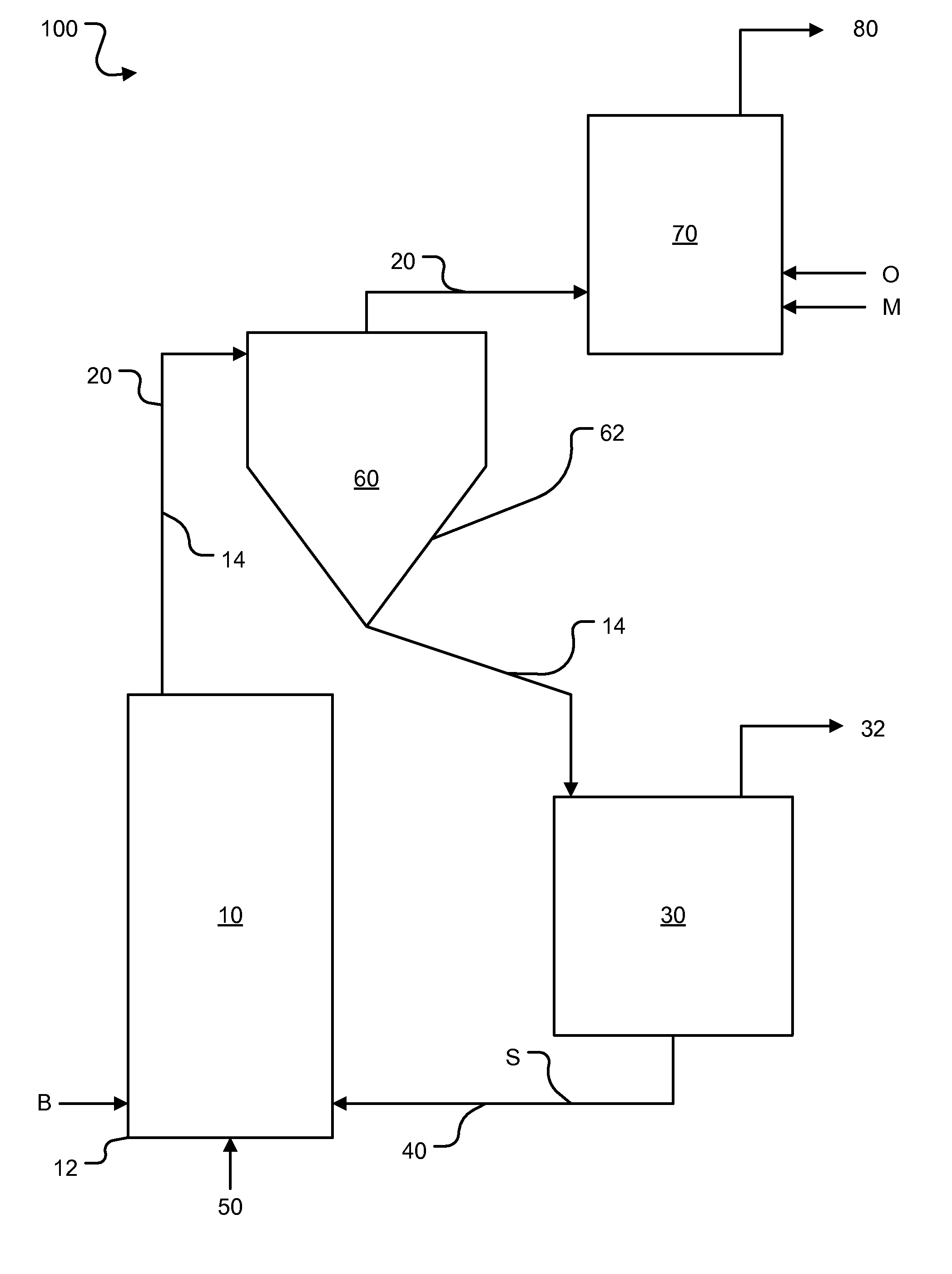

Process for producing ammonia from biomass

ActiveUS20100040527A1Methane significantly reduced.Eliminate all inertsProductsReagentsHydrogenActive component

This invention provides a process for making ammonia from biomass. The biomass may be first reacted with oxygen and steam to generate a biosyngas comprising hydrogen (H2) and carbon monoxide (CO) as the active components. The gasification step may be regulated to reduce the amount of methane in the biosyngas that may leave the gasifier.

Owner:SYNT

Systems and methods for oxidation of synthesis gas tar

Owner:RES USA LLC

Systems and methods for oxidation of synthesis gas tar

InactiveUS20090090053A1Improve propertiesMuffle furnacesGas purification by catalytic conversionTarProduct gas

Owner:RES USA LLC

Process for the treatment of waste streams

The present invention is directed to a process for treating, reducing, and / or stabilizing various wastes or flue gases. In one embodiment, the process is directed to treatment of alkali bearing wastes that include nitrate and / or nitrite-rich wastes. Optionally, the disclosed method can be utilized for treatment of hazardous wastes, including radioactive hazardous waste compounds. In general, the present invention includes processing a waste or gaseous stream with the addition of suitable carbon-containing additives to treat and reduce nitrogen-containing compounds in the waste. Additives may be gaseous, liquid or solid reduction-promoting agents, catalysts, and the like. The reaction products obtained from the process of the invention include mainly alkali carbonate, nitrogen, hydrogen, carbon monoxide and carbon dioxide.

Owner:MFG & TECH CONVERSION INT

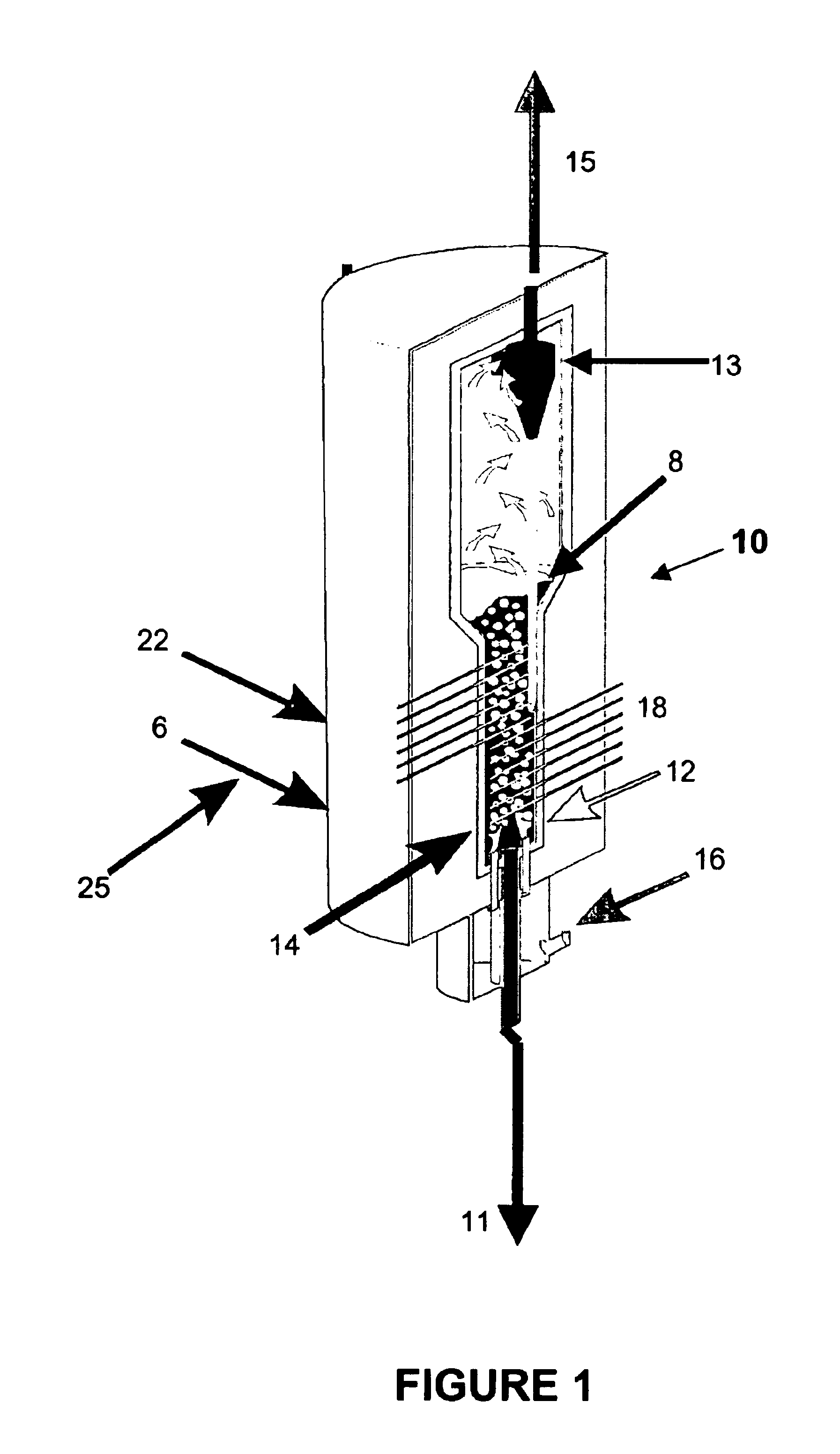

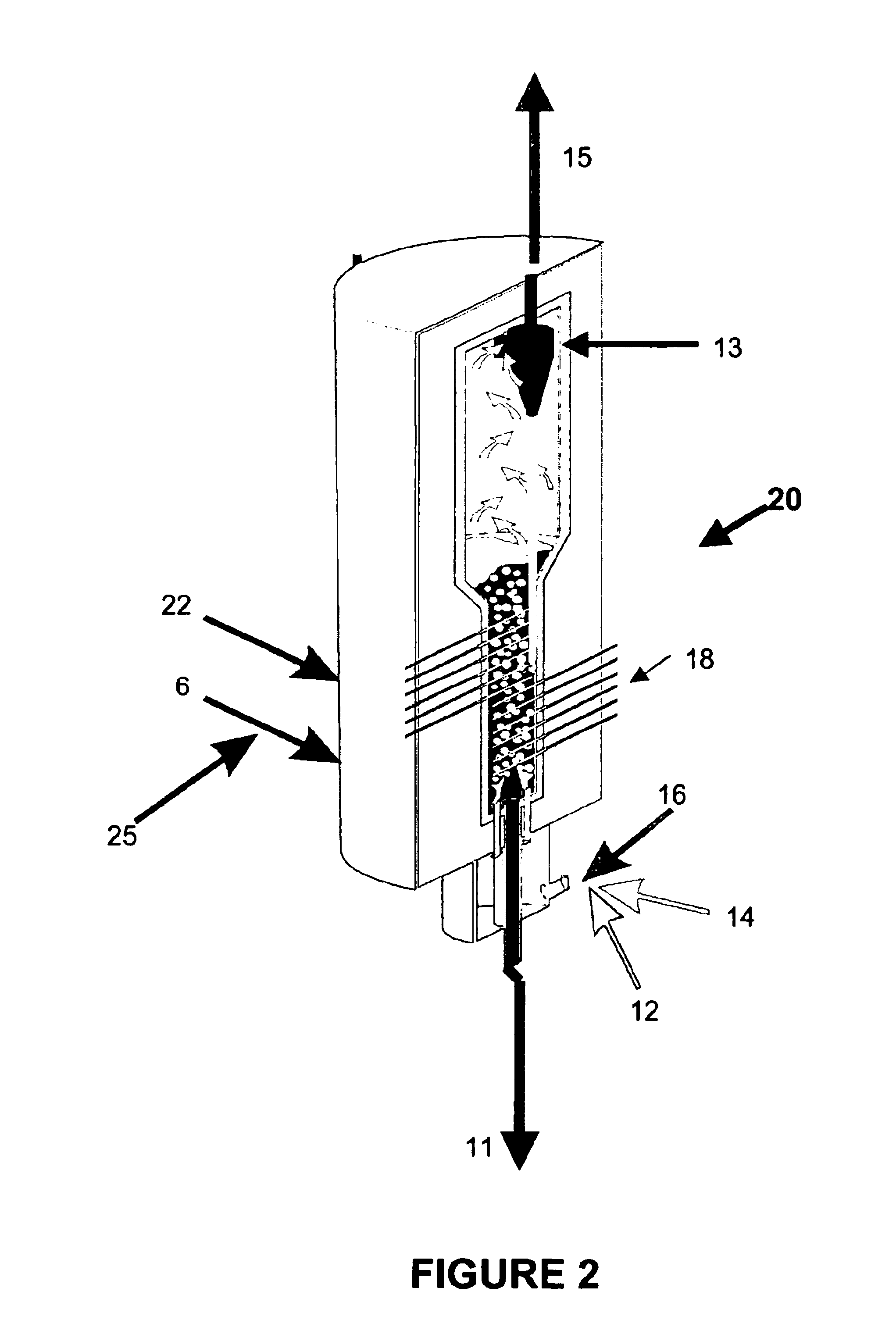

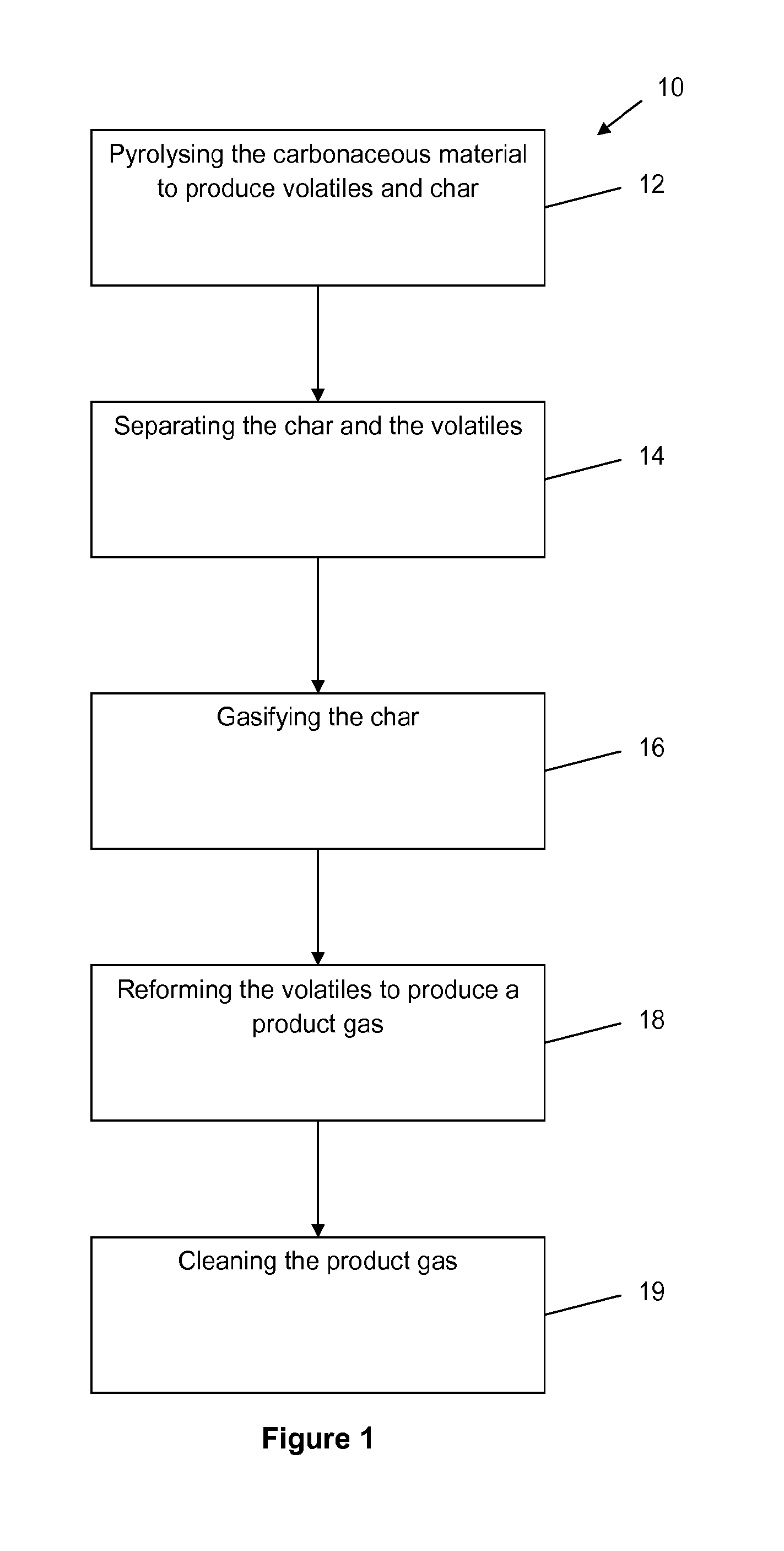

Method of gasifying carbonaceous material and a gasification system

InactiveUS20130306913A1Minimize interactionHigh hydrogen contentCombustible gas coke oven heatingGasifier mechanical detailsProduct gasOrganic chemistry

A method of gasifying carbonaceous material is described. The method comprises a first step of pyrolysing and partially gasifying the carbonaceous material to produce volatiles and char. The volatiles and the char are then separated and, subsequently, the char is gasified and the volatiles are reformed. The raw product gas is then finally cleaned with char or char-supported catalysts or other catalysts.

Owner:CURTAIN UNIV OF TECH

Low temperature gasification facility with a horizontally oriented gasifier

A low-temperature gasification system comprising a horizontally oriented gasifier is provided that optimizes the extraction of gaseous molecules from carbonaceous feedstock while minimizing waste heat. The system comprises a plurality of integrated subsystems that work together to convert municipal solid waste (MSW) into electricity. The subsystems comprised by the low-temperature gasification system are: a Municipal Solid Waste Handling System; a Plastics Handling System; a Horizontally Oriented Gasifier with Lateral Transfer Units System; a Gas Reformulating System; a Heat Recycling System; a Gas Conditioning System; a Residue Conditioning System; a Gas Homogenization System and a Control System.

Owner:PLASCO CONVERSION TECH INC

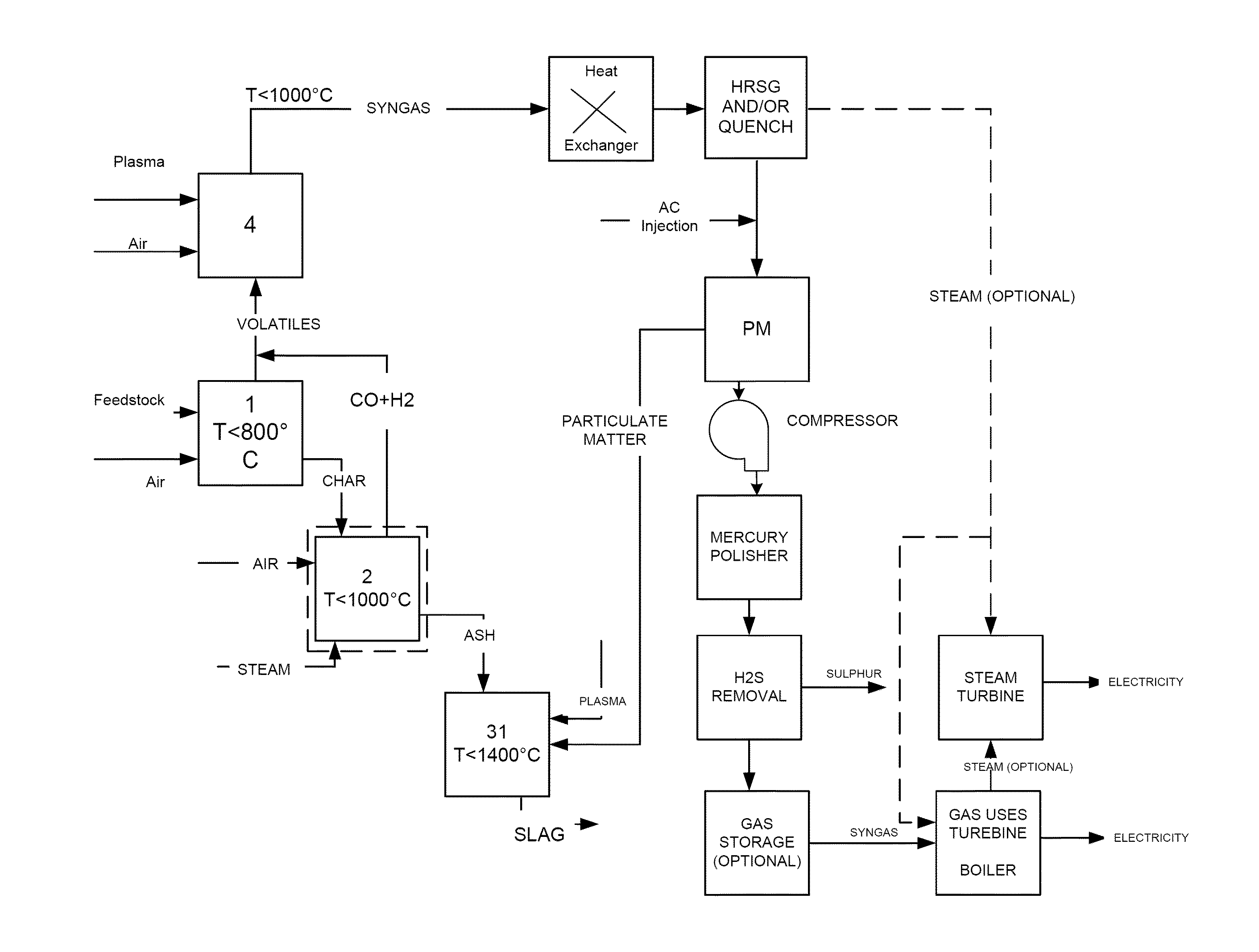

Gasification system with processed feedstock/char conversion and gas reformulation

ActiveUS20140332724A1Gasifier mechanical detailsCombustible gas thermal treatmentSyngasVitrification

The invention provides a system designed for the complete conversion of carbonaceous feedstock into syngas and slag. The system comprises a primary chamber for the volatilization of feedstock generating a primary chamber gas (an offgas); a secondary chamber for the further conversion of processed feedstock to a secondary chamber gas (a syngas) and a residue; a gas-reformulating zone for processing gas generated within one or more of the chambers; and a melting chamber for vitrifying residue. The primary chamber comprises direct or indirect feedstock additive capabilities in order to adjust the carbon content of the feedstock.The system also comprises a control system for use with the gasification system to monitor and regulate the different stages of the process to ensure the efficient and complete conversion of the carbonaceous feedstock into a syngas product.

Owner:PLASCO CONVERSION TECH INC

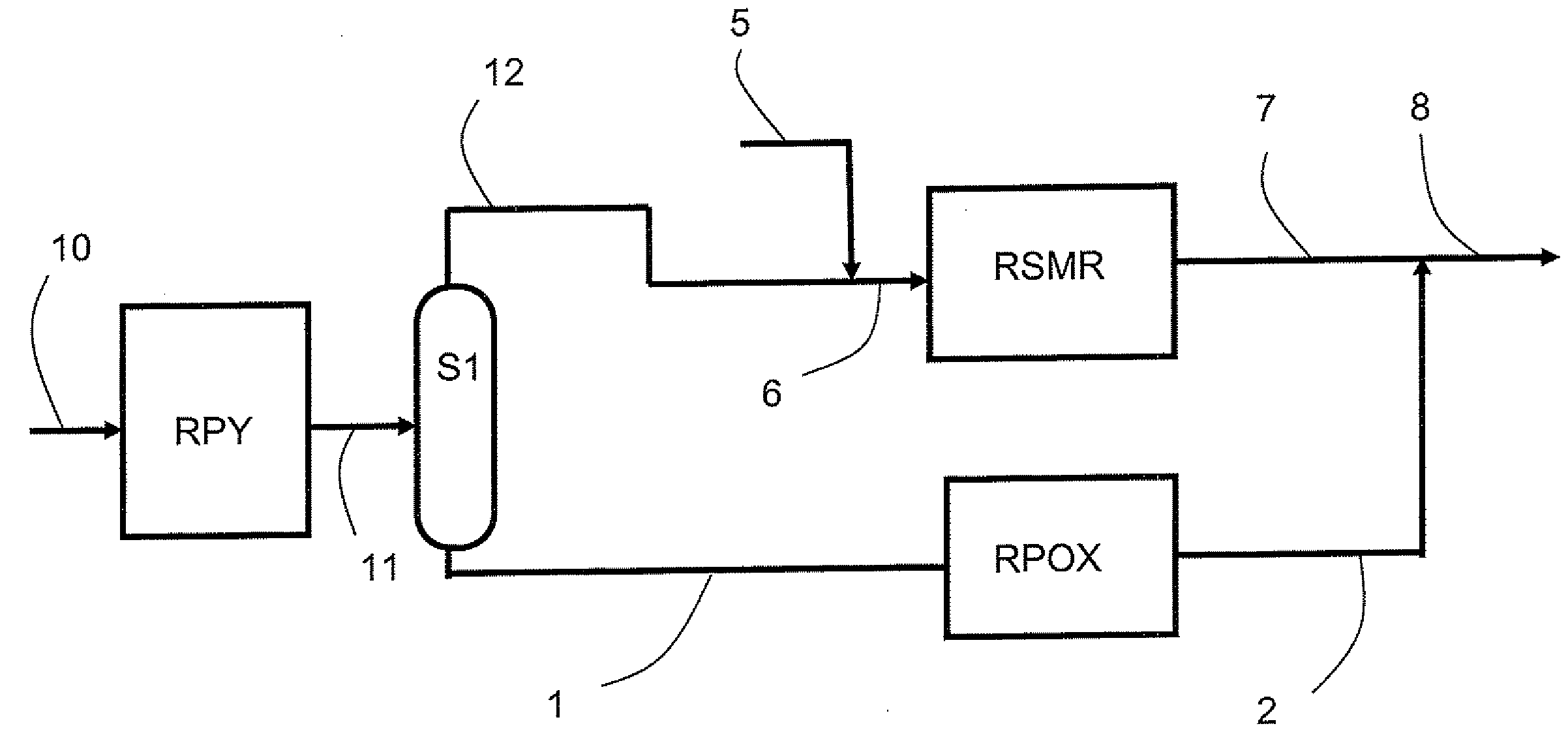

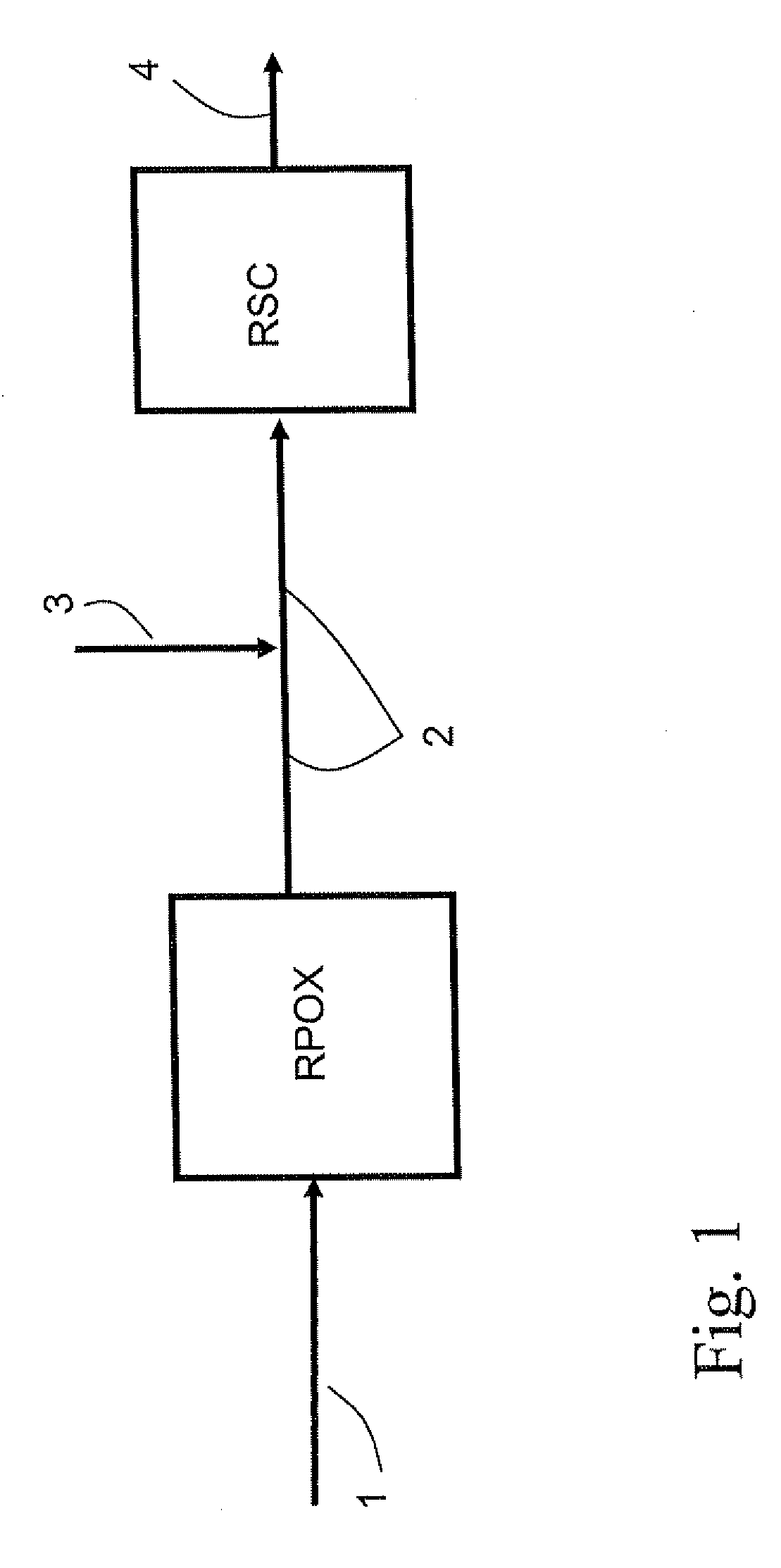

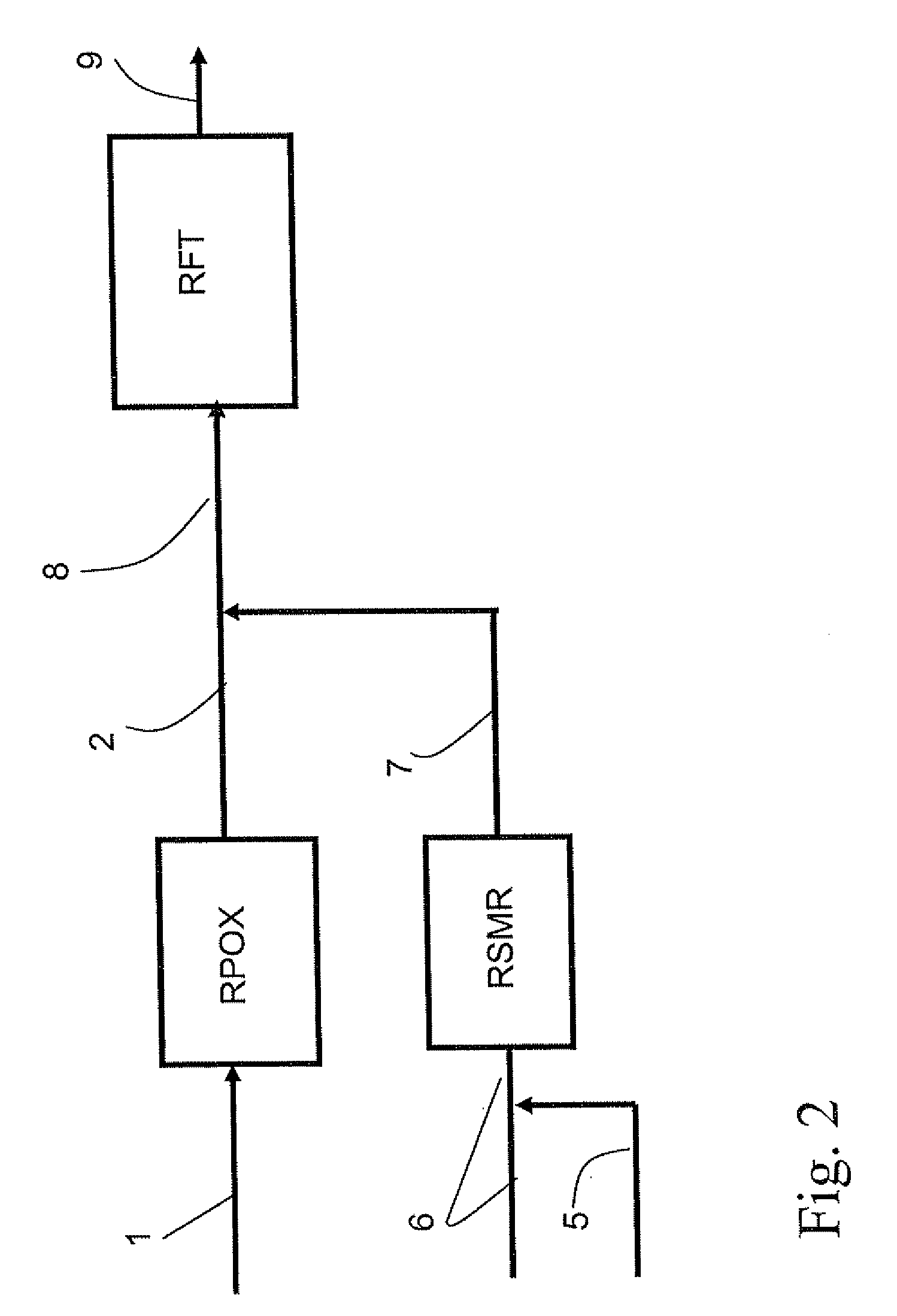

Method of producing synthetic gas with partial oxidation and steam reforming

InactiveUS20100298449A1Gas modification by gas mixingLiquid hydrocarbon mixture productionSteam reformingSyngas

Process for producing liquid hydrocarbons from a heavy feedstock such as biomass, carbon, lignite, or heavy petroleum residue comprising:A partial oxidation b) of the heavy feedstock, producing a synthesis gas SG1, with an H2 / CO ratio <1;A vapor reforming c) of a light feedstock that comprises hydrocarbons having at most 4 carbon atoms, for the production of a synthesis gas SG2 with an H2 / CO ratio >3;A Fischer-Tropsch conversion into liquid hydrocarbons of a synthesis gas SG, mixture of at least a portion of SG1 and at least a portion of SG2, in proportions such that SG has an H2 / CO ratio of between 1.2 and 2.5.The light feedstock comprises hydrocarbons that have less than 10 carbon atoms C1-C10 that are obtained from a pretreatment of the heavy feedstock and / or are produced in the Fischer-Tropsch stage and / or during a downstream hydrocracking.

Owner:INST FR DU PETROLE

Methods for sequestering carbon dioxide into alcohols via gasification fermentation

The present invention is directed to improvements in gasification for use with synthesis gas fermentation. Further, the present invention is directed to improvements in gasification for the production of alcohols from a gaseous substrate containing at least one reducing gas containing at least one microorganism.

Owner:JUPENG BIO HK LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com