Method of Operation of Process to Produce Syngas from Carbonaceous Material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

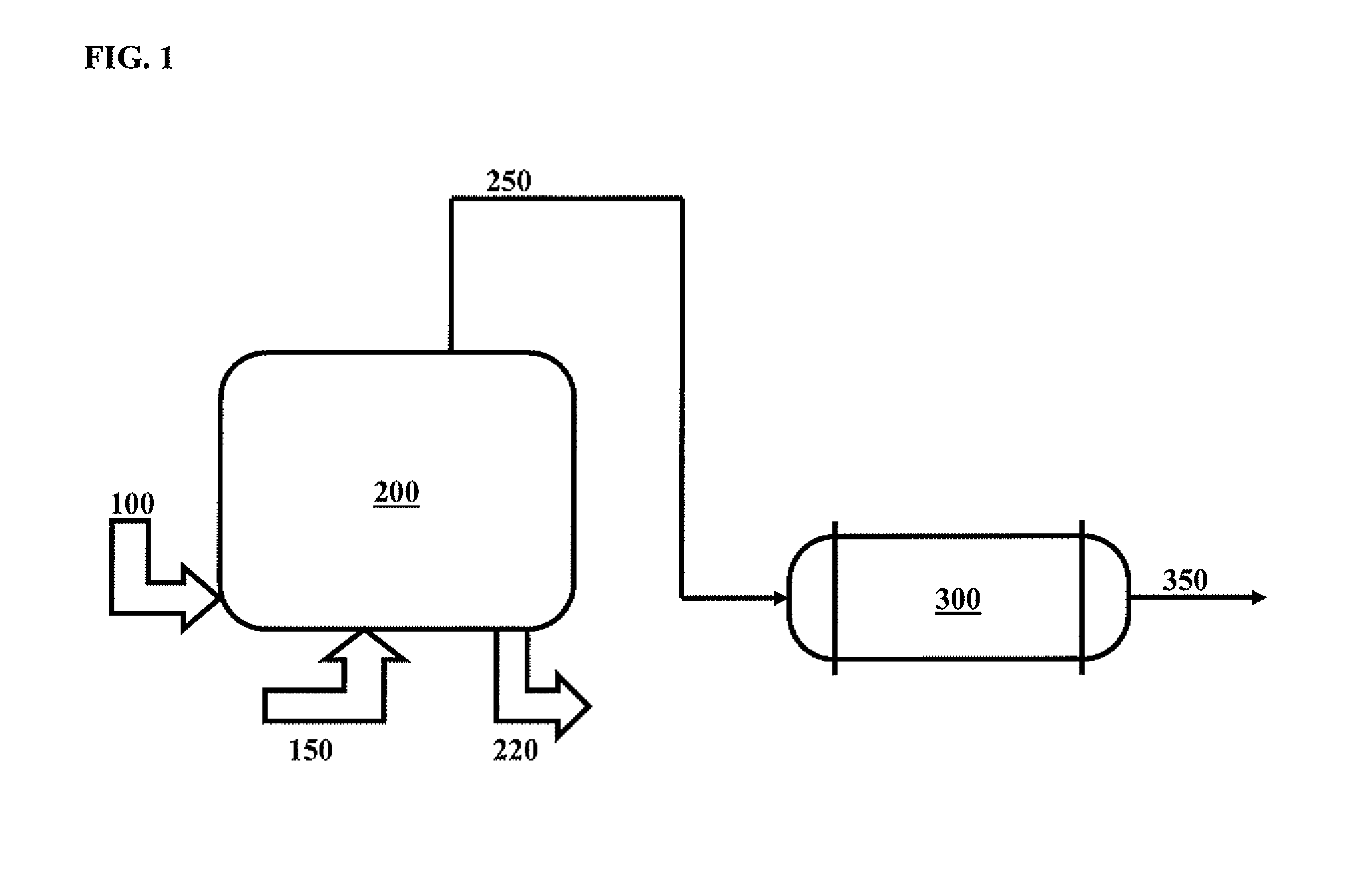

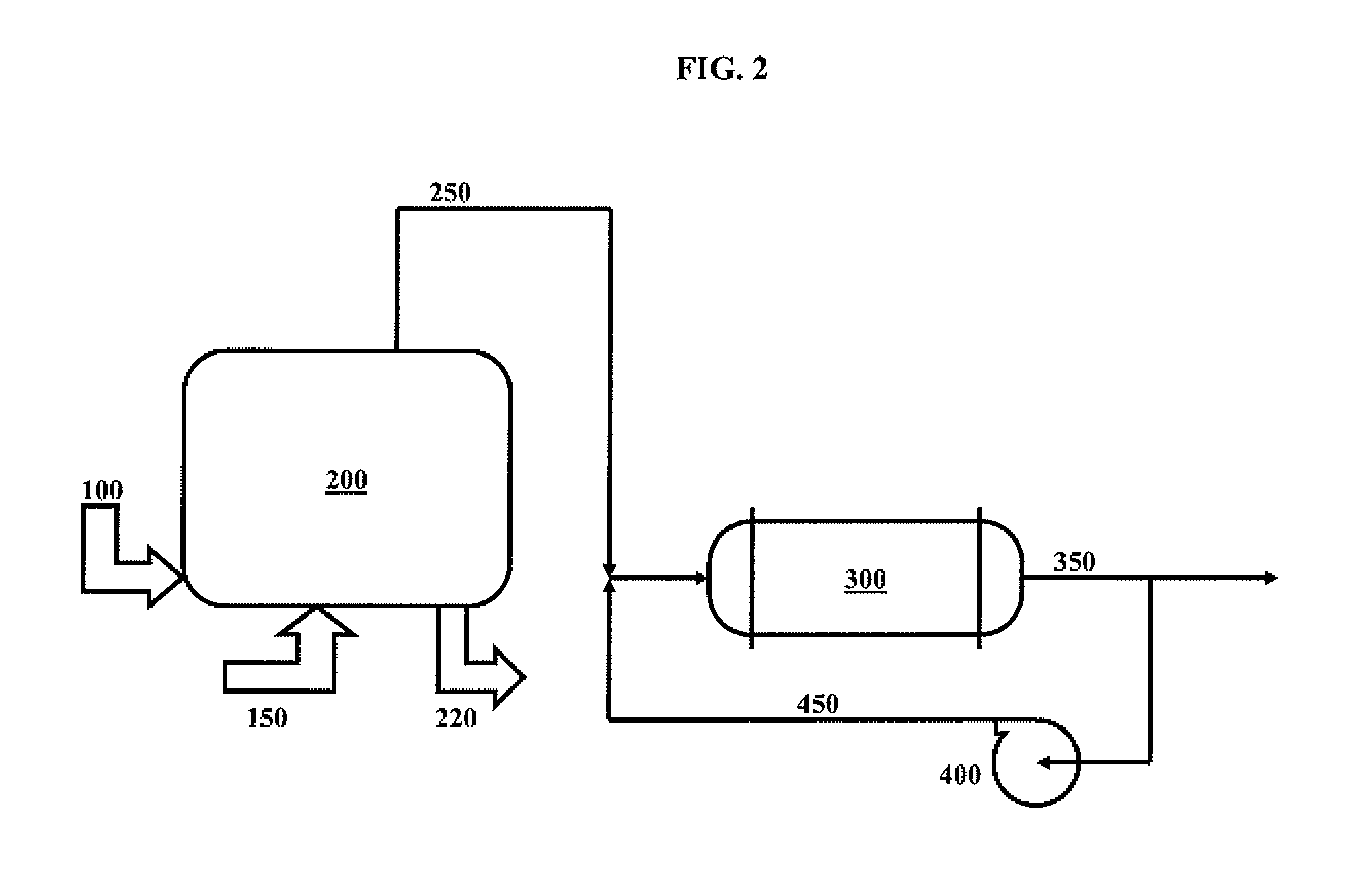

Image

Examples

example 1

Solid Load of Syngas Produced by Gasification in Production Mode

[0061]The gasification apparatus was operated in a start-up mode by providing carbonaceous materials to the gasifier at a feed rate of about half as much as that used in a production mode. Oxygen was supplied to the gasifier at a feed rate of about 40 to 50 lb-mole ton of carbonaceous material on a dry basis. As described previously, some air leakage into the gasifier was allowed that increase oxygen availability.

[0062]Upon starting up a gasifier under start-up mode as described above to obtain a first target temperature in a range of about 700° C. to about 1000° C., a carbonaceous material feed rate was increased into the gasification apparatus. A molecular oxygen containing gas was supplied to the gasification apparatus at the rate of about 50 to about 90 lb-moles per ton of water-free carbonaceous material. The gasifier was also fed a stream of carbon dioxide at the rate of about 10 to about 15 lb-moles per ton of wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com