Method of gasifying carbonaceous material and a gasification system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

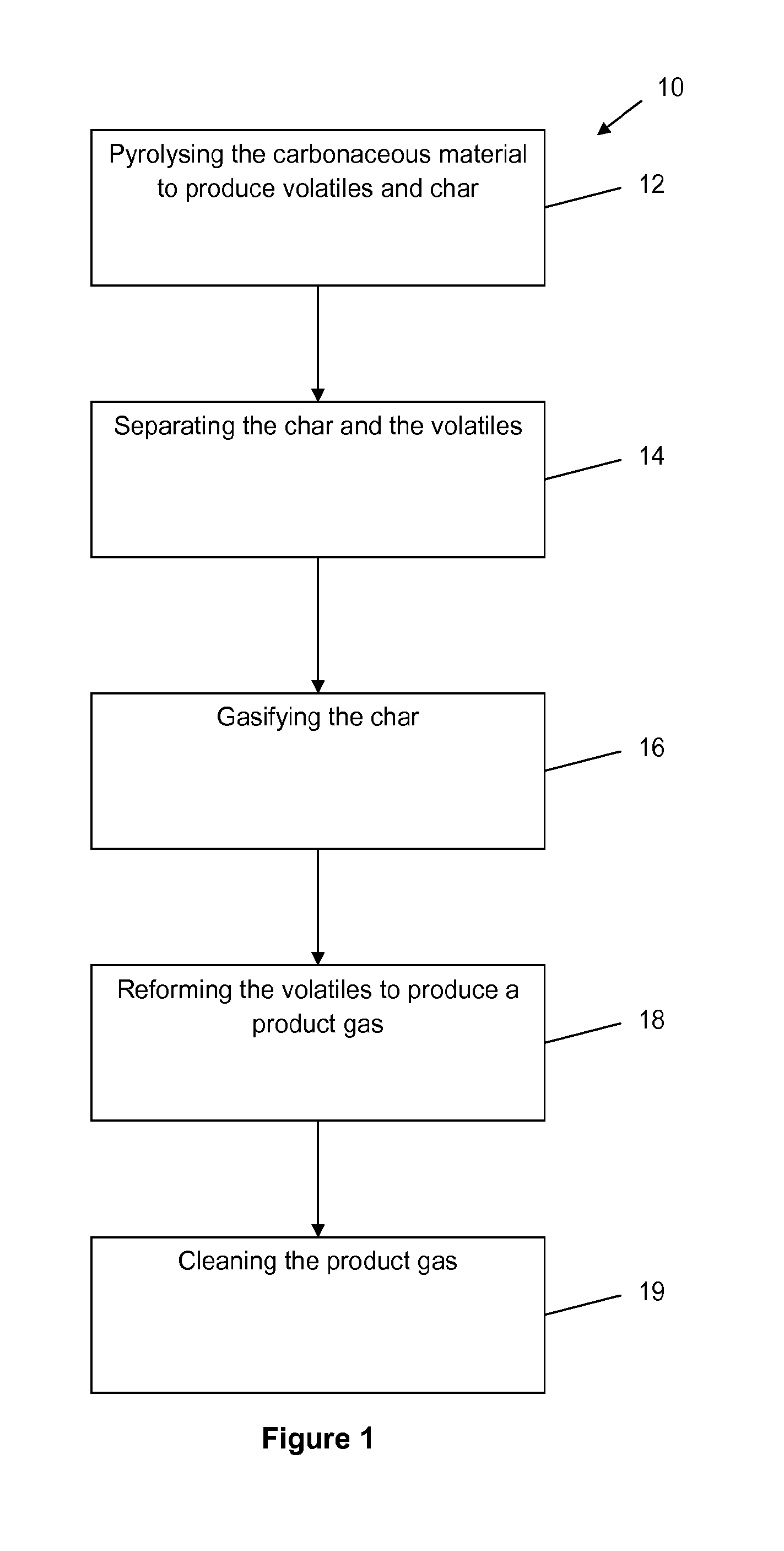

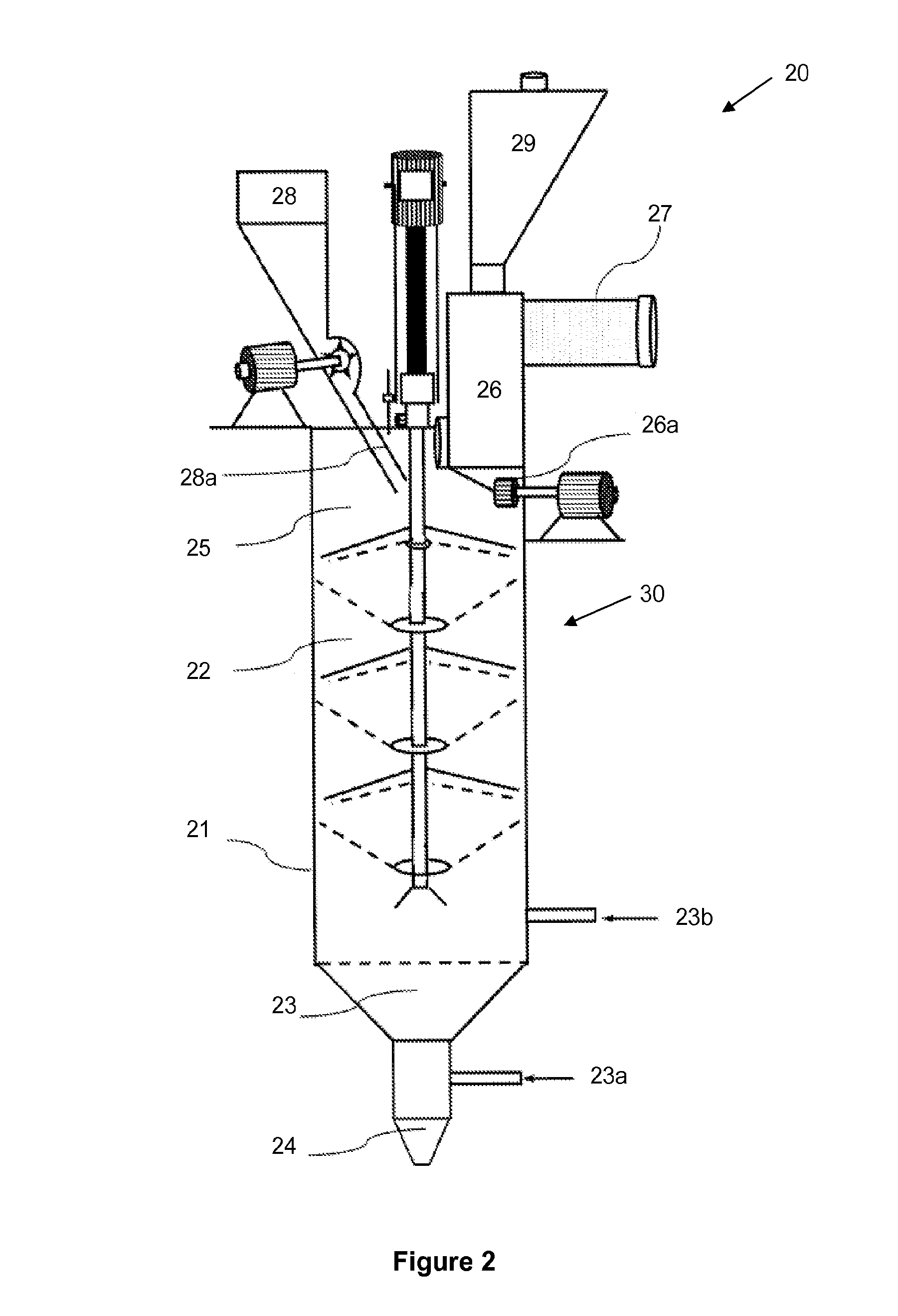

[0058]Embodiments of the present invention relate to a method 10 of gasifying a carbonaceous material, a gasification system 20, 40, and an apparatus 30 for pyrolysing carbonaceous material as described with reference to FIGS. 1 to 4.

[0059]It will be appreciated that the method 10 may be performed in a gasification vessel having integrally defined therein a pyrolysis zone for pyrolysing carbonaceous material, a char gasification zone for gasifying the char with steam and an oxygen-containing gas, a reforming zone for reforming volatiles with steam to produce a product gas, and a gas cleaning zone to clean the product gas. An embodiment of the gasification vessel in accordance with the present invention will be described in more detail in later pages in the description.

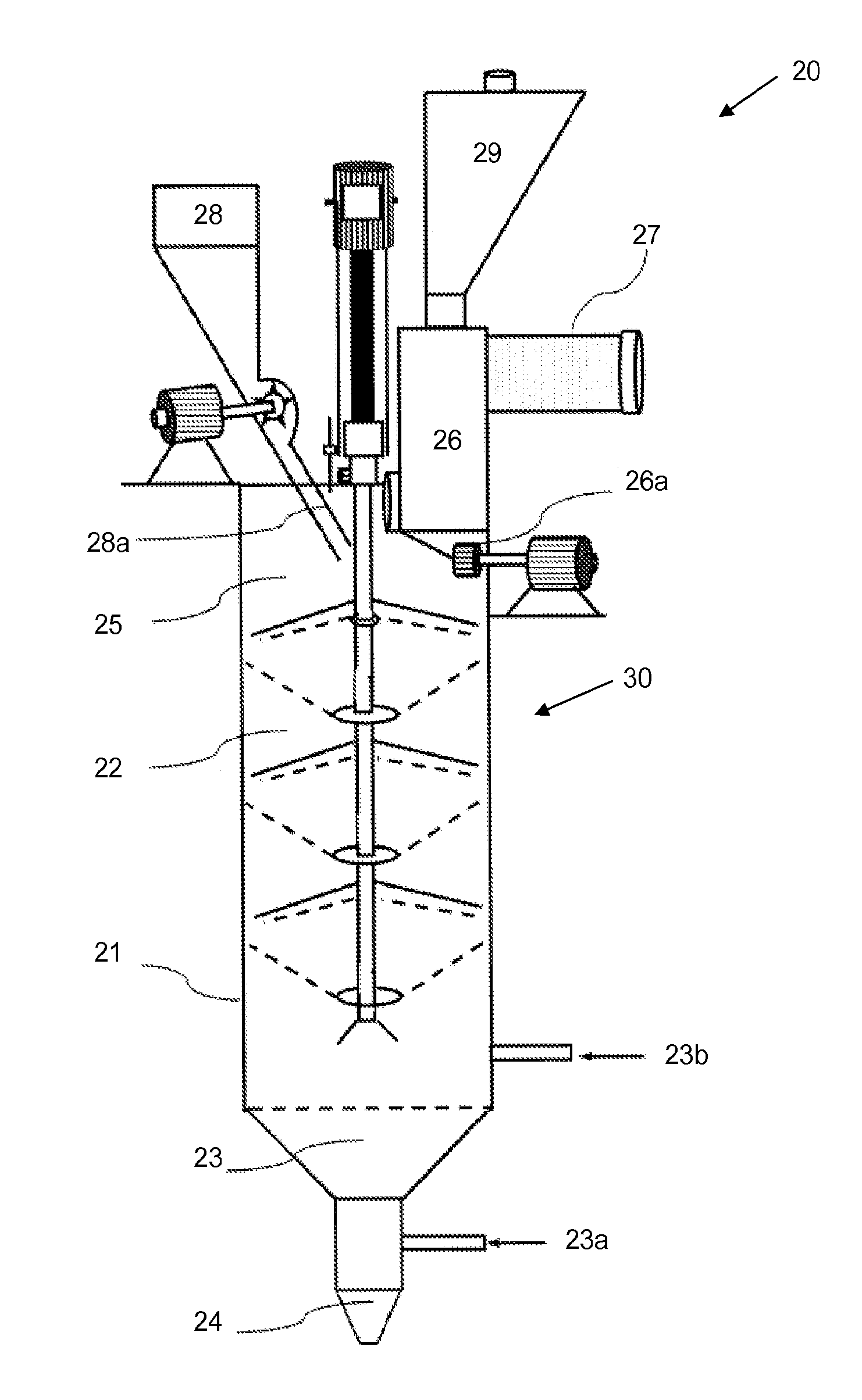

[0060]In its broadest form, and as shown in FIG. 1, the gasification method 10 comprises the steps of pyrolysing 12 the carbonaceous material to produce volatiles and char, separating 14 the char and the volatiles, gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com