SNCR (Selective Non-catalytic Reduction) denitration device and denitration method

A denitrification and control device technology, applied in the denitrification device and denitrification field, can solve the problems of difficulty in forming a stable reaction temperature zone, low denitrification efficiency, incomplete reaction, etc., and achieve simple equipment, good heat recovery benefits, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

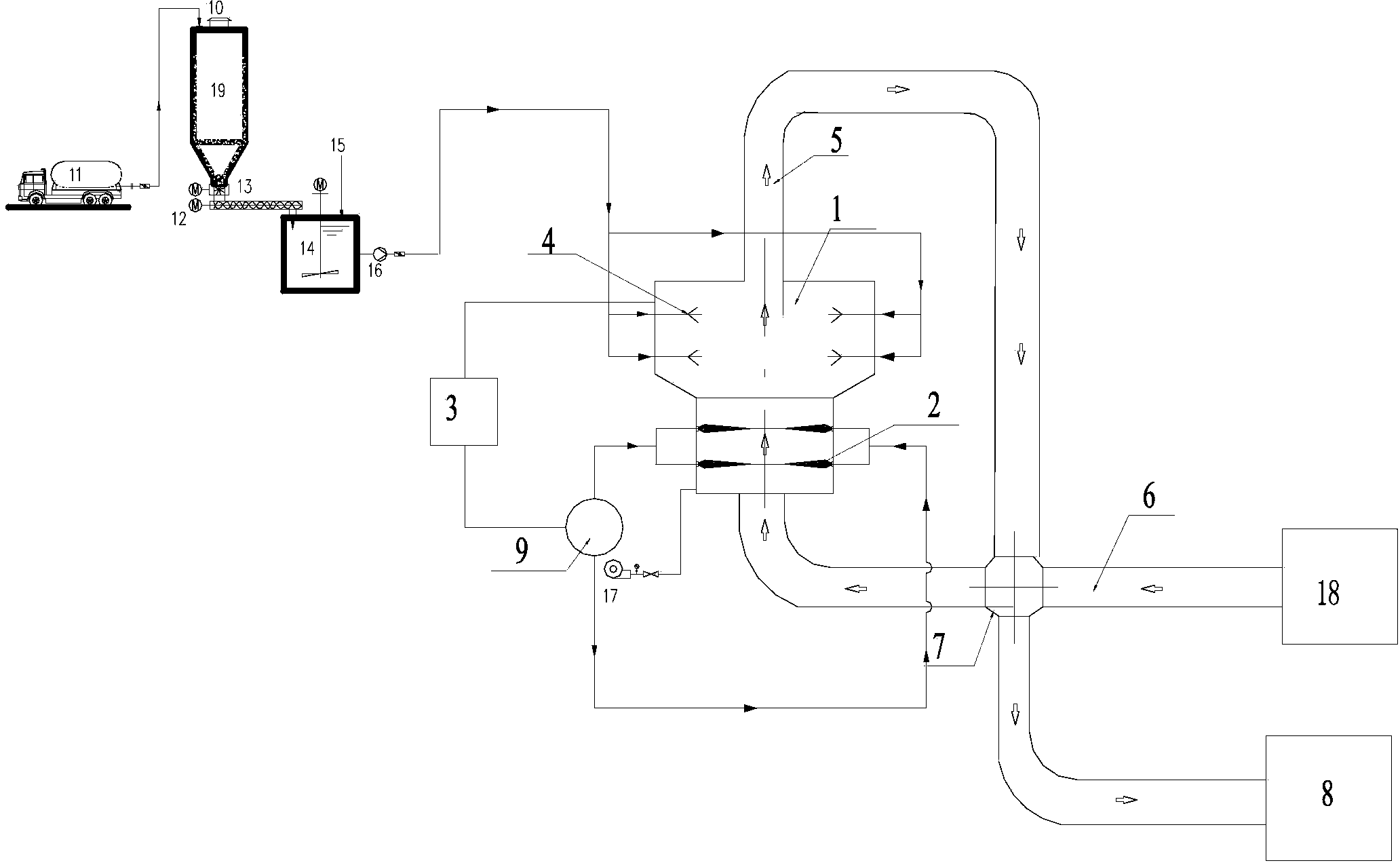

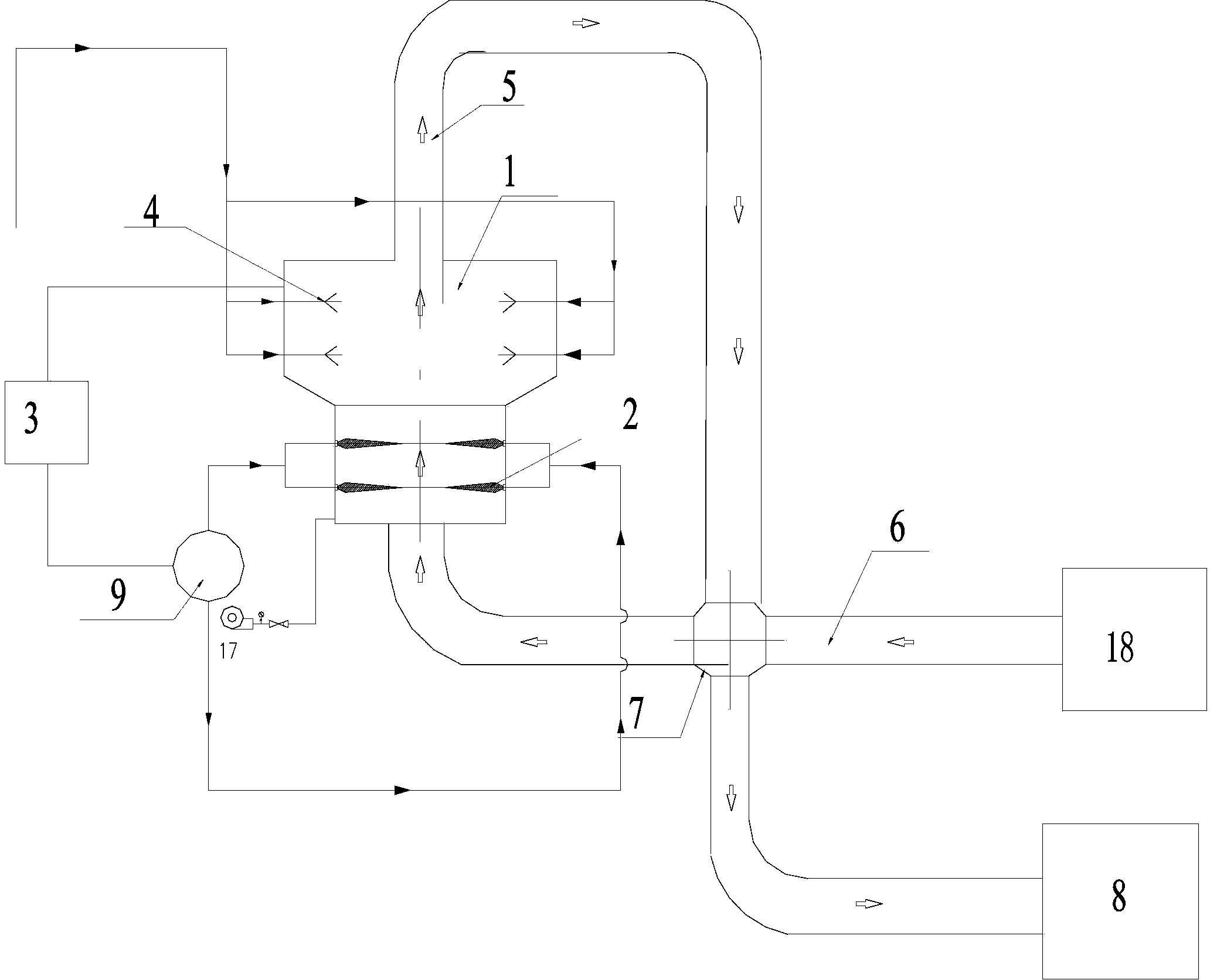

[0037] The SNCR denitration device of the present invention comprises a denitration reactor (1), a fuel injection control device (2), a temperature control device (3), a reducing agent injection device (4), a denitration reactor outlet flue (5), a denitration reactor A reactor inlet flue (6), a fuel system controller (9), the fuel injection control device (2) is connected to the temperature control device (3) through the fuel system controller (9).

[0038] In the denitration method of the present invention, the above-mentioned denitration device is used, and the temperature in the denitration reactor (1) is 800-1100°C, preferably 850-1050°C, more preferably 950-1050°C; the reducing agent injection device ( The reducing agent in 4) is urea; the net flue gas coming out of the outlet flue (5) of the denitrification reactor heats the raw flue gas coming in from the inlet flue (6) of the denitrification reactor; the denitrification reactor The temperature of the net flue gas comin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com