Enriched high conductivity geothermal fill and method for installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

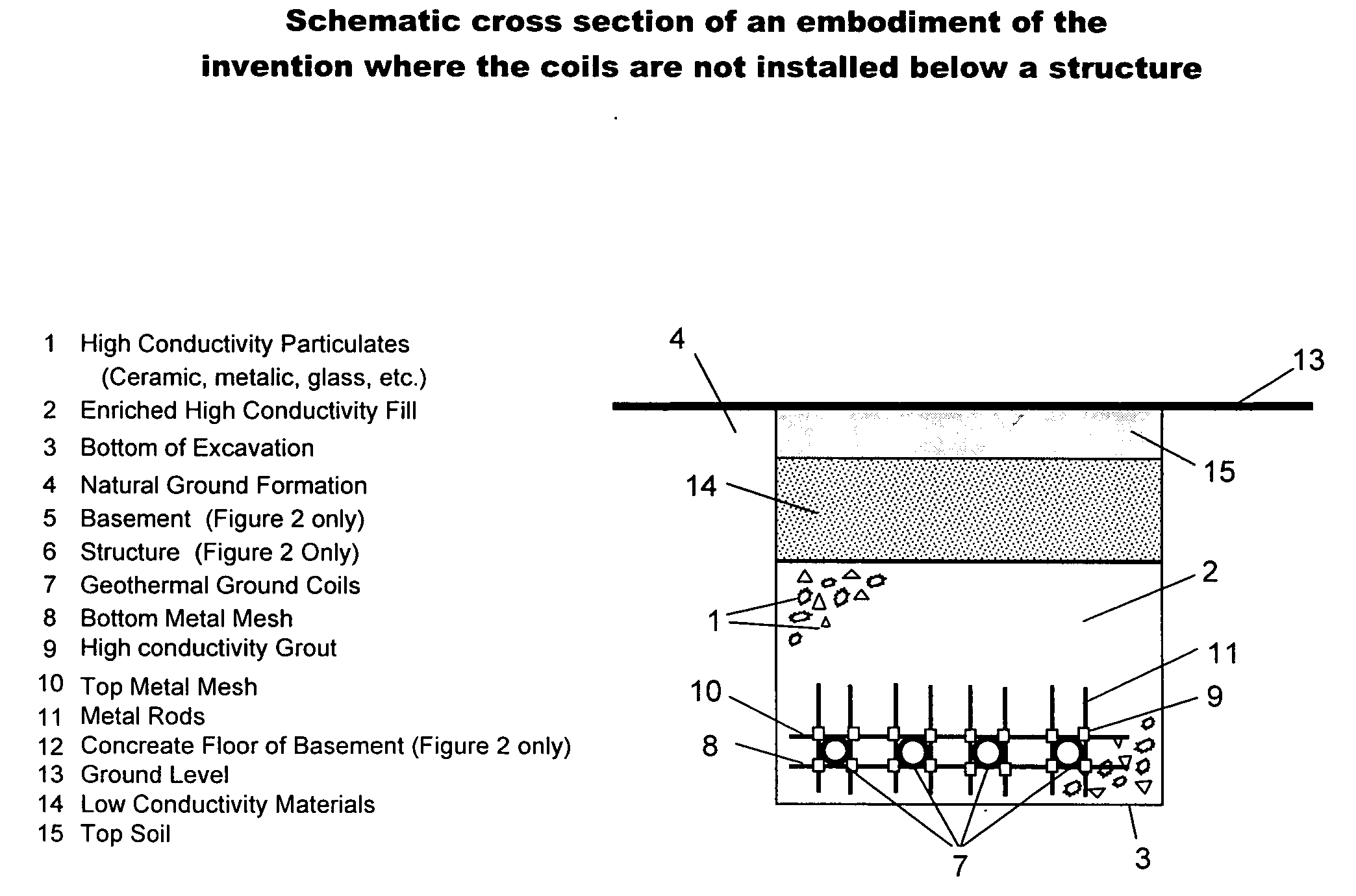

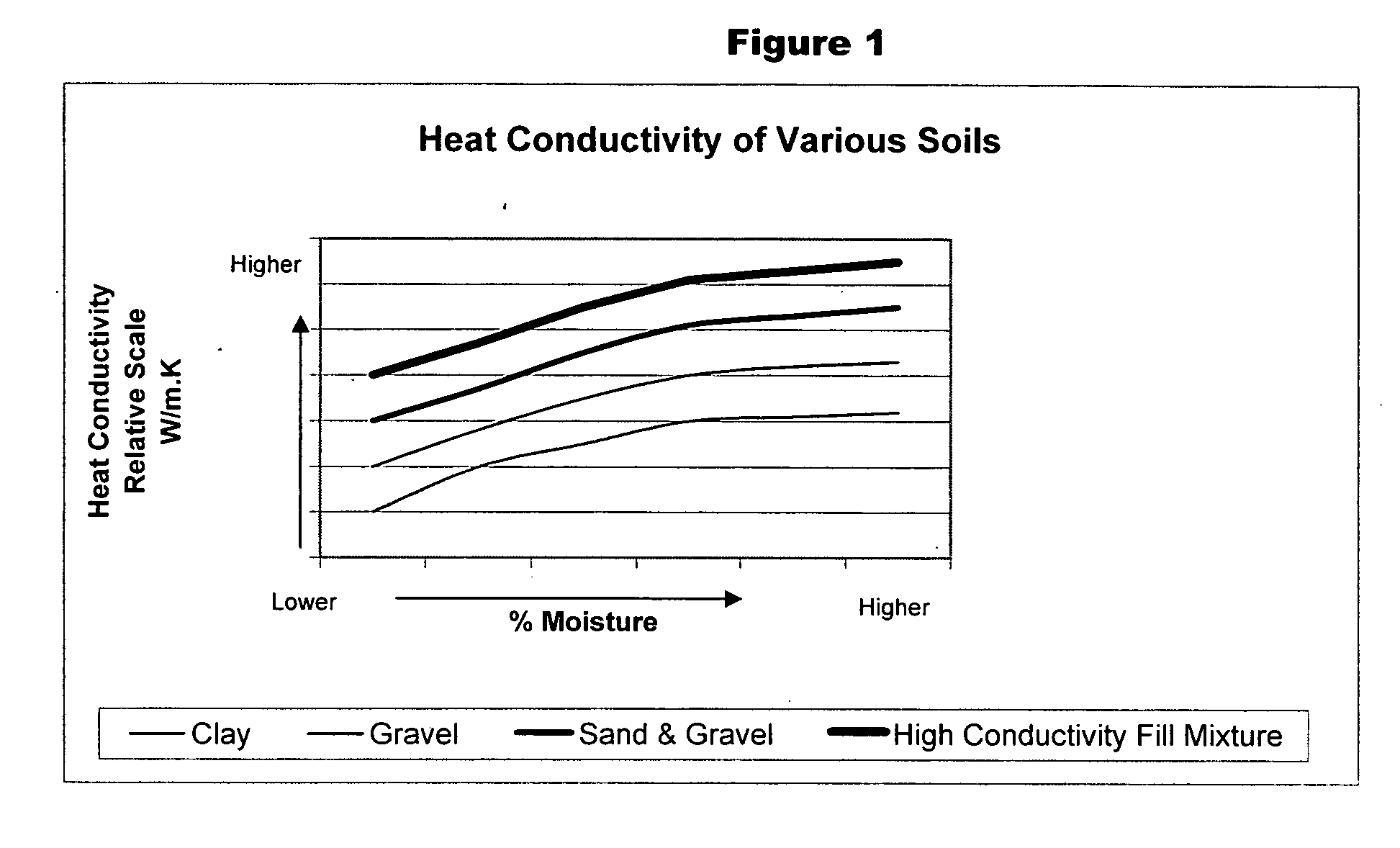

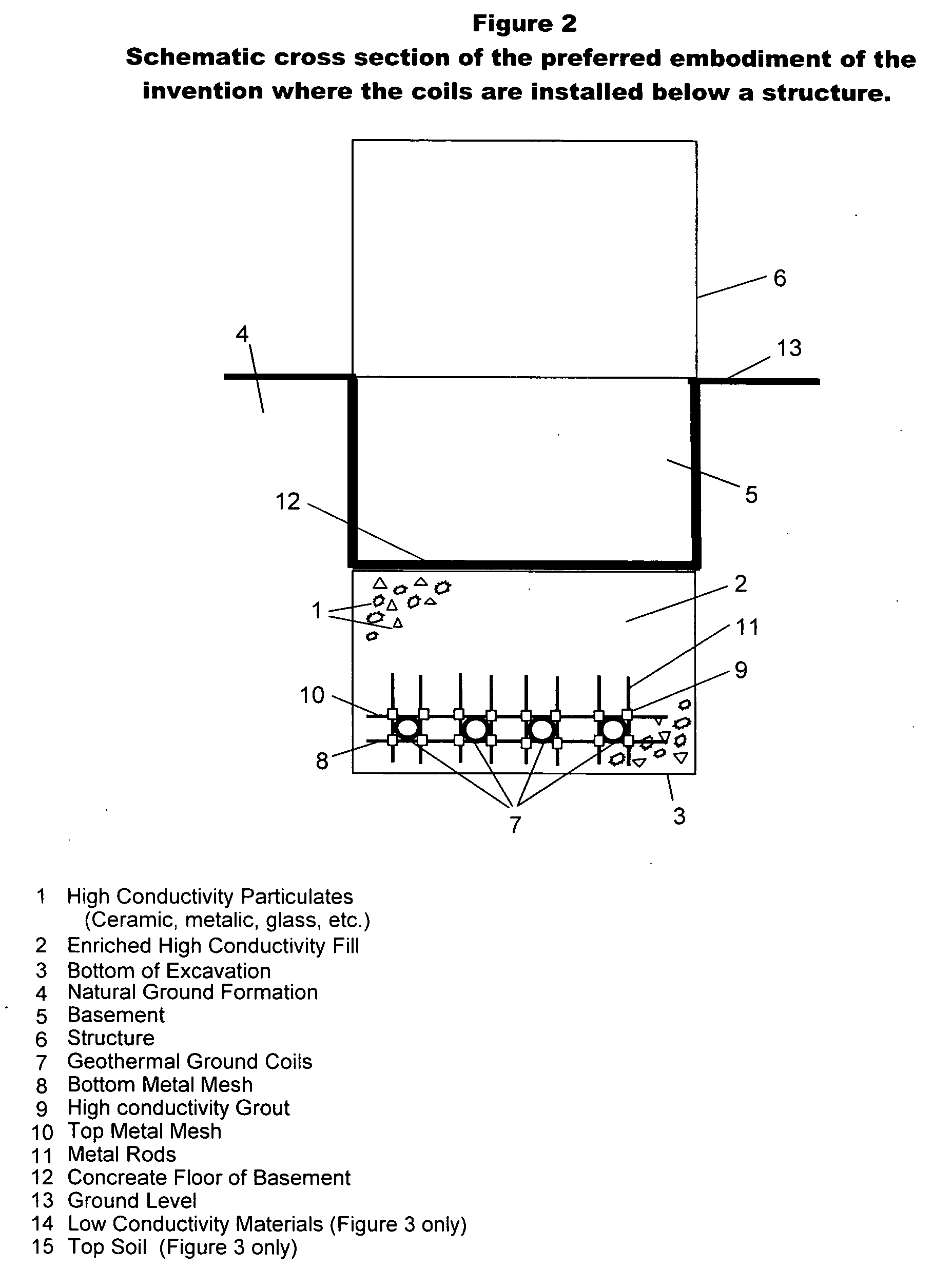

[0017] Materials that are tested to have higher heat conductivity properties than natural ground formation, which can be lower than 1.0 W / m.K, and that have the proper chemical, physical and drainage characteristics to make them suitable for ground fill are used in combination with each other and natural good conductivity ground fill to cover and encapsulate geothermal ground coils installed in excavations. Improving the conductivity of the fill that covers and encapsulates the coils to above 1.5 w / m.K, will improve the heat transfer rate from the bulk of the ground to the fluid inside the coils, and more importantly, increase the rate of heat recovery of the fill in the vicinity of the ground coils. This minimizes or eliminates the need for supplemental electric heating coils, improving the overall efficiency of the geothermal heating system.

[0018] In the summer when cooling is required, the higher conductivity fill improves the rate of heat removal from the fill around the ground...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com