Synthetic natural gas prepared from one-step process coal and system thereof

A synthetic natural gas and coal-based technology, applied in the field of synthetic natural gas process and system, can solve the problems of unavailable turbine drive, high equipment investment cost, complex heat exchange network, etc., to reduce steam consumption and reduce production and operation costs , The effect of simplifying the heat recovery system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0041] The composition of the normal temperature crude gas from the upstream coal gasification unit after heat recovery is: H 2 : 17.95% mol; CH 4 : 30ppm; N 2 : 0.8%mol; CO: 52.47%mol; CO 2 : 7.45% mol; H 2 S: 0.43%; COS: 3 +HCN: 0.032%mol; Ar: 0.06%mol; H 2 O: 20.8% mol. Temperature: 168°C, pressure: 3.8MPag, flow rate: 680676Nm3 / h.

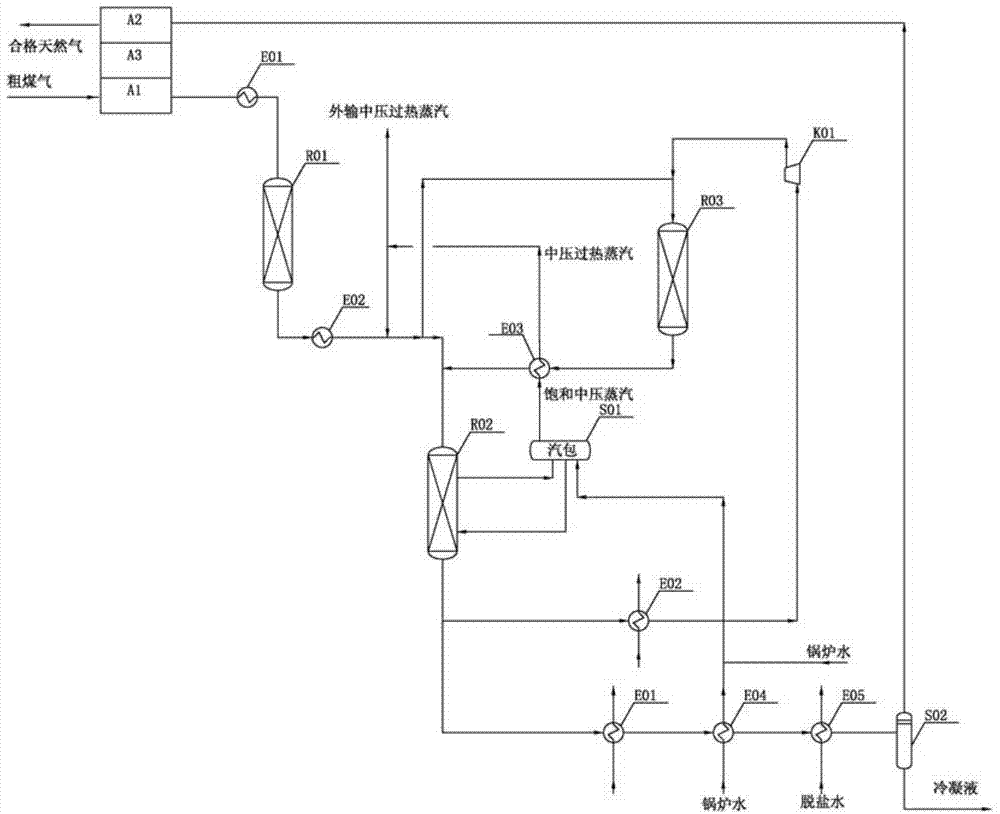

[0042] The crude gas at room temperature passes through the first absorption tower of the low-temperature methanol washing device to remove A1 and remove H 2 Purified gas is obtained from impurities such as S, and the purified gas goes through the heat exchange between the shell side of the first raw material preheater E01 and the second reaction gas of the tube side to 170°C-230°C, and then enters the deep purification desulfurizer R01 for removal. Sulfur and other impurities, and then through the shell side of the second raw material preheater E02 and the first reaction gas of the tube side, the heat is exchanged to 280°C-320°C, and med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com