Thermal recovery system with improved thermal efficiency and thermoelectric combined production system equipped with the thermal recovery system

A heat recovery rate, heat recovery technology, applied in the direction of combined combustion mitigation, lighting and heating equipment, components of steam boilers, etc., can solve problems such as reduced combustion efficiency, deformation or cracking, and reduced durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

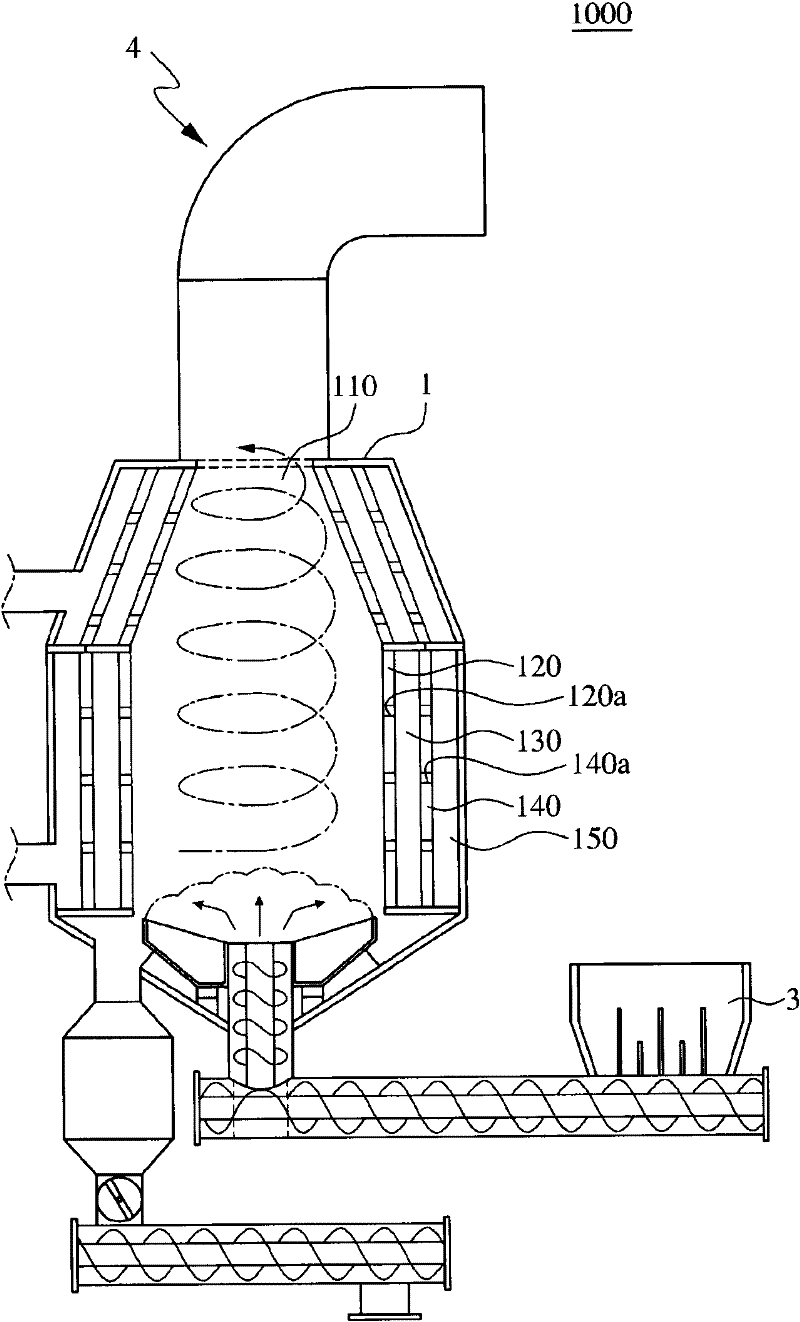

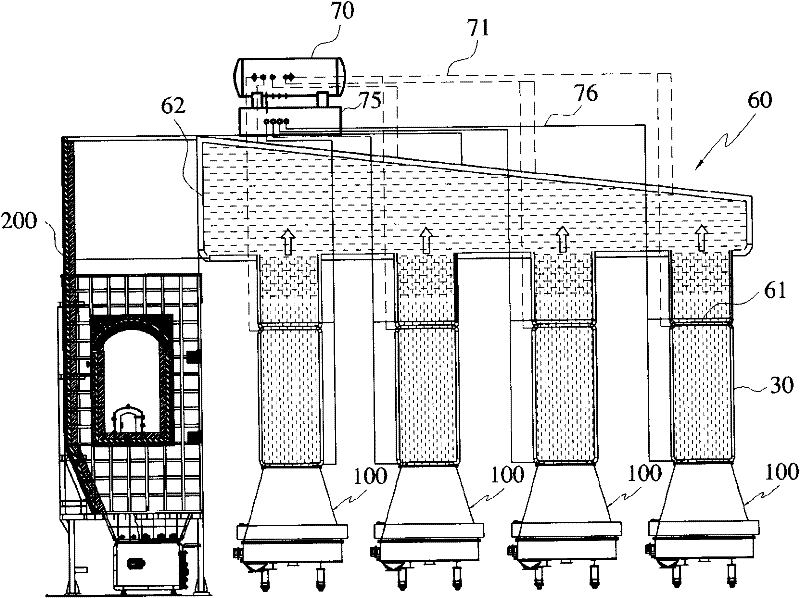

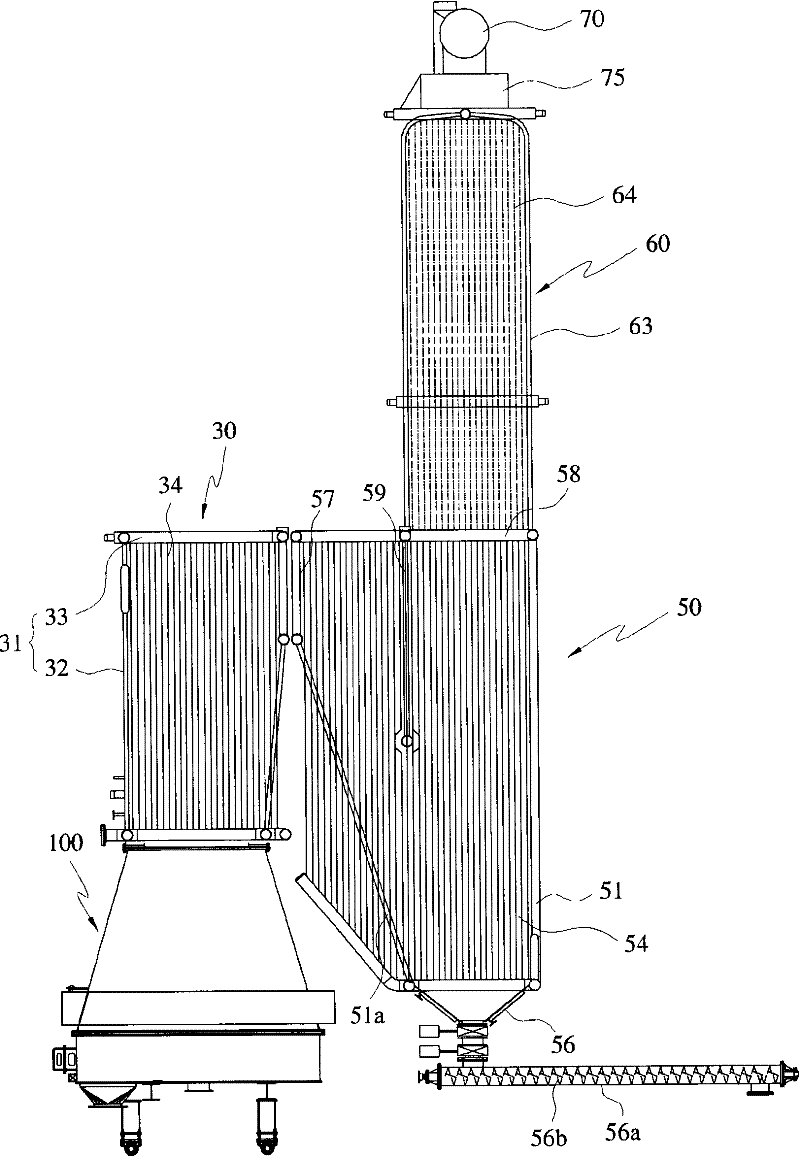

[0037] With reference to the accompanying drawings ( Figure 2 to Figure 8 ) to describe the heat recovery system with improved heat recovery rate according to the first embodiment of the present invention.

[0038] figure 2 A schematic diagram showing a heat recovery system with improved heat recovery rate according to a first embodiment of the present invention. image 3 yes figure 2 side view. Figure 4 show image 3 Schematic plan view of the gas discharge unit with U-shaped flow gas chamber. Figure 5 A sectional view of a combustion device according to the invention is shown. Image 6 show Figure 5 A cross-sectional view of one side of the combustion equipment. Figure 7 A sectional view of a feed unit of a combustion plant according to the invention is shown. Figure 8 is a longitudinal sectional view of the boiler in the heat recovery system according to the present invention.

[0039] According to the first embodiment of the present invention, a heat recov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com