Rich-oxygen and pure oxygen burning tunnel kiln

A tunnel kiln and burner technology, which is applied in the field of ceramic kilns, can solve the problems of large amount of nitrogen oxides, large amount of combustion products, and large atmospheric hazards, so as to increase the oxidation rate, improve combustion efficiency, and reduce firing rate. cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited.

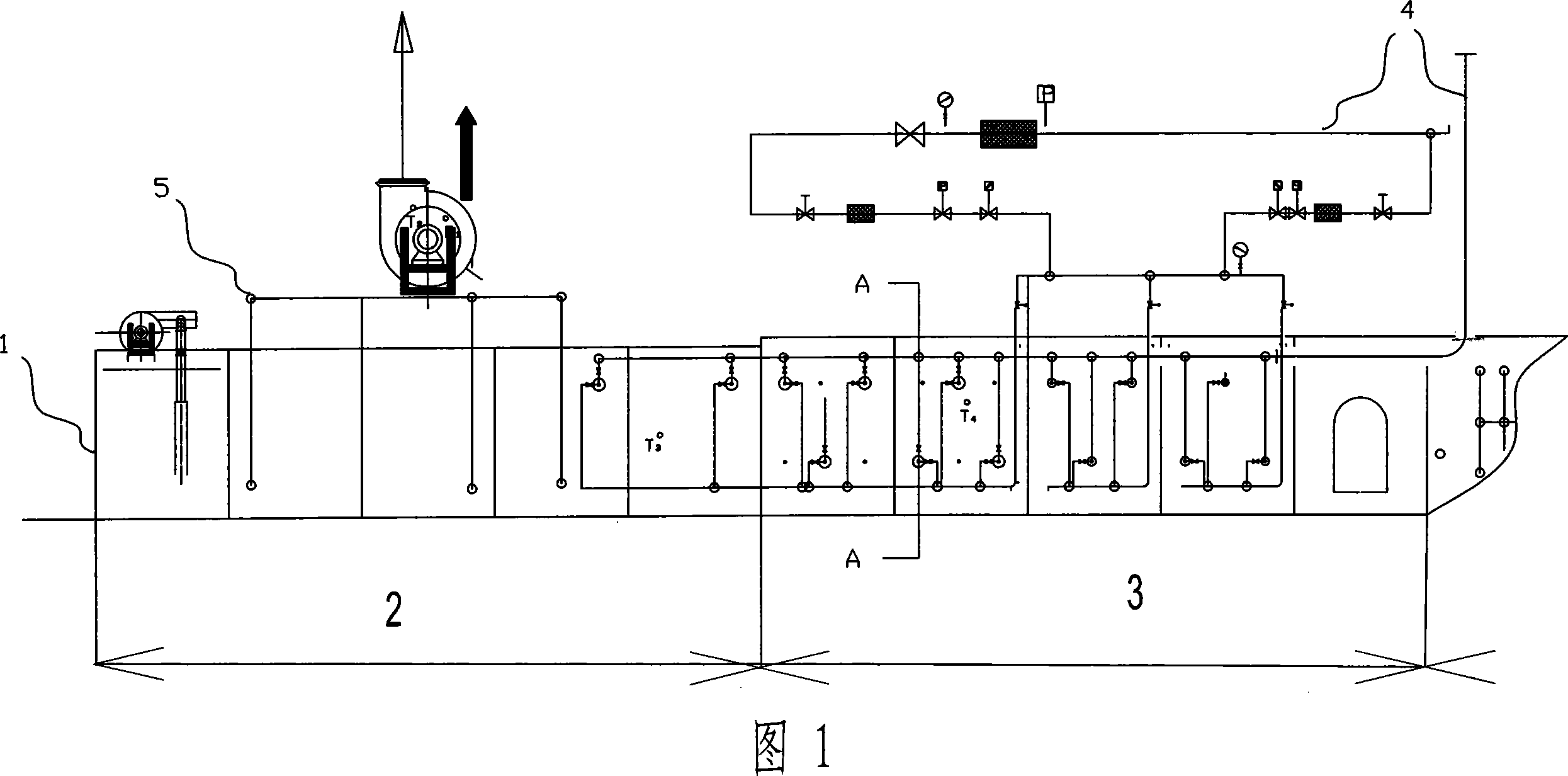

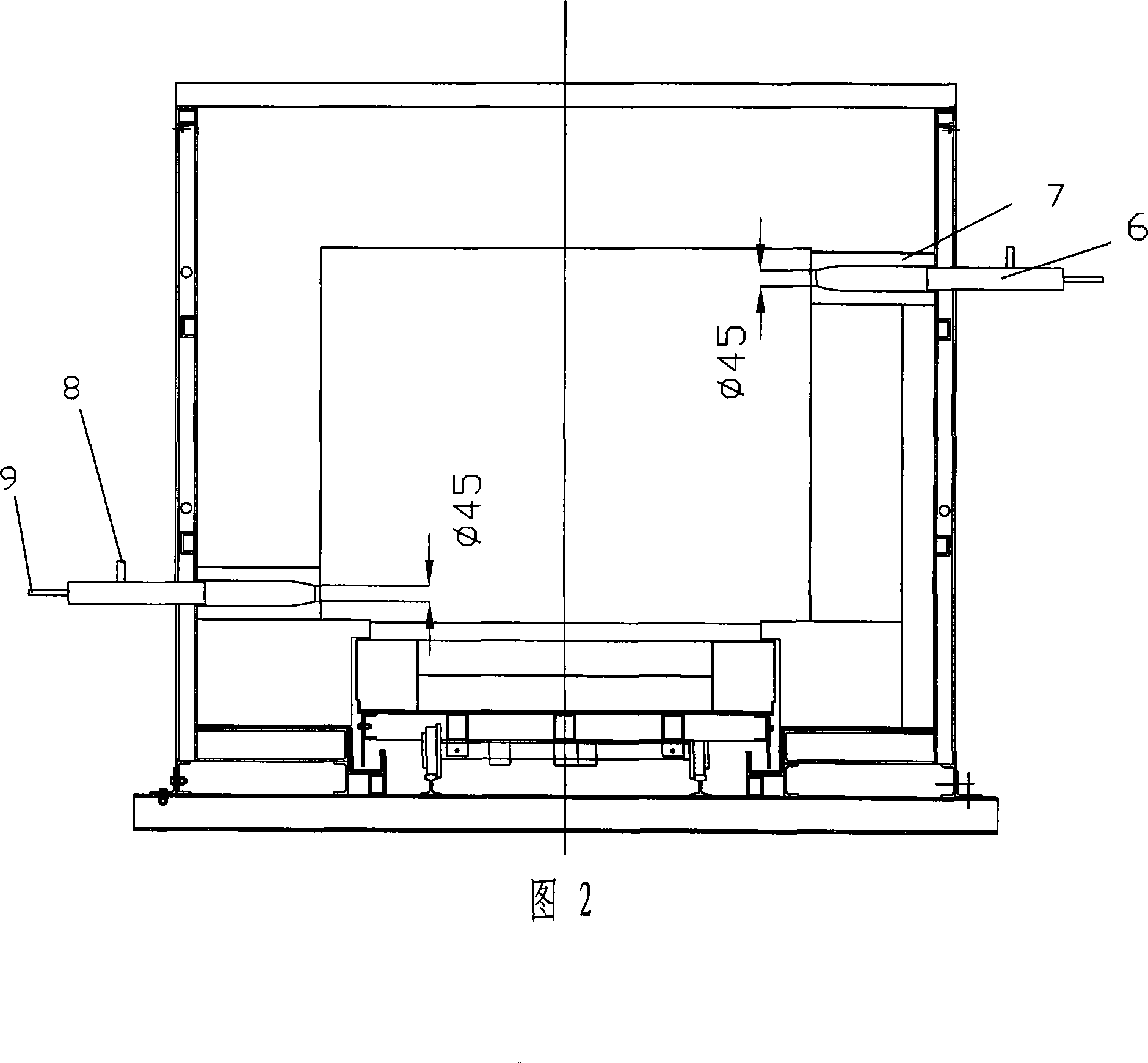

[0017] The oxygen-enriched and pure oxygen combustion tunnel kiln provided by the present invention has a structure as shown in Figure 1 and Figure 2: a combustion-supporting medium with a volume concentration of at least 21% oxygen burns in the burner 6 together with the fuel, and does not Oxygen-enriched and pure oxygen combustion tunnel kilns that require air combustion fans. The burner 6 is installed at the burner brick 7. The kiln body 1 of the tunnel kiln includes a preheating zone 2, a firing zone 3, a smoke exhaust system 5, a quenching zone, a cooling zone, a fuel and combustion-supporting delivery system, a temperature control system, a combustion system, a quenching and waste heat system, and the preheating zone Zone 2 and firing zone 3 are connected through high-concentration oxygen combustion-suppo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com