Method Of Patterned Plasma-Mediated Laser Trephination Of The Lens Capsule And Three Dimensional Phaco-Segmentation

a laser trephination and lens capsule technology, applied in the field of ophthalmic surgical procedures and systems, can solve the problems of difficult, if not impossible, formation of lens capsules using conventional, purely manual techniques, etc., and achieve the effects of reducing the duration of the procedure, reducing the risk of capsule opening and hard nucleus fragmentation, and increasing the precision of the procedur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

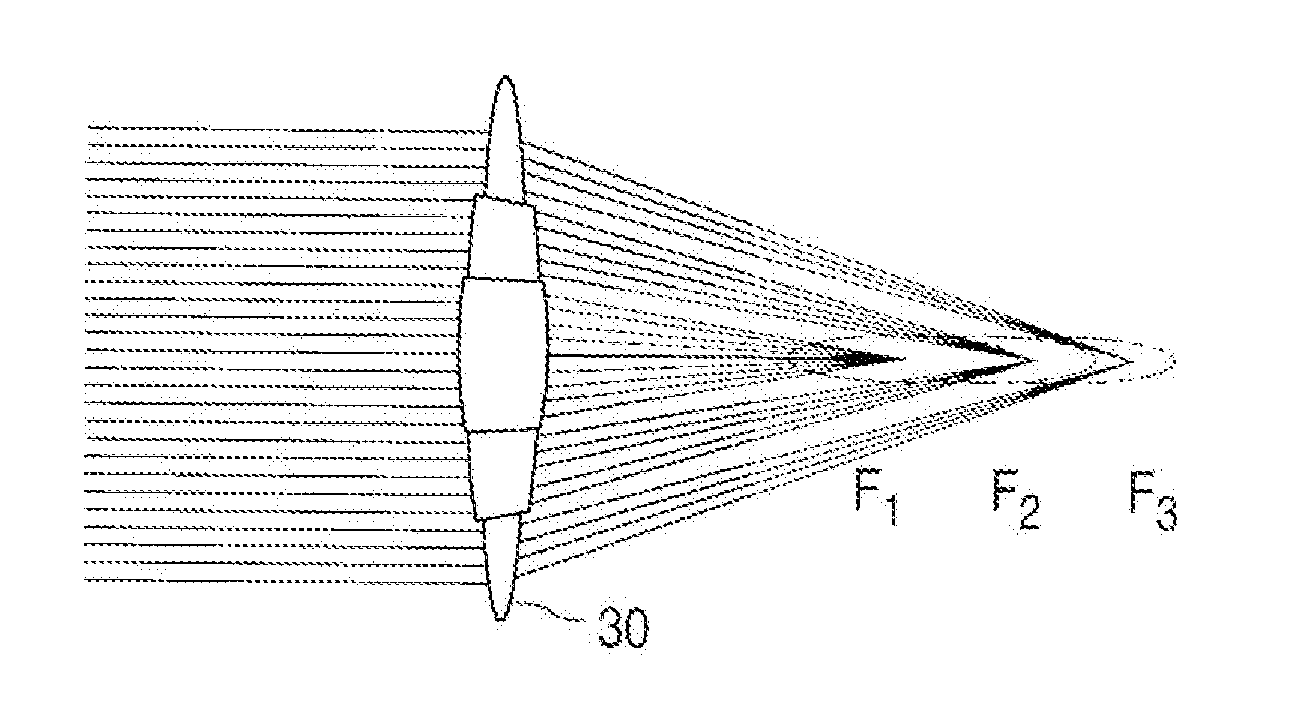

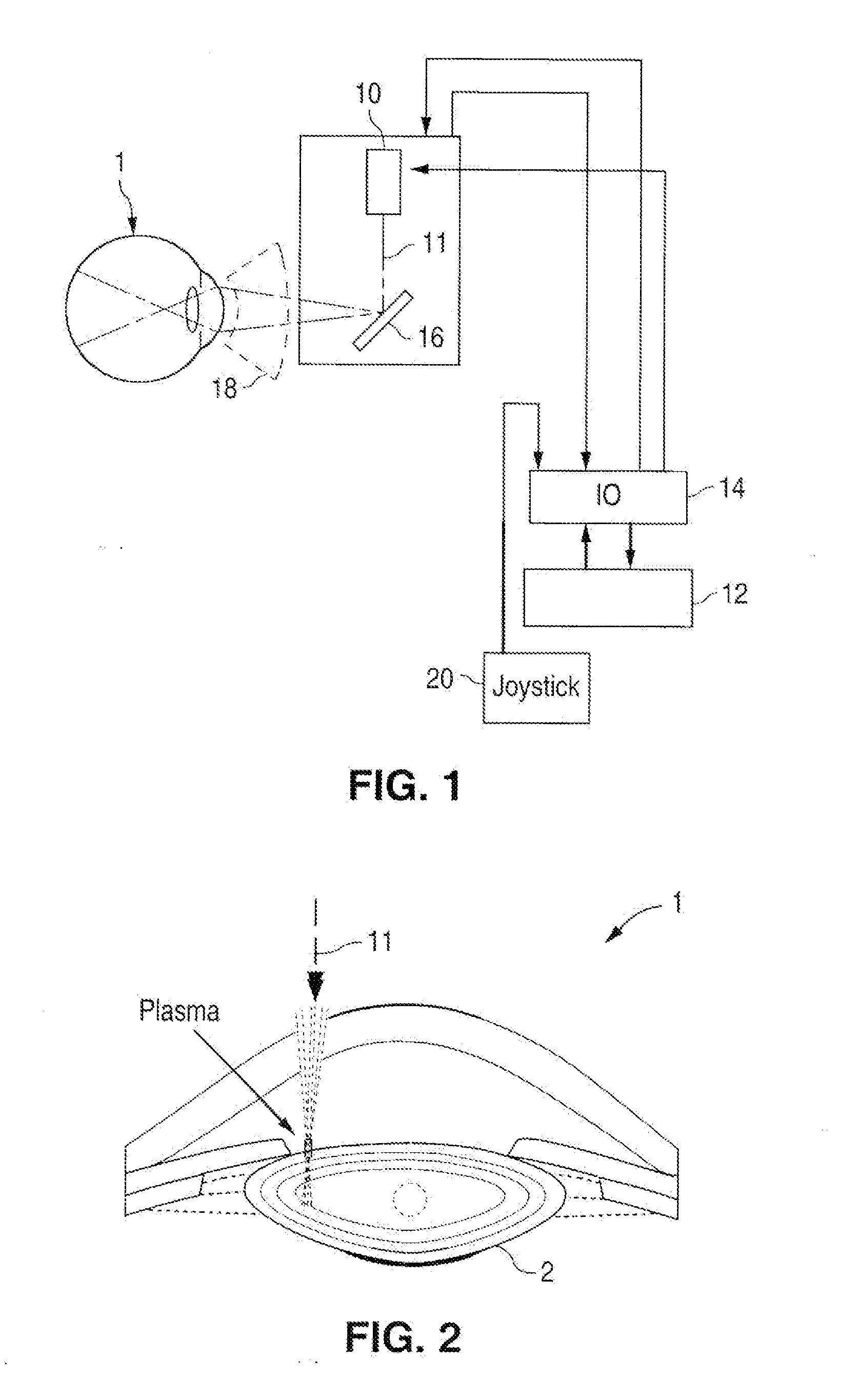

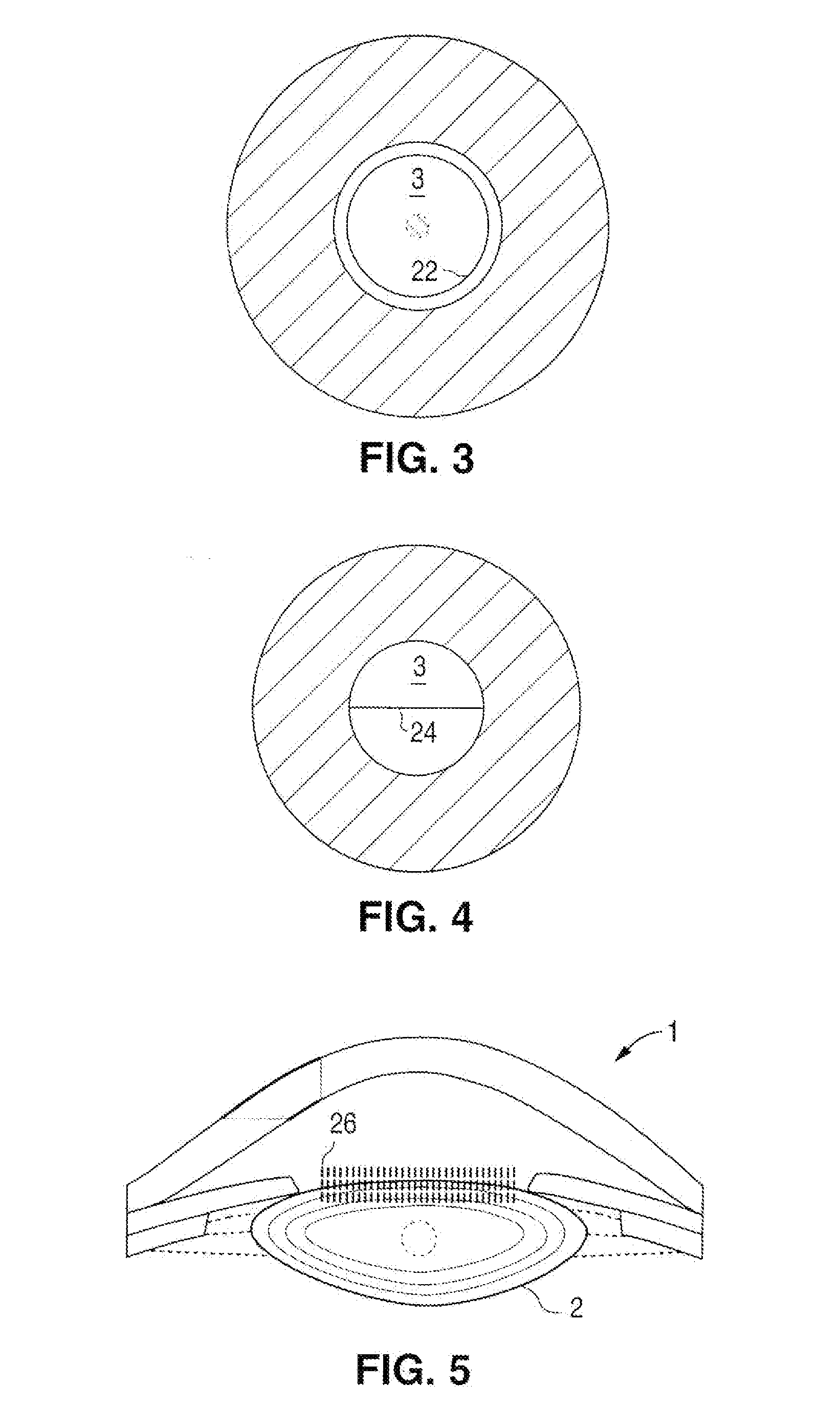

[0045]The present invention can be implemented by a system that projects or scans an optical beam into a patient's eye 1, such as the system shown in FIG. 1. The system includes a light source 10 (e.g. laser, laser diode, etc.), which may be controlled by control electronics 12, via an input and output device 14, to create optical beam 11 (either cw or pulsed). Control electronics 12 may be a computer, microcontroller, etc. Scanning may be achieved by using one or more moveable optical elements (e.g. lenses, gratings, or as shown in FIG. 1 a mirror(s) 16) which also may be controlled by control electronics 12, via input and output device 14. Mirror 16 may be tilted to deviate the optical beam 11 as shown in FIG. 1, and direct beam 11 towards the patient's eye 1. An optional ophthalmic lens 18 can be used to focus the optical beam 11 into the patient's eye 1. The positioning and character of optical beam 11 and / or the scan pattern it forms on the eye may be further controlled by use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com