Solar photoelectric photo-thermal integrated assembly and solar combined heat and power generation system thereof

A technology of cogeneration and solar energy, applied in the fields of photovoltaic thermoelectric hybrid power generation, photovoltaic power station, energy industry, etc., can solve the problems of large contact thermal resistance, high construction cost, complex heat collecting structure, etc., to eliminate contact thermal resistance and reduce construction cost. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

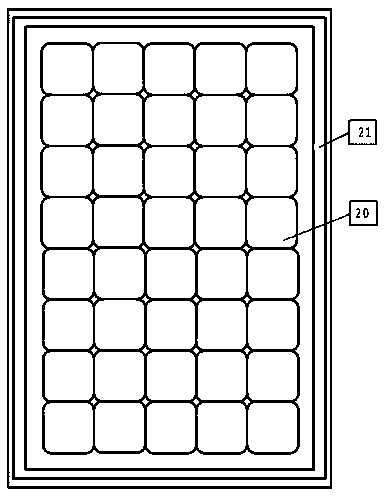

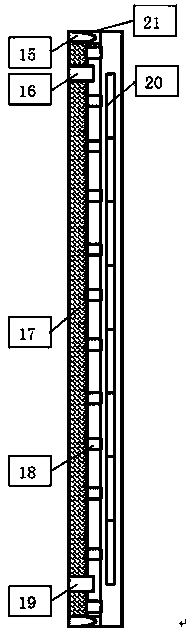

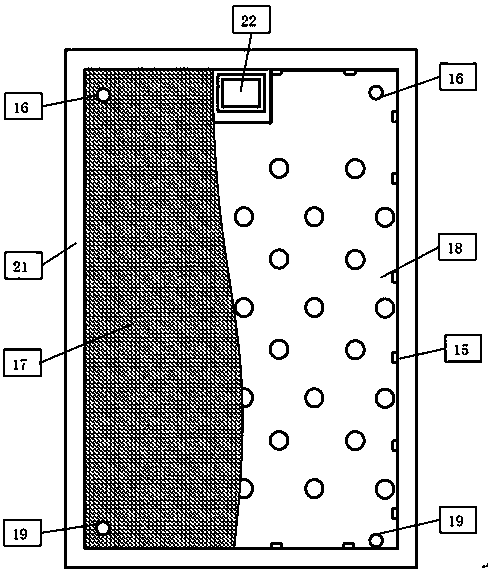

[0044] see figure 1 , 2 , 3, 4, the present invention discloses a solar photoelectric photothermal integrated assembly including a photovoltaic cell panel 20, and a thin metal plate heat exchanger 18 and an insulating material layer 17 arranged parallel and overlapping on the back of the photovoltaic cell panel 20 in sequence .

[0045] It also includes a metal frame 21 for installing photovoltaic cell panels 20, metal sheet heat exchangers 18 and insulation material layers 17, such as Figure 5 As shown, the metal outer frame 21 is composed of a side frame 21a and a back frame 21b on the back of the side frame 21a.

[0046] The photovoltaic battery panel 20 is fixed in the side frame 21a of the metal outer frame 21, and there is a gap between the back frame 21b and the metal sheet heat exchanger 18 and the insulation material layer 17 for installation.

[0047] The thin metal plate heat exchanger 18 is a flat metal plate body that is integrally in contact with the back of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com