Three-dimensional inner and outer finned tube cold and heat exchanger for air conditioner

A heat exchanger, three-dimensional technology, applied in the direction of heat exchange equipment, tubular elements, lighting and heating equipment, etc., can solve the problems of shortened service life, reduced heat exchange performance, increased contact thermal resistance between tubes and fins, etc., to achieve Long service life, slow heat transfer performance attenuation, and the effect of eliminating contact thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

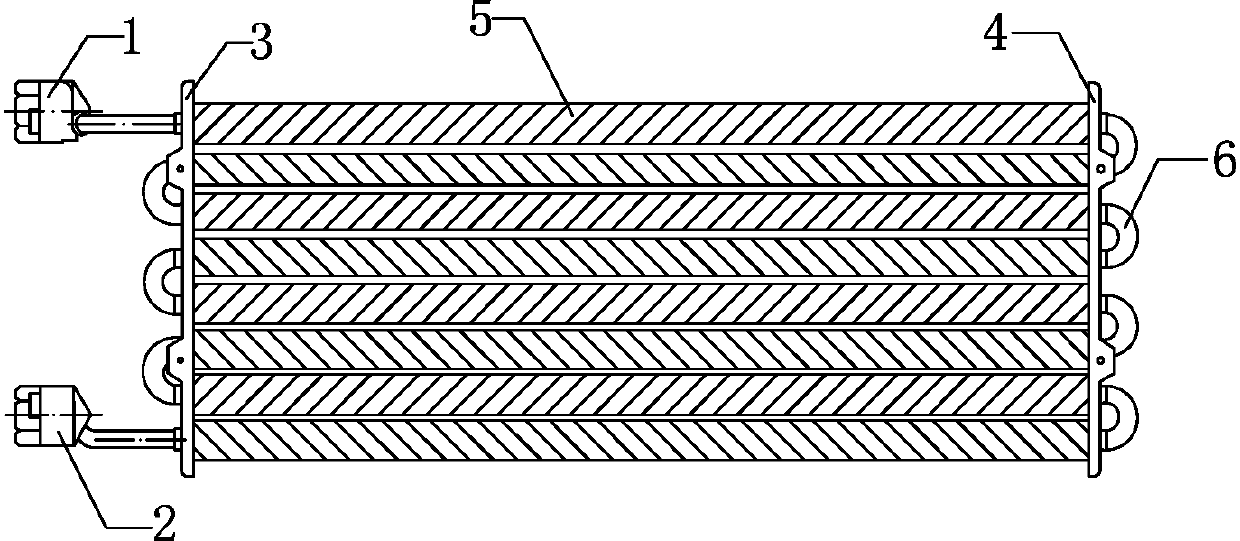

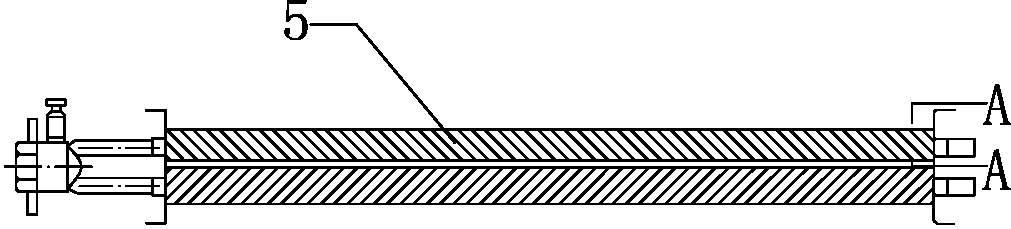

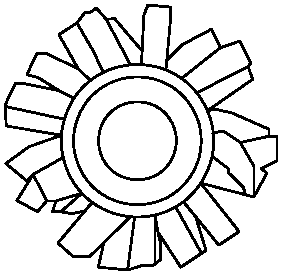

[0018] Such as Figures 1 to 3 As shown, the air conditioner uses a three-dimensional finned tube cooling and heat exchanger, including an inlet 1, an outlet 2, and a flow line between the two. The flow line includes a three-dimensional finned tube 5 as a heat transfer element, The three-dimensional ribbed tube refers to a metal tube with ribs cut on the tube wall. The ribs are carved and cut on the surface wall of the metal tube (along the direction of the central axis of the metal tube) by several circularly arranged blades, and each blade is precisely controlled by a CNC machine tool.

[0019] The three-dimensional rib tube cooling and heat exchanger for the air conditioner comprises a left orifice plate 3, a right orifice plate 4, and a three-dimensional rib tube 5. There are several mounting holes on the orifice plate, and the three-dimensional rib tube 5 passes through the left orifice plate 3 and the right orifice plate 4. Fixed, the pipes of the three-dimensional ribb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com