Patents

Literature

55results about How to "Eliminate thermal contact resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

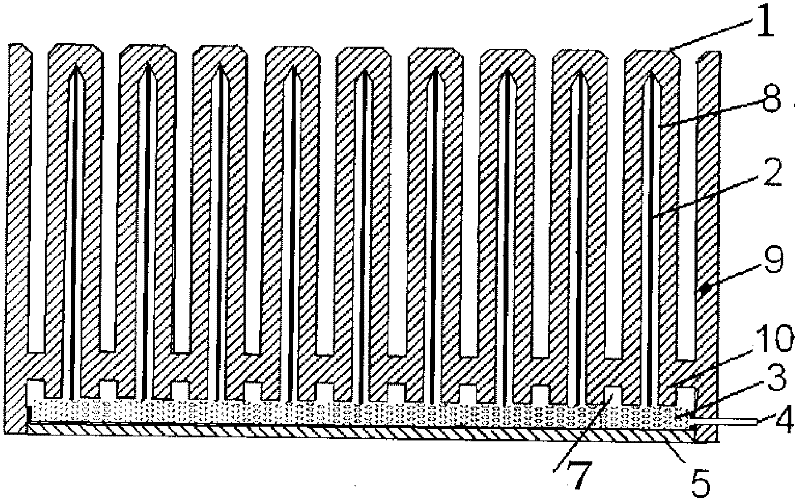

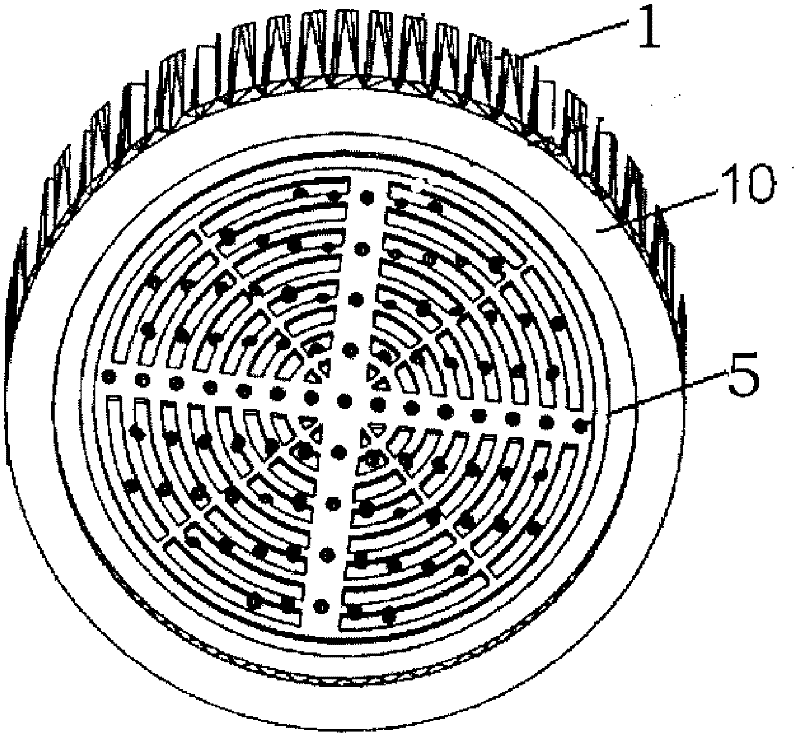

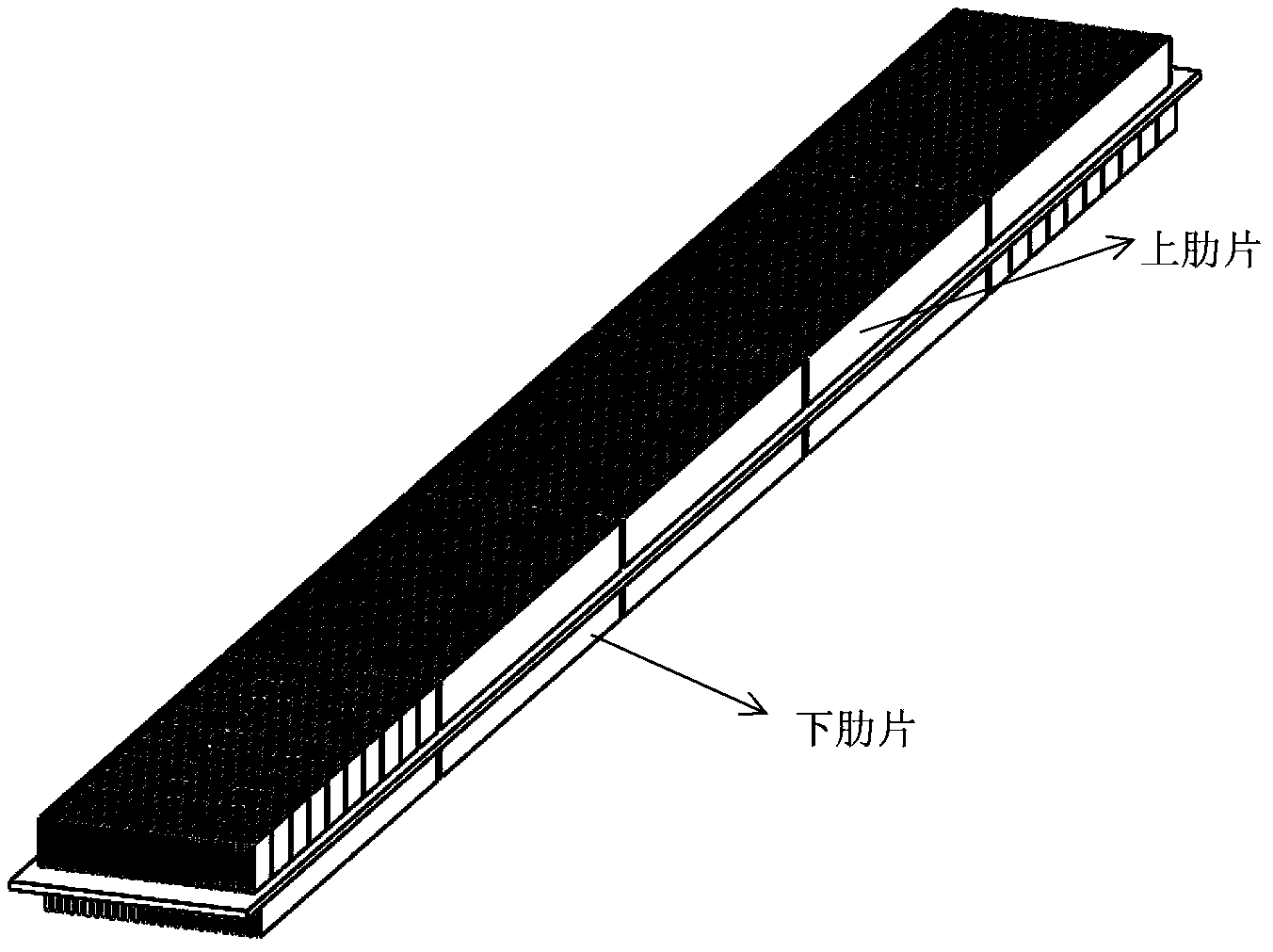

Extended integral flat heat pipe at condensation end

ActiveCN102506600AImprove cooling effectEasy to processIndirect heat exchangersBoiling pointEngineering

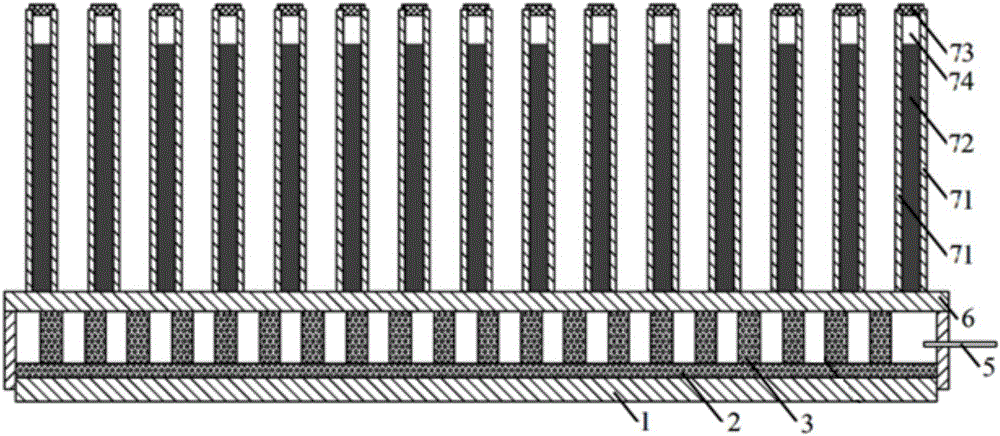

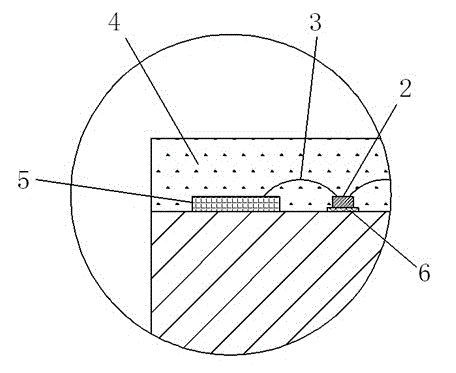

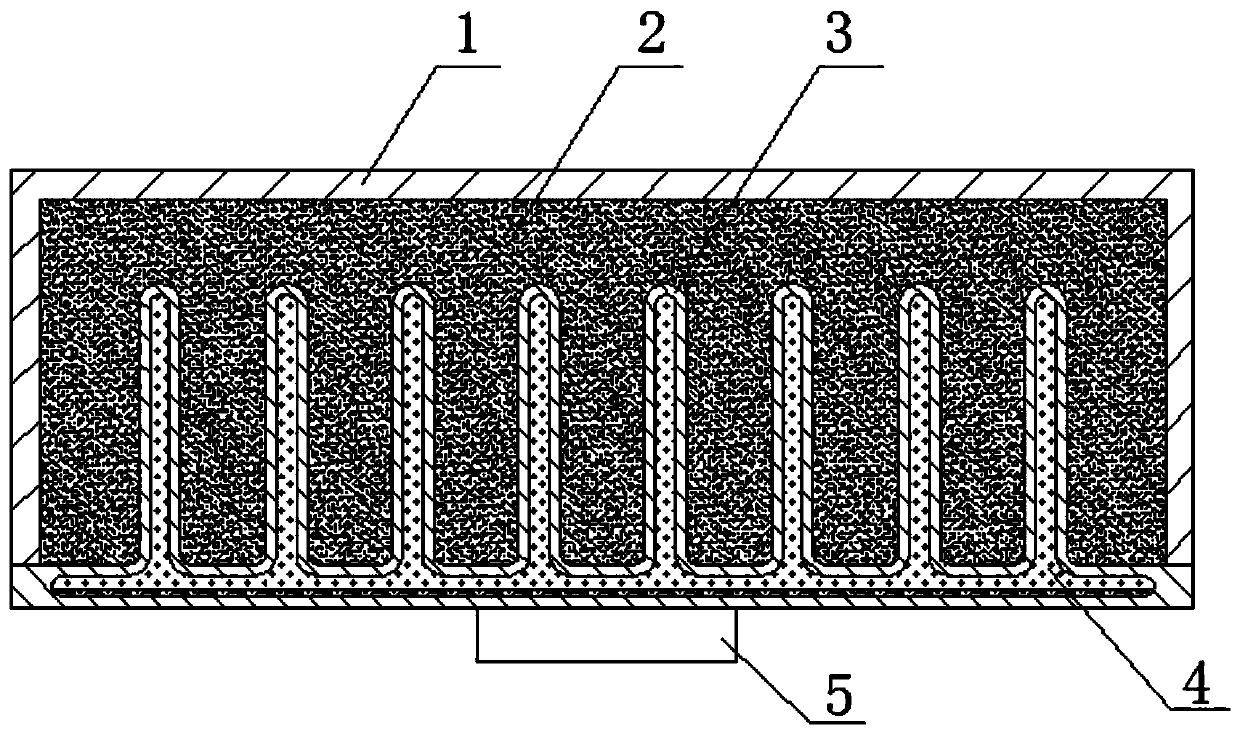

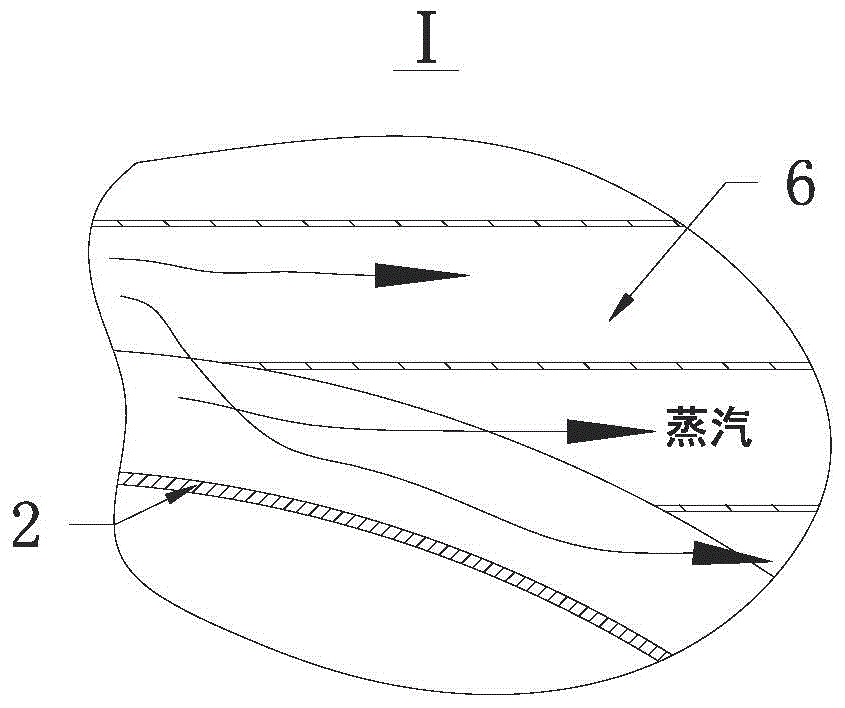

The invention discloses an extended integral flat heat pipe at a condensation end, which belongs to radiating devices. A flat heat pipe is manufactured in a radiating fin, namely, outer-layer fins of the radiating fin are fixed to a bottom plate, a porous metal material layer is attached onto the bottom plate, and capillary liquid sucking cores are manufactured in inner cavities of various middle fins; grooves are formed on a base of the radiating fin by the middle fins; and when low-boiling liquid in the porous metal material layer is heated and vaporized, steam flows out from insides of porous materials under tiny pressure, and uniformly flows to the inner cavities, which is used as condensation channels and arranged inside the fins, of the middle fins via the grooves at the bottom of the radiating fin. The flat heat pipe and the radiating fin are integrated, contact thermal resistance between the flat heat pipe and the radiating fin is eliminated, simultaneously, condensation area of the steam is increased, longitudinal heat conduction capacity of the flat heat pipe is improved, and radiating efficiency of a radiating device is enhanced. In addition, the extended integral flat heat pipe operates and runs at low cost and low energy consumption, and brings a good way for solving the problem that heat dissipation of high-power photoelectric chips is restricted.

Owner:淳华氢能源科技(湖南)有限公司

Composite heat dissipation device

InactiveCN106793685AImprove performancePromote escapeHeat storage plantsMachines using electric/magnetic effectsEvaporationIntegrated design

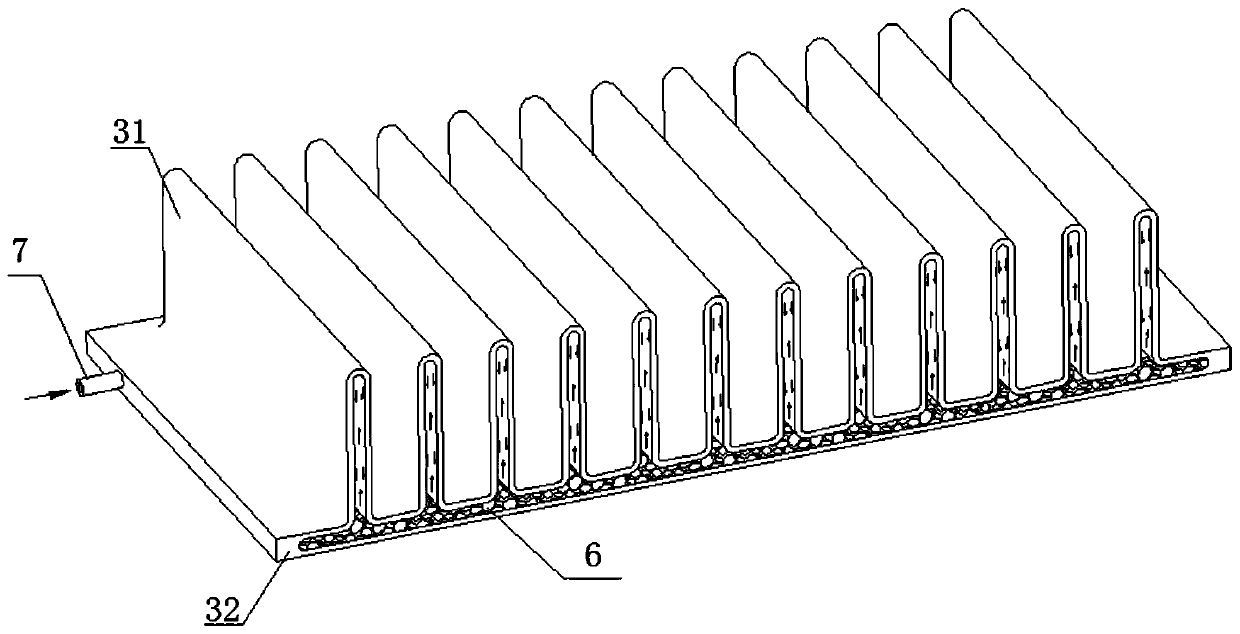

The invention discloses a composite heat dissipation device. The device comprises a flat plate heat tube and multiple sandwiched phase transition material composite boards. The evaporation end of the flat plate heat tube is used for taking heat from a heating element. The condensation end of the flat plate heat tube is connected with base parts of the sandwiched phase transition material composite boards. A multi-hole capillary liquid adsorbing core layer is arranged on the inner wall of the evaporation end. A bionic capillary liquid adsorbing core is arranged on the multi-hole capillary liquid adsorbing core layer. Each sandwiched phase transition material composite board comprises an enclosed inner cavity. Phase transition materials are arranged in each inner cavity. The side wall of each inner cavity is a metal plate. According to the invention, the flat plate heat tube with the capillary liquid adsorbing core has good temperature averaging ability; through the phase transition materials, temperature peaks are inhibited, so normal work of the whole electronic device is ensured; and through the integrated design of the flat plate heat tube and the sandwiched phase transition material composite boards, contact thermal resistance between a traditional flat plate heat tube and a heat sink is eliminated. In one word, the heat dissipation device is better in temperature averaging ability, stronger in heat dissipation ability, high in safety and simple to process.

Owner:淳铭散热科技股份有限公司 +1

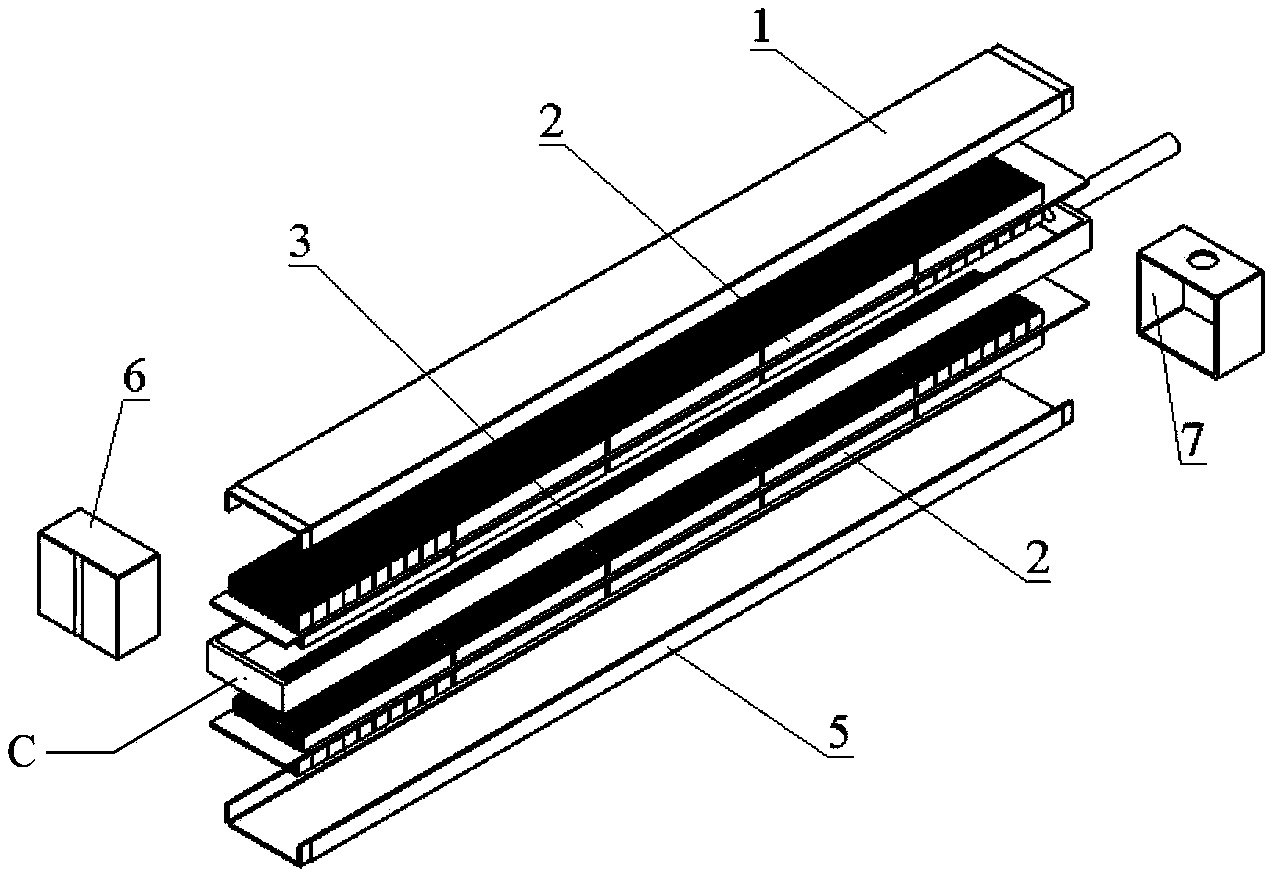

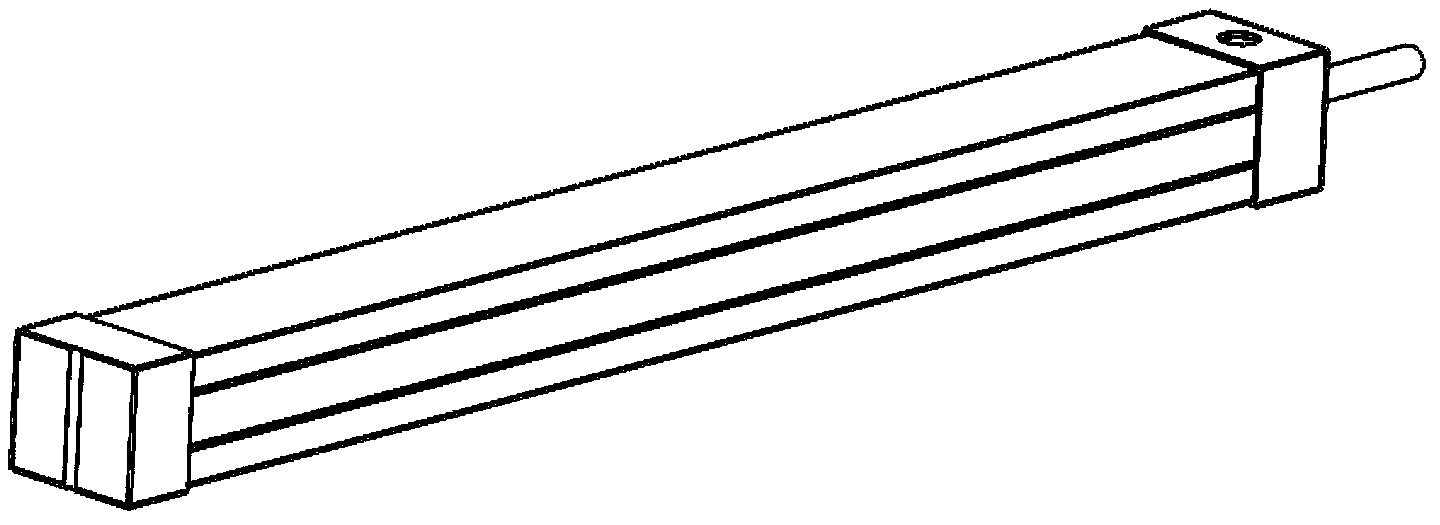

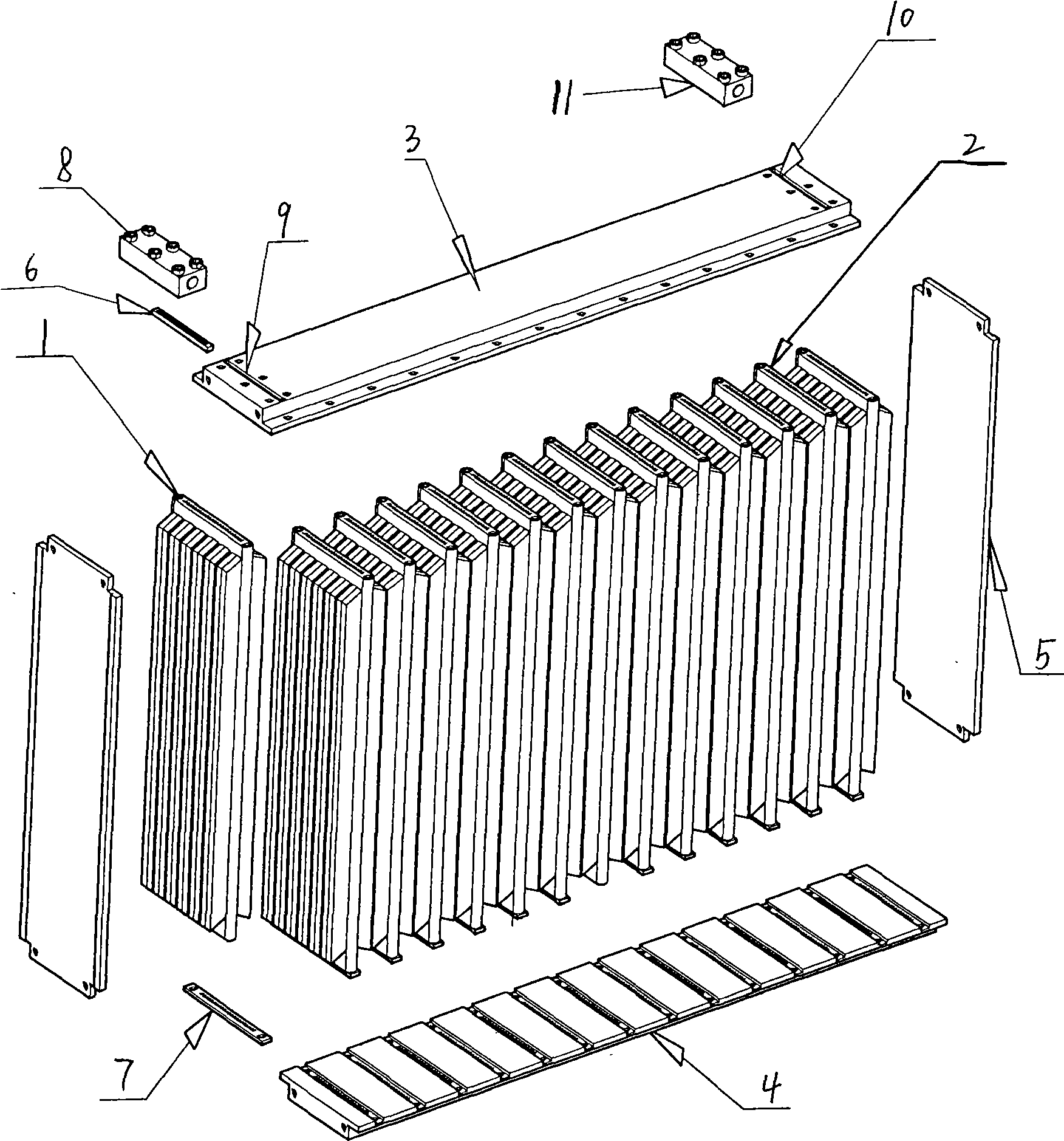

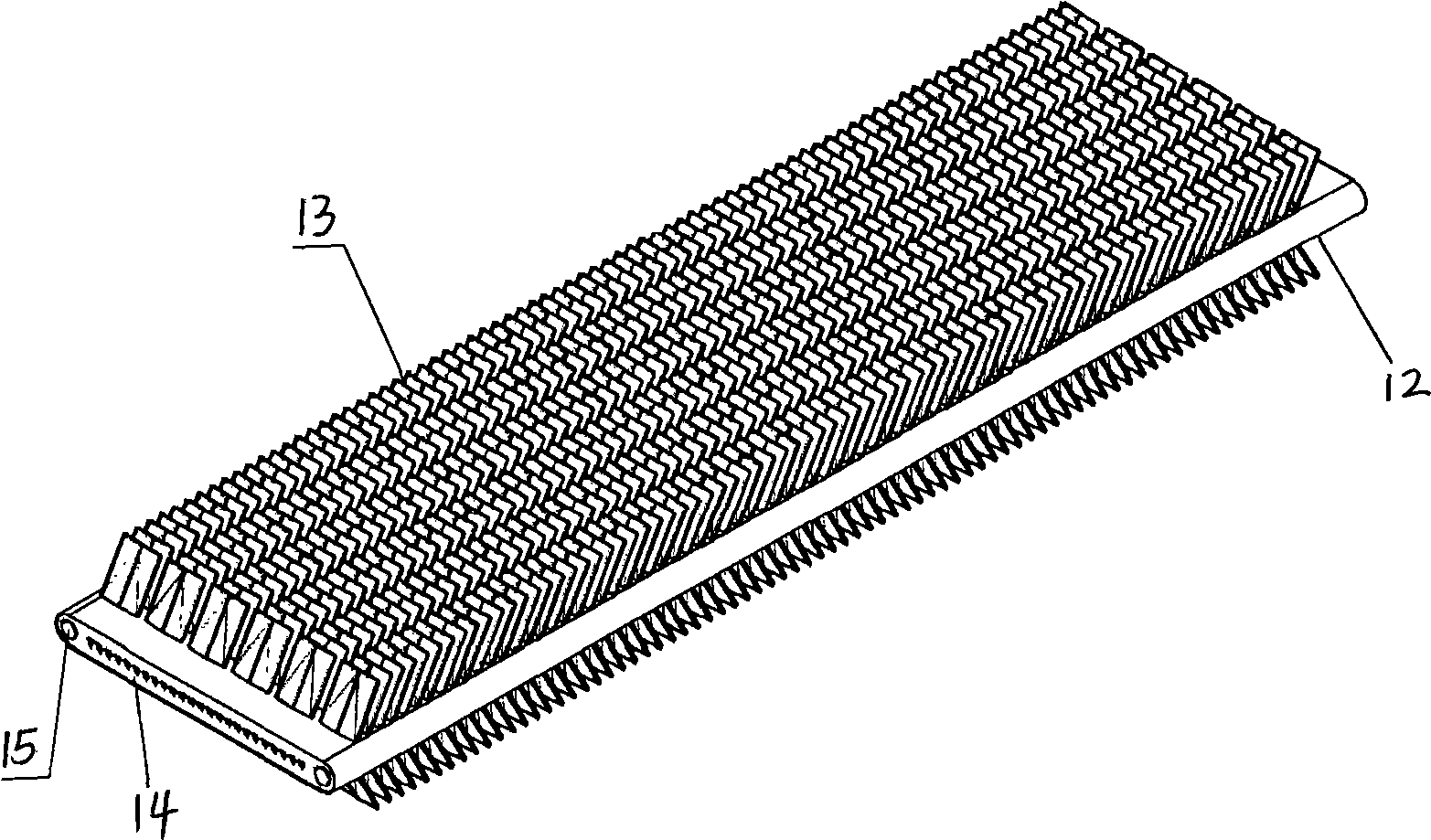

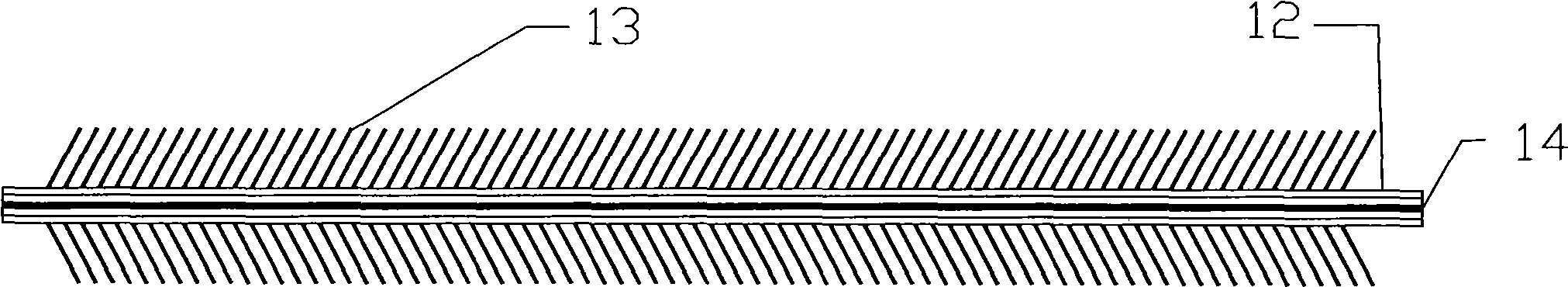

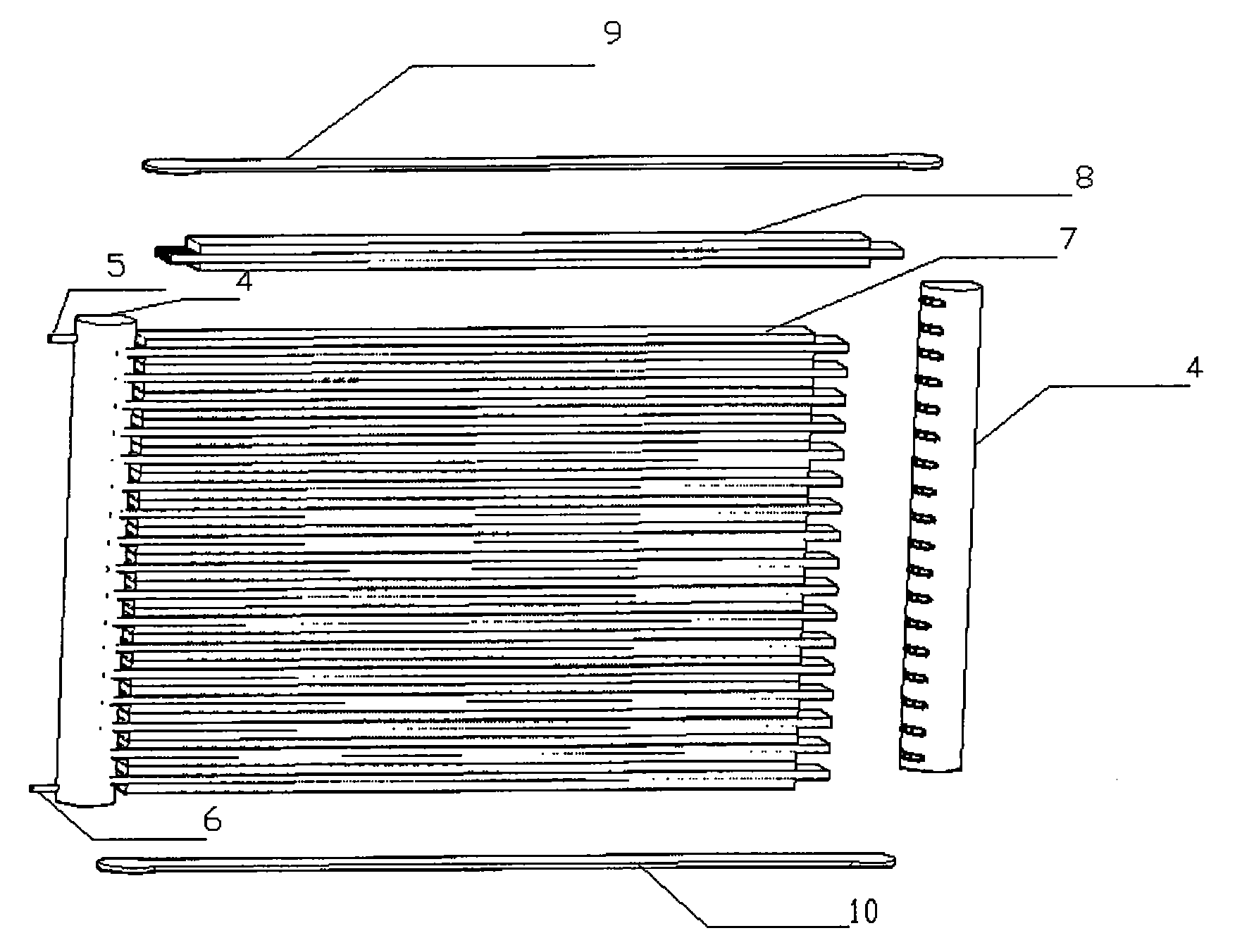

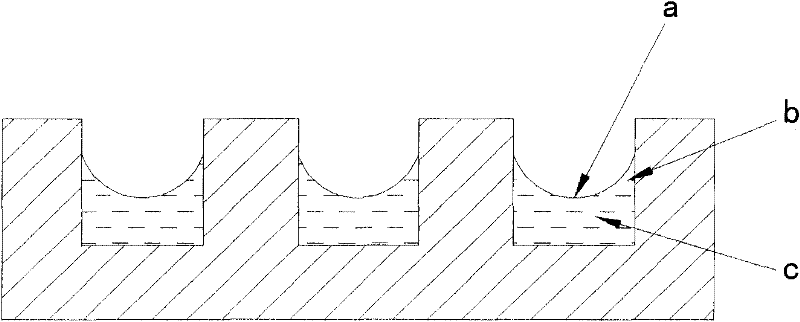

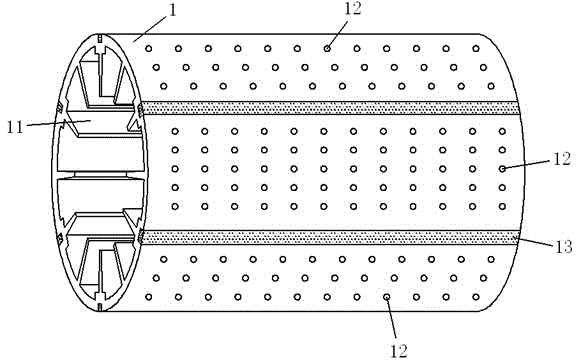

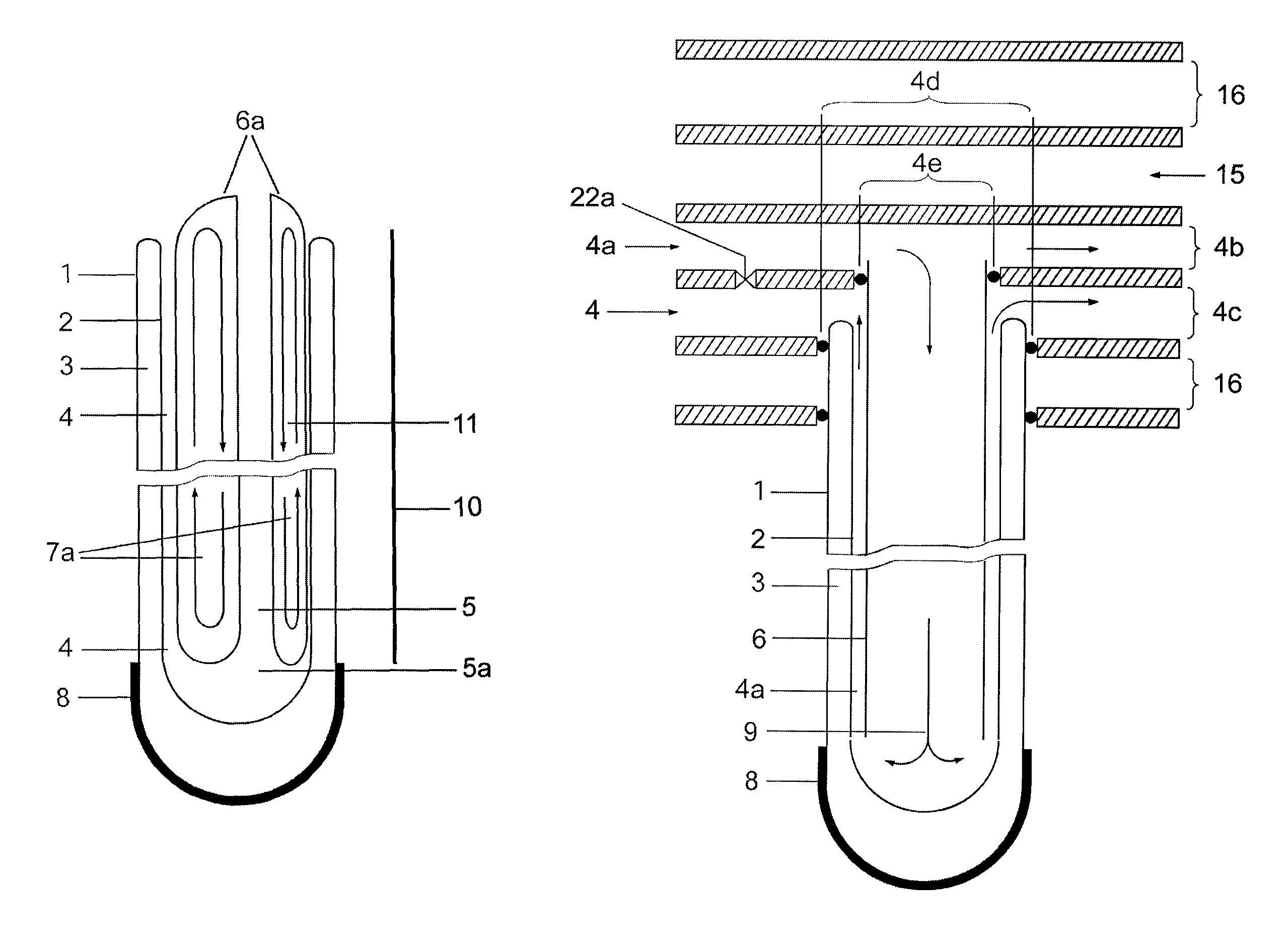

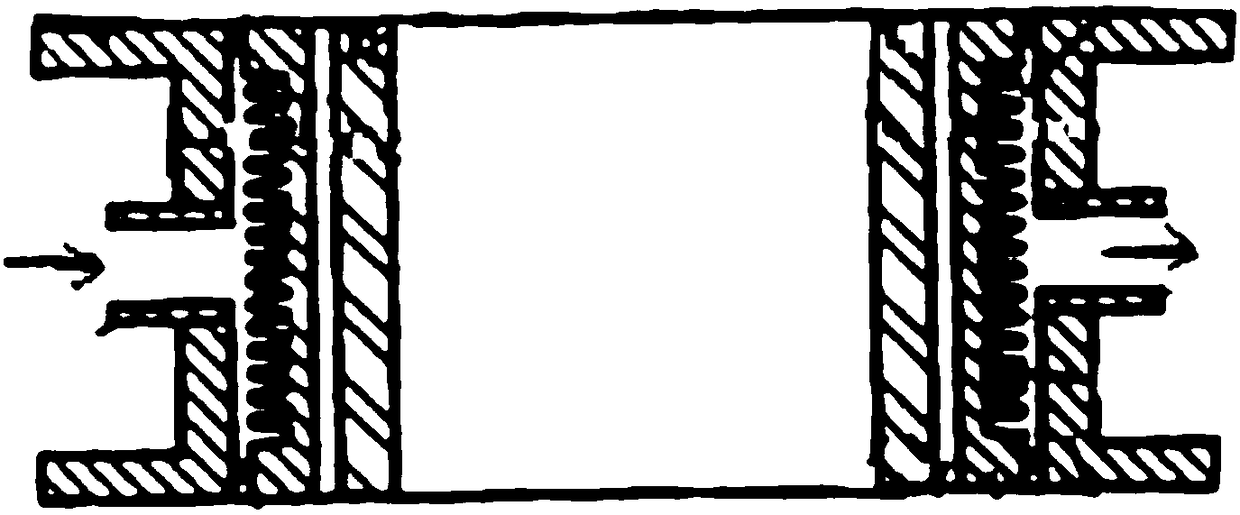

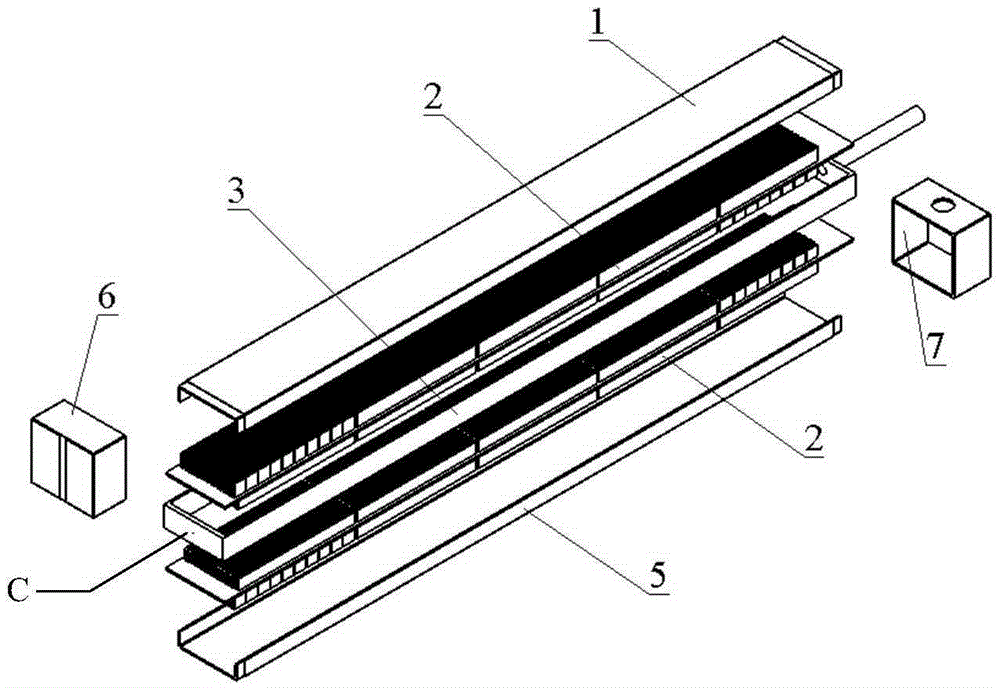

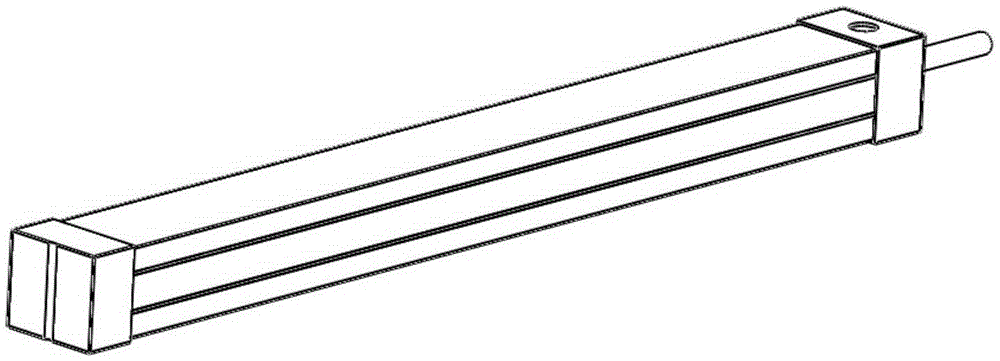

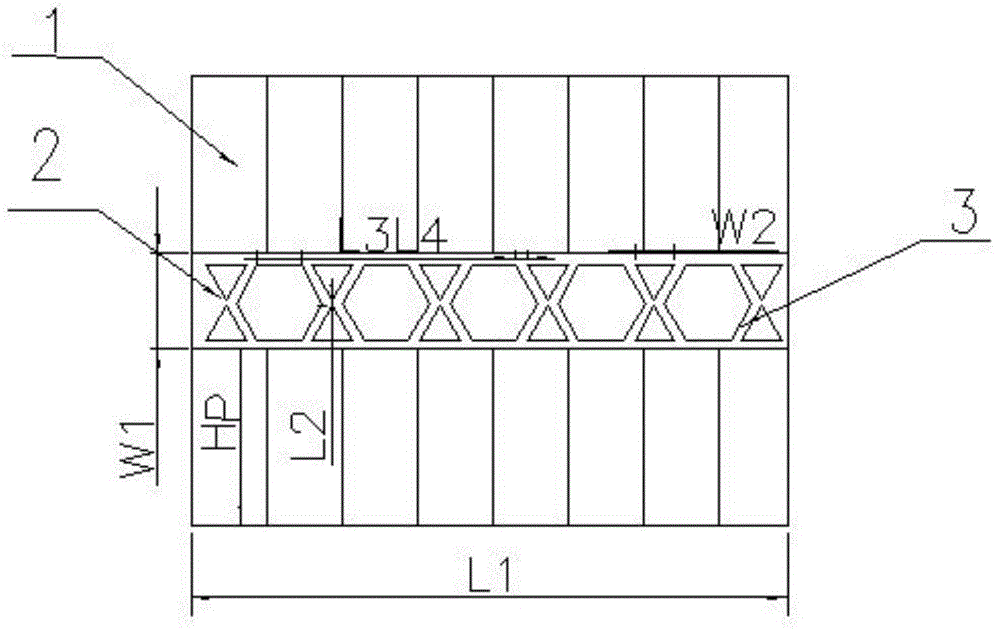

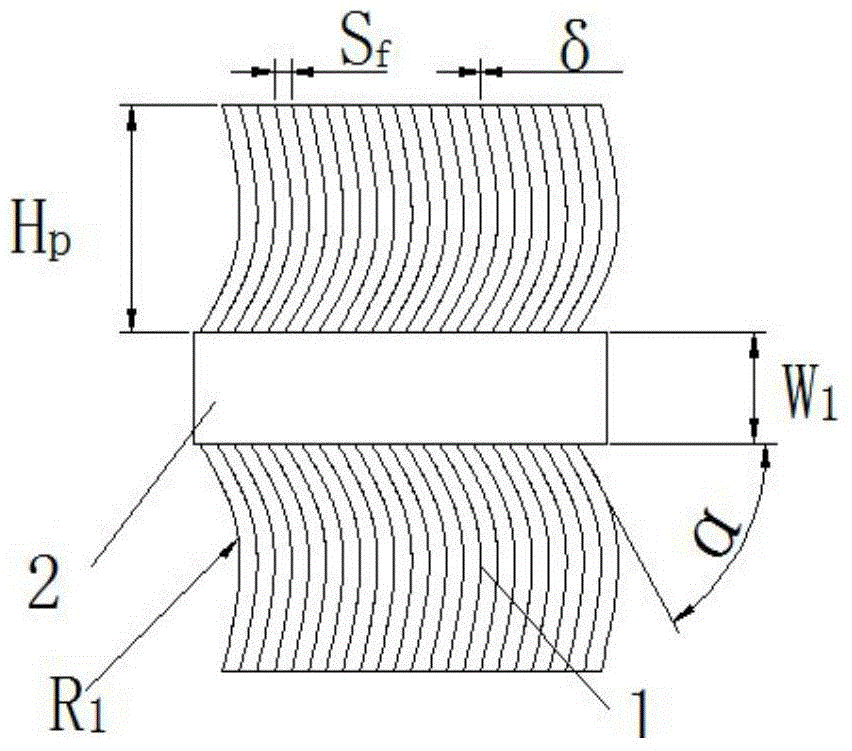

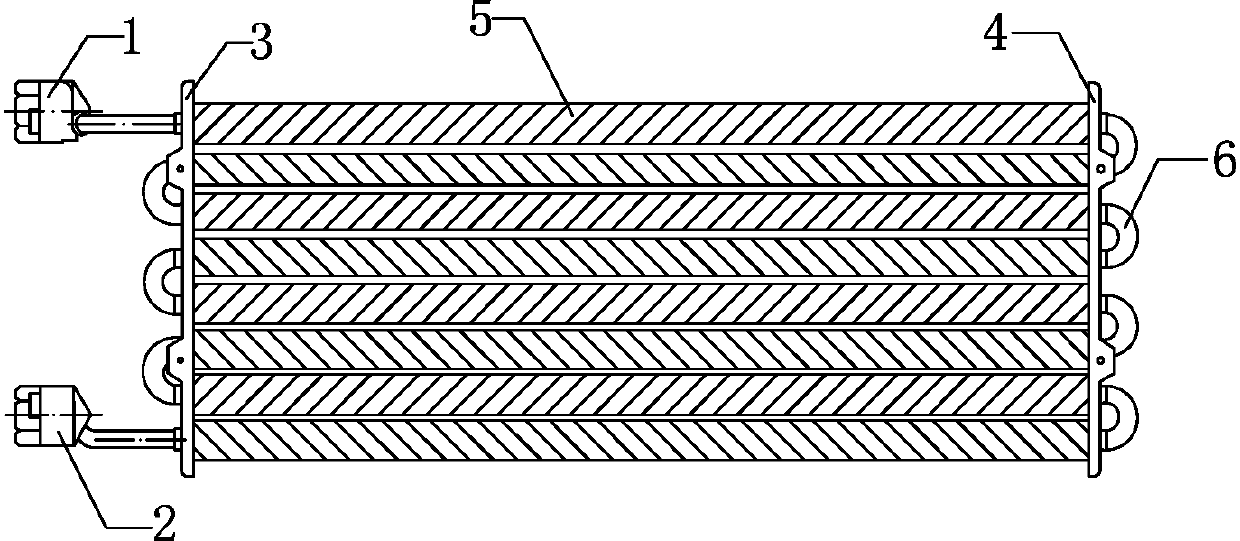

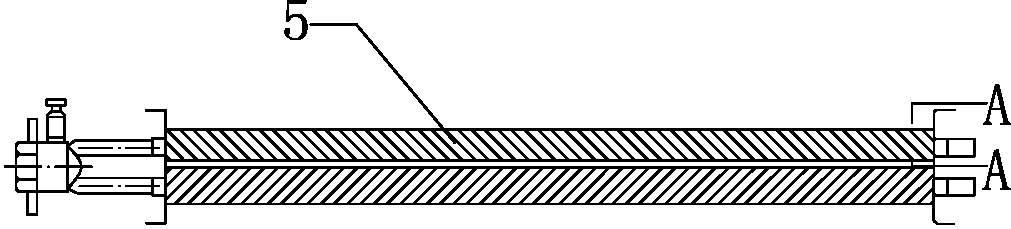

Miniature throttling refrigerator

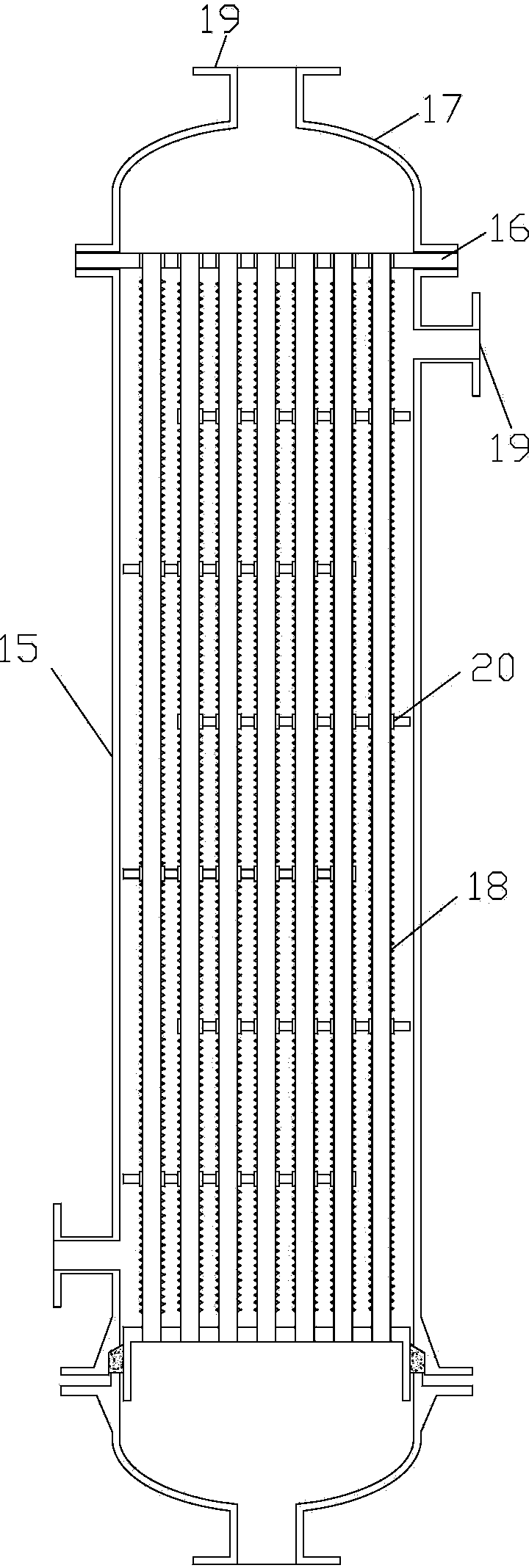

ActiveCN104142034AEliminate thermal contact resistanceSmooth welding surfaceFluid circulation arrangementMechanical apparatusEngineeringHigh pressure

The invention discloses a miniature throttling refrigerator which is composed of an upper cover plate, a lower cover plate, a heat-exchange core body and a cold-end seal head. An upper rib sheet and a lower rib sheet are fixed on the two sides of a panel base of the heat-exchange core body; channels which are in disjunction distribution and vertical to the long side edges of the panel base are formed in the length direction of both the upper and lower rib sheets; the upper rib sheet is located in a lower groove of the upper cover plate; the lower rib sheet is located in an upper groove of the lower cover plate; a through hole and an air inlet are formed in the top part of one end of the upper cover plate while the other end is unsealed and provided with a throttling hole; a through hole and an air outlet are formed in the top part of one end of the lower cover plate while a throttling hole is formed in the other end thereof; the upper cover plate, the lower cover plate and the heat-exchange core body compose a throttling refrigeration body; the cold-end seal head is arranged on one end, at which the throttling hole is, of the throttling refrigeration body in a sleeved manner; a low-pressure passageway is formed between the upper cover plate and the upper rib sheet; a high-pressure passageway is formed between the lower cover plate and the lower rib sheet; a high-temperature and high-pressure fluid enters into the high-pressure passageway from the air inlet, is changed into a low-temperature and low-pressure fluid after passing through the throttling hole, then enters into the low-pressure passageway, and finally flows out of the air outlet. The miniature throttling refrigerator has big specific surface area and high heat exchange efficiency, can bear high-pressure operation and is easy for large-scale production.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

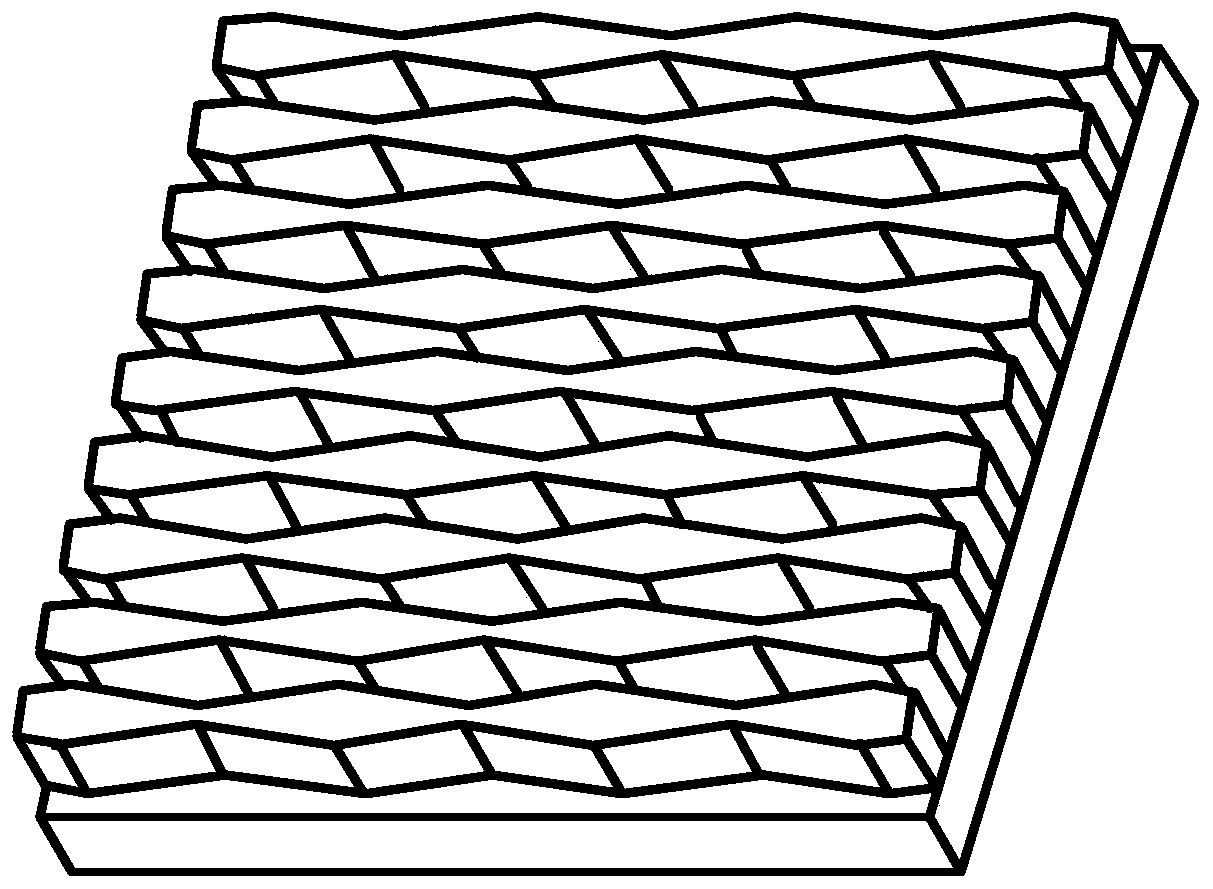

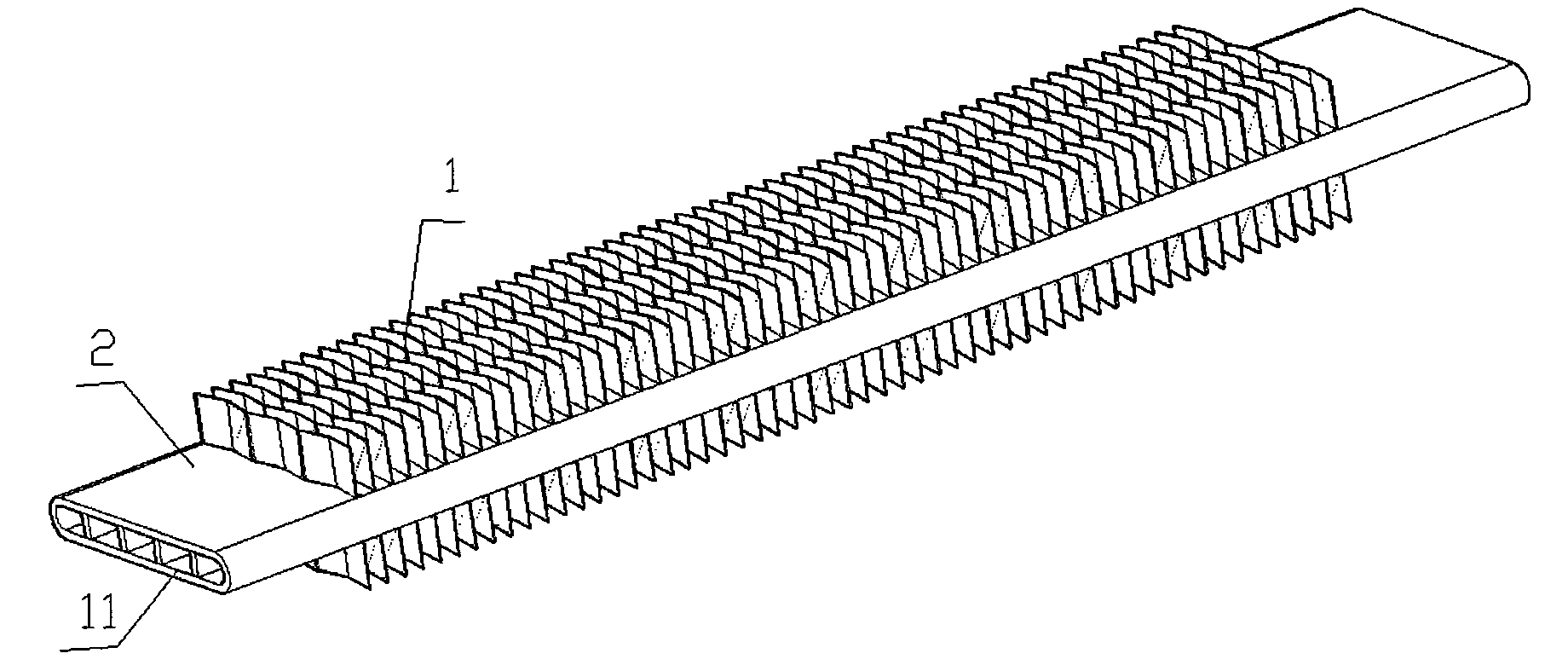

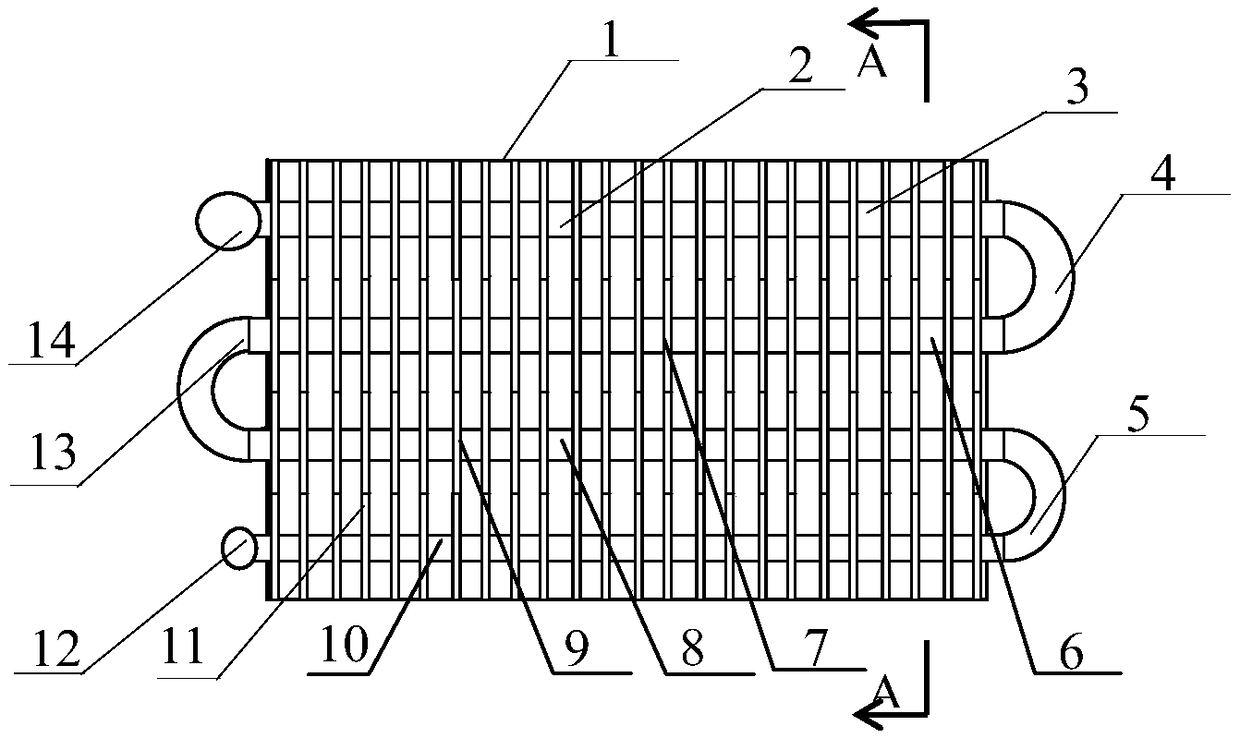

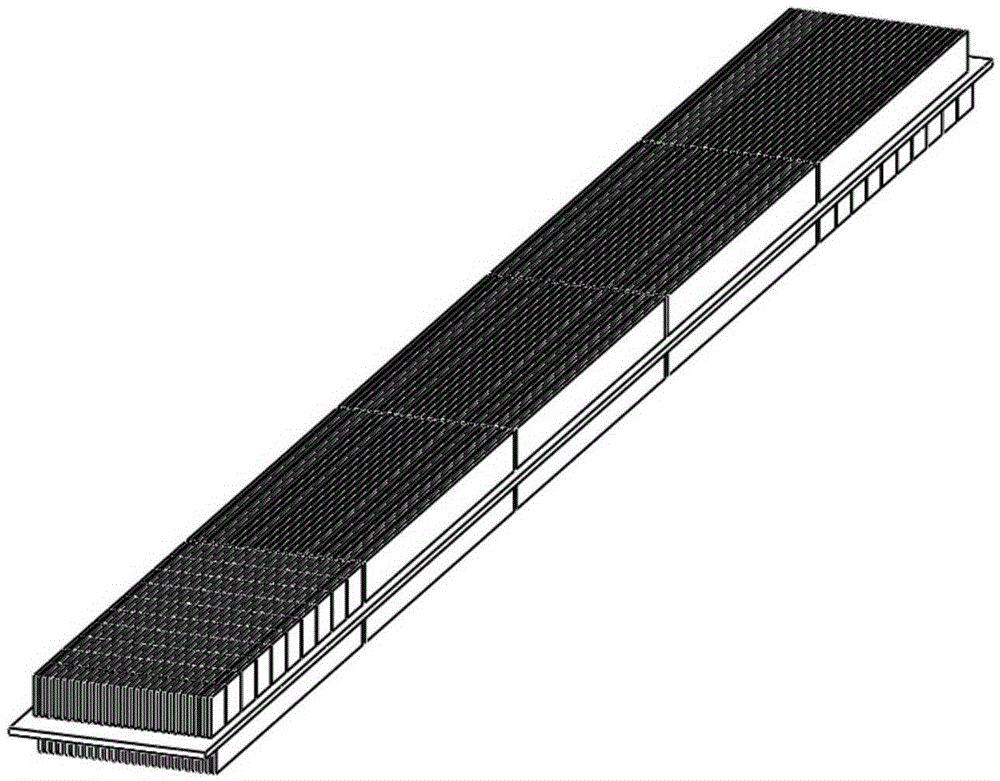

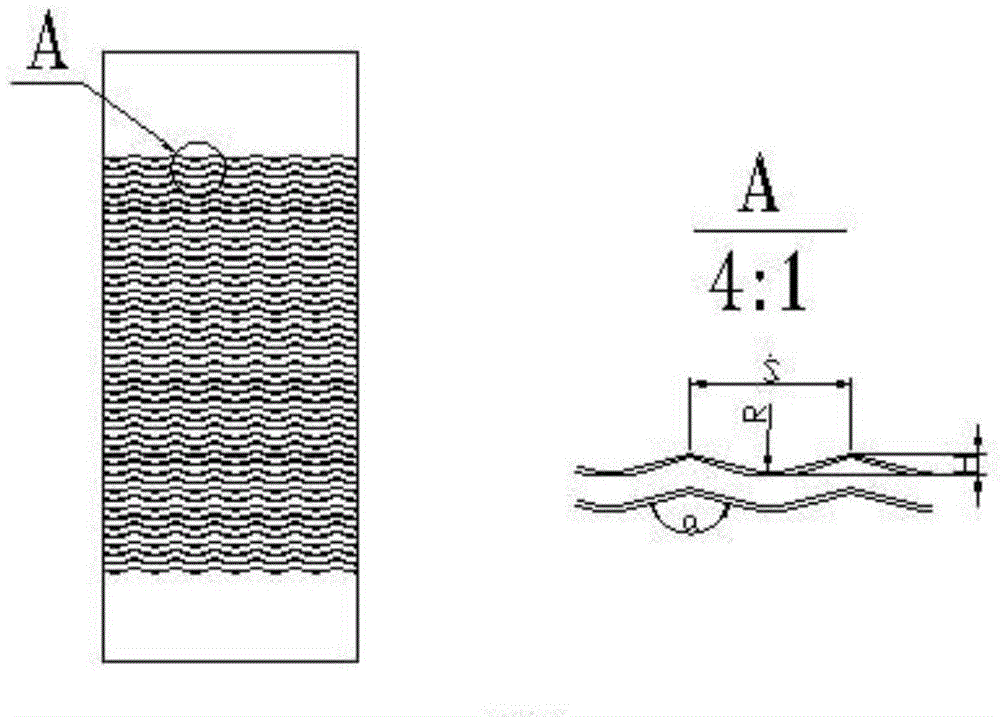

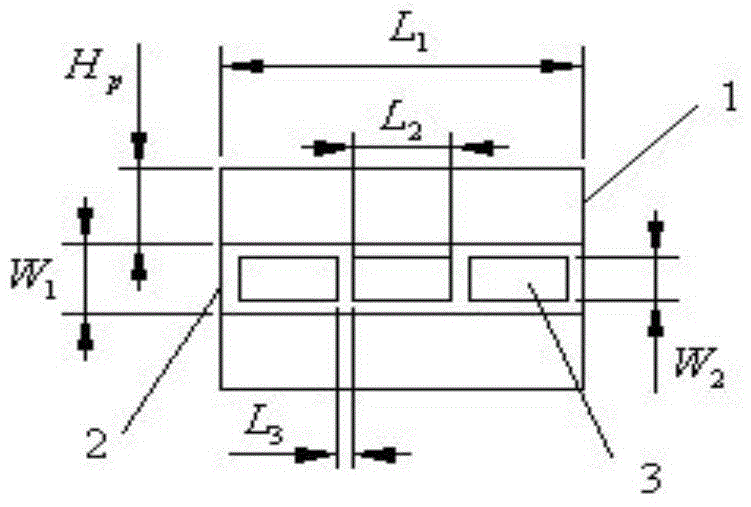

Special-shaped microchannel and exterior corrugated fin integration molding heat exchanger

InactiveCN101509731AAvoid cloggingReduce volumeStationary conduit assembliesLaminated elementsEngineeringHeat sink

The invention discloses a heat exchanger integrally formed by a profiled micro-channel and an external corrugated fin. The heat exchanger comprises a fin group, an upper cover plate, a lower cover plate, a side plate, an air inlet and an air outlet; the fin group is connected in parallel by a plurality of fins; each fin is made of plate material; two sides of the fin is provided with a corrugated fin and the middle part of the fin is provided with a plurality of profiled micro-passage structures; the corrugated fin and the plate material are integrally formed; the upper cover plate and the lower cover plate are respectively provided with a trough which is used for arranging the fin; two adjacent troughs of the upper cover plate and the lower cover plate are communicated with each other intermittently, thus leading the refrigerant to flow through a plurality of fins sequentially; and the profiled micro-passage is a square passage with the side length of 0.8-1mm. The heat exchanger utilizes the micro-pore passage technology, integral external fin technology and no-welding refrigerant high-pressure sealing technology, is applicable to CO2 refrigeration systems, and effectively solves the problem of the high-pressure running of the system. The heat exchanger has compact structure, high heat-exchanging efficiency, small volume, light weight, is made of full-aluminium composite, and greatly reduces the cost.

Owner:SOUTH CHINA UNIV OF TECH

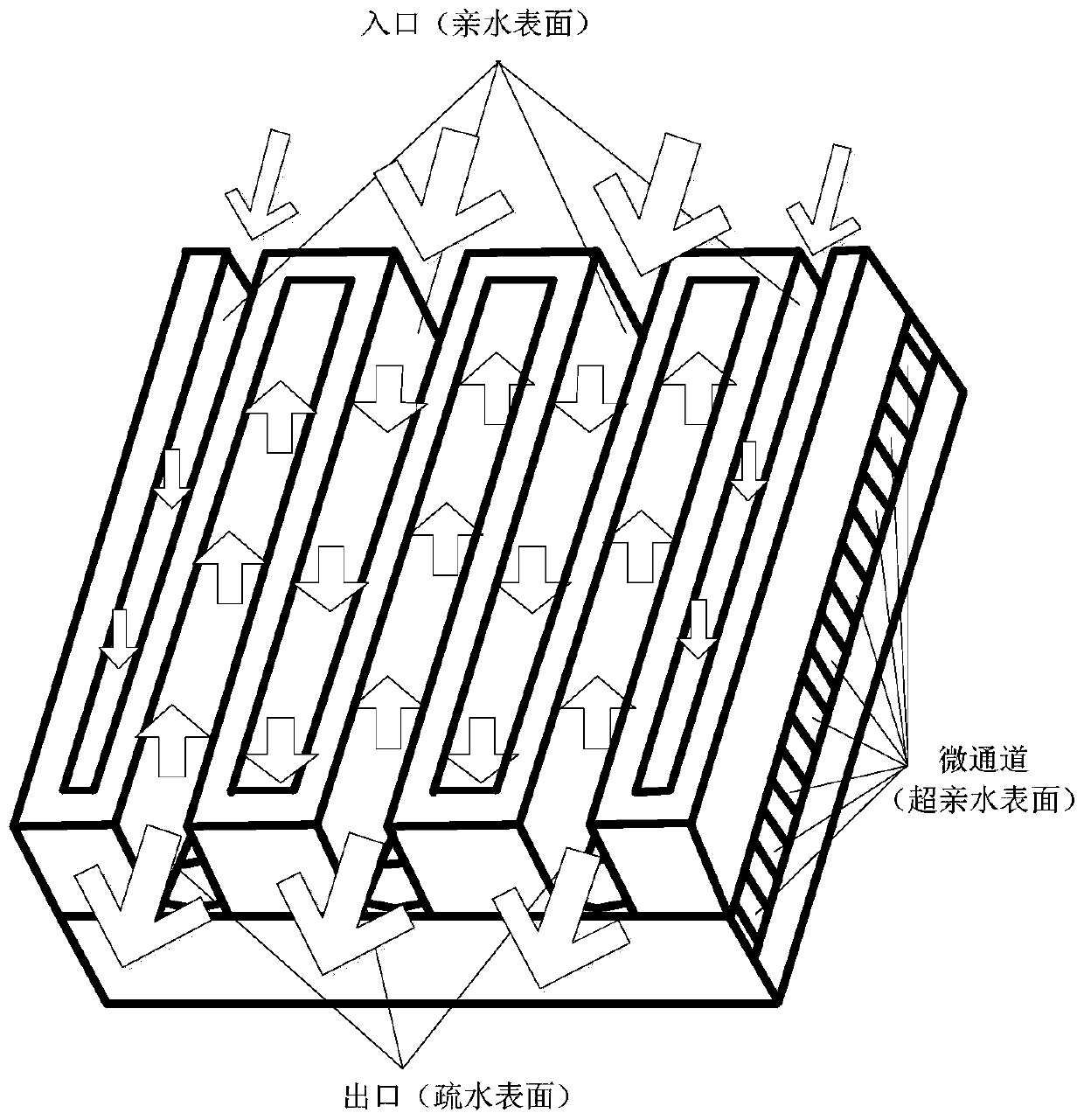

Low-resistance enhanced heat transfer structure based on nanometer super-wetting interface

ActiveCN110425914AShorten the length of the runnerReduce thicknessCoatingsModifications by conduction heat transferIsosceles trapezoidEnhanced heat transfer

The invention discloses a low-resistance enhanced heat transfer structure based on a nanometer super-wetting interface. The low-resistance enhanced heat transfer structure comprises a lower embedded microchannel layer and an upper manifold channel layer, wherein embedded microchannels are perpendicular to manifold channels; the lower embedded microchannel layer consists of a plurality of embeddedmicrochannel units; the cross section of each embedded microchannel of each unit is a rectangular divergent cross section along the flowing direction of a cooling working medium; the shape of each embedded microchannel of each unit is isosceles trapezoid; the upper manifold channel layer is composed of the S-shaped manifold channels; and two adjacent S-shaped manifold channels form inlets and outlets of the manifold channels. According to the low-resistance enhanced heat transfer structure, a microchannel radiator is constructed by utilizing a layered flow structure, the heat transfer characteristic and the resistance characteristic can be simultaneously improved by combining the microchannel radiator with the nano super-wetting interface and the divergent microchannel section, and the low-resistance enhanced heat exchange of the microchannel radiator is achieved under the condition of higher heat dissipation efficiency.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

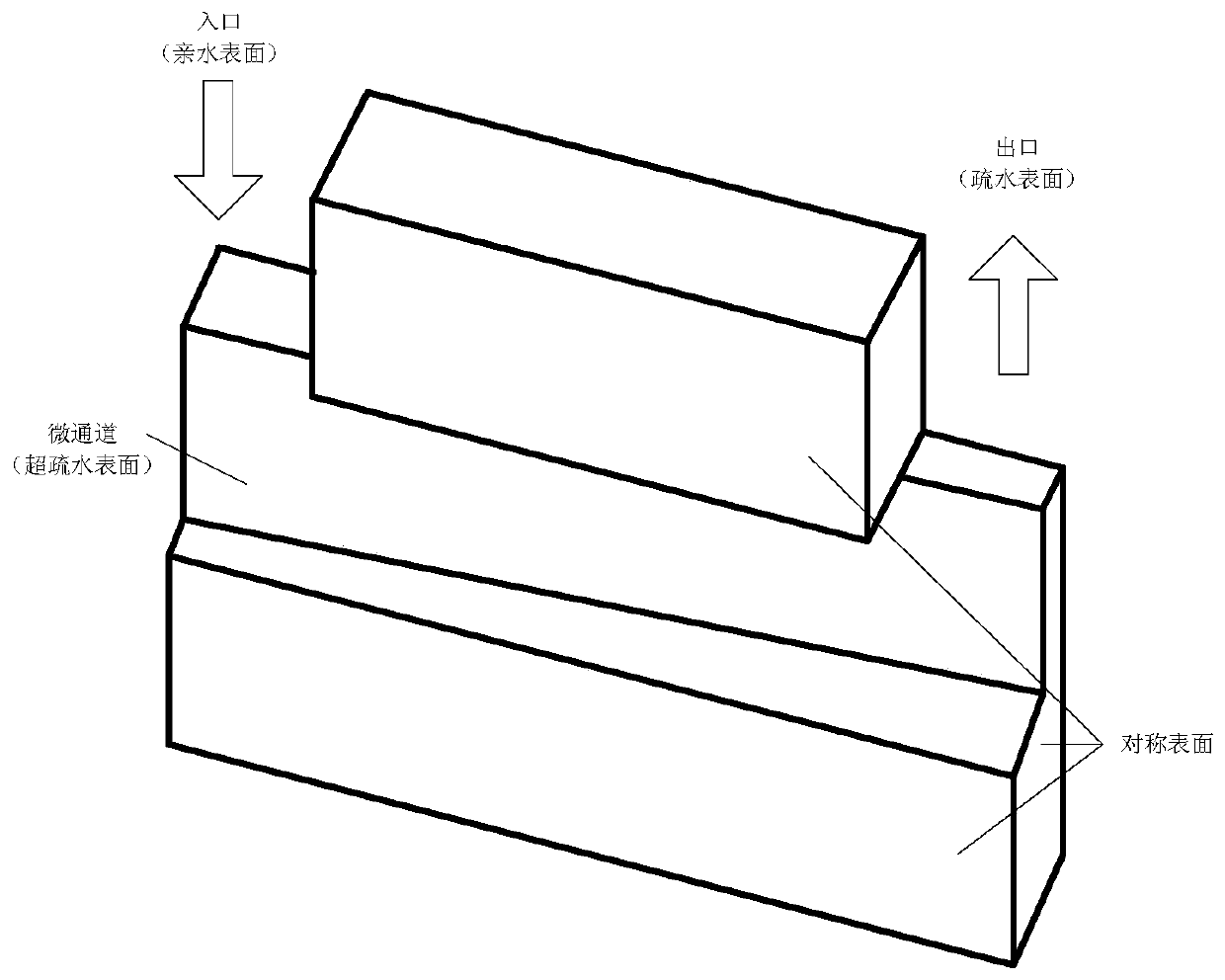

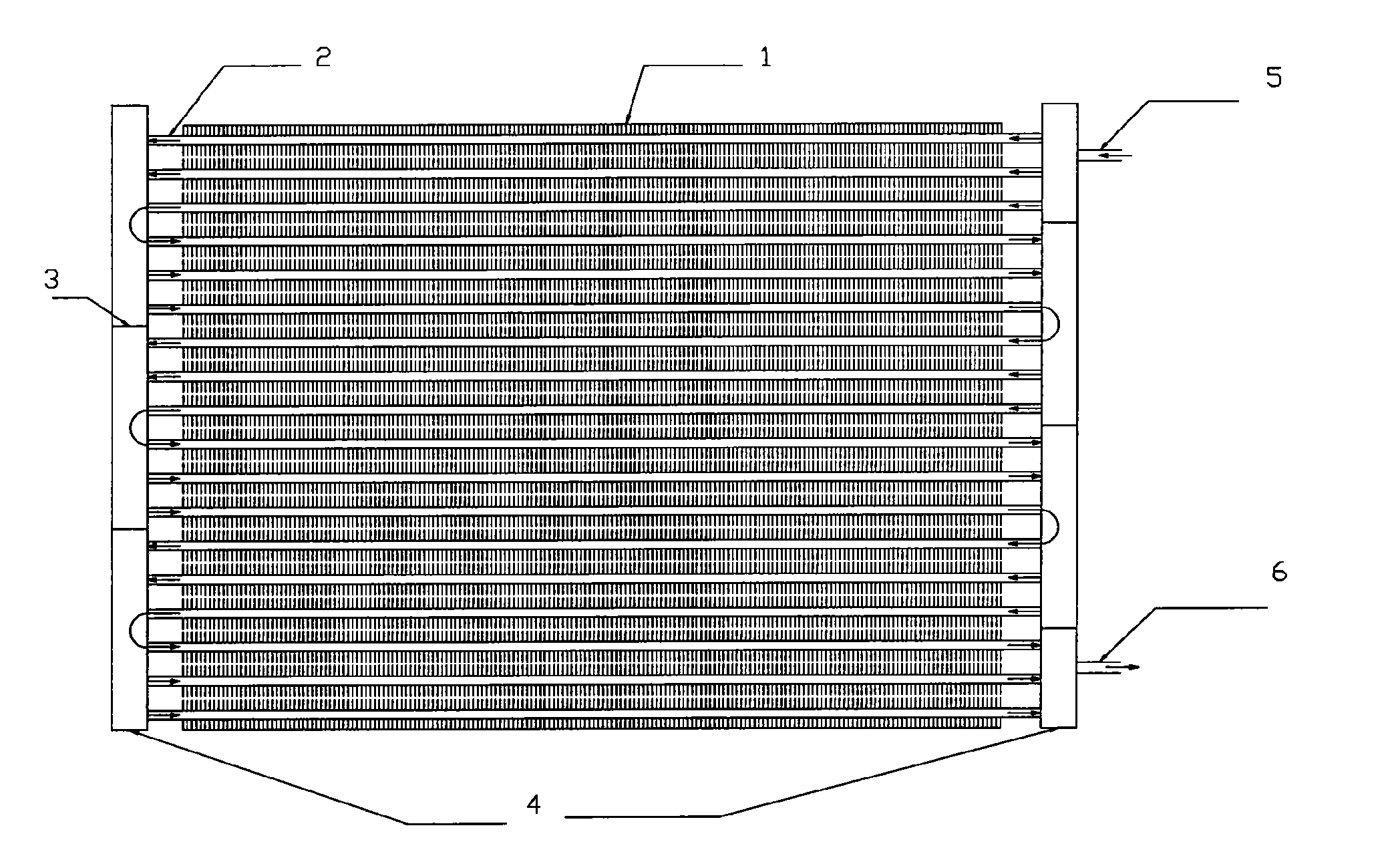

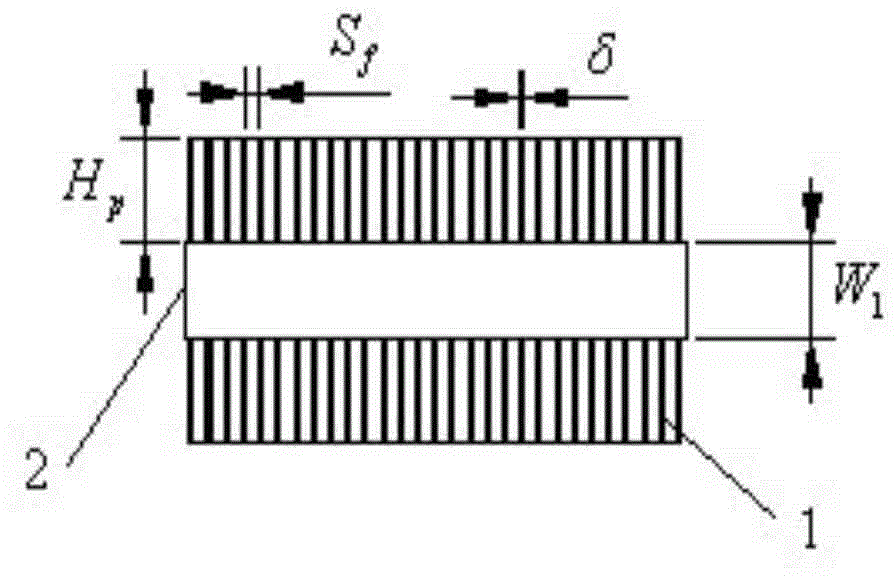

Parallel stream heat exchanger integrated with microchannel and outer fin

InactiveCN101672553AEliminate thermal contact resistanceImprove heat transfer performanceEvaporators/condensersLaminated elementsHeat sinkAluminum composites

The invention discloses a parallel stream heat exchanger integrated with a microchannel and an outer fin, comprising a left collector tube, a right collector tube, an upper cover board, a lower coverboard, a cooling fin set, an air inlet pipe and a liquid outlet pipe; the cooling fin is integrated with a fin and aluminium profile, a microchannel is arranged on the aluminium profile, and the diameter or edge distance of the microchannel is 0.5-3mm; the microchannel of the cooling fin is communicated with the left collector tube and the right collector tube, distance pieces which are arrayed ina staggering way are arranged in the middle of the left and right collector tubes at interval, the left and right collector tubes are divided into a plurality of areas, the air inlet pipe and the liquid outlet pipe and the left and right collector tubes are connected by welding, and the upper cover board and the lower cover board are respectively connected with the left and right collector tubes;by utilizing the microchannel technology, integral outer fin technology and collector tube technology, the invention effectively solves the problem of thermal contact resistance of sheets and the fins; the structure is compact, heat exchanging efficiency is high, the volume is small, the quality is light, the processing is simple, and the heat exchanger adopts all aluminium composite material, thereby greatly reducing the cost.

Owner:SOUTH CHINA UNIV OF TECH

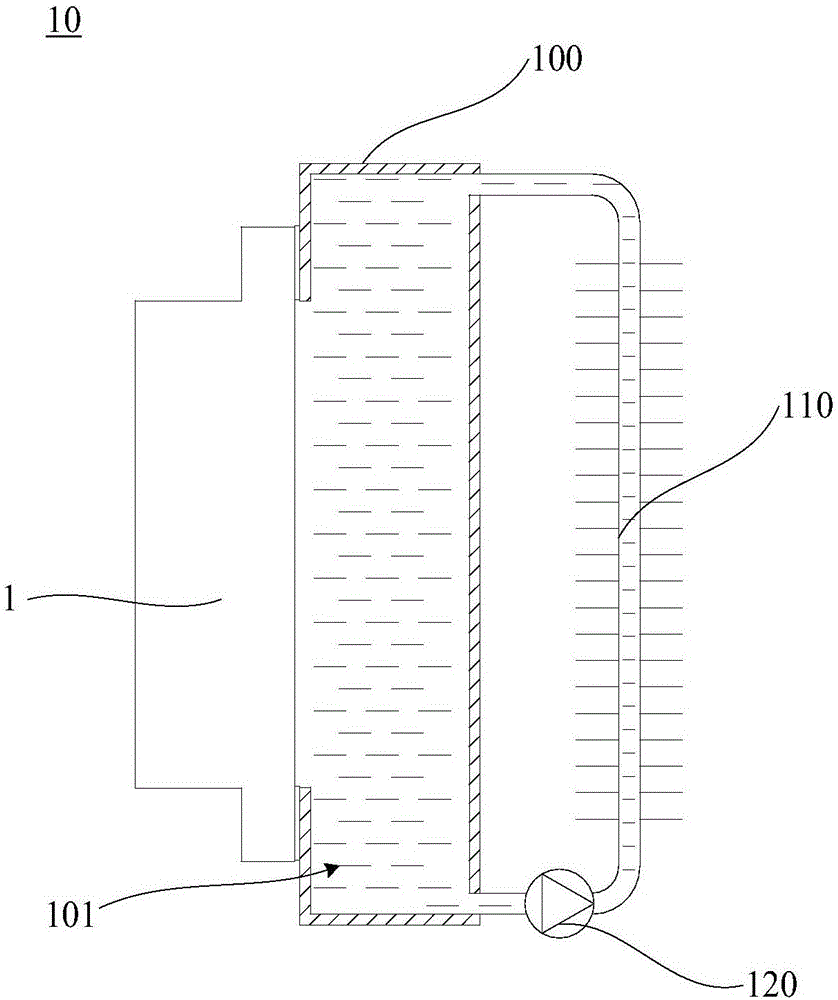

Heat pipe radiator of phase change drive loop

InactiveCN102997729AEliminate thermal contact resistanceEnhanced convective heat transferIndirect heat exchangersEvaporationLiquid storage tank

The invention discloses a heat pipe radiator of a phase change drive loop. According to the heat pipe radiator, a wick is arranged on the upper portion of an evaporation section of a heat pipe, the bottom end of the evaporation section is a heating surface, and an inlet of a working medium circulation pipe is connected with the wick; an outlet of the working medium circulation pipe is connected inside a space interlayer formed by the wick and the heating surface; a liquid storage tank is arranged between the inlet of the working medium circulation pipe and the wick; the evaporation section of the heat pipe is a flat pipe, and the height of the space interlayer formed by the wick and the heating surface is 0.1-2mm; and fins are arranged on the outer side of the working medium circulation pipe to strengthen condensation effects. A heat-transfer mechanism that hydrodynamic forces are driven by phase change to circularly cool a high heating flux heating device is completely a heat-transfer mechanism of a traditional loop heat pipe, and a thermal contact resistance between a uniform temperature board and a radiator bottom board in a traditional radiating method is simultaneously eliminated. Low resistance circulation of the heat pipe can be achieved without any auxiliary gravity, and the heat pipe radiator can be used as an efficient cooling device and used for cooling and radiating various high heating flux heaters.

Owner:TIANJIN UNIV OF COMMERCE

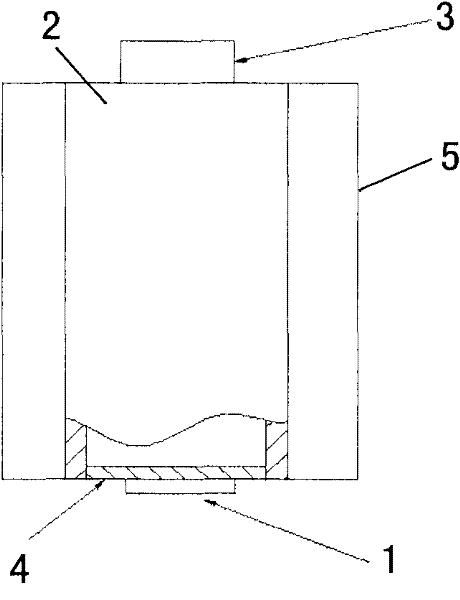

Cavity-type light emitting diode lamp

InactiveCN102235615AThe overall thickness is thinReduce heat transfer resistancePoint-like light sourceElectric circuit arrangementsLED lampLight-emitting diode

The invention relates to a cavity-type light emitting diode lamp. A cooler is an enclosed metal cavity which is internally filled with a liquid working medium with latent heat of vaporization; a microgroove group metal plate is arranged on the cavity wall of the side or bottom of the metal cavity, and the periphery of the metal cavity is fixedly connected to the cavity wall of the metal cavity in a sealing mode; the back side of the metal cavity is provided with a microgroove group which is sealed in the cavity inward, and the frontage of the metal cavity is outward; the microgroove group is provided with a plurality of open-type microgroove channels, thus an open-type microgroove group is formed; an LED (light emitting diode) chip is encapsuled on the frontage of the metal plate, the light emitting surface of the chip is outward, the outer surface of the cavity wall at the top of the metal cavity is fixedly connected with a power supply, and the chip is electrically connected with a power supply; and the outer side wall of the cooler, except for the microgroove metal plate, is provided with fins. When the lamp works, the heat transfer process is intensified by high-strength minuteness scale composite phase-change of nucleate boiling of the liquid working medium, the liquid working medium is changes into steam, and the heat is taken away, expands on the surface of the metal cavity, and is released into the environment through the fins. The problems of insufficient heat radiation, over-heavy weight and overlarge volume of the existing LED lamp chip are solved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

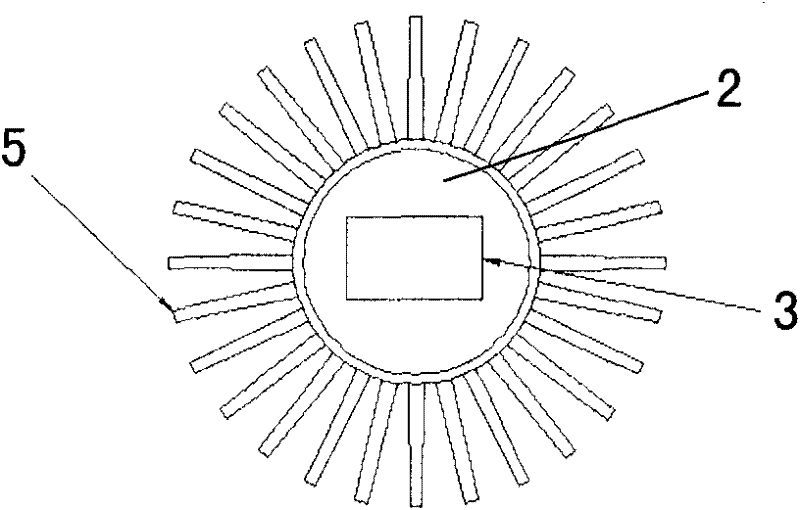

LED (Light Emitting Diode) integrated light source with tubular structure

InactiveCN102980077AEffective distributionEliminate thermal contact resistancePoint-like light sourceLighting heating/cooling arrangementsHeat conductingLead bonding

The invention discloses an LED (Light Emitting Diode) integrated light source with a tubular structure. The LED integrated light source is provided with a heat radiating structure and is luminous within a range of 360 degrees. According to the invention, the LED integrated light source comprises a tubular packaging bracket, wherein an LED packaging chamber, in which a plurality of strip-shaped recesses are formed, is formed in the outer wall of the tubular packaging bracket; a plurality of chip heat conducting glues are arranged on the bottom surfaces of the recesses of the LED packaging chamber; LED chips are arranged on the chip heat conducting glues; the LED chips are connected with each other through chip interconnecting wires; lead bonding pad plates are arranged at two ends of the LED packaging chamber; the LED chips are connected with the lead bonding pad plates through chip interconnecting wires; a fluorescent powder colloid is arranged in the LED packaging chamber; and a plurality of air convection holes are formed in the tubular packaging bracket. The LED integrated light source with the tubular structure has the advantages of simple structure, uniformity of luminance, large irradiation range and convenient application; and through the adoption of the tubular packaging bracket with heat radiation fins and the air convection holes, the heat generated by the LED chips is effectively radiated.

Owner:DONGGUAN SINOINNOVO SEMICON LIGHTING

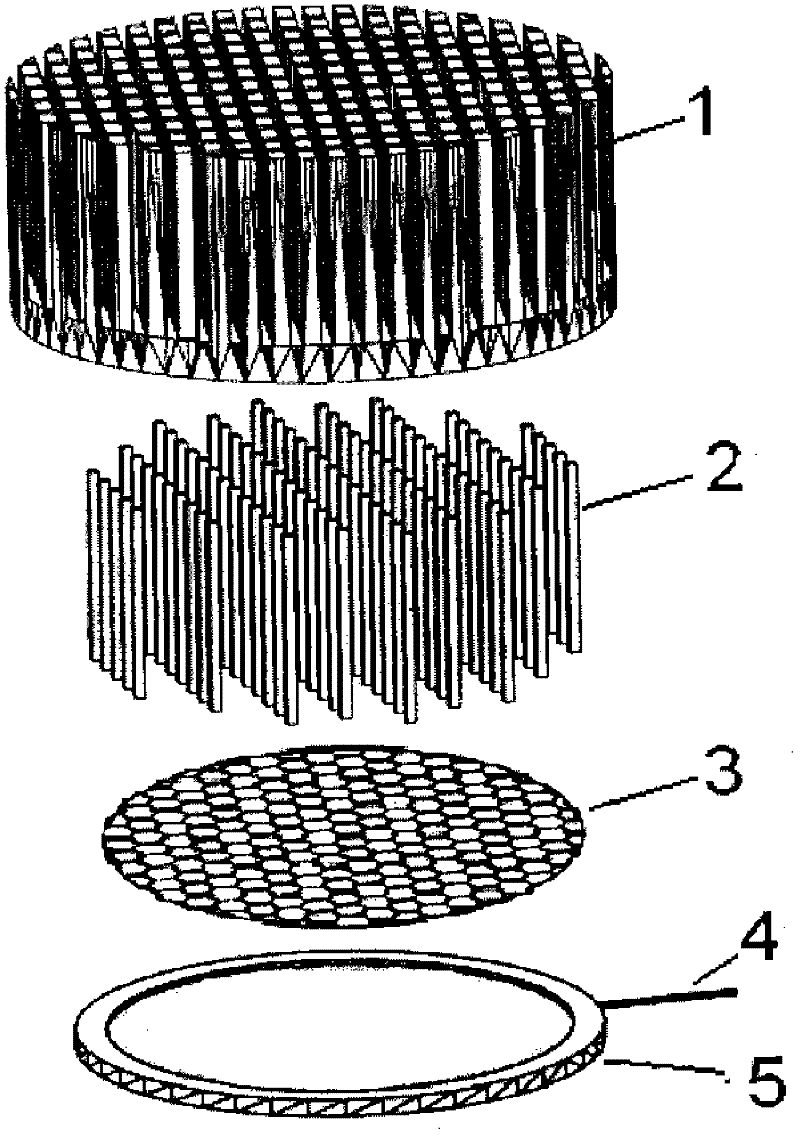

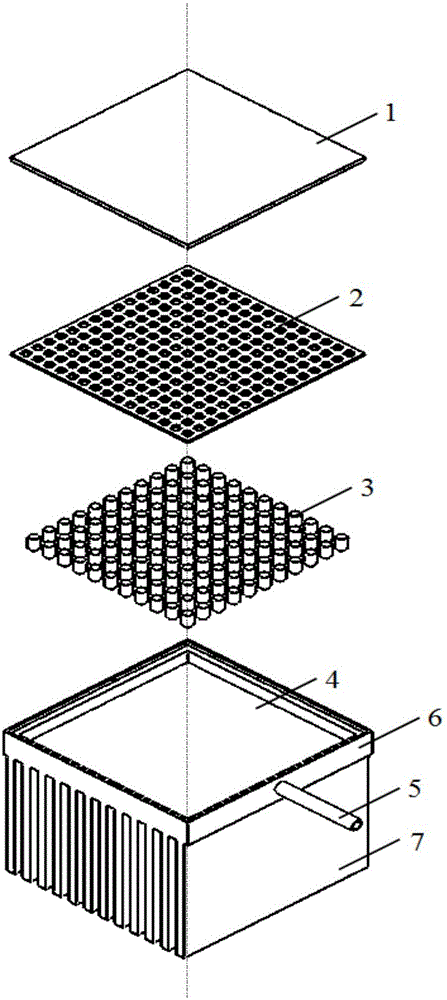

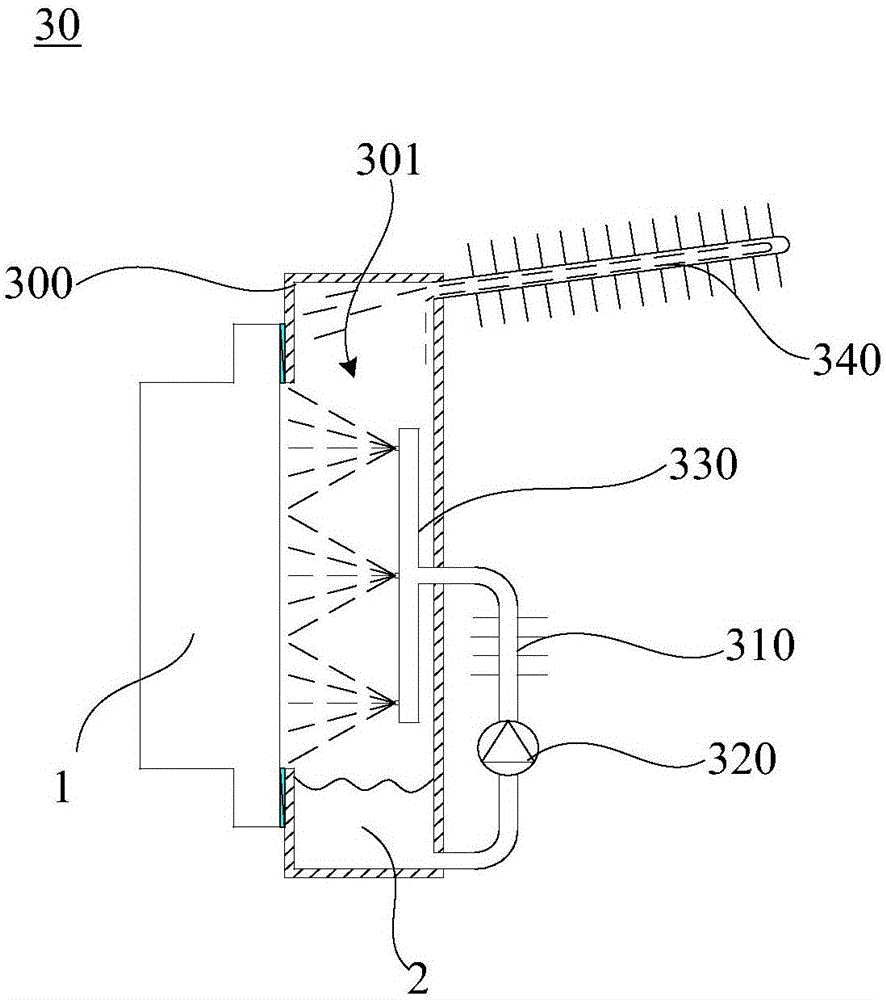

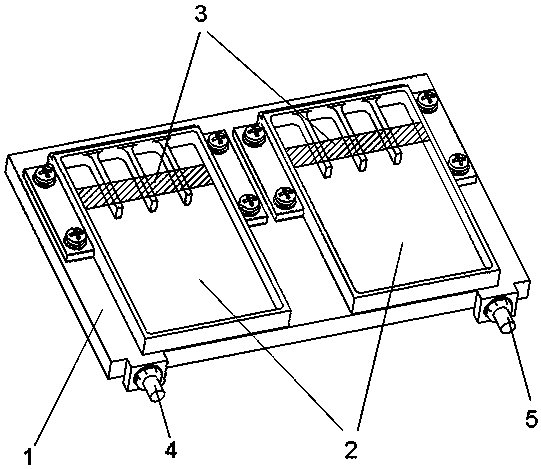

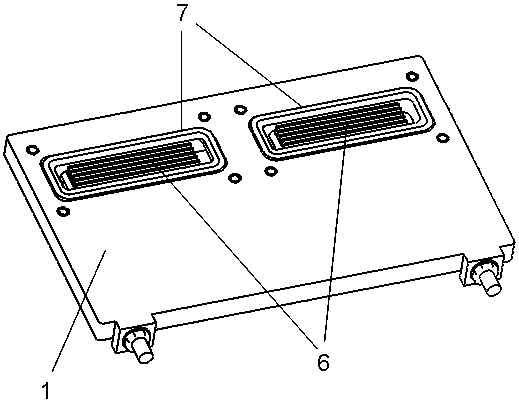

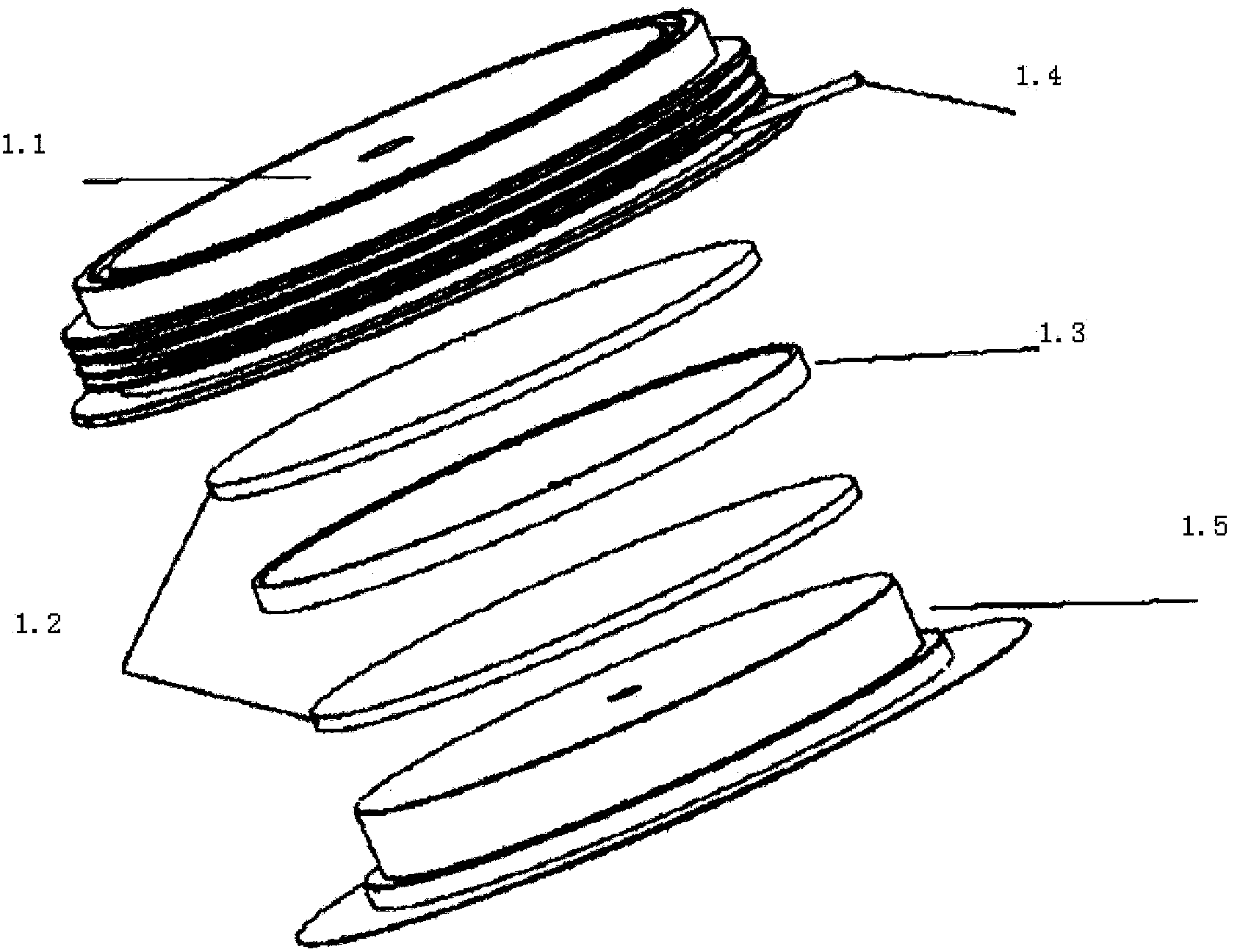

Integrated micro-jet vapor chamber radiator and manufacturing method thereof

PendingCN111477599AEliminate thermal contact resistanceImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesHeat spreaderPhysics

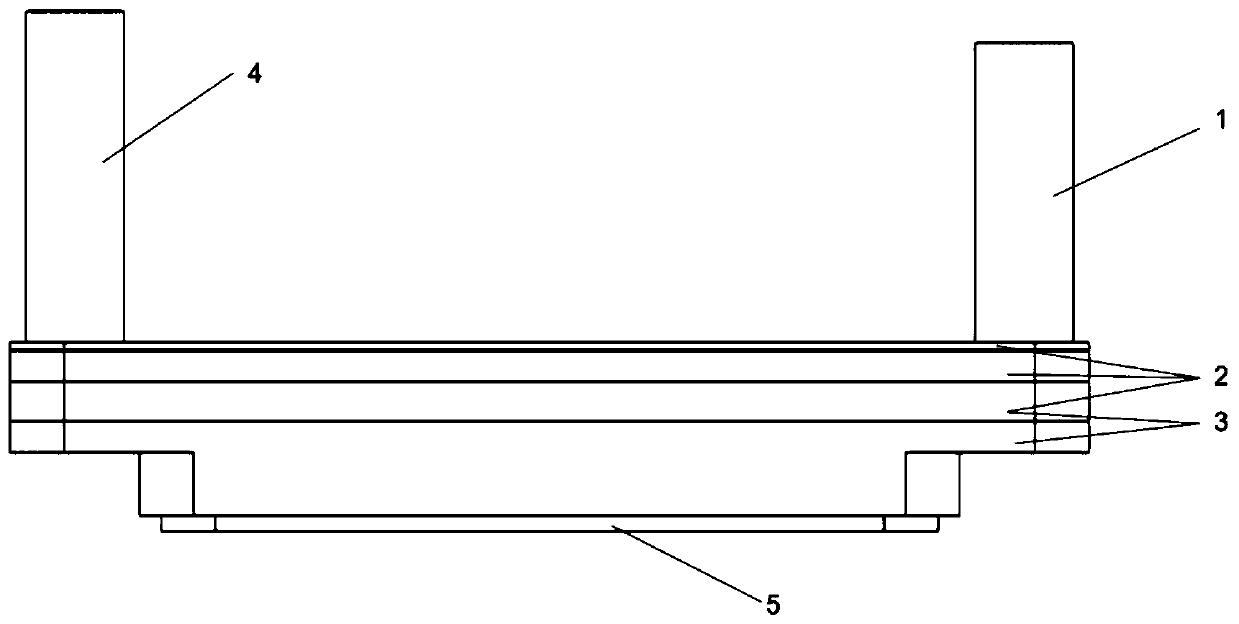

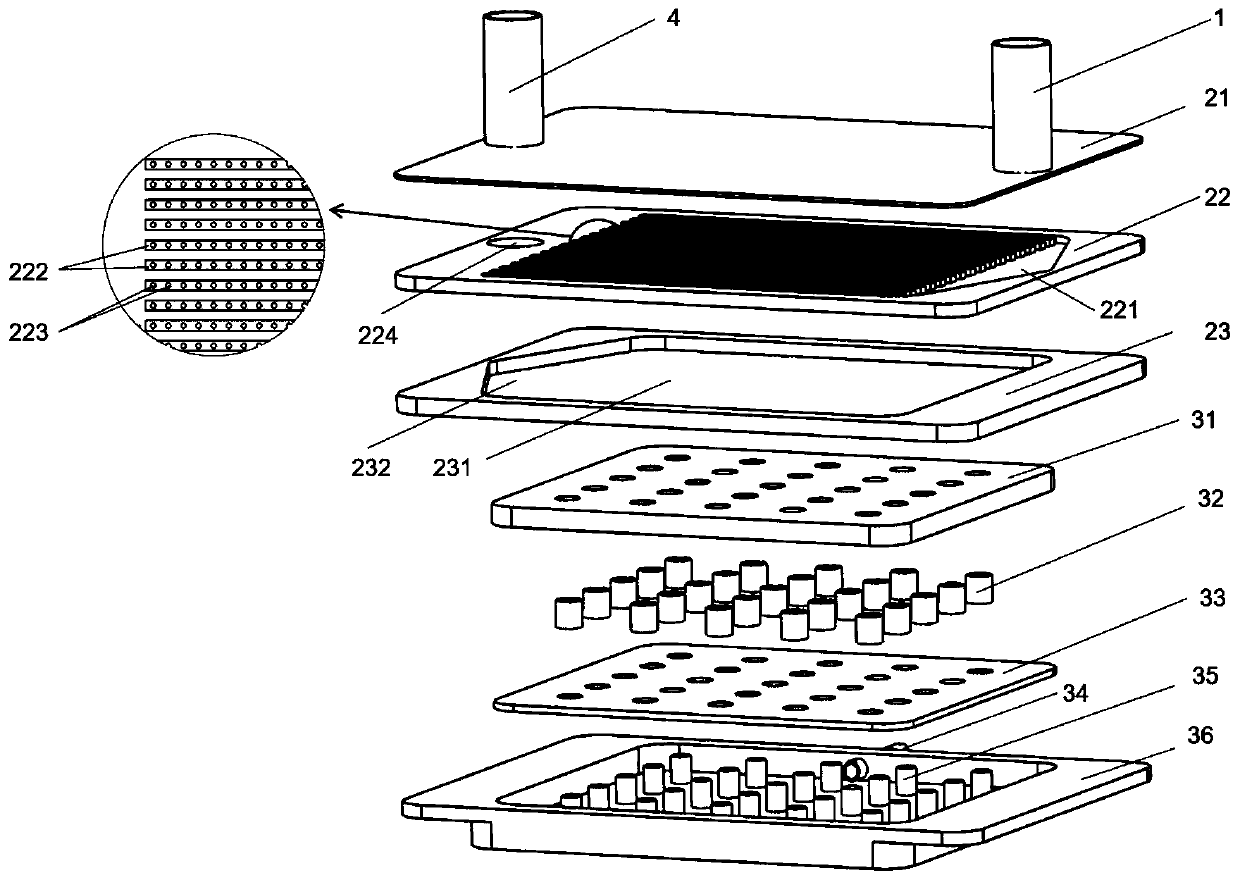

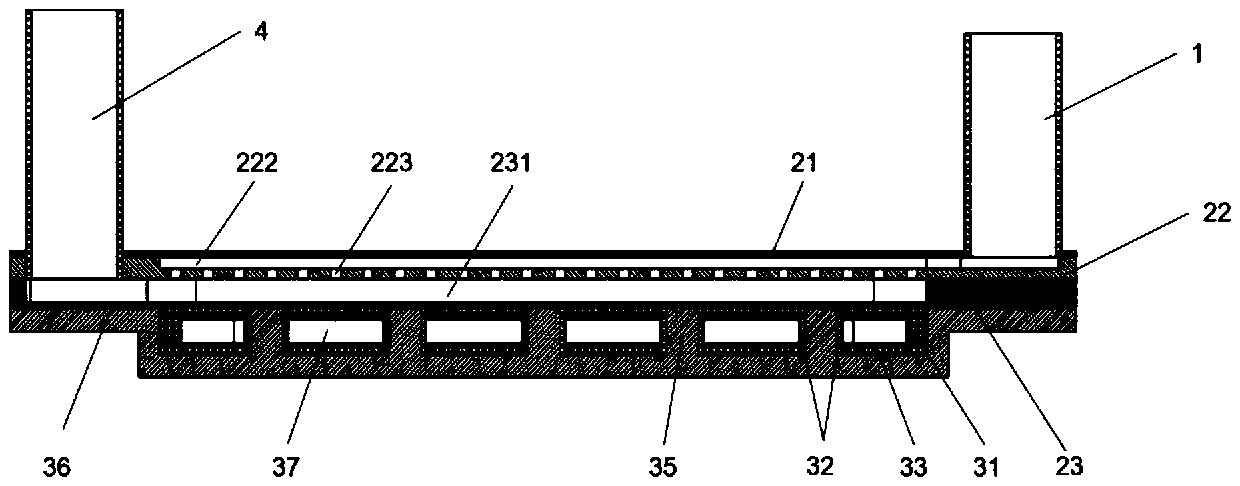

The invention discloses an integrated micro-jet vapor chamber radiator and a manufacturing method thereof. The integrated micro-jet vapor chamber radiator comprises an inlet pipeline, a micro-jet assembly, a vapor chamber body assembly and an outlet pipeline, the micro-injection assembly comprises a cover plate, at least one injection plate and a condensation plate which are sequentially arrangedin an overlapped mode. The vapor chamber body assembly comprises a condensation end liquid suction core, a copper powder ring, an evaporation end liquid suction core, a solid copper column and an evaporation plate. The condensation plate of the vapor chamber body assembly and the injection bottom plate of the micro-injection assembly are integrally designed, contact thermal resistance caused by split design between the vapor chamber and a heat sink of the micro-injection assembly is eliminated, and the heat dissipation performance is improved.

Owner:SOUTH CHINA UNIV OF TECH +1

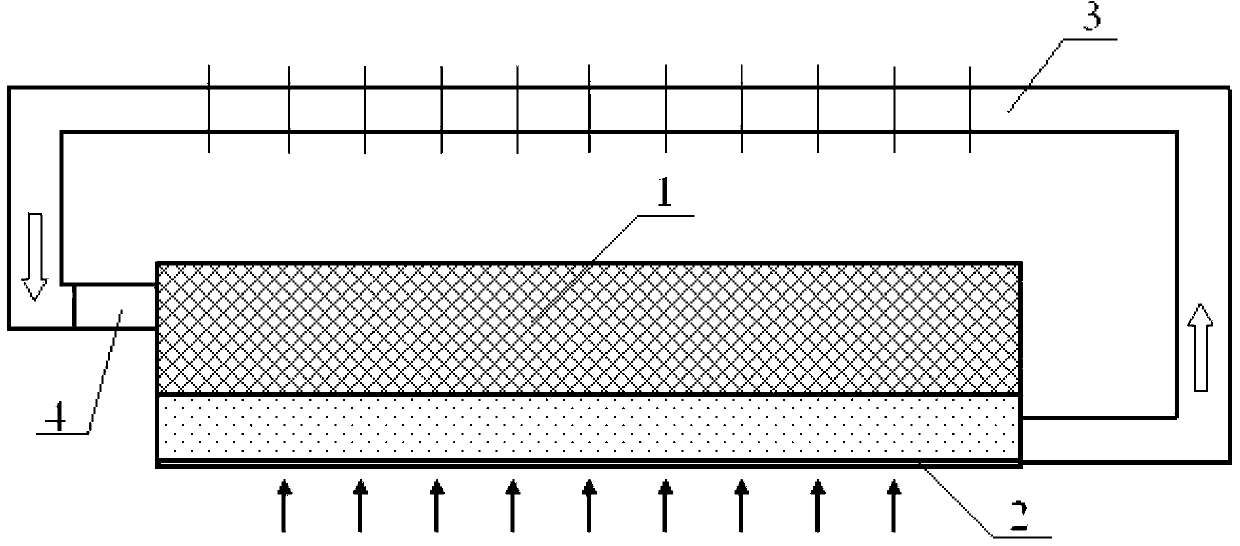

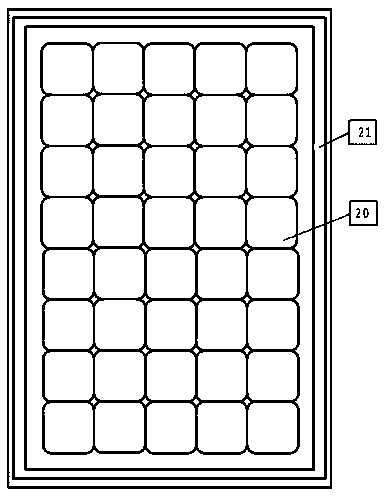

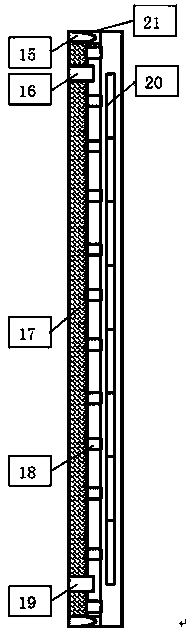

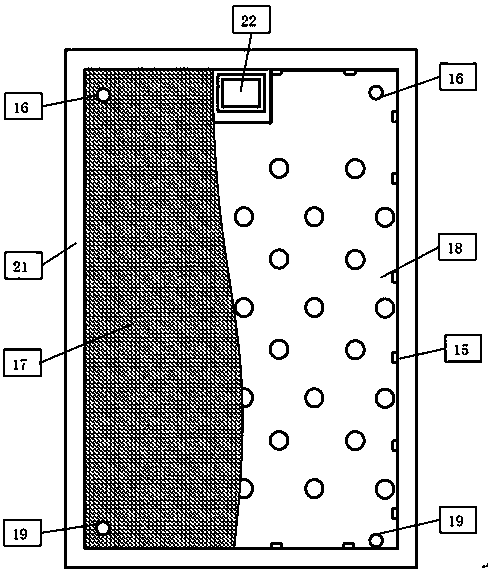

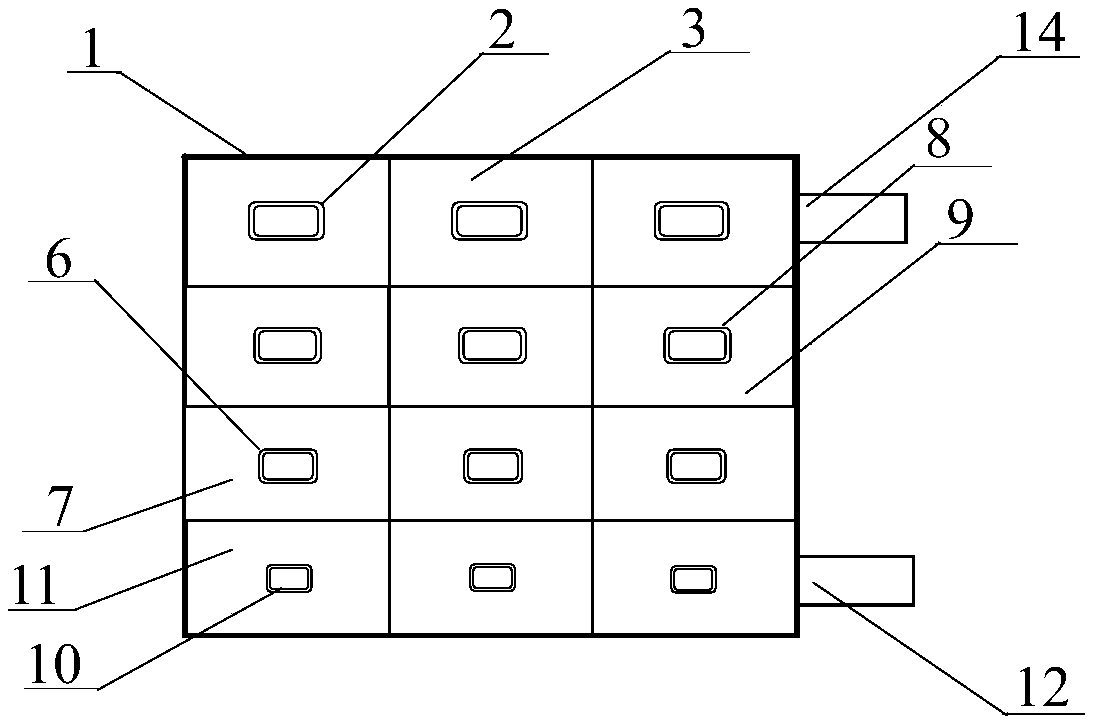

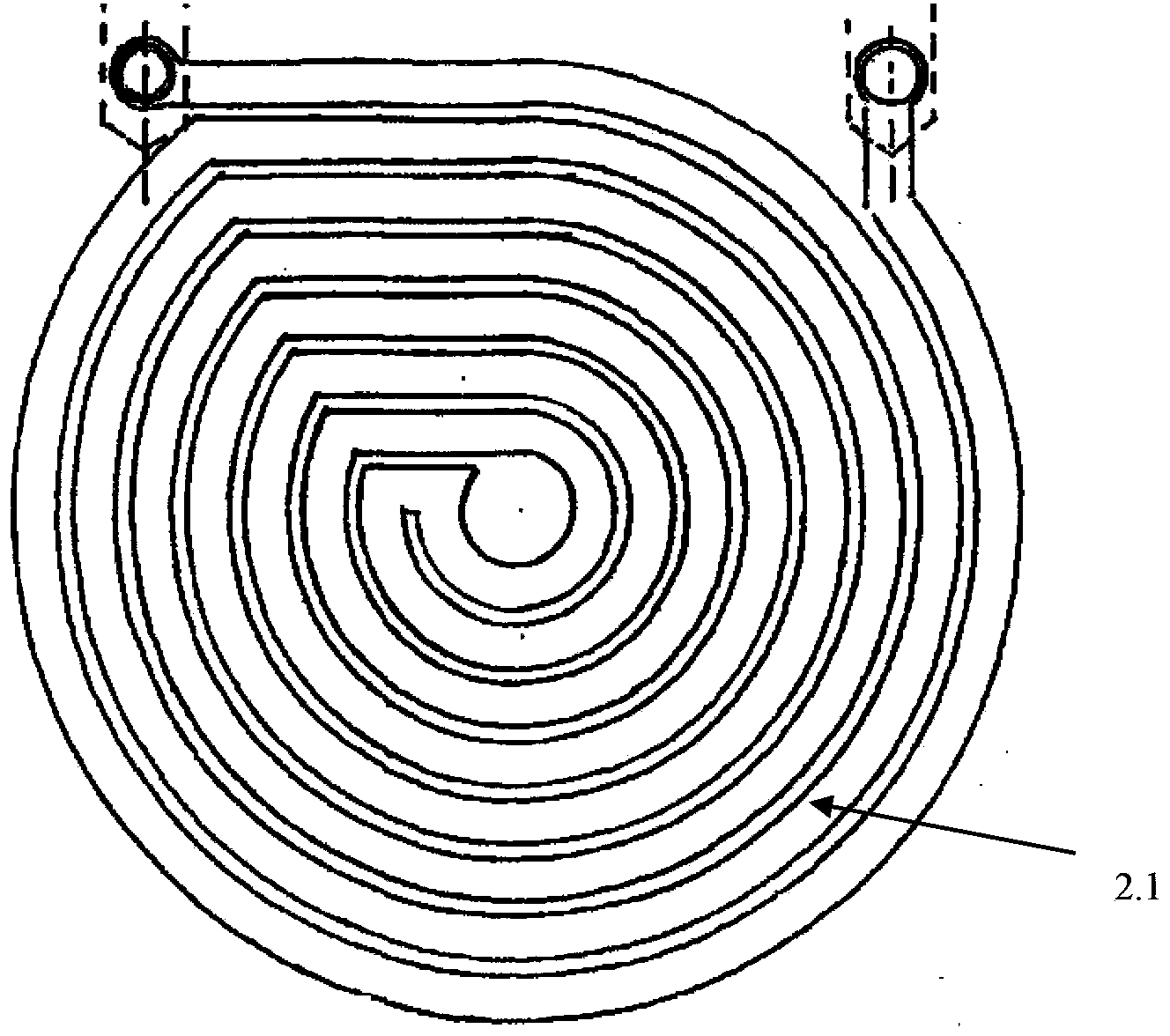

Solar photoelectric photo-thermal integrated assembly and solar combined heat and power generation system thereof

InactiveCN103594538AEliminate thermal contact resistanceGood hardnessPV power plantsEnergy industryCells panelCorrosion

The invention relates to a solar photoelectric photo-thermal integrated assembly and a solar combined heat and power generation system of the solar photoelectric photo-thermal integrated assembly. The solar photoelectric photo-thermal integrated assembly is characterized by comprising a photovoltaic cell panel provided with a metal outer frame, a metal sheet type heat exchanger and a heat-preservation material layer, wherein the metal sheet type heat exchanger and the heat-preservation material layer are sequentially arranged on the back surface of the photovoltaic cell panel in parallel and in an overlapped mode, and are rapidly fixed in the metal outer frame of the photovoltaic cell panel through a metal fixing clamp, and the standard photovoltaic cell panel can be rapidly modified into the photoelectric photo-thermal integrated assembly. The photoelectric photo-thermal integrated assembly has the advantages of being compact in structure, high in efficiency, small in pressure loss, light in weight, flexible to install, high in pressure bearing performance, resistant to corrosion, low in cost and the like, further reduces the initial investment and installation space of a medium and low temperature solar thermoelectric system, lowers the operation expenses of the system, and is suitable for civil and industrial occasions requiring for both heat and power.

Owner:SHANGHAI LVJIAN ENERGY TECH

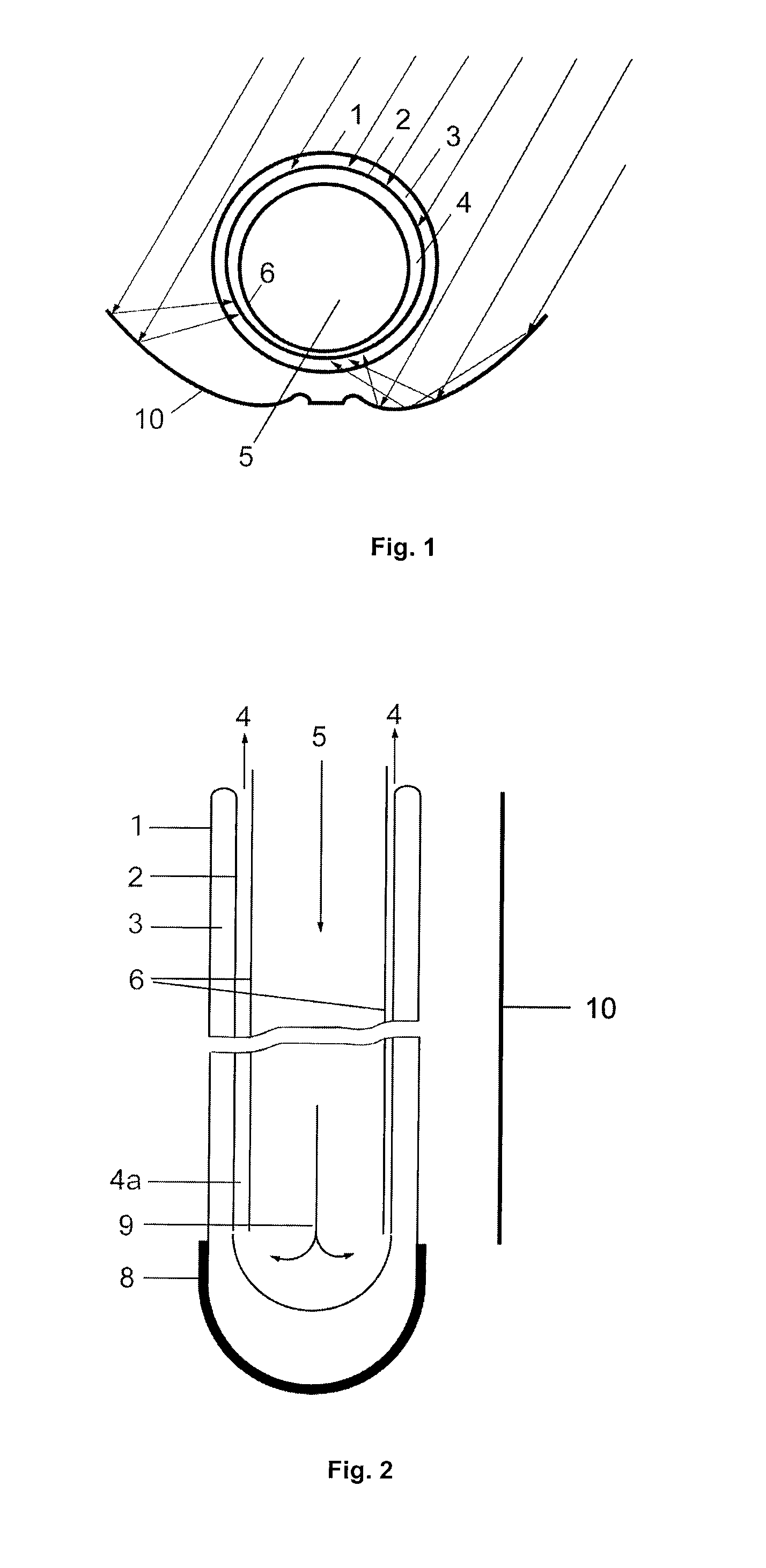

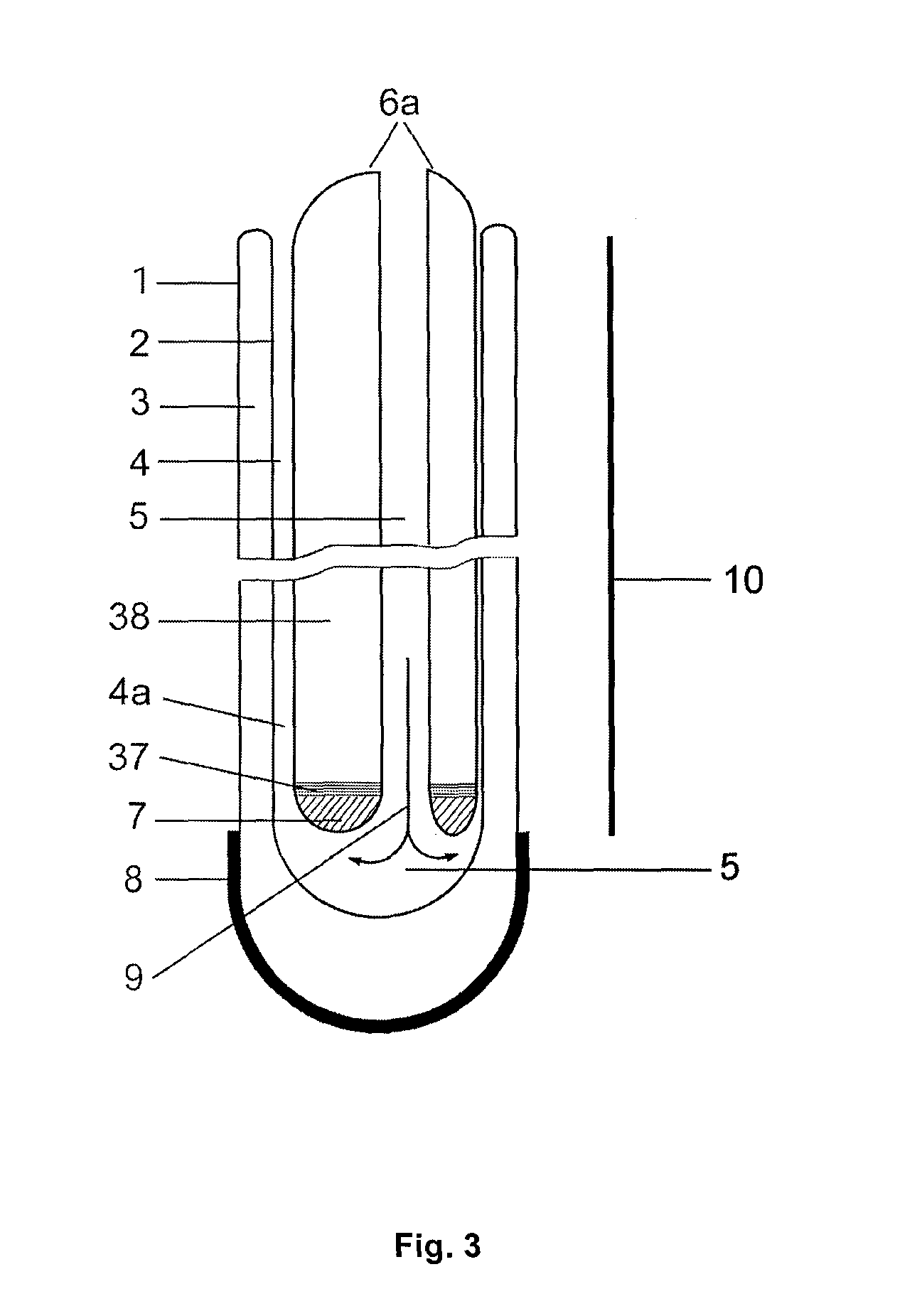

Tube collector with variable thermal conductivity of the coaxial tube

InactiveUS8191549B2Avoid overall overheatingHeat dissipation fastSolar heating energySolar heat collector controllersCoaxial cableHeat carrier

Collector tube for a solar collector, having an envelope tube, an absorber tube which is arranged within the envelope tube and into whose interior a heat carrier medium can be carried, characterized by an inner tubular element which is arranged within the absorber tube and has a thermal conductivity which is variable. Distributor segment for at least one collector tube which is designed in particular according to one of the preceding claims, having at least one first opening for supplying a heat carrier medium into the at least one collector tube, at least one second opening for carrying the heat carrier medium away from the at least one collector tube, a channel for supplying the heat carrier medium from outside the at least one collector tube into the at least one collector tube, a channel for carrying the heat carrier medium away from the collector tube to outside the at least one collector tube, with the supply channel and the output channel being arranged such that the distributor segment can be directly coupled to at least one further identical distributor segment in a heat carrier medium circuit.

Owner:SCHEDLETZKY MAIK

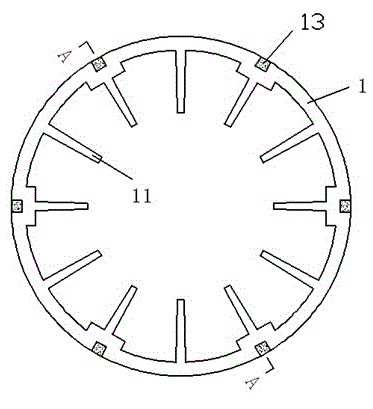

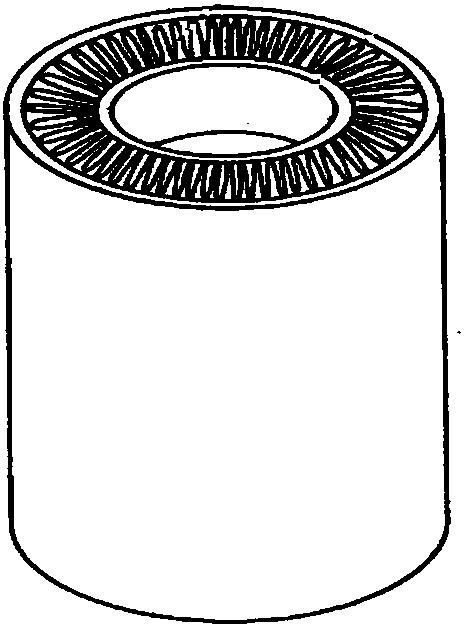

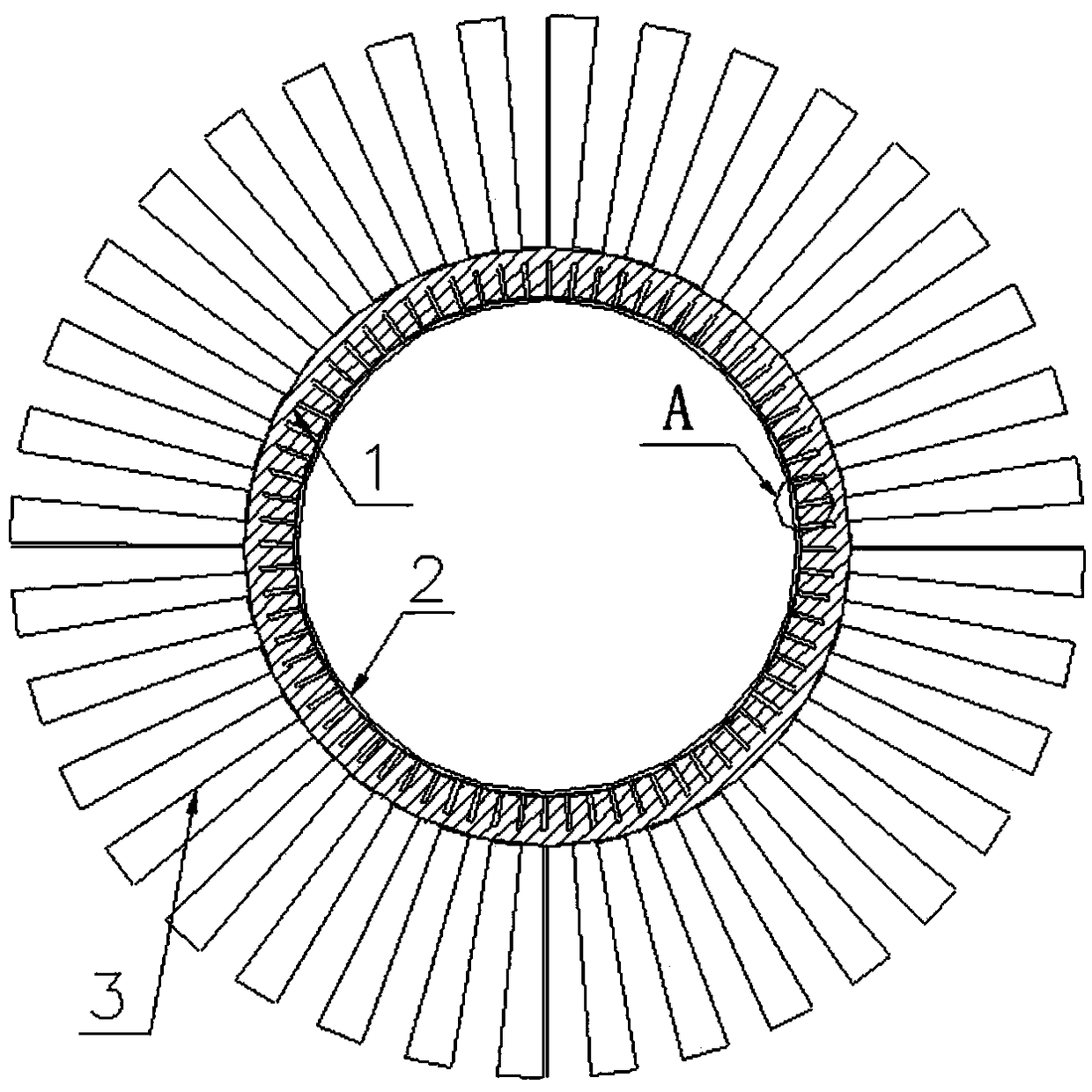

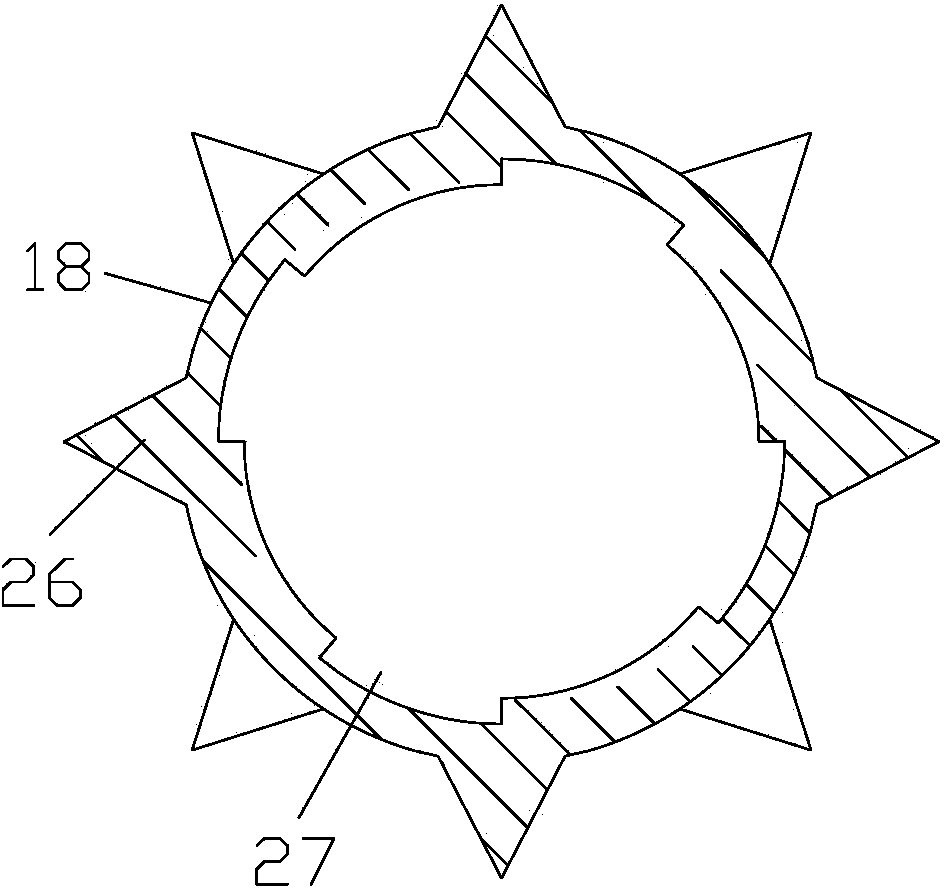

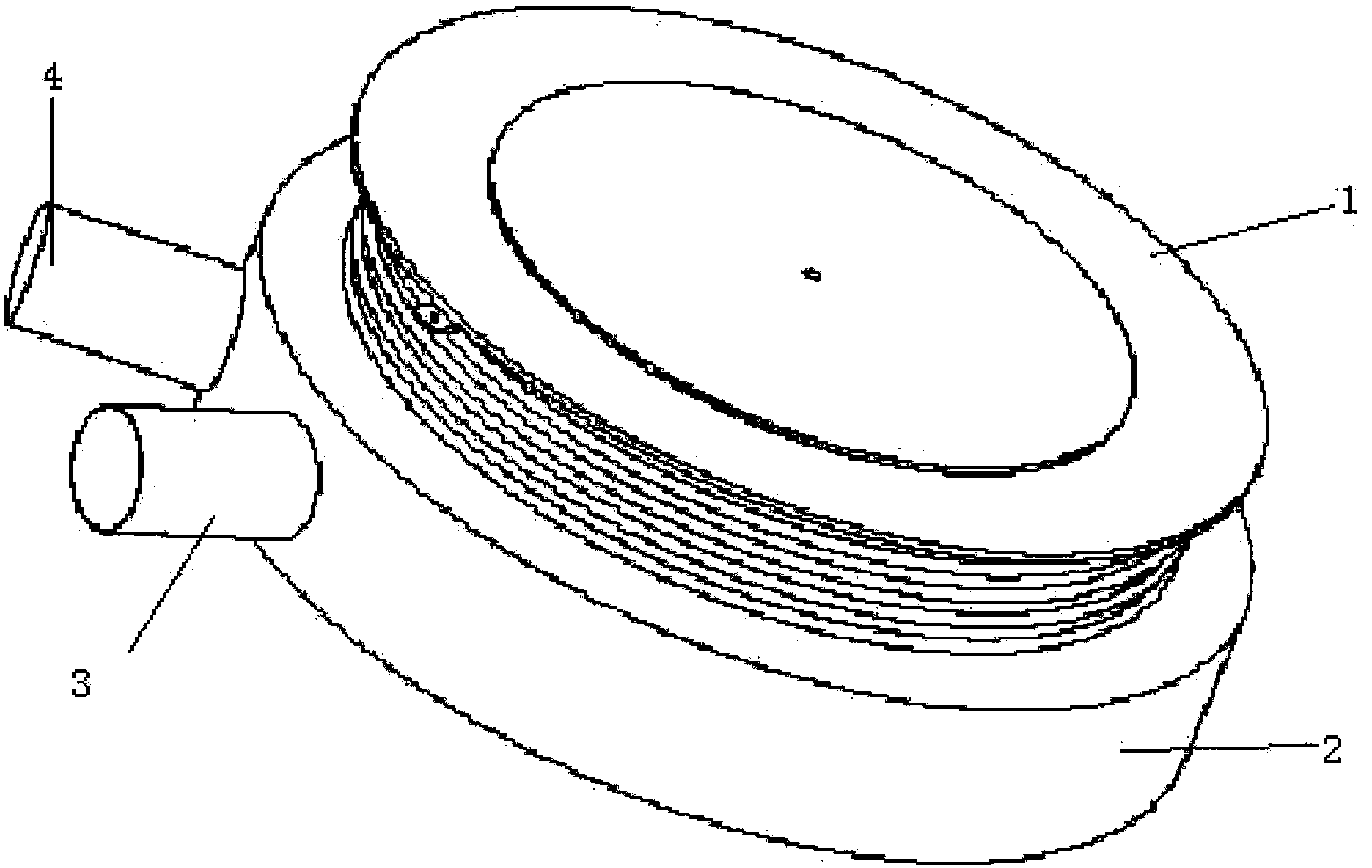

Heat exchanger provided with annular slots and used for sound-energy refrigerating machine

PendingCN108195214AImprove cooling effectImprove heat transfer coefficientCompression machinesIndirect heat exchangersInterference fitSound energy

The invention discloses a heat exchanger provided with annular slots and used for a sound-energy refrigerating machine, and belongs to the technical field of heat exchangers. The heat exchanger provided with the annular slots and used for the sound-energy refrigerating machine comprises an inner rib body and an inner sleeve. The inner rib body is an annular cylinder with the inner annular surfaceopen towards the outer annular surface. The inner sleeve is arranged in the inner rib body in a sleeved mode and is in interference fit with the inner rib body. The multiple slots are formed in the inner annular surface of the inner rib body at intervals, so that a slot channel allowing air to flow therein is formed between the inner rib body and the inner sleeve. According to the heat exchanger provided with the annular slots and used for the sound-energy refrigerating machine, forced-convection heat change between alternately-flowing working medium gas and the inner wall of the heat exchanger is achieved, and the heat exchange coefficient is large; in the heat conduction direction towards the outside, through interference fit between the inner rib body and the inner sleeve as well as a welding structure of the inner rib body and outer fins, contact heat resistance is eliminated; and in addition, the inner rib body is made of red copper with small heat conduction resistance, and thusthe heat exchanger provided with the annular slots in the hot end has a good cooling effect.

Owner:陕西仙童科技有限公司

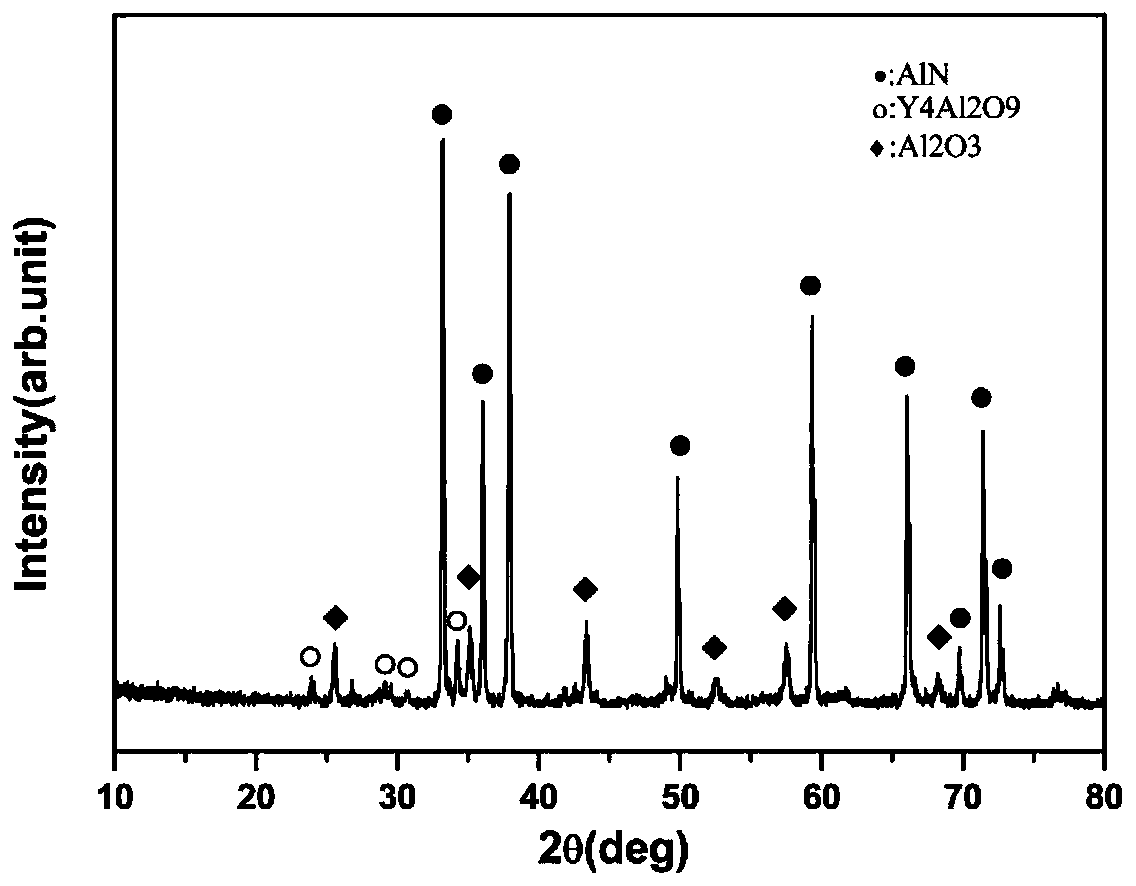

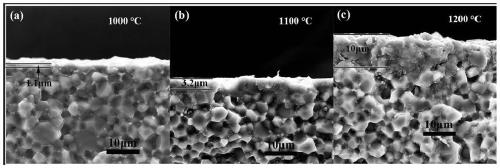

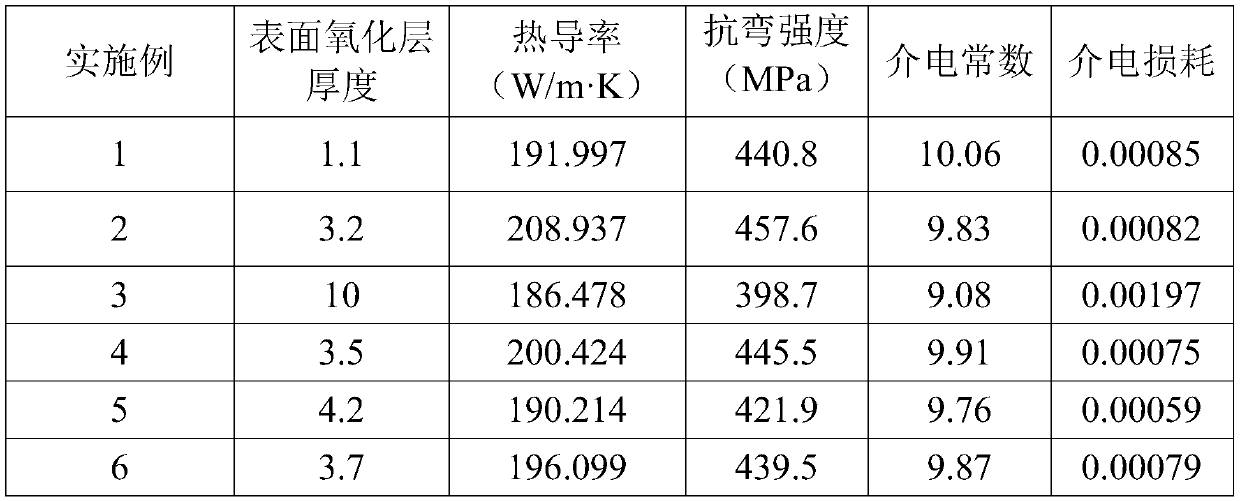

Aluminum nitride ceramic with high thermal conductivity and high strength and preparation method thereof

InactiveCN111484333AIncrease the residual compressive stressPrevent extensionDielectric lossDielectric permittivity

The invention belongs to the technical field of ceramic materials, and particularly relates to preparation of pressureless sintering high-thermal-conductivity and high-strength aluminum nitride ceramic. The aluminum nitride ceramic is prepared by carrying out oxidation treatment on an aluminum nitride sintered body obtained by pressureless sintering, a compact oxide layer with a proper thickness can be formed on the surface of the aluminum nitride sintered body through proper oxidation treatment, the residual compressive stress in an aluminum nitride matrix can be increased through the formation of the oxide layer, and the change of the residual compressive stress is beneficial to preventing expansion of cracks in the aluminum nitride ceramic and reducing the contact thermal resistance ofan aluminum nitride grain boundary. According to the aluminum nitride ceramic provided by the invention, after oxidation treatment, the thermal conductivity can be improved to 185-210 W / (m.K), the bending strength is improved to 390-460 MPa, the dielectric constant is 9-10, the dielectric loss is 0.8*10<-3> to 2.4*10<-3>, and the application requirements of industries such as semiconductor devicesand integrated circuits can be met.

Owner:HUAZHONG UNIV OF SCI & TECH

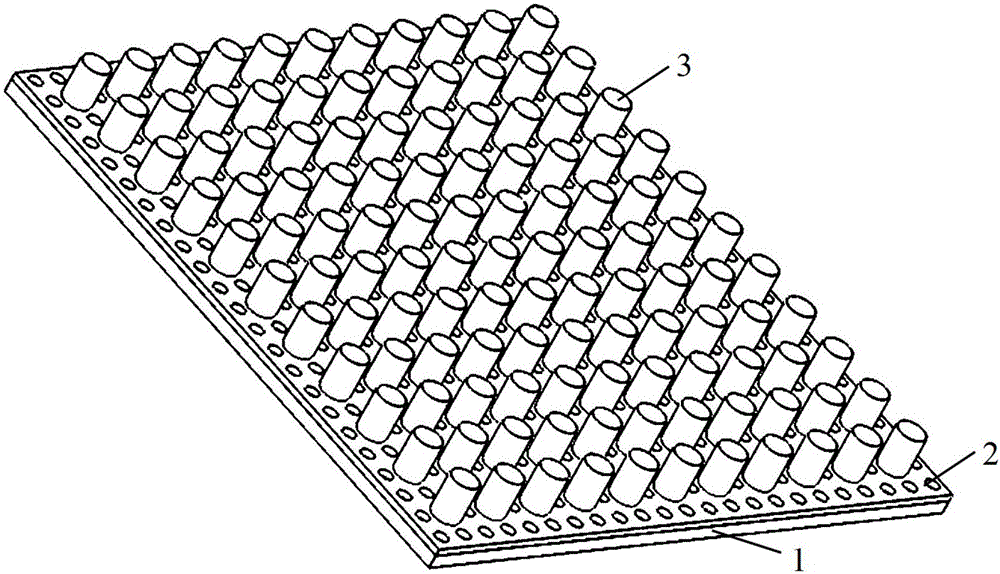

Three-dimensional steam cavity type phase change heat storage device

InactiveCN111397418AImprove cooling effectImprove heat transfer performanceHeat storage plantsModifications by conduction heat transferHeat flowEngineering

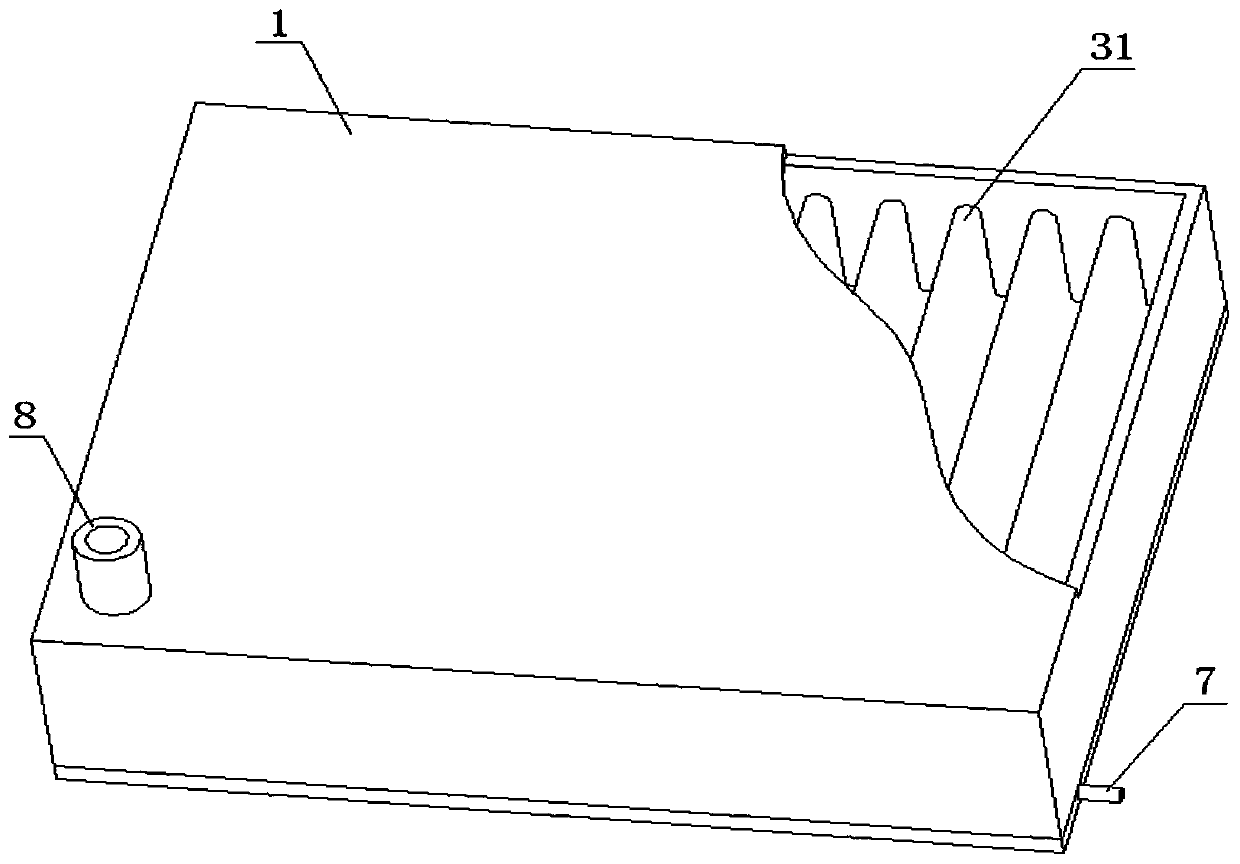

The invention discloses a three-dimensional steam cavity type phase change heat storage device. The device comprises a three-dimensional steam cavity and a packaging shell; the three-dimensional steamcavity comprises a heat transfer substrate and heat dissipation teeth, the heat transfer substrate and the heat dissipation teeth are all hollow structures to form an integrated closed cavity, and aphase change medium is sealed in the steam cavity; a sealed cavity is also formed between the packaging shell and each heat dissipation tooth of the three-dimensional steam cavity, and a proper amountof a phase change material is arranged in the sealed cavity; and one side of the heat transfer substrate of the steam cavity serves as a heat plane, heat flows in from the heat plane and diffuses through the three-dimensional steam cavity to the phase change materials on the outer sides of the heat dissipation teeth. According to the design, based on the characteristics of the good heat diffusionperformance of the three-dimensional steam cavity and the high-efficiency heat absorption of the phase change materials, the novel phase change heat storage device with the high-efficiency heat transfer and heat dissipation performance and the low cost is provided, and the heat dissipation problem under the occasions with the high heat flow density and periodic thermal shock in a limited closed space such as being onboard is solved.

Owner:NANJING 6902 TECH

Embedded type combined heat sink as well as preparation method thereof

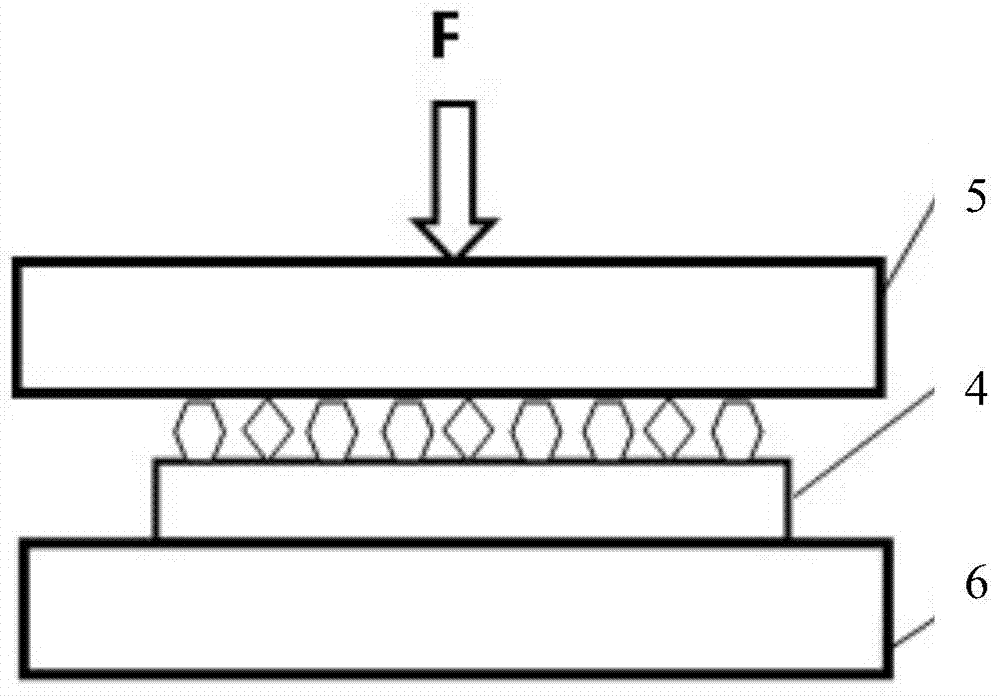

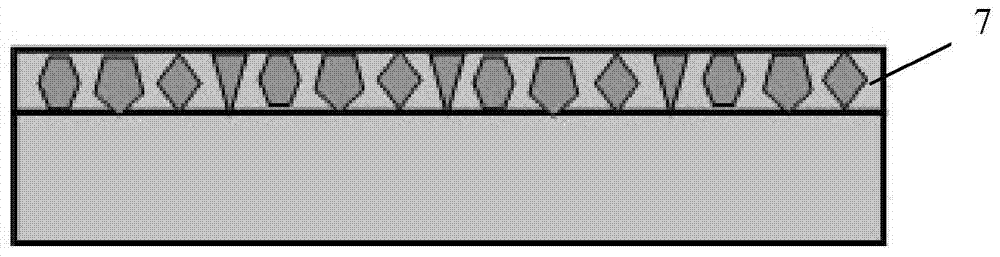

ActiveCN103496215AGuaranteed thermal conductivitySmall coefficient of thermal expansionLaminationLamination apparatusHeat resistanceEngineering

The invention discloses an embedded type combined heat sink as well as a preparation method thereof. The heat sink comprises a primary radiator and a secondary radiator. By taking the secondary radiator as a base body, the primary radiator is embedded into a surface layer of the base body to form a composite layer located on the surface layer of the base body. The integrated structure is the embedded combined heat sink. The preparation method comprises the following steps: (1) by taking a secondary radiator material as the base body, carrying out softening annealing heat treatment on the base body; (2) preparing diamond powder into a suspension liquid, wherein the diamond powder subsides on the surface of the base body; under the premise that distribution of diamond on the surface of the base body is not changed, reducing the liquid level to be under the surface of a sample and taking out the sample; and (3) reducing the thickness of a diamond powder-containing liquid film on the surface of the sample; then, pressing the diamond powder into the base body; and finally, carrying out diffusion annealing treatment on the sample and cooling to obtain the heat sink. The primary and secondary radiators are integrated to eliminate the contact heat resistance. The thickness of the heat sink is just dozens of microns, so that the heat resistance is small. The process links are reduced and the cost is lowered.

Owner:SOUTH CHINA UNIV OF TECH

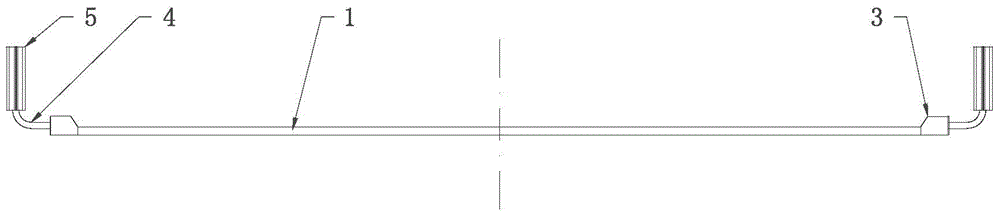

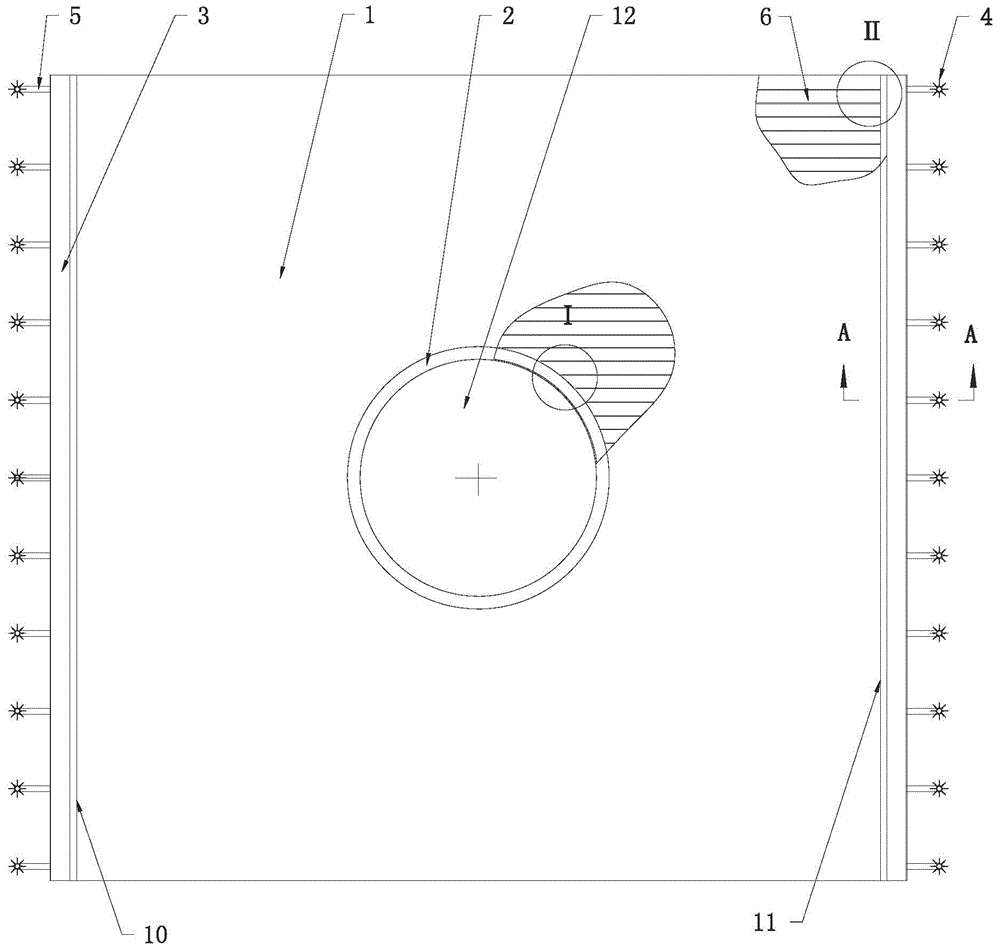

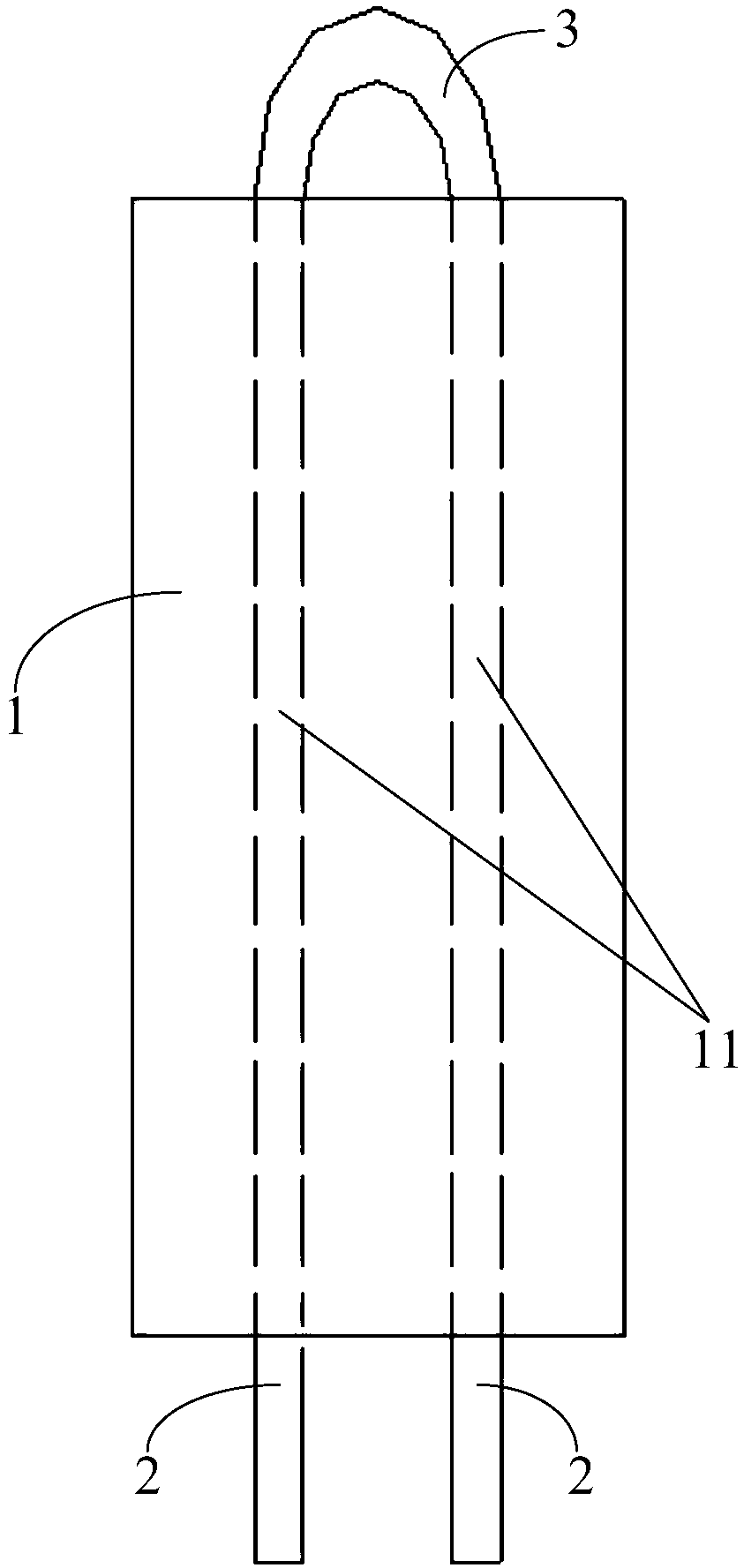

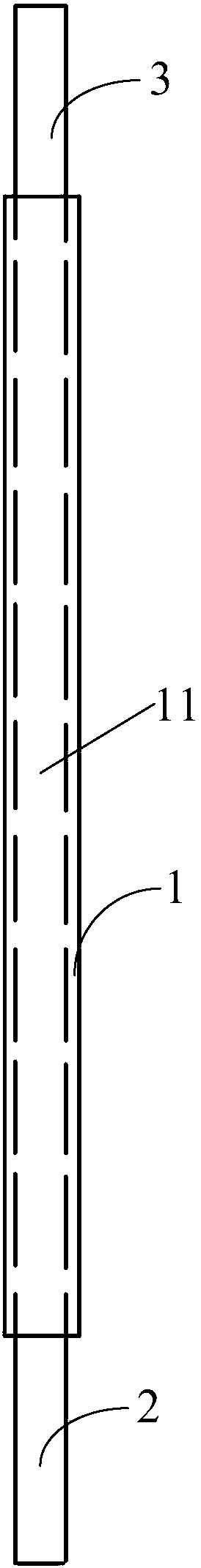

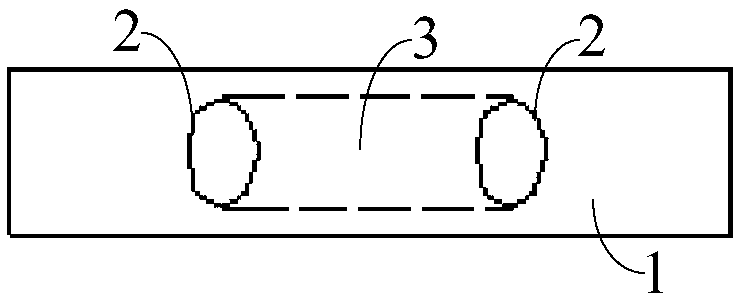

Plate type integral heat tube for heat radiation of electric magnetic iron remover

ActiveCN104994709AGood effectWorking fluid pressure automatic balanceCooling/ventilation/heating modificationsEvaporationEngineering

The invention relates to a plate type integral heat tube for heat radiation of an electric magnetic iron remover. The plate type integral heat tube comprises a rectangular flat plate; evaporation groove channels parallel to each other are distributed on the rectangular flat plate uniformly and are located between an upper surface and a lower surface of the rectangular flat plate; and the axis is parallel to the upper surface and the lower surface of the rectangular flat plate. A through hole is formed in the center of the rectangular flat plate, wherein the axis of the through hole is perpendicular to the upper surface and the lower surface of the rectangular flat plate. A hollow ring is arranged at the periphery of the through hole; and the evaporation groove channels penetrating the periphery of the through hole are communicated with the inner cavity of the hollow ring. Branch pipes are respectively arranged at a first side surface and a second side surface of the rectangular flat plate, wherein the branch pipes are hollow ones with two closed ends; ports of the evaporation groove channels located at the first side surface or second side surface are communicated with inner cavities of the branch pipes arranged at the corresponding side surfaces; straight finned tubes connected with the inner cavities of the branch pipes are arranged on the branch pipes. According to the invention, the structure is simple and reliable; the heat-transfer capability is high; and the cost performance is high. Compared with the heat radiator having the independent multi-heat-tube structure, the heat radiation capability, the temperature uniformity effect, and the processing mounting efficiency are improved and the production cost is lowered. The plate type integral heat tube is suitable for industrialized application.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

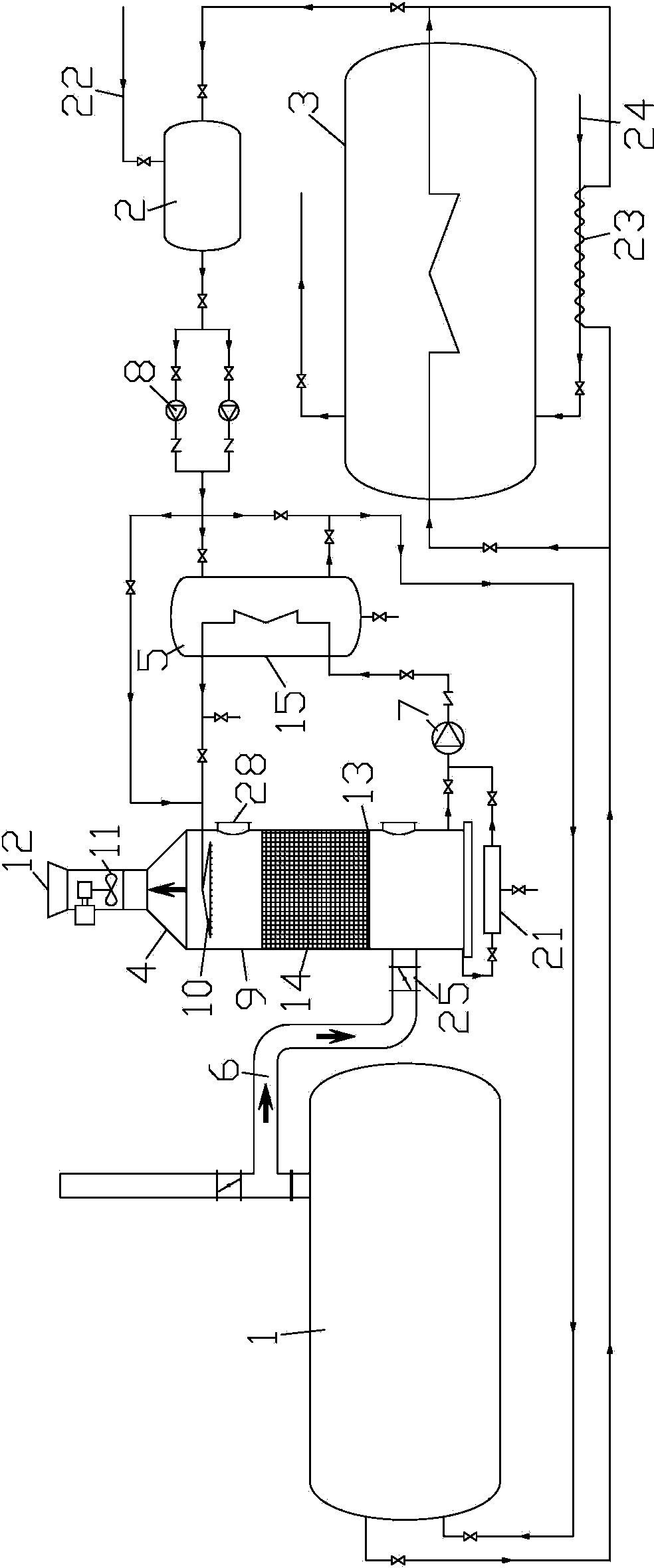

Crude oil gathering and transportation heating furnace tail gas waste heat recycle and emission reduction device

InactiveCN104251553AHigh thermal efficiencyImprove thermal efficiencyStorage heatersCorrosion preventionNitric oxideCarbon dioxide

The invention relates to a crude oil gathering and transportation heating furnace tail gas waste heat recycle and emission reduction device. The crude oil gathering and transportation heating furnace tail gas waste heat recycle and emission reduction device comprises a heating furnace, a water return tank and a crude oil preheaing device, and also comprises a tail gas waste heat recoverer and an anticorrosion heat exchanger, wherein a smoke guide channel is arranged in the heating furnace; the other end of the smoke guide channel is communicated with the lower part of the tail gas waste heat recoverer; a water inlet pipe and a water outlet pipe in the heat release end of the anticorrosion heat exchanger are respectively communicated with the water outlet end and the water inlet end of the tail gas waste heat recoverer; a water inlet pipe of the heated end of the anticorrosion heat exchanger is connected with the water outlet of the water return tank; the water outlet pipe of the heated end of the anticorrosion heat exchanger is connected with the water inlet of the heating furnace; crude oil gathering and transportation heating furnace tail gas is guided into the tail gas waste heat recoverer, a lot of sensible heat in the recovered tail gas and the condensation latent heat of vapour contained in the tail gas are capable of improving the thermal efficiency of the heating furnace to over 10%, sulfur oxide, nitric oxide, carbon monoxide, carbon dioxide, fly ash and smoke in the tail gas can partially and wholly dissolve in water, and the environment protection is facilitated.

Owner:中能纪(北京)国际科技有限公司

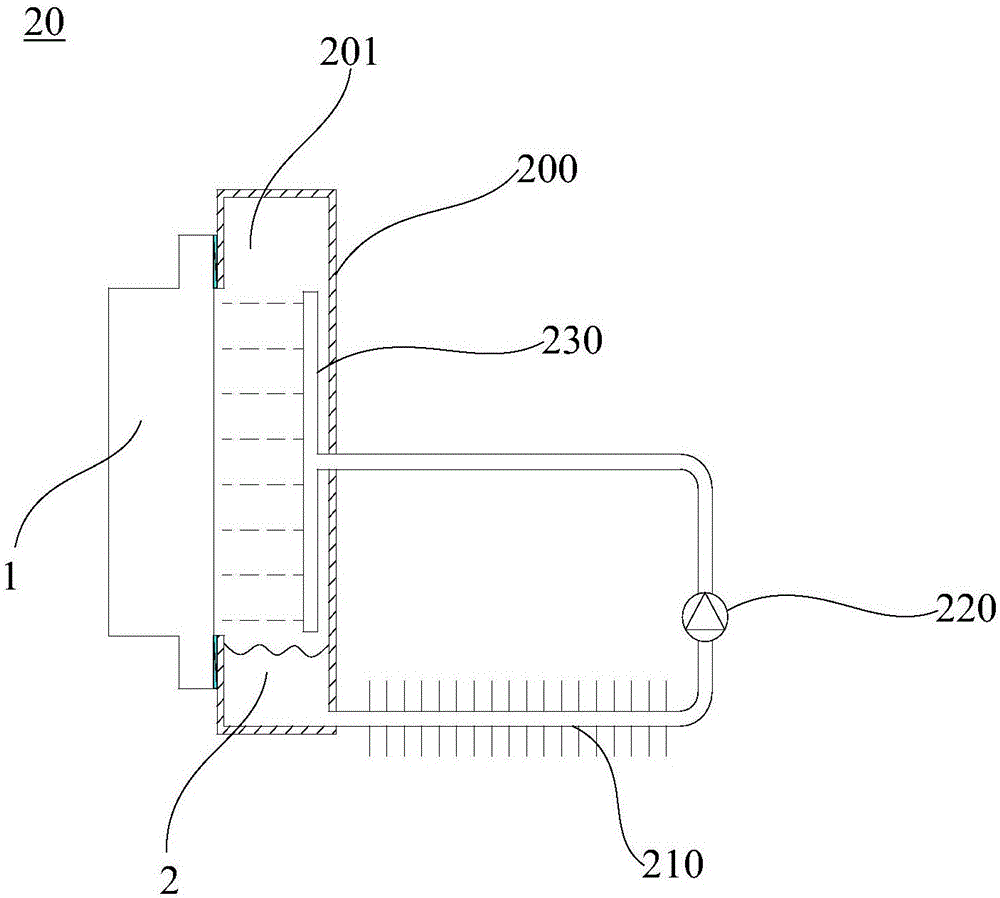

Liquid direct contact type cooling device

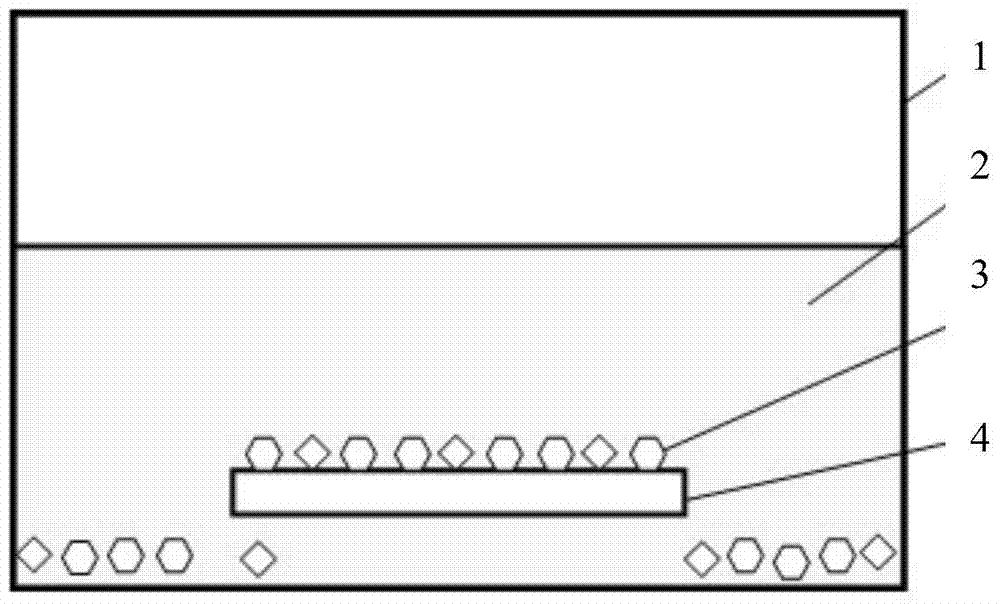

PendingCN106783770AImprove cooling efficiencyExtended service lifeSemiconductor/solid-state device detailsSolid-state devicesEngineeringContact type

The invention relates to a liquid direct contact type cooling device. The liquid direct contact type cooling device comprises a cooling device body, a heat exchanging mechanism and a circulating pump, wherein the periphery of the connector of the cooling device body is used for being coordinated with a power device to seal a cooling cavity, and the cooling cavity of the cooling device body and the heat exchanging structure can allow cooling media to form a circulating loop through the circulating pump. During work, the cooling media in the direct contact type cooling device can directly contact with the radiating surface of the power device to take away heat; compared with a radiating manner with low specific heat capacity, the liquid direct contact type cooling device eliminates the contact heat resistance between the radiating surface of a traditional power device and the radiating plate of a cooling device and can evidently increase heat transfer performance; the heat exchanging structure can constantly take away the heat by the circulating flowing of the cooling media, and the overall radiating efficiency of the power device is increased greatly. In addition, the liquid direct contact type cooling device can allow the temperature of the radiating surface of the power device to be even and prolong the service life of the power device.

Owner:广东西江数据科技有限公司

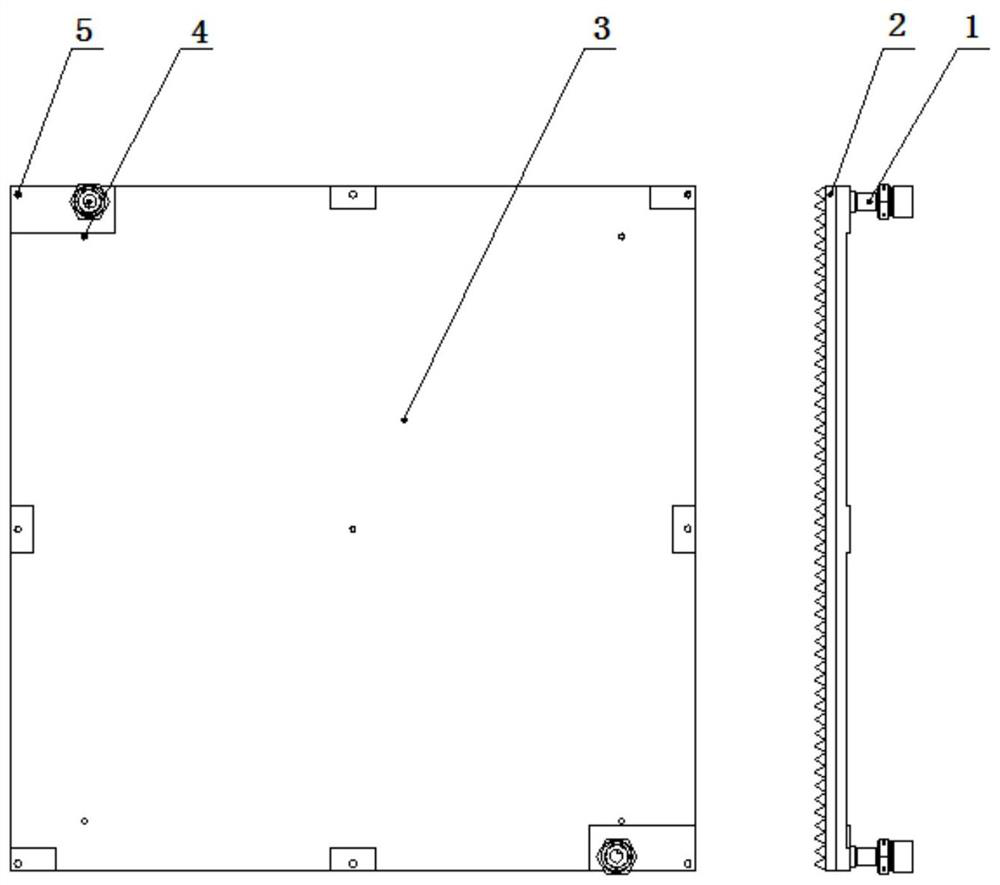

Air cooler for finned flat tube integrated structure

PendingCN108826479AEliminate thermal contact resistanceImprove thermal performanceLighting and heating apparatusSpace heating and ventilation detailsTemperature differenceEngineering

The invention discloses an air cooler for a finned flat tube integrated structure. The air cooler comprises a frame and at least one group of heat exchange modules which are arranged in the frame; each heat exchange module comprises a plurality of flat tubes and flat tube fins, wherein the flat tubes are arranged in parallel; the internal section of each flat tube is of a rectangular structure; the flat tube fins are formed on the flat tubes; the size of the rectangular area of the internal section of each flat tube is sequentially reduced from one side to the other side; every adjacent flat tubes are connected by a reducing bent tube to form a structure in an S-shaped direction; the flat tubes and the flat tube fins form a single integrated structure formed by overall cold-machining formation; the other end of one flat tube positioned at one side is connected with an air collecting tube; and the other end of another flat tube positioned at the other side is connected with a liquid supply pipe. According to the air cooler disclosed by the invention, the finned flat tube integrated structure is machined by adopting a cold-extrusion drawing way, thus contact heat resistance of the fins and a circular tube is eliminated, the heat transfer effect is improved, water generated by defrosting is cleared completely, heat transfer temperature difference is reduced, and the thermal performance of a refrigeration system is improved.

Owner:TIANJIN UNIV OF COMMERCE

A miniature throttling refrigerator

ActiveCN104142034BEliminate thermal contact resistanceThe welding surface is smooth and beautifulMechanical apparatusFluid circulation arrangementEngineeringRefrigeration

A miniature throttling refrigerator, which is composed of upper and lower cover plates, a heat exchange core and a cold end head: the upper and lower fins are fixed on both sides of the plate base of the heat exchange core; There are grooves distributed at intervals perpendicular to the long side of the flat base; the upper ribs are located in the lower groove of the upper cover; the lower ribs are located in the upper groove of the lower cover; one end of the upper cover has a through hole on the top And the air inlet, the other end is not closed to set a throttling hole; the top of one end of the lower cover plate has a through hole and an air outlet, and the other end has a throttling hole; the upper and lower cover plates and the heat exchange core constitute the throttling refrigeration body; The end seal head is set on the end of the throttling refrigeration main body with a throttling hole; the low-pressure flow channel is formed between the upper cover plate and the upper fin; the high-pressure flow channel is formed between the lower cover plate and the lower fin; the high-temperature and high-pressure fluid flows from the air inlet It enters the high-pressure flow channel, passes through the orifice, and becomes a low-temperature and low-pressure fluid, enters the low-pressure flow channel, and finally flows out from the air outlet; it has a large specific surface area, high heat exchange efficiency, can withstand high-pressure operation, and is easy to scale.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

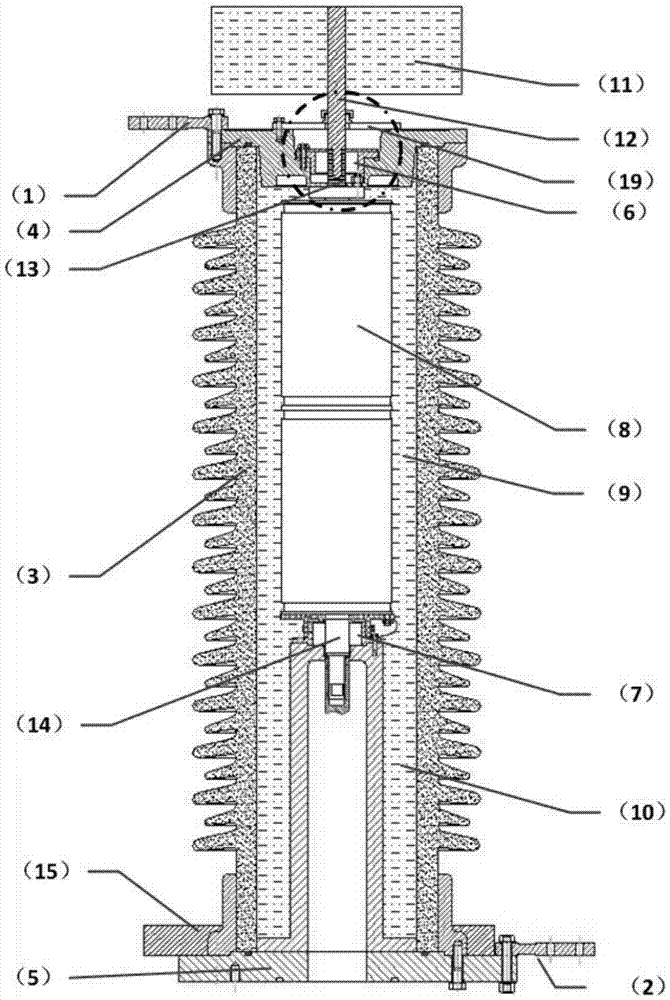

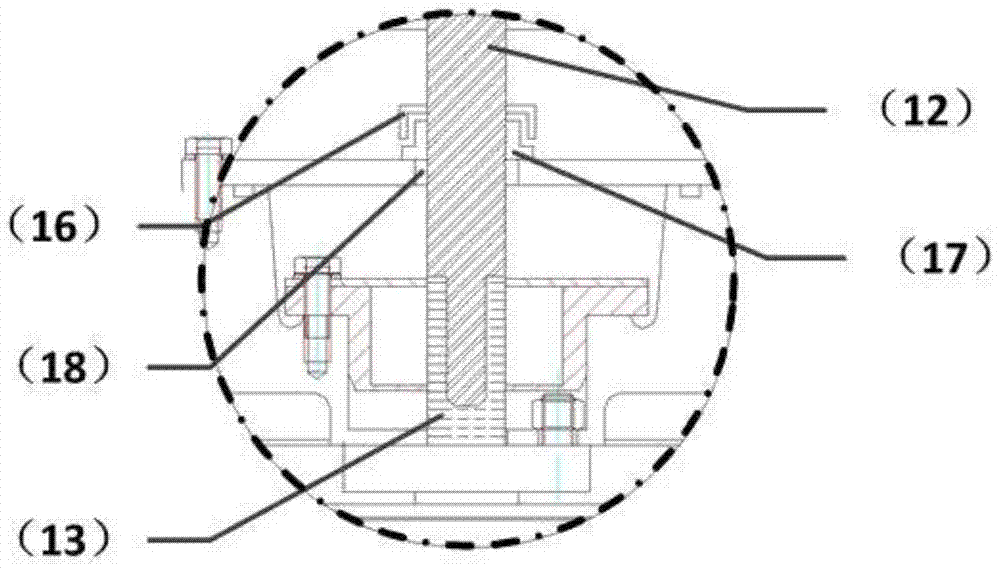

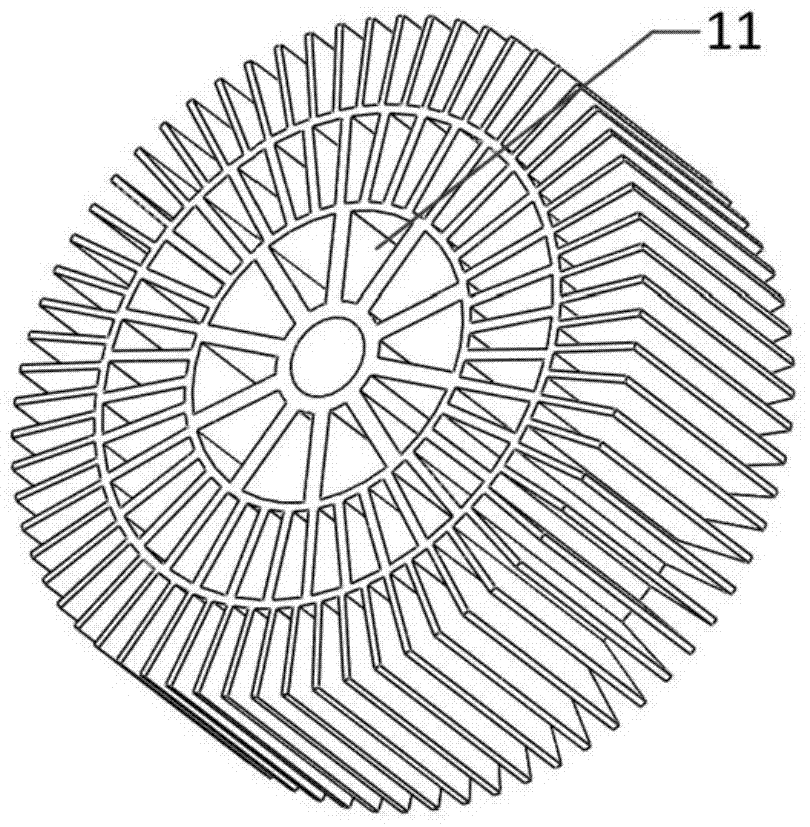

A heat dissipation structure of a high-voltage and high-current vacuum circuit breaker

InactiveCN105374597BIncrease the rated currentReduce thermal contact resistanceElectric switchesHigh pressureHigh voltage

The invention discloses a heat dissipation structure of a high-voltage and high-current vacuum circuit breaker. , the heat dissipation guide rod and the upper end cover of the vacuum circuit breaker are sealed by a shaft seal; it also includes a finned radiator arranged on the outer periphery of the lower flange and extending out of the outer edge of the lower flange, and the finned radiator is connected to the lower flange. The flange is integrally cast; this design can effectively increase the heat dissipation area of the circuit breaker, reduce the temperature rise, and significantly increase the rated current of the high-voltage vacuum circuit breaker. The manufacturing process is simple, the cost is low, and the reliability is high.

Owner:XI AN JIAOTONG UNIV +1

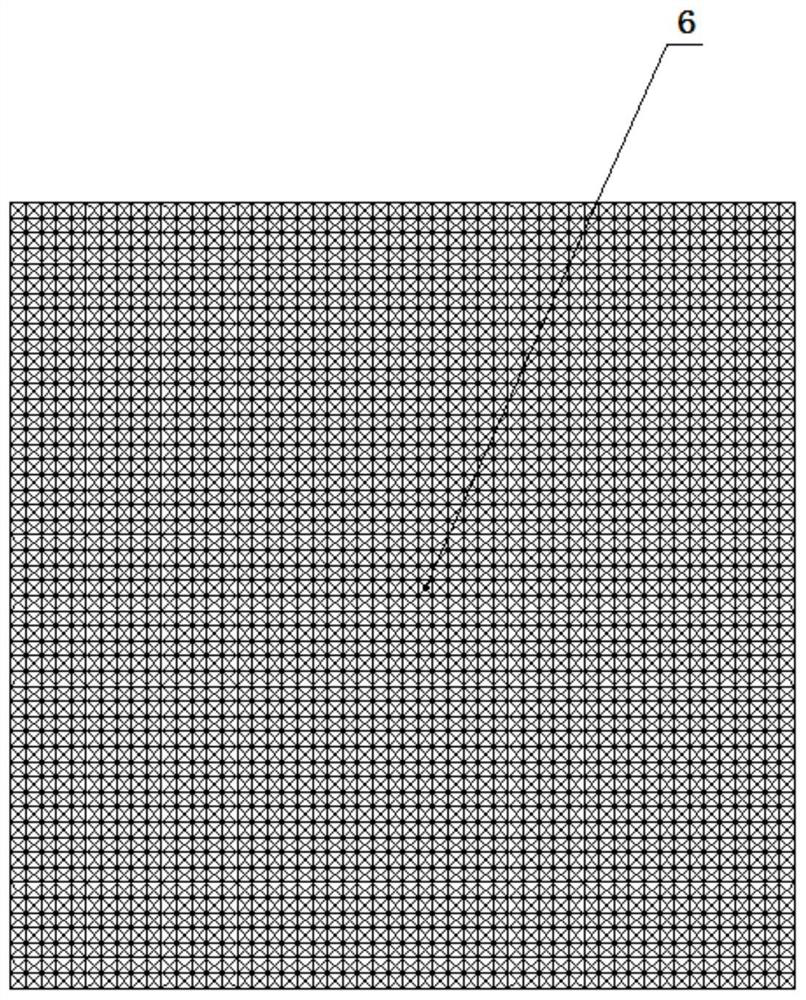

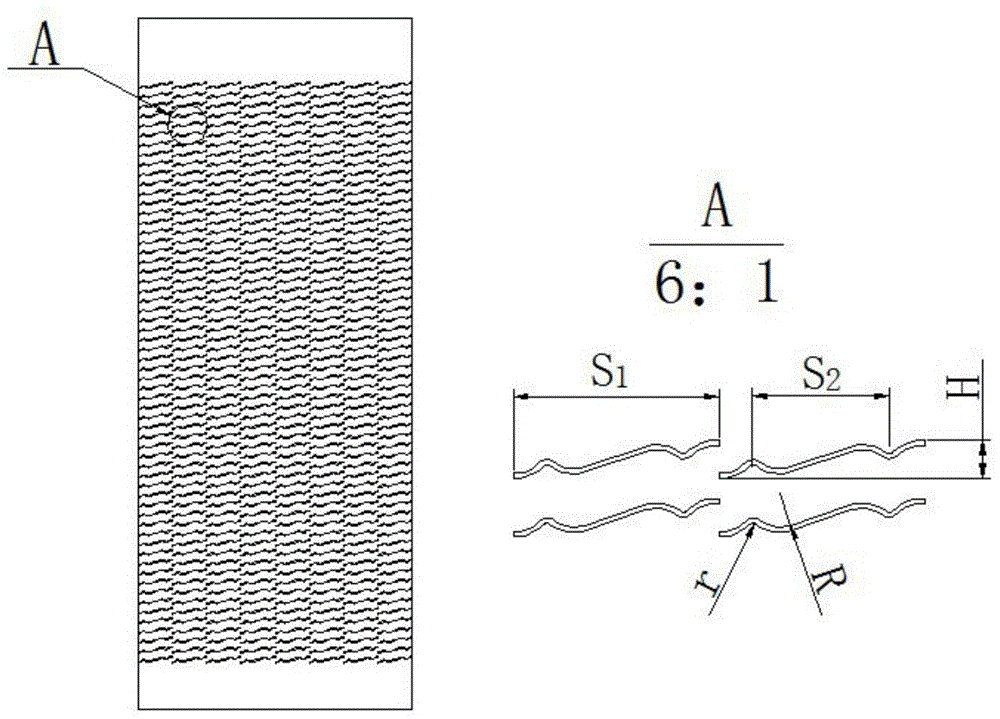

Hexagonal and ditrigonal mixed channel contact-heat-resistance-free heat transfer element

InactiveCN104006694AImprove heat transfer performanceIncrease heat dissipation ratioTubular elementsEngineeringHeat transfer efficiency

The invention provides a hexagonal and ditrigonal mixed channel contact-heat-resistance-free heat transfer element applied to various heat exchangers, and belongs to the technical field of heat exchange. The element is composed of corrugated cooling fins and a rectangular heat transfer flat tube, the rectangular heat transfer flat tube is evenly provided with hexagonal pipelines and ditrigonal pipelines, and the mixed pipelines greatly increase the cooling ratio and greatly improve collision resistance, pressure resistance and bearing force. According to the hexagonal and ditrigonal mixed channel contact-heat-resistance-free heat transfer element, strength of the heat transfer element is enhanced, the ability to work under severe conditions is improved, the corrugated cooling fins and the heat transfer flat tube are integrally machined and formed, and welding is not needed; contact heat resistance does not exist, and heat transfer efficiency is high; the manufacturing process is simple, the structure is compact, the size is small, vibration resistance is high, and accordingly the hexagonal and ditrigonal mixed channel contact-heat-resistance-free heat transfer element can be widely used in heat exchangers of various products such as air conditioners, refrigerating equipment and vehicles.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

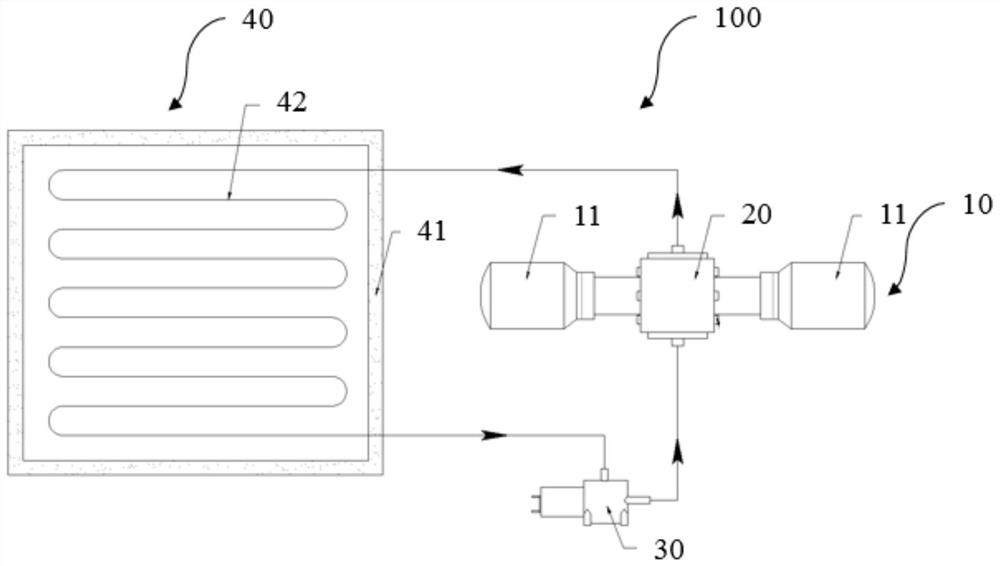

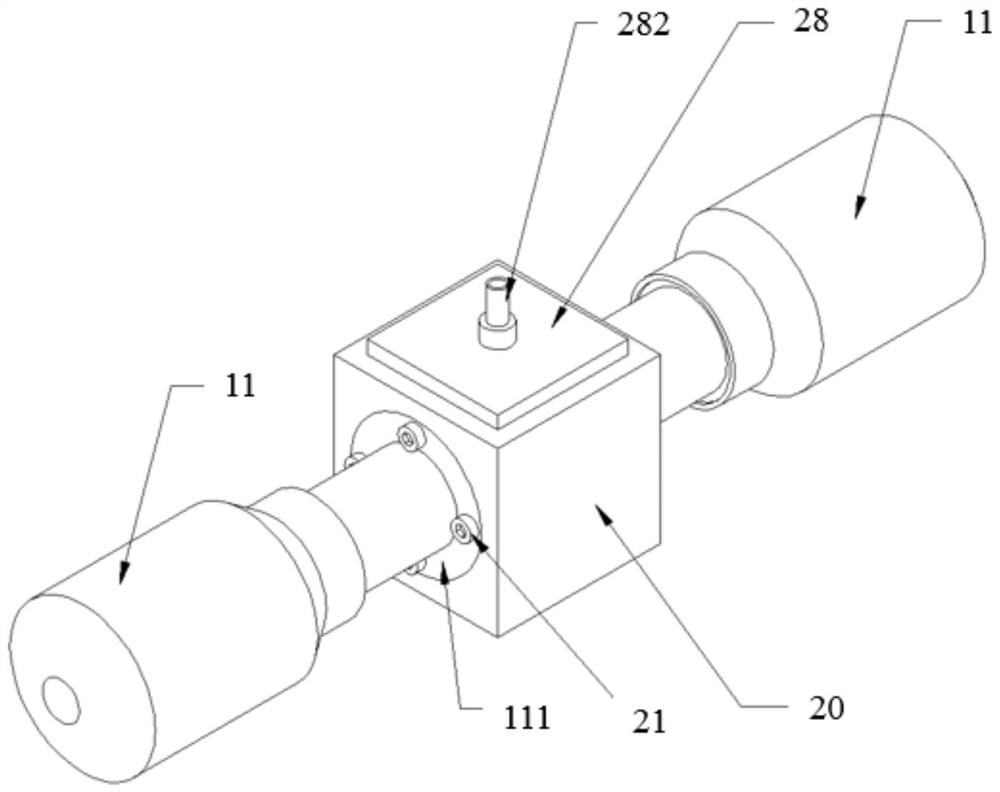

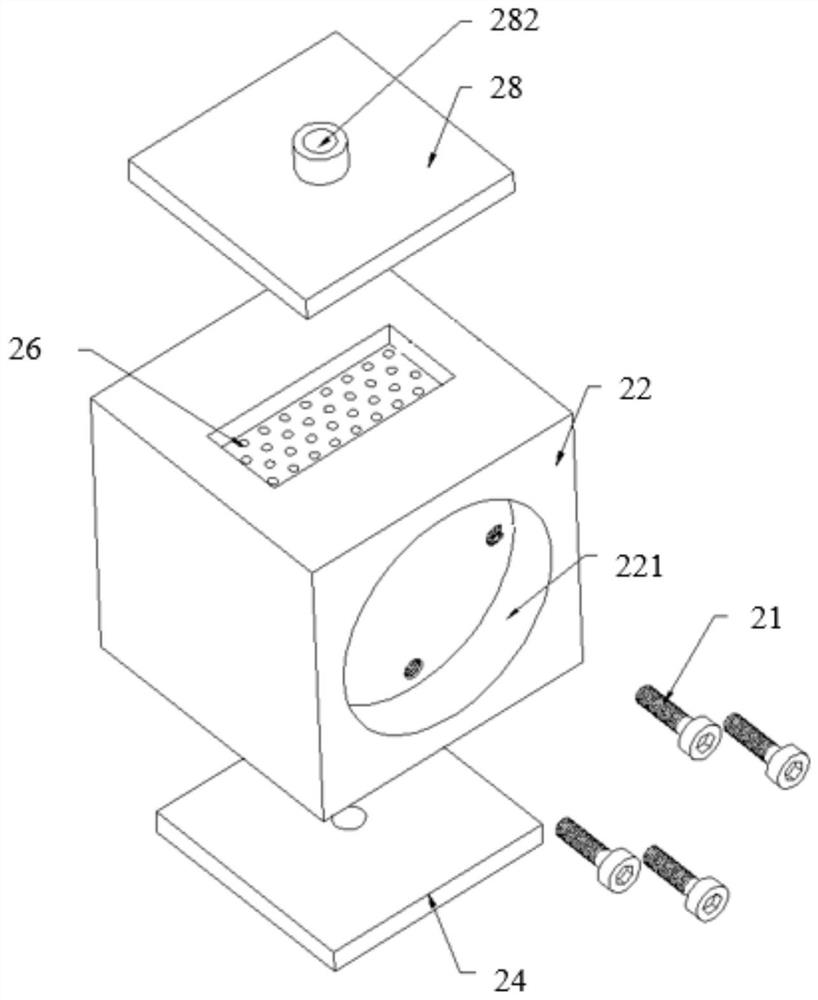

Surface source black body temperature control structure with high temperature uniformity

InactiveCN113008386AEliminate thermal contact resistanceReduce heat transfer temperature differencePyrometry using electric radation detectorsTemperature controlFlow boiling heat transfer

The invention discloses a surface source black body temperature control structure with high temperature uniformity. According to the surface source black body structure, a black body and a temperature control cold plate are integrally designed, a two-phase working medium flow channel is designed in the black body, and the two-phase working medium in the flow channel directly acts on the black body, so that the contact thermal resistance between the temperature control cold plate and the black body is eliminated, and the heat exchange temperature difference between the two-phase working medium and the black body is effectively reduced; and the temperature adjusting capability of the two-phase working medium on the black body surface is enhanced. The two-phase working medium flow channel is formed by connecting a plurality of parallel micro channels in parallel and is uniformly distributed in the black body, so that the two-phase working medium is uniformly distributed in the black body, the two-phase working medium flows and boils in the black body, the heat exchange coefficient is higher than that of a single-phase loop by one order of magnitude, the temperature control capability is high, the temperature control range is large, the stability is good, and the precision is high. Meanwhile, the surface temperature of the black body is measured through embedded contact type temperature measurement, environmental interference is avoided, and the temperature measurement precision is high.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

Opposite-rounded-corner oblique-breaking-type finned tube non-contact thermal resistance heat transmission element

InactiveCN104006693AImprove heat transfer performanceEliminate thermal contact resistanceTubular elementsHeat transfer efficiencyEngineering

The invention discloses an opposite-rounded-corner oblique-breaking-type finned tube non-contact thermal resistance heat transmission element and belongs to the technical field of heat exchanging. The opposite-rounded-corner oblique-breaking-type finned tube non-contact thermal resistance heat transmission element comprises radiating fins and a rectangular heat transmission flat tube. The radiating fins are oblique opposite-rounded-corner ripple breaking fins, the fins and the heat transmission flat tube are integrally formed, and welding is of no need. Contact heat resistance is of no need, heat transmission efficiency is high, a manufacturing technology is simple, the structure is compact, size is small, anti-shocking capacity is high, and accordingly the opposite-rounded-corner oblique-breaking-type finned tube non-contact thermal resistance heat transmission element can be widely used in heat exchangers of various products such as an air conditioner, cooling equipment and vehicles.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A cooling device used in conjunction with a module to be cooled

ActiveCN103179846BElimination of thermal contact resistance differencesEliminate thermal contact resistanceCooling/ventilation/heating modificationsCooling effectEngineering

Owner:南京国睿防务系统有限公司

Novel integrated water cooled thyristor

InactiveCN104167396AEliminate thermal contact resistanceImprove cooling efficiencyThyristorSemiconductor/solid-state device detailsThyratronElectrical and Electronics engineering

The invention relates to a novel integrated water cooled thyristor comprising a tube seat and a tube cover, and a chip having a protection layer is arranged between the tube seat and the tube cover; the other end of the tube seat is connected with a heat dissipation device. Through external press mounting force, the bottom face of the tube seat of the thyristor is enabled to be connected with the heat dissipation device; the base seat and the heat dissipation device share a face, contact thermal resistance between a conventional thyristor and the heat dissipation device can be reduced, and therefore heat can be transmitted to the heat dissipation device from a chip of the thyristor; heat dissipation efficiency can be improved.

Owner:STATE GRID CORP OF CHINA +2

Variable-frequency air conditioner driver module chip cooling device and variable-frequency air conditioner

InactiveCN107591379AEfficient heat transferImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesLow voltageHeat conducting

The invention provides a variable-frequency air conditioner driver module chip cooling device and a variable-frequency air conditioner. The cooling device includes a heat conducting plate. The heat conducting plate is provided with at least one through hole penetrating the heat conducting plate along the plane where the heat conducting plate is so that a first end and a second end of the heat conducting plate form interfaces. Refrigerant pipes are connected to the interfaces in a sealing manner. In the scheme, the refrigerant directly contacts the heat conducting plate, and the problem that the cooling efficiency is decreased due to poor contact between the refrigerant pipes and the heat conducting plate in the prior art is avoided. In the prior art, the refrigerant needs to transfer heatthrough the walls of the refrigerant pipes and the heat conducting plate to cool the chip. While in the scheme, the refrigerant only needs to transfer heat through the heat conducting plate to cool the chip. The thermal contact resistance between the heat conducting plate and the refrigerant pipes is eliminated, and the efficiency of heat transfer is improved. The chip can be cooled efficiently. The cooling device can effectively cool a driver module chip under adverse conditions, such as too low voltage and too high ambient temperature, so as to ensure the output ability of the unit.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

Three-dimensional inner and outer finned tube cold and heat exchanger for air conditioner

InactiveCN103148724AGuaranteed heat exchange effectEliminate thermal contact resistanceTubular elementsEngineeringMicro heat exchanger

The invention discloses a three-dimensional inner and outer finned tube cold and heat exchanger for an air conditioner. The three-dimensional inner and outer finned tube cold and heat exchanger comprises a flow inlet, a flow outlet and a flow pipeline between the flow inlet and the flow outlet, wherein the flow pipeline comprises a three-dimensional finned tube which is fixedly arranged on left and right perforated plates as a heat transfer element; and the three-dimensional finned tube indicates a metal tube with fins cut on the tube wall. According to the three-dimensional inner and outer finned tube cold and heat exchanger, the technical defects of low heat exchange performance between the tube and fins of the heat (cold) exchange tube for an air conditioner and short service life in the prior art are overcome; and the three-dimensional inner and outer finned tube cold and heat exchanger for the air conditioner with high heat exchange performance and long service life is provided.

Owner:CHONGQING HUIKUN ELECTRICAL APPLIANCE

A refrigerator device

ActiveCN108302878BEliminate the effects ofSufficient heat exchangeMechanical apparatusCompression machinesCool storageEngineering

The invention provides a refrigerated box device, comprising: a cooling part, used to generate cooling capacity, including at least two symmetrically arranged refrigerators; a certain amount of brine; the brine pump communicates with one end of the cold guide part and is used to provide brine; and the box body of the refrigerator includes an accommodating chamber and a serpentine coil, and the accommodating chamber is used for accommodating items to be refrigerated. The serpentine coil is used for the flow of the refrigerant and supplies the cold energy to the items to be refrigerated. The cooling part includes: the cooling shell, the cooling unit, multiple sets of cooling channels, the liquid separation tank and the liquid collection tank, and the cooling shell The two sides of the two refrigerators are respectively connected to two refrigerators; the cooling unit is set in the cooling shell and is in contact with the Stirling refrigerator to take away the cold; multiple sets of cooling channels are set in the cooling cavity and are cooled by the cooling block Surrounded, one end communicates with the liquid separation tank, and the other end communicates with the serpentine coil in the refrigerator box to transmit the cold energy to the refrigerator box.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com