Novel integrated water cooled thyristor

A technology of thyristor and water cooling, which is applied in the direction of thyristor, electric solid-state device, semiconductor device, etc., can solve the problem of temperature rise of thyristor chip, achieve the effect of reducing thermal resistance, reducing contact thermal resistance, and improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

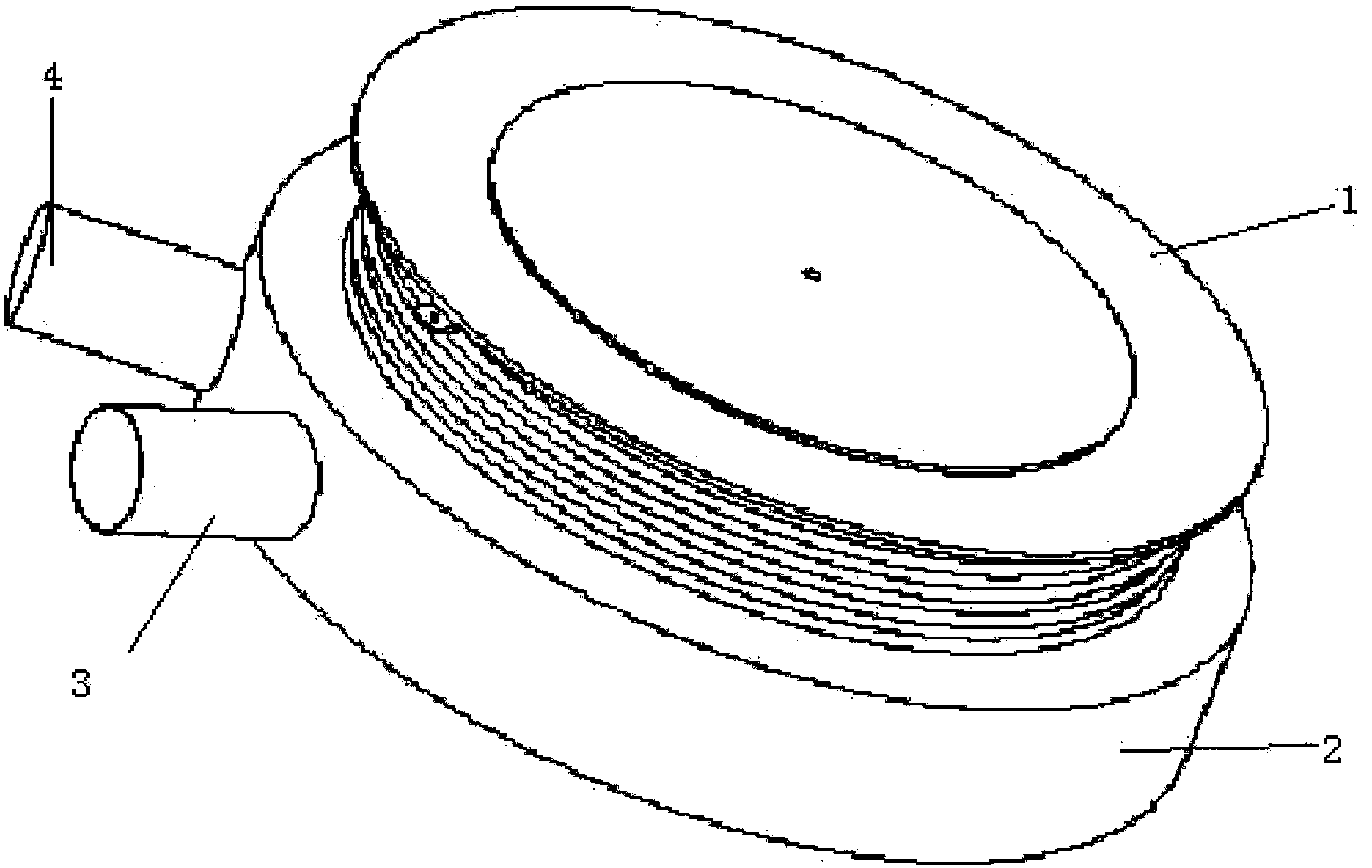

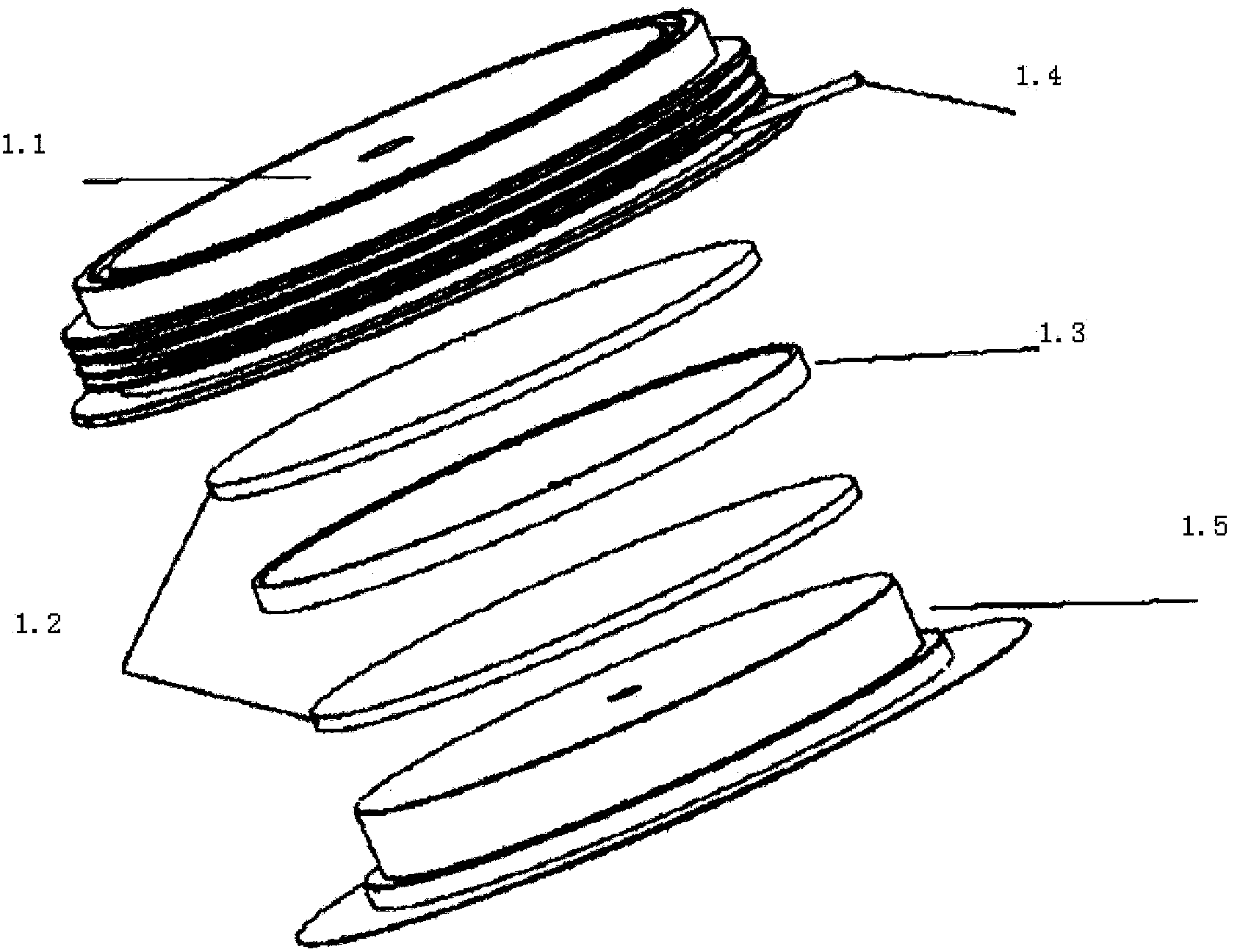

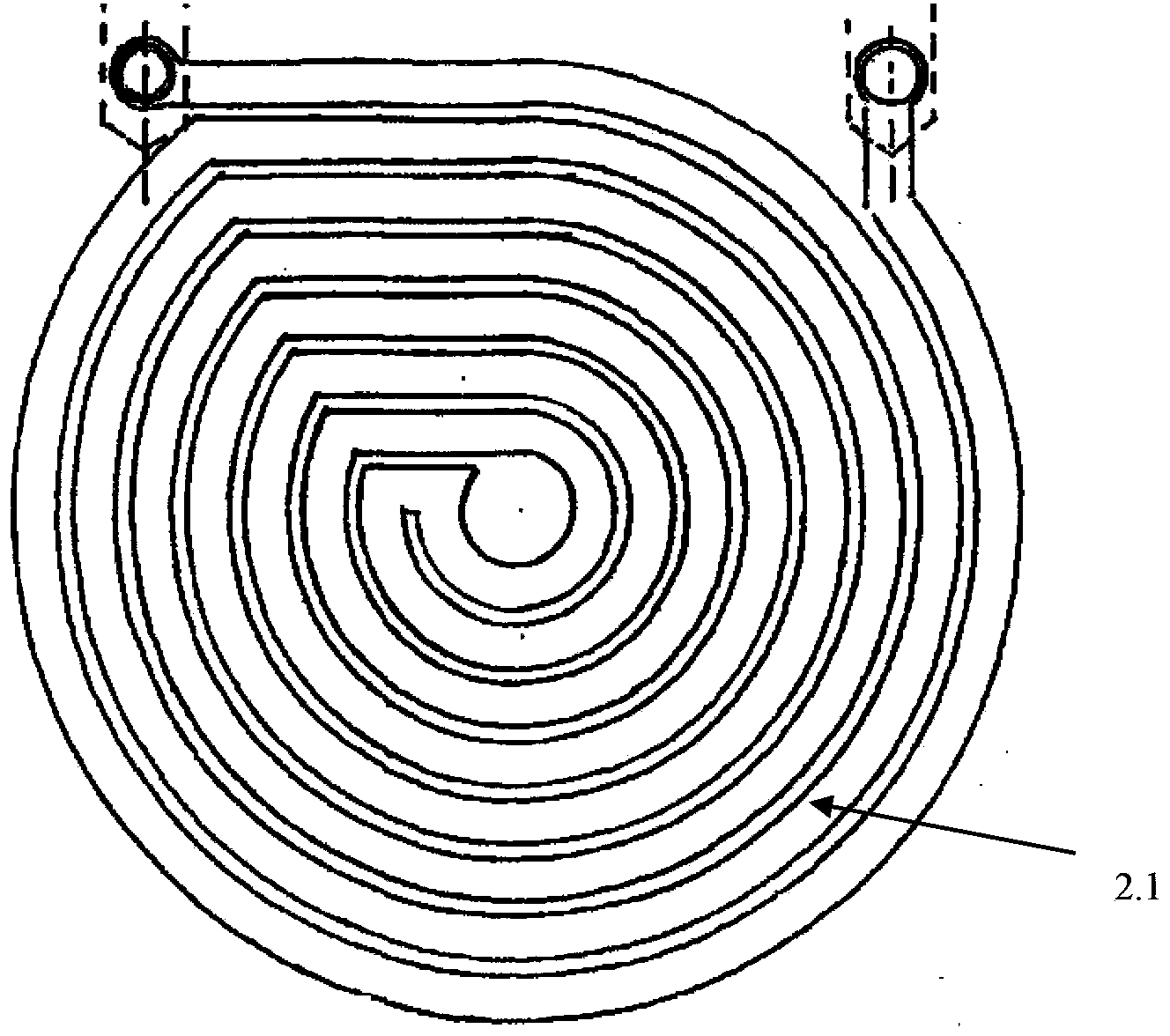

[0033] Such as Figure 1-3 As shown, the invention of this example is mainly carried out on a 6-inch integrated water-cooled thyristor. The thyristor 1 includes a tube base 1.1, a ceramic ring shell, a protective layer 1.2, a chip 1.3 and a tube cover 1.5 arranged in sequence along the axial direction; the chip 1.3 The outer edge is covered with a rubber sleeve; the protective layer 1.2 and the chip are sequentially buckled into the ceramic ring shell; a radiator is provided under the axial direction of the tube base 1.1.

[0034] The chip 1.3 includes an anode-side molybdenum sheet, a silicon sheet, and a cathode-side molybdenum sheet arranged axially in sequence; the silicon sheet includes a phosphorous expansion region N+, a short base region P1, a long base region N, a short base region, and District P2 and concentrated boron diffusion region P+; said phosphorus expansion region N+ is provided with a cathode and a gate electrode, said boron-concentrated diffusion region P+...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com